Professional Documents

Culture Documents

Wood

Uploaded by

Arkitek Jagz Cabuhat CapianCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wood

Uploaded by

Arkitek Jagz Cabuhat CapianCopyright:

Available Formats

Wood

Study online at quizlet.com/_dea33

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

- traditional building

material

- durable, beautiful, rust

and corrosion free

wood

16.

symbols for dressed lumber

Physical properties - 6

- fibrous

- viscoelastic

- anistropic

- hygroscopic

- easily worked with

- durable and beautiful

S1S - smooth 1

side, dressed 1

side

S2S - smooth 2

sides, dressed 2

sides

S4S - smooth 4

sides, dressed 4

sides

17.

wood structure - 3

- sapwood

- heartwood

- core

18.

sapwood

- outer portion of

a tree

- softer, younger

layer

- more

permeable, less

durable

19.

heartwood

- older, harder

inner portion

- darker in color,

denser and less

permeable

20.

core

- inactive cells

-mechanical

support of the

tree

21.

defects of wood - 6

- decay

- checks

- shakes

- knots

- pitch pockets

- warping

- fungi caused

- usually if with moisture

decay

- lengthwise cracks across the annual

growth rings of the tree

- caused by irregular shrinkage

during drying

checks

- cracks parallel to the annual growth

rings

- cracks formed while the tree is living

shakes

irregular growths in the body of a tree

which interrupt the smooth curve of

the grain

knots

well defined openings or pockets

between the annual rings and

contains solid or liquid pitch

pitchpockets

variations with the plane surface of

the wood caused by uneven shrinkage

of the board

warping

wood physical property:

fibrous

- fibers run parallel to its

length

- allows to have large flexual

strength

- good for tension

wood physical property:

viscoelastic

vibrates and dissipates

sound (good as an acoustic

material)

wood physical property:

anistropic

properties perpendicular to

the fibers are different

wood physical property:

hygroscopic

- will absorb moisture

- will keep moisture equal to

ambient air

- has to be seasoned and

dried

classification of trees - 2

hardwood and softwood

deciduous trees with broad

leaves (fibers are more

dense)

hardwood

conifer trees that have

needles

softwood

types of wood according to

use - 3

- yard lumber

- structural lumber

- shop/factory lumber

used in general building

purposes (found in shops)

yard lumber

min size of 2x2x0.5 in

structural lumber

- lumber that is remanufactured

- for furniture and cabinets

shop/factory lumber

types of wood according to

manufacture - 3

- rough lumber

- dressed lumber

- smooth lumber

- cut plainly

- smoother than rough

lumber

dressed lumber

22.

23.

24.

25.

26.

27.

kinds of warping - 4

crook, bow, cup,

twist

warping: edge is convex or concave

longitudinal

crook

warping: face is convex or concave

longitudinal

bow

31.

warping: face is convex or concave

cup

32.

one corner is raised

twist

- term used for wood used in

construction

- size/dimensions in inches

lumber

four classifications of lumber

- strips

- board lumber

- dimension

lumber

- timber

lumber: less than 2" thick and less

than 8" wide

strips

lumber: less than 2" thick and at

least 8" wide

board lumber

lumber: more than 2" thick and less

than 5" in any dimension

dimension lumber

lumber: 5" more on the smallest

dimension

timber

size of lumber right after it was cut

from the log

nominal size

(actual size is 1/2"

shorter)

measurement of lumber (used in

price/estimate)

board foot =

[thickness(in) x

W(in) x L(ft)] / 12

lumber is sold in length from...

6'-20' (increments

of 2') [longer

lumber, more

expensive]

28.

29.

