Professional Documents

Culture Documents

Us 5305572

Uploaded by

antonamxCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 5305572

Uploaded by

antonamxCopyright:

Available Formats

l l l l l l l l l l l l l lIl l l l lIl l l l l l l l l lIl l l l l l l l l

US005305572A

United States Patent [19]

[11] Patent Number:

Yee

[45]

[54]

LONG SPAN POST-TENSIONED

Apr. 26, 1994

Primary Examiner-James L. Ridgill, Jr.

F MAKING SAME

_

Date of Patent:

740121 11/1955 United Kingdom ............ .. 52/223 L

gTEEL/CONCRETE TRUSS AND METHOD

[76] Inventor:

5,305,572

Attorney, Agent, or Firm-Jacobson, Price, Holman &

Alfred A. Yee, 1441 Kapiolani Blvd.,

Stem

Honolulu, Hi. 96814

[57]

ABSTRACT

[21] Appl' No: 7o8712

[22] Filed;

May 31, 1991

A long span truss of substantially conventional steel

construction provided with concrete encasement of the

[51]

[52]

Int. GL5 ......................... .. E04C 3/10; B28B 5/00

US. Cl. ................................... .. 52/223.8; 264/35;

being reinforced and the concrete encasement on the

bottom chord and optionally on the top cord including

[58]

_

264/228; 52/643; 52/690

Field of Search .................... .. 52/223 R, 639-644,

post-tensioned steel tendons. The invention further re

laws to a method of making the truss as described above

52/690 223 L 174 230; 264/351 228

in which the light structural steel truss is ?rst erected

top and bottom chords with the concrete encasement

[56]

References Cited

and provided with ftemporaiy lriteelf scaffolding and

bracing to support ormwor .

Us PATENT DOCUMENTS

128,349 6/1872 Zellweger ............................... .. 14/6

995,437

11153-411

6/1911

Casanova ------ --

-- 52/690

9/ 1915 wuczkowski ----- --

l412'O96 4/1922 VP" EmPe-rg"

2'15 1267 3/1939 Fmiwwalder

truss. The steel tendons are post-tensioned to provide

52/653

maximum load support capability. The truss of the pres

52/225

52/690

ent invention can be used in situation where trusses are

used to carry heavy loads over long spans such as brid

2,685,194

8/ 1954

A'minkian . . . . . . . . . . .

. . . . .. 52/229

2,712,750

7/1955

Finsterwalder

.. 52/223 R

es Stadiums convention halls and the like and is es e_

g.

2,898,757 8/1959 Finsterwalder ................. .. 52/223 _R

FOREIGN PATENT DOCUMENTS

l/l964

'

'

tinuous trusses of two or more spans in which one or

more intermediate supports are emPlOYed

France .......... ..

301716 10/1942 Switzerland .................... ,. 52/223 R

5 Claims, 2 Drawing Sheets

64

//// /// / y /////////// / /

'

22*.

N 01

many bwF?clal when 58; a busy hlghway 0 Wa'

terway with the trusses including a single span or con

550103 12/1922 France ................................ .1 52/634

1387437

ein orcing steel and

steel tendons are placed in the formwork and concrete

is poured to encase the top and bottom chords of the

26

US. Patent

N

\

Ki

Apr. 26, 1994

Sheet 1 of 2

5,305,572

ON

P1.a+Rl?r

TUE

.01N

:52.

QUE

\of?

,

Pl|-I.

US. Patent

Apr. 26, 1994

Sheet 2 of 2

5,305,572

34

PH

FIG.4

//////////////////

l8/_

22

26

L\ \\\\\\\

\\\\

\\\\\\ \ \l

5,305,572

together with reinforcement materials being arranged in

LONG SPAN POST-TENSIONED

STEEL/CONCRETE TRUSS AND METHOD OF

MAKING SAME

the formwork prior to pouring concrete to reinforce

and strengthen the truss with the reinforced concrete

having the steel tendons positioned therein being post

tensioned by using conventional post-tensioning tech

BACKGROUND OF THE INVENTION

niques thereby materially increasing the strength and

1. FIELD OF THE INVENTION

rigidity of the truss.

