Professional Documents

Culture Documents

Copy of SmartBeamNon CompositeCastellatedDesign

Uploaded by

ImranSohailOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Copy of SmartBeamNon CompositeCastellatedDesign

Uploaded by

ImranSohailCopyright:

Available Formats

CMC Steel Products Non-Composite Castellated Beam Design Program

NOMENCLATURE

INTRODUCTION:

This program will assist in sizing simply supported, castellated beams with point and uniformly distributed loads.

All a reas in sh ade d yell ow req uire i nforma ti on to be in pu t. C ontac t C MC Steel Products toll fre e at (877 ) 7 64 -232 6

for fur the r inform ation or a ssista nc e.

STEPS:

1. Enter job name and design mark (not required).

2. Enter span, unbraced length, material strength and conx. type.

3. Enter loading. Program allows (1) uniform live load, (1) uniform dead load, and (4) point loads. Note, beam wt. is included.

4. Press Stnd. Geom. button. This enters the standard castellation pattern corresponding to the given wide flange.

OPTIMIZATION:

Three modes of failure and their corresponding interaction values are shown in the results section. All values must

be less than or equal to 1.0 for the beam to be ok. Press the "Find lightest shape" button to have the program select

the lightest shape with standard castellation geometry. Significant strength changes can be achieved by modifying

the castellation pattern. The following guidelines will help the optimization process.

1. To increase shear or web post strength, increase "e".

2. To increase bending strength, decrease "e".

3. If point loads are a significant portion of the load, increase "dt".

CONSTRUCTION BRIDGING:

VARIABLES

Construction bridging is required for castellated beams that spans longer than the maximum bridging spacing.

Maximum bridging spacing is controlled by connection type at end of beam.

OSHA requires construction bridging to be installed to meet the following loading conditions:

1. A 300 lb. Man @ midspan - requires bolted X-bridging to be installed before hoisting cables are removed.

d = depth of root beam

bf = flange width

tf = flange thickness

tw = web thickness

e = web post width & tee length

b = width of sloped portion

dt = tee depth

dg = castellated beam depth

ho = height of hole

wo = width of hole

2. One 4000 lb. Bundle of deck to be placed over three beams no further than 1 ft from the end of the beam requires horizontal bridging to be in place before deck bundles are placed.

WARNINGS:

1. "e<emin" - e must be at least 3" to provide end conx. material.

2. "dt<dtmin" - dt must be greater than dtmin for fabrication reasons.

3. "e/tw>30", "2h/e>8", "Phi>62", "Phi<43" - research on web post buckling is valid only within these limitations.

4. "Top tee slender" or "Bottom tee slender" - allowable stress on tee section is reduced per Qs. This will not

cause error in program.

The in fo rmatio n prese nted in th is pub lica ti on an d desi gn so ftwa re has be en pre pa re d in a ccorda nce wi th re cogn ized

en gin eeri ng pri ncip les, in con formity with the AISC Sp ecifica ti on for Strucura l Ste el in Bu ild in gs (A SD,198 9) and i s for ge ne ral

in fo rmation onl y. w hil e it i s b eli eved tha t a ll da ta a nd in fo rmatio n fu rnish ed is accu rate , n o perso n, co rpo ra tion , asso ciatio n, o r

othe r e ntity i nvol ved in the p rep aratio n of thi s p ub lica ti on rep resen ts or wa rrants th at th is informa ti on is fit or suitab le for any

ge nera l or particu lar use o r purp ose, or assume s a ny resp onsi bil ity in th is informa ti on. Th is info rmation mu st be u sed i n

con juctio n with sou nd e ngi nee ring j udg ment and i s i nten ded to be u sed o nly by comp etent stru ctu ral en gin ee rs, arch itects o r

othe r l icen sed pro fessio nal s.

CMC Steel Products

2305 Ridge Road

Suite 202

Rockwall, T X 75089

800-308-9925

www.cmcsteelproducts.com

Non-Composite Castellated SmartBeam Design Program PRODUCTS

BEAM INFORMATION

Job Name:

Beam Mark #

Span

Unbraced Length

Mat. Strength-Fy

LOADING INFORMATION

Sample Project

CB1

54.000

ft

5.000

ft

50

50

ksi

Castellated Beam

Root beam

d

bf

tf

CB36X76

W24X76

tw

W24X76

Uniform Distributed Loads

Live Load

800

plf

Anet

Agross

Dead Load

Ix net

800

plf

Concentrated Point Loads

Load #

Magnitude

Dist from

Perc. DL

(#)

(kips)

Lft. End (ft)

(%)

P1

P2

P3

P4

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

RESULTS

23.9

in

8.99

in

0.68

in

Failure Mode

0.44

in

7.500

0%

0%

0%

0%

16.908

27.380

in^2

in^2

4774.037

in^4

Ix gross

5268.3

in^4

Sx net

Sx gross

rx net

rx gross

Iy

Sy

ry

rT

266.706

294.321

16.803

13.871

82.420

18.336

2.208

2.444

in^3

in^3

in

in

in^4

in^3

in

in

Interaction

Status

Bending

Shear

0.985

0.567

<=1.0 OK!!