30.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

seasoning of lumber - 2

- air drying

- kiln drying

- lumber is strip piled at a slope on a

solid foundation

- allows air to circulate around every

piece while sloping allows water to

run off quickly

air drying

- more expensive than kiln drying

- minimal movement

- used for furniture

- lumber is dried artificially to the

correct moisture content in a dry

kiln

kiln drying

lumber that was subjected to

pressure and injected with

chemicals or salts to insure that it

will not rot

pressure treated

lumber

46.

kinds or pressured treated lumber - 4

- wolmanized

- permanized

- tanalized

- boliden

47.

treatment of lumber - 2

- resistance to

decay

(creosote

solutions)

- fire retardant

treated

48.

manufactured wood - 7

- plywood

- hardboard

- chipboard

- HDF or

MDF

- Gypsum

board

- fibercement

boards

- millwork

- manufactured using several thin sheets

or plies of wood peeled from log

(generally odd no. of plies)

- grain direction is alternate

plywood

50.

size and thickness of plywood

size: 4' x 8'

thickness:

1/8", 1/4",

1/2", 3/4", 1"

51.

types of plywood - 3

- marine

plywood

- ordinary

plywood

- fancy

plywood

52.

fancywood - 4

- Narra

bookmatched

- Tanguile

ribbon

grained

- Kalantas

rotary cut

- Rosewood

- made from processed wood chips

- chips of controlled size are subjected to

high pressure steam in pressure vessels

to form uniform grains

hardboard

types of hardboard - 3

- standard

hardboard

- panel

hardboard

- tempered

hardboard

hardboard: interior use only, no

moisture allowed

standard

hardboard

49.

53.

54.

55.

56.

hardboard: denser than the standard but not as dense as tempered

panel hardboard

57.

hardboard: densest, made by impregnated standard board with a tempering compound

tempered hardboard

- rigid board with a smooth surface

- wood chips are bound together, then subjected to heat and pressure

chipboard

59.

board made of fiber pressed into sheets and bound by glue

HDF or MDF

60.

High Density Fiber - used in flooring

HDF

61.

Medium Density Fiber - used in cabinets, fire retardant than other woods

MDF

62.

wall made of plywood and structural lumber (hardiflex, gypsum board)

dry walls

- board with a gypsum core sandwiched between tough, smooth paper

- insulation and acoustic

- prone to moisture attack

- easy to finish

- combustible

gypsum board

used to cover for aesthetic purposes

veneer

- commercial name is hardiflex or hardisenepa

- made of mineralized cellulose fibers and calcium carbonate bound by cement(72%)

- can be wet, used above bathroom

fibercement boards

- processed in lumber mill

- doors, windows, moldings, trimmings

millwork

58.

63.

64.

65.

66.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Dao2000 63Document7 pagesDao2000 63Anskee Tejam100% (8)

- Full-Size Wood Toy: Kenworth Dump TruckDocument36 pagesFull-Size Wood Toy: Kenworth Dump Truckhulusi67100% (4)

- Brochure Davies WallArt Lune 1Document4 pagesBrochure Davies WallArt Lune 1Arkitek Jagz Cabuhat CapianNo ratings yet

- Swimming Pool DesignDocument49 pagesSwimming Pool Designcashlover100% (1)

- Armor and Collectible Item ListingDocument192 pagesArmor and Collectible Item ListingZic WhiteNo ratings yet

- Mannington Hardwood Brochure Adams Family FloorsDocument20 pagesMannington Hardwood Brochure Adams Family FloorsTerriNo ratings yet

- Bidding Form No. 5 Bill of Materials - 0Document6 pagesBidding Form No. 5 Bill of Materials - 0Kim Aljon CalveloNo ratings yet

- LABORATORY and PATHOLOGY Online Report: Patient InformationDocument2 pagesLABORATORY and PATHOLOGY Online Report: Patient InformationArkitek Jagz Cabuhat CapianNo ratings yet

- Bidding Form No. 5 Bill of Materials - 0Document6 pagesBidding Form No. 5 Bill of Materials - 0Kim Aljon CalveloNo ratings yet

- Easytrip Terms and Conditions for RFID Tag UseDocument3 pagesEasytrip Terms and Conditions for RFID Tag UseArkitek Jagz Cabuhat CapianNo ratings yet

- Technical Design DocumentDocument21 pagesTechnical Design Documentmanderin87No ratings yet

- Brochure Davies AcreexDocument3 pagesBrochure Davies AcreexArkitek Jagz Cabuhat CapianNo ratings yet