>

The present invention generally relates to a long span

A further object of the invention is to provide a truss

truss of substantially conventional steel construction

and method in accordance with the preceding objects in

provided with concrete encasement of the top and bot 10

which only the bottom chord is provided with post-ten- tom chords with the concrete encasement being rein

sionable steel tendons in a truss that is supported only at

forced and the concrete encasement on the bottom

its opposite ends with both the bottom chord and top

chord and optionally on the top chord including post

chord being provided with post-tensionable steel ten

tensioned steel tendons. The invention further relates to

dons when the truss is in the form of a continuous truss

a method of making the truss as described above in

which the light structural steel truss is ?rst erected and

with intermediate as well as end supports.

provided with temporary steel scaffolding and bracing

Still another object of the present invention is to

to support formwork. Reinforcing steel and steel ten

provide a long span truss and method of making the

dons are placed in the formwork and concrete is poured

same in which the truss is constructed of a steel frame

to encase the top and bottom chords of the truss. The 20 having the top and bottom chords thereof encased in

steel tendons are post-tensioned to provide maximum

concrete with the bottom chord and optionally the top

load support capability. The truss of the present inven

chord being provided with post-tensionable steel ten

tion can be used in situation where trusses are used to

dons which can be post-tensioned to provide maximum

carry heavy loads over long spans such as bridges, stadi

ums, convention halls and the like and is especially 25 load support capabilities to the truss with the truss being

especially useful when used as a long span truss in the

bene?cial when spanning a busy highway or waterway

construction of bridges, stadiums, conventions halls and

with the trusses including a single span or continuous

trusses of two or more spans in which one or more

other structures in which a long span truss would be

intermediate supports are employed.

bene?cial.

30

2. DESCRIPTION OF THE PRIOR ART

Trusses of various con?gurations and arrangements

have been utilized in structures and usually include a

top chord and a bottom chord interconnected by verti

These together with other objects and advantages

which will become subsequently apparent reside in the

details of construction and operation as more fully here

inafter described and claimed, reference being had to

cal and diagonal brace members rigidly connected to 35 the accompanying drawings forming a part hereof,

wherein like numerals refer to like parts throughout.

gether with the ends of the truss being supported which

introduces tension forces to the bottom chord and com

pression forces to the top chord. In other instances, a

BRIEF DESCRIPTION OF THE DRAWINGS

continuous truss is supported at intermediate points as

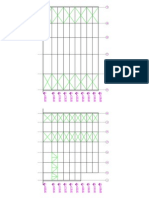

FIG. 1 is a schematic elevational view illustrating a

well as at the ends thus introducing tension forces to the 4-0 basic truss structure of lightweight steel having a

top chord as well a the bottom chord depending upon

curved bottom chord and a straight top chord intercon

the relationship between the truss and the support

points. It is well known to encase or clad components of

the truss in concrete for increasing the strength of the

nected by vertical and diagonal bracing.

FIG. 2 is a view similar to FIG. 1 illustrating the top

truss, insulation, ?reproo?ng and other well known 45 and bottom chords encased in concrete with the ends of

the truss being supported by support structures.

purposes. Prior truss structures do not include the con

FIG. 3 is a transverse sectional view of a plurality of

cept of encasing the top and bottom chords in concrete

after the truss has been erected with the truss being

trusses illustrating formwork supported in relation

constructed of relatively lightweight steel which sup-I

thereto by scaffolding connected to the trusses by brace

ports formwork to pour the concrete to encase the top 50 members.

and bottom chords of the truss with the bottom chord

and optionally the top chord including steel tendons

that are post-tensioned to obtain maximum load sup

FIG. 4 is a transverse, sectional view, on an enlarged

scale, taken substantially upon a plane passing along

porting characteristics for the truss.

section line 4-4 on FIG. 2 illustrating the structure of

concrete encasement of the top and bottom chords with

tensioned to provide maximum load supporting capabil

the bottom chord and optionally the top chord and

bottom chord being provided with steel tendons which

ity to the truss.

