Professional Documents

Culture Documents

Protection Against Icing

Uploaded by

GabrielRobbaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Protection Against Icing

Uploaded by

GabrielRobbaCopyright:

Available Formats

Texto de Aplicacin N22

Protection Against lcing

10

The fact that jet engines do not have carburetors to plague a pilot with carburetor icing

problems does not mean that such engines are immune to the effect of freezing water.

Whenever visible moisture is present in the outside air and the ambient temperature is near

freezing, or even quite a number of degrees above freezing, axial flow compressor engines are

susceptible to the formation of ice on the compressor inlet guide vanes, the first-stage

compressor blades, and the surrounding walls of the compressor inlet. Another icing condition

can arise from ice forming on the fuel inlet filter whenever the temperature of the fuel entering

the filter drops to 32F, or below, as may frequently happen on long flights at high altitude.

These two icing problems, common to gas-turbine-powered aircraft, and the systems which

overcome them are not related and will be described separately.

Compressor Inlet Anti-Icing - Centrifugal Compressor Engines

15

20

25

Centrifugal compressor turbojet engines are relatively free from the danger of ice

collecting at the compressor inlet. The formation of airplane wing ice is much more serious

than engine icing, and is the limiting factor governing flight in icing conditions of aircraft

powered by engines of this type.

Although protective screens for the compressor air inlet are almost a thing of the past for

the larger turbojet and turbofan engines, such screens at one time caused so much trouble when

they were used on some centrifugal compressor turbojets that a word should be said about them.

Except in the case of some modern turboprop and turboshaft engines, as will be explained later,

practically all gas turbine engines equipped with non-retractable air inlet screens are very prone

to icing. Ice forms on the inlet screen, and restricts the flow of inlet air to the engine. This

causes a loss of thrust and a rapid rise in exhaust gas temperature. As the airflow decreases, the

fuel/air ratio increases, which, in turn, raises the turbine inlet and turbine discharge (exhaust

gas) temperatures. The fuel control attempts to correct for any loss in engine rpm by adding

more fuel, which aggravates the condition. The only way to eliminate the formation of ice

during icing conditions in aircraft powered by the older turbojet engines that are fitted with

non-retractable air inlet screens is to avoid flying into icing conditions in the first place.

Compressor Inlet Anti-lcing - Axial Flow Compressor Engines

30

35

40

45

The rapid rise of exhaust gas temperature that is indicative of air inlet icing on engines having

their primary control on rpm does not necessarily hold true for a turbojet or turbofan engine

with a single! or dual axial flow compressor that is controlled by both burner pressure and rpm.

In such engines, the rise in exhaust gas temperature commonly associated with ice forming at

the engine inlet may come too late to give the pilot a timely warning of a possibly impending

engine flameout. With either single or dual axial flow compressor engines, the first indication

of ice building up at the compressor inlet may be a compressor surge, as will be explained in

more detail later. For any given icing condition, small engines with close spacing of the inlet

guide vanes are more seriously affected by icing conditions than large engines having guide

vanes which are spaced farther apart or engines without inlet guide vanes.

Some engines are designed with hollow inlet guide vanes and inlet struts. Hot,

high-pressure air is bled from the rear of the engine compressor .and is ducted through an

anti-icing-system control valve to the hollow sections of the inlet struts and guide vanes.

50

55

60

65

70

The heat provided prevents the adhesion of ice. Because such a system may not melt the

ice, once it is formed, but will cause it. to loosen and break off, and enter the compressor in big

chunks which may possibly damage the compressor blades, icing conditions should,

when possible, be anticipated in advance, and the anti-icing system should be turned on before

ice commences to accumulate.

An anti-icing air regulator is sometimes incorporated in the system, which automatically

varies the quantity of the flow of anti-icing air with the changing temperature of the air bled

from the engine. The anti-icing regulator reduces anti-icing airflow when the air is hot, and

less

air will therefore be required to anti-ice the engine inlet. Anti-icing systems cause some

reduction in the thrust produced by the engine and/or some increase in the engine specific fuel

consumption when the system is operating. because taking bleed air from inside the engine is

the same as extracting power. By reducing the airbleed flow when the air is very hot, the

anti-icing regulator permits anti-icing to be accomplished with a minimum loss in thrust and a

minimum penalty in specific fuel consumption. Obviously, the anti-icing system should be

used only when necessary. A light on a panel in the aircraft illuminates to tell the pilot when

the anti-icing system is operating.

Fighter aircraft equipped with long inlet ducts are frequently provided with an inlet ice

detection system. A small probe is placed at some strategic location inside the duct. Ice

forming on the probe causes an electrical circuit to close, which, in turn, activates the engine

inlet anti-icing system. The same hot, anti-icing air which serves to prevent the formation of

ice at the compressor inlet is also used to anti-ice the nose cone. On most nonafterburning,

multiengine, turbine-powered, aircraft installations anti-icing air must be turned on manually

by the pilot in the aircraft.