<=1.0 OK!!

in

Web Post

0.659

<=1.0 OK!!

End Connection type

6.500

in

Overall

0.985

<=1.0 OK!!

6.000

in

Live Load Deflection

1.189''

=L/545

Min No. Of Bridging Rows

Max. Bridging. Spacing (ft)

28.000

in

Dead Load Deflection

1.302''

=L/498

Castellation Parameters:

e

b

dt

S

EXPAND'D. SXN. PROP'S

dg

phi

35.800

in

61.356

deg

ho

23.800

in

wo

20.500

in

WARNINGS

deffec

33.459

in

CONSTRUCTION BRIDGING

Shear Tab

1

44

MAXIMUM PASSABLE DUCTS

(Diam.

(in)

Round

17.491

RECTANGULAR

Width (in) x Height (in)

9.750

18.265

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AIJ Design Standard For Steel StructuresDocument14 pagesAIJ Design Standard For Steel StructurescristinelbNo ratings yet

- Quotation Commercial DesignDocument2 pagesQuotation Commercial DesignImranSohailNo ratings yet

- STRUCTURAL DESIGN ReportDocument25 pagesSTRUCTURAL DESIGN ReportRajendra AcharyaNo ratings yet

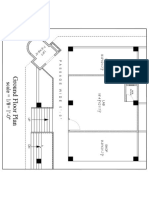

- Revised Final Proposed Floor PlanDocument1 pageRevised Final Proposed Floor PlanImranSohailNo ratings yet

- OwnerDocument1 pageOwnerImranSohailNo ratings yet

- O.h.w.tank & U.g.w.tan Sectional DetailDocument1 pageO.h.w.tank & U.g.w.tan Sectional DetailImranSohailNo ratings yet

- Submission - 17-12-2022Document1 pageSubmission - 17-12-2022ImranSohailNo ratings yet

- Stair & Wall Column DetailsDocument1 pageStair & Wall Column DetailsImranSohailNo ratings yet

- RPDocument24 pagesRPImranSohailNo ratings yet

- First Floor PlanDocument1 pageFirst Floor PlanImranSohailNo ratings yet

- STR 30X40 5Document1 pageSTR 30X40 5ImranSohailNo ratings yet

- Arc 30X40 5Document1 pageArc 30X40 5ImranSohailNo ratings yet

- Site Plan: Building No.3 Building No.2Document1 pageSite Plan: Building No.3 Building No.2ImranSohailNo ratings yet

- Bruchure Design PDFDocument8 pagesBruchure Design PDFImranSohailNo ratings yet

- Al-Rafay New RatesDocument2 pagesAl-Rafay New RatesImranSohailNo ratings yet

- A 2Document1 pageA 2ImranSohailNo ratings yet

- StructureDocument1 pageStructureImranSohailNo ratings yet

- A 1Document1 pageA 1ImranSohailNo ratings yet

- 1-0 Introduction 1: Results of InvestigationDocument23 pages1-0 Introduction 1: Results of InvestigationImranSohailNo ratings yet

- MUMTYDocument1 pageMUMTYImranSohail100% (1)

- Ground Floor Lab PDFDocument1 pageGround Floor Lab PDFImranSohailNo ratings yet

- Concrete Steel Brick CalculatorDocument12 pagesConcrete Steel Brick CalculatorVisas Siva0% (1)

- BH-1 BH-2Document1 pageBH-1 BH-2ImranSohailNo ratings yet

- Form A-2 Submission Drawing Responsibility CertificateDocument1 pageForm A-2 Submission Drawing Responsibility CertificateImranSohailNo ratings yet

- Capital Development Authority: Form A-1Document2 pagesCapital Development Authority: Form A-1ImranSohailNo ratings yet

- Two-Way Slab DesignDocument18 pagesTwo-Way Slab DesignImranSohailNo ratings yet

- MUMTYDocument1 pageMUMTYImranSohailNo ratings yet

- Plaza Closing ElevationDocument1 pagePlaza Closing ElevationImranSohailNo ratings yet

- Concrete Design Excel SheetDocument16 pagesConcrete Design Excel SheetCleth Hiren Santos25% (4)

- P 1 PDFDocument1 pageP 1 PDFImranSohailNo ratings yet

- Hindustan Construction Co. Ltd. Mumbai. Subject: Design of RC Column Standard Excel Design DetailsDocument28 pagesHindustan Construction Co. Ltd. Mumbai. Subject: Design of RC Column Standard Excel Design DetailsImranSohailNo ratings yet