FIG. 5 is an elevational view similar to FIG. 2 but

the trusses including the reinforced concrete encasing

55

SUMMARY OF THE INVENTION

the top and bottom chords with the top chord including

reinforcing in the concrete and the bottom chord in

An object of the present invention is to provide a

cluding reinforcing and steel tendons which are post

long span truss constructed of steel with reinforced

are post-tensioned to provide optimum support capabil

ity to the truss.

illustrating an arrangement in which the truss is a con

tinuous truss provided with at least one support in the

Another object of the invention is to provide a

center

and illustrating an arrangement in which the top

method of making a long spa truss in which the rela 65

chord is also provided with post-tensioned steel tendons

tively lightweight steel truss is ?rst erected and form

work is supported therefrom to enable concrete to be

poured to encase the top and bottom chords of the truss

with steel tendons being arranged in the formwork

since the intermediate support 0 supports for the contin

uous truss may introduce tension forces into the top

chord.

5,305,572

DESCRIPTION OF THE PREFERRED

EMBODIMENTS '

Referring now to the drawings, FIG. 1 illustrates a

conventional truss 10 and depicts the ?rst step in the '

method of forming the long span, post-tensioned steel/

concrete truss of the present invention. The truss 10 is

of conventional construction and includes a top chord

12, a bottom chord 14 rigidly connected at their ends at

alternative is to encase only a portion of the top chord

without any encasement of the brace rods in which

event the steel tendons in the concrete encasement

which does not extend all of the way to the ends of the

top chord can be separately post-tensioned to increase

the tensile strength of the top chord when a intermedi

ate support or supports are used with the long span

truss.

'

As described above, the light structural steel truss 10

16 and provided with vertical bracing 18 and diagonal

is ?rst erected to serve as a support for formwork to

bracing 20. The components of the truss 10 are rela

contain and support the concrete encasement when it is

poured into the formwork to encase the top and bottom

tively lightweight steel I-beams or other suitable shapes

with the components being rigidly interconnected as by

using various fastening means such as bolts or welding.

chords. The concrete encasement is reinforced and is

used to accommodate post-tensioned steel tendons

The length of the truss 10 as well as the speci?c con?gu 15 which, when stressed, add substantial strength to the

ration may be varied. For example, the top and bottom

truss as the steel tendons have an ultimate strength of

chords 12 and 14 may be straight, curved or angled

270,000 psi as compared ordinary structural steel that

depending upon the installational requirements.

FIG. 2 illustrates a truss 22 which has been con

has ultimate yield strengths ranging from 36,000 to

50,000 psi. The post-tensioning of the steel tendons also

structed in accordance with the present invention with 20 reduces the sag that would result in a long span heavily

the truss 22 being the same as the truss 10 except that the

loaded truss. The concrete encasing the bottom and top

top chord 12 is now encased in concrete 24 and like

chords increase structural stiffness in the members and

wise, the bottom chord is also encased in concrete 26

the top chord could also serve as the primary compres

and schematic load supports 28 are supportingly en

sion member of the truss. This truss construction will

gaged with the outer ends of the truss.

25 thus provide maximum and optimum load supporting

FIG. 3 is a view illustrating several parallel trusses in

capability at substantial cost savings which is accom

spaced relation with the trusses being shown in trans

plished by utilizing to advantage the structural steel

verse section. Attached to the trusses 10 is scaffolding

properties of lightness in weight and ease in erection to

30 spaced below the upper chord 12 and scaffolding 32

conveniently provide an elevated formwork support to

spaced below the lower chord 14 with the scaffolding

pour the reinforced concrete top and bottom chords. By

being supported by bracing 34 connected to the braces

using the lightweight steel truss to support the form

18 and 20 of the trusses 10 or connected to the trusses in

work, the need for temporary or permanent shoring is

any other suitable manner to effectively support the

avoided thereby eliminating expensive construction

scaffolding 30 and 32. The scaffolding 30 supports form

techniques that also have the disadvantage of blocking

work 36 for the upper chord 12 and the scaffolding 32 35 traffic and obstructing the view which is especially

supports formwork 38 for the lower chord 14 with the

important in building bridges, overpasses and other

similar installations where traffic is involved.

formwork 36 and 38 being schematically illustrated as

open-topped U-shaped forms in which concrete 24 and

Also, the use of the steel trusses to support the form

26 can be poured so that it encases the top chord 12 and

work enables the concrete to be pumped into place

bottom chord 14.

along the top and bottom chords of the steel truss

FIG. 4 illustrates the completed trusses 22 in which

the top chord 12 is encased in concrete 24 and the con

thereby eliminating substantial cost in erecting heavy

employed.