- Brochure Davies MortaflexDocument4 pagesBrochure Davies MortaflexArkitek Jagz Cabuhat Capian0% (1)

- Technical Design DocumentDocument21 pagesTechnical Design Documentmanderin87No ratings yet

- Brochure Davies WallArt Textura 1Document6 pagesBrochure Davies WallArt Textura 1Arkitek Jagz Cabuhat CapianNo ratings yet

- Architects Resource WebsiteDocument2 pagesArchitects Resource WebsiteArkitek Jagz Cabuhat CapianNo ratings yet

- 01 Summary - SpecificationsDocument2 pages01 Summary - SpecificationsArkitek Jagz Cabuhat CapianNo ratings yet

- 211 A 9922Document1 page211 A 9922Arkitek Jagz Cabuhat CapianNo ratings yet

- Justice League 2k17Document1 pageJustice League 2k17Arkitek Jagz Cabuhat CapianNo ratings yet

- Captain 2k17Document1 pageCaptain 2k17Arkitek Jagz Cabuhat CapianNo ratings yet

- Landscape Photography 2k17Document1 pageLandscape Photography 2k17Arkitek Jagz Cabuhat CapianNo ratings yet

- Climate in Santa Rosa: Tropical, Wet SummersDocument2 pagesClimate in Santa Rosa: Tropical, Wet SummersArkitek Jagz Cabuhat CapianNo ratings yet

- Captain 2k17 PDFDocument1 pageCaptain 2k17 PDFArkitek Jagz Cabuhat CapianNo ratings yet

- Shell TileDocument1 pageShell TileArkitek Jagz Cabuhat CapianNo ratings yet

- Bubble DiagramDocument1 pageBubble DiagramArkitek Jagz Cabuhat CapianNo ratings yet

- Home Theater Design Plans2Document1 pageHome Theater Design Plans2Arkitek Jagz Cabuhat CapianNo ratings yet

- Laur Nueva EcijaDocument2 pagesLaur Nueva EcijaArkitek Jagz Cabuhat CapianNo ratings yet

- 1plus1 Hyper LRDocument32 pages1plus1 Hyper LRArkitek Jagz Cabuhat CapianNo ratings yet

- Brand: Canyon Rock Description: Wall Cladding Size: 2 X 8, 4 X 8 Code: GREYDocument1 pageBrand: Canyon Rock Description: Wall Cladding Size: 2 X 8, 4 X 8 Code: GREYArkitek Jagz Cabuhat CapianNo ratings yet

- Climate:: Aduas NorteDocument2 pagesClimate:: Aduas NorteArkitek Jagz Cabuhat CapianNo ratings yet

- CabanatuanDocument2 pagesCabanatuanArkitek Jagz Cabuhat CapianNo ratings yet

- Robinson PDFDocument113 pagesRobinson PDFDinesh TamilNo ratings yet

- 4 Transportation SystemsDocument32 pages4 Transportation SystemsJeff Callanta100% (1)

- Cinematic Techniques Terms and ExamplesDocument22 pagesCinematic Techniques Terms and ExamplesArkitek Jagz Cabuhat CapianNo ratings yet

- CONTACTS Dubai Wood2012Document23 pagesCONTACTS Dubai Wood2012Suji ChaNo ratings yet

- Top View Kitchen: Keterangan FinishingDocument2 pagesTop View Kitchen: Keterangan Finishingmaratur rohmaniaNo ratings yet

- ClassicSolid Wood DoorDocument9 pagesClassicSolid Wood DoorAnuar MahatNo ratings yet

- Sl. No. Exporters Name Contact Person Designation Address 1 Address 2 State PIN Telephone E-Mail 1 Company Products Exporter Reg. NoDocument100 pagesSl. No. Exporters Name Contact Person Designation Address 1 Address 2 State PIN Telephone E-Mail 1 Company Products Exporter Reg. NoSWAPNILNo ratings yet

- Unilever Palm Oil Mills List 2021Document19 pagesUnilever Palm Oil Mills List 2021IshakNo ratings yet