Compressor Inlet Anti-Icing - Turboprop and Turboshaft Engines

75

80

85

90

Anti-icing systems for turboprop and turboshaft engines vary with the size and design of

the engine. Large models, for instance, are often provided with a compressor air inlet anti-icing

system similar to that commonly found on axial flow compressor turbojet and turbofan engines.

The Pratt & Whitney Aircraft JFTD12 free-turbine turboshaft engine for helicopters (which is

in the 4,000 horsepower class) is a typical example of an engine of this kind. On the JFTD12,

anti-icing of the engine air inlet is provided by hot air bled from the compressor discharge. The

hot air is metered by an orifice in the airbleed manifold, and is piped forward to the inlet

section. On-Off control is provided by an electrically operated valve that is actuated by a switch

in the aircraft. Anti-icing air enters the outer annulus of the air inlet section, and) flows inward

through hollow compressor inlet guide vanes to an inner annulus. Provision is made at the front

of the engine for an airframe manufacturer to connect to the inner annulus, and use the

anti-icing discharge air for other anti-icing purposes, if desired.

Some smaller turboprops, notably the PT6 manufactured by United Aircraft of Canada,

Limited, can utilize an inlet air duct design that provides inertial separation for water, ice, and

snow particles which may be in the incoming airstream. The duct design introduces a sudden

turn to the stream of air flowing to the engine. The relatively heavy water and ice particles,

however, continue undeflected, due to)their greater momentum, and are ducted harmlessly

overboard through a bypass passage in the duct.

95

100

105

110

115

120

Fuel-Deicing Systems

Turbine engine fuel systems in which the fuel passes through a fine-mesh filter before it

enters the engine-driven fuel pump may experience icing of the filter element when the fuel in

the aircraft fuel tanks becomes severely chilled. On centrifugal compressor engines, such

systems are often equipped with a small, alcohol tank. A tap is provided to permit injection of

the alcohol (or similar deicing fluid) into the fuel line to assist in removal of ice from the low

pressure filter screen.

On larger, axial flow compressor engines, a fuel deicing system may be provided which

operates as a heat exchanger, using hot, compressor bleed air as a source of heat. The function

of this air/fuel heater or heat exchanger is to thaw the fuel filter whenever the flow of fuel is

restricted by ice. Some aircraft use an oil/fuel heater instead of an air/fuel heater to anti-ice the

fuel. Under all normal engine operating conditions, the heater, which is manually operated,

will be permitted to remain in the Off position so that no heat will be added to the fuel.

The fuel filter is fitted with a pressure drop warning switch. This switch indicates when

the filter is iced, by illuminating a warning light on the aircraft instrument panel. As ice collects

on the surface of the filter, the filter pressure drop will slowly increase. When the filter pressure

drop reaches a predetermined value, the pressure drop warning light goes on to warn the flight

crew that fuel icing is being encountered.

The fuel deicing system is designed to be used intermittently when the fuel temperature drops to

or below 32F in the vicinity of the fuel pump filter. When either this fuel temperature is

reached or the pressure drop warning light goes on, the pilot or one of his crew will turn on the

fuel heater for a period of approximately one minute, which will normally be sufficient to thaw

the filter and restore the fuel pressure drop across the filter to normal. This, in turn, will cause

the pressure drop warning light to go off. This procedure is either repeated when necessary

or, in severe fuel icing conditions, at periods of about thirty minutes.

Actividades posteriores a la lectura.

Actividad 1. A qu hacen referencia las siguientes palabras o frases?

a. this type (lnea 16)

b. they (lnea 19)

c. them (lnea 19)

d. this (lnea 22)

e. which (lnea 26)

f. In such engines (lnea 34)

g. which (lnea 40)

h. i1 (lnea 50)

Actividad 2. Busque relaciones lgicas en los prrafos de los tres primeros

subttulos.

Mencione el tipo de relacin, cul es el marcador que la indica y qu ideas, conceptos

o hechos se relacionan.

Actividad 3. Conteste las preguntas con informacin del texto.

a. Cules son las dos situaciones de congelamiento que se mencionan?

b. Cul es la condicin de congelamiento ms importante en un avin con turborreactor de

compresor centrfugo?

c. Por qu los propios sistemas del avin agravan la situacin en este tipo de aviones?

d. Sucede lo mismo en una aeronave con compresor de flujo axial? Justifique su

respuesta.

e. De qu manera se puede lograr que el regulador anticongelante acte con una mnima

prdida de empuje y menos consumo de combustible?

f. Cmo funciona el sistema anticongelante en un motor JFTD12?