can be reduced as concrete is a relatively inexpensive

long span trusses. While the post-tensioning steel em

crete 24 is provided with steel reinforcement 40. The

bedded in the bottom chord or optionally the top chord

bottom chord 14 is encased in concrete 26 and is pro

costs about twice the cost of structural steel, it will

vided with reinforcement 42 and steel tendons 44 which 45 provide approximately ?ve times the strength. With the

are post-tensioned after the concrete 26 has hardened

concrete providing the stiffness and the ?reproof en

with conventional post-tensioning techniques being

casement aspects required by the truss chords, the cost

FIG. 5 illustrates a truss 46 similar to the truss 22

material as compared to structural steel. However, high

except that in this case, only a portion of the top chord 50 dead weight of concrete makes it dif?cult to precast and

48 is encased in concrete 50 with all of the lower chord

erect in long span trusses such as in high ceilings, over

52 being encased in concrete 54. In this structure, the

land traf?c or over waterway traf?c conditions.

concrete 50 which encases a portion of the top chord 48

also extends diagonally downwardly at 56 and encases

As illustrated in FIG. 4, the trusses may be used to

support, concrete slabs 64 and ceiling structures 66,

diagonally extending brace members 58. Also, as illus 55 metal decking and the like. The temporary scaffolding

trated in FIG. 5, an intermediate support 60 is provided

30, 34 and 32 can be left in place to serve as a framing

for the truss along with the end supports 62 which can

introduce tension forces in the top chord due to the

intermediate support or supports 60. Thus, in the con

perform installation of wiring, piping, lighting ?xtures,

crete encasement in the top chord 48 and on the braces

maintenance, replacement, repairs and the like. As illus

58, steel tendons are encased in the same manner as

trated in FIG. 5, a continuous truss of two or more

illustrated in FIG. 4 with the steel tendons extending

throughout the length of the concrete encasement 50

and 56 with the same tendons also extending to the ends

to hang the ?nished ceiling of the structure as well as to

provide a platform support and access for personnel to

spans between the ends can effectively utilize concrete

cladding and post-tensioning over the support areas in a

drape fashion as shown in FIG. 5 or in a longitudinal

of the concrete encasement 54 so that the steel tendons 65 fashion in which the concrete cladding does not extend

in the top chord encasement and the bottom chord

along the diagonal bracing but the extent of the con

encasement are all post-tensioned at the ends of the truss

crete cladding along a portion of the top chord is post

using conventional post-tensioning techniques. Another

tensioned in the same manner. Thus, the concrete clad

5,305,572

ding on the top chord of the trusses could extend from

end-to-end of the trusses or terminate short of the ends

or extend downwardly of the braces with the post-ten

bottom chord, a plurality of vertical and diagonal

braces interconnecting the top and bottom chords to

sioning taking place only where it is needed in the top

these variables being dependent upon the installation

structed of light structural steel and being assembled for

support at end points, concrete cladding encasing said

top and bottom chords and including steel reinforce

ment, said chords providing support for formwork for

said concrete when poured, and a plurality of spaced,

requirements involved.

longitudinal steel tendon embedded in the concrete

The foregoing is considered as illustrative only of the

principles of the invention. Further, since numerous

modi?cations and changes will readily occur to those

being post-tensioned after the concrete has hardened to

increase the strength of the bottom chord, and a plural

form a rigid truss, said chords and braces being con

chord. Also, the shape of the steel truss can be of differ

ent con?gurations from that shown and the same princi

ple can be applied to multi-spans of 3, 4 or 5 spans with

cladding encasing the bottom chord, said steel tendons

ity of spaced, longitudinal steel tendons embedded in

skilled in the art, it is not desired to limit the invention

to the exact construction and operation shown and

the concrete cladding encasing the top chord of the

truss and being post-tensioned to increase the strength

of the top chord when the truss is supported at end

described, and, accordingly, all suitable modi?cations

and equivalents may be resorted to, falling within the

scope of the invention.

1 claim:

points, said concrete cladding encasing the top chord

extending less than the full length of the top chord to

increase the strength of the top chord in the area re

1. A long span post-tensioned light steel/concrete

truss encased in concrete comprising an elongated bot 20 quired by an intermediate support point.