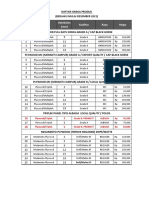

- Daftar Harga Produk Plywood dan MDF Desember 2021Document3 pagesDaftar Harga Produk Plywood dan MDF Desember 2021Nadia lita saibaNo ratings yet

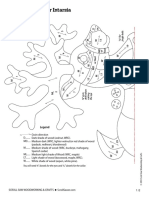

- WEB JGR Reindeer PatternDocument2 pagesWEB JGR Reindeer PatternonurNo ratings yet

- Cooking Oil Smoking PointDocument6 pagesCooking Oil Smoking PointblacksuitboyNo ratings yet

- Pengaruh Ukuran Potongan Kopra Dalam Proses Pengeringan: Effect of The Copra Cut Size in The Drying ProcessDocument5 pagesPengaruh Ukuran Potongan Kopra Dalam Proses Pengeringan: Effect of The Copra Cut Size in The Drying ProcessAlexia Desi Ratnasari Loi 1841100210No ratings yet

- 2 Naputak PDFDocument26 pages2 Naputak PDFMihael VorelNo ratings yet

- Characteristics of Laminated WoodDocument12 pagesCharacteristics of Laminated WoodhamdyNo ratings yet

- Nagaland Company 1Document4 pagesNagaland Company 1Ramagopalan KNo ratings yet

- Wood Substitutes - Industrial Products As Substitutes ForDocument18 pagesWood Substitutes - Industrial Products As Substitutes ForashimaNo ratings yet

- ACACIA MANGIUM and other plantation woods for furnitureDocument3 pagesACACIA MANGIUM and other plantation woods for furnitureMandel Battikin Gup-ayNo ratings yet

- 1 Cart 3 Ways Project Diagram: Case Exploded ViewDocument3 pages1 Cart 3 Ways Project Diagram: Case Exploded Viewpavel1425No ratings yet

- Cert. Gyplac Resistencia Al Fuego Tab. RF 8 Marzo-RFDocument12 pagesCert. Gyplac Resistencia Al Fuego Tab. RF 8 Marzo-RFCarlosRobertoCamposJaraNo ratings yet

- Analisa Faktor-Faktor Yang Mempengaruhi Produksi Minyak VCO Industri Kecil Waipiah Coconut Di Kec. TNS Kab. Maluku TengahDocument10 pagesAnalisa Faktor-Faktor Yang Mempengaruhi Produksi Minyak VCO Industri Kecil Waipiah Coconut Di Kec. TNS Kab. Maluku TengahClippy ZonkNo ratings yet

- ListofmillsDocument416 pagesListofmillsCompany Hoang Giang phuongNo ratings yet

- Perusahaan PlywoodDocument10 pagesPerusahaan PlywoodhendraNo ratings yet

- Scaff Accessories-Arabic EnglishDocument8 pagesScaff Accessories-Arabic EnglishMohamed AdelNo ratings yet

- All Furniture DetailDocument4 pagesAll Furniture DetailsampathNo ratings yet

- Ilomba: Pycnanthus Angolensis WarbDocument2 pagesIlomba: Pycnanthus Angolensis WarbObazie isiomaNo ratings yet

- Offer-Vietnam Incense StickDocument4 pagesOffer-Vietnam Incense StickDinh xuan BaNo ratings yet

- Ghana Exports Refer Page 18Document31 pagesGhana Exports Refer Page 18Dhaval ThackerNo ratings yet

- PriceList - Buffalo Plafon - 2023-02-03Document4 pagesPriceList - Buffalo Plafon - 2023-02-03dual sainsNo ratings yet

- Fitocenološka Analiza Mezofilnih Šuma Pitomog KESTENA (Castanea Sativa Mill.) U OKOLINI KOSTAJNICE (Bosna I Hercegovina)Document20 pagesFitocenološka Analiza Mezofilnih Šuma Pitomog KESTENA (Castanea Sativa Mill.) U OKOLINI KOSTAJNICE (Bosna I Hercegovina)Jaroslav BiresNo ratings yet