- Mumty Floor Plan: Bath 5'-3"X8'-0"Document1 pageMumty Floor Plan: Bath 5'-3"X8'-0"ImranSohailNo ratings yet

- Full Download Solution Manual For Mechanics of Materials Beer Johnston Dewolf Mazurek 6th Edition PDF Full ChapterDocument36 pagesFull Download Solution Manual For Mechanics of Materials Beer Johnston Dewolf Mazurek 6th Edition PDF Full Chaptermooneye.beeve.r572100% (19)

- Sfex Pad Eyes Calculations 35T - 32MMDocument1 pageSfex Pad Eyes Calculations 35T - 32MMJohn Rom CabadonggaNo ratings yet

- Early Thermal Cracking in Concrete ExplainedDocument5 pagesEarly Thermal Cracking in Concrete ExplainedAshrafNo ratings yet

- Earthquakes: Class 9 - Total Geography Morning StarDocument7 pagesEarthquakes: Class 9 - Total Geography Morning StarLEKHRAJ YADAV K MNo ratings yet

- Truss Problem 6.1 Johnston and Beer Book-Static 1-1Document15 pagesTruss Problem 6.1 Johnston and Beer Book-Static 1-1mahfuzul_haqueNo ratings yet

- Fabrication Order Cut Length and Reinforcement DetailsDocument2 pagesFabrication Order Cut Length and Reinforcement DetailsAngelineNo ratings yet

- Undrained Soil Behavior (And Modeling) : Gioacchino (Cino) ViggianiDocument45 pagesUndrained Soil Behavior (And Modeling) : Gioacchino (Cino) ViggianiFelipe Ignacio Alarcon ArayaNo ratings yet

- Theories of FailureDocument31 pagesTheories of FailureHarishVenkatesanNo ratings yet

- 11, Stability of Slopes-LectureDocument91 pages11, Stability of Slopes-LectureRajesh KhadkaNo ratings yet

- Soil Dynamics and Earthquake Engineering: ArticleinfoDocument9 pagesSoil Dynamics and Earthquake Engineering: ArticleinfoHamza CheemaNo ratings yet

- Wood Compression Test ResultsDocument10 pagesWood Compression Test ResultsianzkieeNo ratings yet

- 3) Bearing CapacityDocument19 pages3) Bearing CapacityhaftamuTekle100% (1)

- Diltancy AngleDocument7 pagesDiltancy AngleGopal PNo ratings yet

- 1 3 Material BehaviorDocument30 pages1 3 Material Behaviorrowaters0% (1)

- ACTIVITY 1 Location of The Earthquake EpicenterDocument2 pagesACTIVITY 1 Location of The Earthquake EpicenterB - HERRERA, Jhian Carlo G.No ratings yet

- Simulation of Crack Propagation in API 5L X52 Pressurized Pipes Using XFEM-Based Cohesive Segment ApproachDocument15 pagesSimulation of Crack Propagation in API 5L X52 Pressurized Pipes Using XFEM-Based Cohesive Segment ApproachAmmarul NafikNo ratings yet

- Understanding Viscosity: Newton's Law of ViscosityDocument2 pagesUnderstanding Viscosity: Newton's Law of ViscosityMufeesNo ratings yet

- Introduction to Cumulative Fatigue Damage Analysis in Pavement LayersDocument10 pagesIntroduction to Cumulative Fatigue Damage Analysis in Pavement LayersKanishka SarkarNo ratings yet

- Nut & Bolt Connection DesignDocument16 pagesNut & Bolt Connection DesignChandana KumaraNo ratings yet

- Project: Dog Legged Stair Design Constant: OK Under ReinforcedDocument4 pagesProject: Dog Legged Stair Design Constant: OK Under ReinforcedlakshminarayanstrNo ratings yet

- Stress Paths Effects On Multistage Triaxial TestDocument10 pagesStress Paths Effects On Multistage Triaxial TestCandra NishfaNo ratings yet

- 2-Mechanisms of StrengtheningDocument18 pages2-Mechanisms of StrengtheningRalph Victor MalimetNo ratings yet

- LRPC Credentials - 1 PDFDocument102 pagesLRPC Credentials - 1 PDFSM AreaNo ratings yet

- Important Questions PDFDocument20 pagesImportant Questions PDFresha bhatiaNo ratings yet

- Scalar and vector quantities, equations of motion, and Newton's lawsDocument7 pagesScalar and vector quantities, equations of motion, and Newton's lawsApollo Wong100% (1)

- Chapter One: Introduction, Materials and Design ConceptsDocument12 pagesChapter One: Introduction, Materials and Design Conceptsdilnessa azanawNo ratings yet

- Reinforced Concrete Design BasicsDocument21 pagesReinforced Concrete Design BasicsThimira Bandara EkanayakeNo ratings yet