4. The truss as de?ned in claim 3 wherein said con

tom chord, an elongated top chord spaced from the

crete cladding on the top chord also extends along

bottom chord, a plurality of vertical and diagonal

diagonal braces to merge and join with the cladding

braces interconnecting the top and bottom chords to

encasing the bottom chord, said steel tendons extending

form a rigid truss, said chords and braces being con

structed of light structural steel and being completely

25

assembled for support at end points, concrete cladding

completely encasing said top and bottom chords and

through the concrete cladding encasing the top chord

and through the concrete cladding encasing the diago

nal braces for post-tensioning to increase the strength of

the truss.

including steel reinforcement, said chords providing

5. The method of forming a long span truss consisting

support for formwork for said concrete when poured,

and a plurality of spaced, longitudinal steel tendons 30 of the steps of completely assembling and erecting a

lightweight steel truss, attaching scaffolding and brac

embedded in the concrete cladding encasing the bottom

ing to the steel truss, supporting concrete forms solely

chord, said steel tendons being post-tensioned after the

from the scaffolding in associate with the top chord and

concrete has hardened to increase the strength of the

bottom chord of the truss, positioning steel reinforcee

bottom chord, and a plurality of spaced, longitudinal

steel tendons embedded in the concrete cladding encas 35 ment in the forms, positioning a plurality of steel ten

ing the top chord of the truss and being post-tensioned

dons longitudinally throughout the length of the bottom

to increase the strength of the top chord when the truss

form associated with the bottom chord of the truss,

is supported at end points.

positioning a plurality of steel tendons lengthwise in the

form associated with the top chord of the truss pouring

2. The truss as de?ned in claim 1 wherein said bottom

chord is downwardly and arcuately curved to generally

correspond with a bending moment diagram.

40 concrete in the forms to encase the top and bottom

3. A long span post-tensioned light steel/concrete

allowing the concrete to harden and post-tensioning the

chords of the truss, steel reinforcement an steel tendons,

steel tendons.

truss encased in concrete comprising an elongated bot

it

tom chord, an elongated top chord spaced from the

45

50

55

65

it

UNITED STATES PATENT AND TRADEMARK OFFICE

CERTIFICATE OF CORRECTION

PATENTNO.

DATED

1 5,305,572

1 April 26 , 1994

INVENTOFKS) 1 Alfred A. YEE

It is certified that error appears in the above-indentified patent and that said Letters Patent is hereby

corrected as shown below:

'

In the Abstract, 'line 16, cancel

"situation" and insert --situations.

Column 1, line 41, cancel "a" and insert as-;

line 65, cancel "spa" and insert span-.

Column 2, line 27, cancel "conventions" and insert

convention;

line 67, cancel "0" and insert or.

Column 4, line 17, after "compared" insert to-;

line 22, cancel "increase" and insert

-increases;

line 30, after "concrete" insert to encase the.

Column 6, line 33, cancel "associate" and insert

association-;

line 39, after "truss" insert -,--;

line 41, cancel "an" and insert and.

Signed and Sealed this

Seventeenth Day of October, 1995

Arrest:

6% W

BRUCE LEHMAN

Arresting O?icer

Commisxioner of Patents and Trademark-x

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Adore Noir 028Document110 pagesAdore Noir 028Alex Scribd-Bernardin100% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- History of Photography Timeline Assignment 1Document14 pagesHistory of Photography Timeline Assignment 1api-357703158No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Drag of A Disk Rotating in A Viscous FluidDocument50 pagesDrag of A Disk Rotating in A Viscous FluidBaptiste RéaudNo ratings yet

- EcDocument299 pagesEcmanuelmanrique100% (1)

- Fundamentals of Deformable BodiesDocument73 pagesFundamentals of Deformable Bodiesacurvz2005No ratings yet

- BMD & SFD Sign ConventionDocument5 pagesBMD & SFD Sign Conventionantonamx100% (1)

- 121 B.P.S. XII - Physics Chapter Notes 2014 15 PDFDocument87 pages121 B.P.S. XII - Physics Chapter Notes 2014 15 PDFkumarnpccNo ratings yet

- Lecture 3 Columns - Oct 12 - EndDocument70 pagesLecture 3 Columns - Oct 12 - EndLiam WilliamsNo ratings yet

- 24-Fracturing Horizontal Wells PDFDocument37 pages24-Fracturing Horizontal Wells PDFmorcaronte08No ratings yet