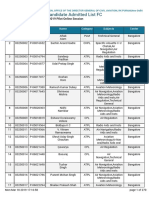

Actividad 4. Complete el cuadro.

Motores

Motores de compresor centrfugo

Motores de compresor de flujo axial

Sistema de descongelamiento de combustible

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- JEPPESEN - Airport SignsDocument18 pagesJEPPESEN - Airport SignsSarvagya Parihar100% (8)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Navy Training System PlanDocument51 pagesNavy Training System Planedgareler100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Case Study of Emirates AirlineDocument10 pagesA Case Study of Emirates AirlineAnonymous kFiZuBUNo ratings yet

- Atr 42-300 01-2004Document82 pagesAtr 42-300 01-2004Pinaki GhoshNo ratings yet

- Performance - WT and BAL for B737-800 flight from Barcelona to MadridDocument23 pagesPerformance - WT and BAL for B737-800 flight from Barcelona to MadridtomrachNo ratings yet

- 675443Document400 pages675443biokomNo ratings yet

- Spitfire Mk. IXC - 148 ScaleDocument5 pagesSpitfire Mk. IXC - 148 ScaleSam AE100% (1)

- Sikorsky Battlhawk Promo (C) Sikorsky Aircraft Corp.Document8 pagesSikorsky Battlhawk Promo (C) Sikorsky Aircraft Corp.Akshay Narker100% (1)

- Birla Institute of Technology and Science, Pilani Pilani Campus Instruction DivisionDocument3 pagesBirla Institute of Technology and Science, Pilani Pilani Campus Instruction DivisionNavik BhandariNo ratings yet

- OU 1046/25 DEC/INN-ZAG: - Not For Real World NavigationDocument35 pagesOU 1046/25 DEC/INN-ZAG: - Not For Real World NavigationDarjan SušaNo ratings yet

- B UhrDocument154 pagesB UhrMiguel SanchNo ratings yet

- CAA Type Certificate for Agusta A109 Helicopter SeriesDocument3 pagesCAA Type Certificate for Agusta A109 Helicopter Seriessebastian becerraNo ratings yet

- EASA E115 TCDS Issue 7 LEAP-1BDocument13 pagesEASA E115 TCDS Issue 7 LEAP-1BliuhkNo ratings yet

- GIJMWQ NimrodwDocument1 pageGIJMWQ NimrodwDemiar QuintoNo ratings yet

- FileDocument26 pagesFilePatrick MbunguNo ratings yet

- Cleartrip Flight E-TicketDocument2 pagesCleartrip Flight E-TicketAnujaShenoyNo ratings yet

- DGCA Pilot Admission ListDocument270 pagesDGCA Pilot Admission ListJay SarmaNo ratings yet

- 346 RLSLDocument19 pages346 RLSLparlindunganNo ratings yet

- Tiket Sulastri Fajarwati WNX - DJJ 13 JunDocument4 pagesTiket Sulastri Fajarwati WNX - DJJ 13 JunLastrie BuluatieNo ratings yet

- 05:20 06:00 G8 227 P 27B - 29 3 CCU / DEL: Kolkata DelhiDocument14 pages05:20 06:00 G8 227 P 27B - 29 3 CCU / DEL: Kolkata DelhiIndranil MukherjeeNo ratings yet

- Briefing Pack: EnrouteDocument32 pagesBriefing Pack: Enroutecap.asantillanNo ratings yet

- 2011 25 09Document7 pages2011 25 09Sundar EswararNo ratings yet

- Booking Details TJ119580364769Document2 pagesBooking Details TJ119580364769indiatoursNo ratings yet

- 2145-001 85 SeriesDocument71 pages2145-001 85 SeriesManuelNo ratings yet

- PNAS - The Promise of Energy-Efficient Battery-Powered Urban AircraftDocument3 pagesPNAS - The Promise of Energy-Efficient Battery-Powered Urban AircraftAUDINETNo ratings yet

- Pilatus Aircraft LTD - PC-12 Spectre PDFDocument2 pagesPilatus Aircraft LTD - PC-12 Spectre PDFsoma0357No ratings yet

- Stratus ES and ESG Installation Instructions STC - Rev 2.3Document45 pagesStratus ES and ESG Installation Instructions STC - Rev 2.3Faras AlsaidNo ratings yet

- Why Airlines Schedule Flights to Arrive LateDocument50 pagesWhy Airlines Schedule Flights to Arrive LateVidhi YadavNo ratings yet

- Study WGB Precursors (v6) 20230120Document212 pagesStudy WGB Precursors (v6) 20230120Burak BiçerNo ratings yet

- Cebu Pacific Air - Boarding PassDocument2 pagesCebu Pacific Air - Boarding PassMarchonie DacaraNo ratings yet