- Chem M2 Laboratory Apparatus, Safety Rules & SymbolsDocument29 pagesChem M2 Laboratory Apparatus, Safety Rules & Symbolsdesidedo magpatigbasNo ratings yet

- Precast FlooringDocument20 pagesPrecast FlooringantonamxNo ratings yet

- Meade Starfinder ManualDocument12 pagesMeade Starfinder ManualPalompon PalNo ratings yet

- Design Working Life (EN 1990: 2002, Table 2.1)Document4 pagesDesign Working Life (EN 1990: 2002, Table 2.1)antonamxNo ratings yet

- Excavation: Typical Examples of Trench ExcavationDocument1 pageExcavation: Typical Examples of Trench ExcavationantonamxNo ratings yet

- Normalized slenderness (λ/λr) : Perfect Curve a0 Curve a Curve b Curve c Curve dDocument1 pageNormalized slenderness (λ/λr) : Perfect Curve a0 Curve a Curve b Curve c Curve dantonamxNo ratings yet

- Rock BoltsDocument4 pagesRock BoltsantonamxNo ratings yet

- Price of Structural SteelDocument1 pagePrice of Structural SteelantonamxNo ratings yet

- Clean Paper & PlasticDocument1 pageClean Paper & PlasticantonamxNo ratings yet

- Perfect Curve A Curve B Curve C Curve DDocument1 pagePerfect Curve A Curve B Curve C Curve DantonamxNo ratings yet

- Eurocodes Design ProcedureDocument5 pagesEurocodes Design ProcedureantonamxNo ratings yet

- Wall Load CapacityDocument1 pageWall Load CapacityantonamxNo ratings yet

- DWG 2 - ReservoirDocument1 pageDWG 2 - ReservoirantonamxNo ratings yet

- Comparison of SMM7 With NRM2Document3 pagesComparison of SMM7 With NRM2antonamxNo ratings yet

- Strand CharacteristicsDocument1 pageStrand CharacteristicsantonamxNo ratings yet

- Shallow FoundationsDocument15 pagesShallow FoundationsChetan PatilNo ratings yet

- Us PatentDocument15 pagesUs PatentantonamxNo ratings yet

- Bracing 2Document1 pageBracing 2antonamxNo ratings yet

- DWG 1 - ReservoirDocument1 pageDWG 1 - ReservoirantonamxNo ratings yet

- Product Integral TableDocument1 pageProduct Integral Tableicehorizon88No ratings yet

- Print 1Document1 pagePrint 1antonamxNo ratings yet

- TocDocument4 pagesTocantonamxNo ratings yet

- Bracing 1Document1 pageBracing 1antonamxNo ratings yet

- 35 - Design of BridgesDocument2 pages35 - Design of BridgesantonamxNo ratings yet

- Print 2Document1 pagePrint 2antonamxNo ratings yet

- Green Roof Pocket GuideDocument26 pagesGreen Roof Pocket GuideantonamxNo ratings yet

- LindumDocument2 pagesLindumantonamxNo ratings yet

- Stress 2 DDocument3 pagesStress 2 DantonamxNo ratings yet

- VSL Post Tensioning SolutionsDocument28 pagesVSL Post Tensioning SolutionsDea NurahmanNo ratings yet

- SL 2.8-2.10 Exponents and LogarithmsDocument26 pagesSL 2.8-2.10 Exponents and LogarithmsZeynep Aysu İskenderNo ratings yet

- Paper 2 2001Document20 pagesPaper 2 2001DisturbedPotatoNo ratings yet

- ANSYS Mechanical APDL Fluids Analysis Guide PDFDocument46 pagesANSYS Mechanical APDL Fluids Analysis Guide PDFda_pinon100% (1)

- R 2008 M.E. Power System SyllabusDocument24 pagesR 2008 M.E. Power System SyllabuskarthikeyanNo ratings yet

- SCD 000105 Spec Gaming TKT THRM NCDocument8 pagesSCD 000105 Spec Gaming TKT THRM NCAleksandar PoljcicNo ratings yet

- Performance Under Cyclic Load of Built-Up T-Stubs For Double T Moment ConnectionsDocument14 pagesPerformance Under Cyclic Load of Built-Up T-Stubs For Double T Moment ConnectionsMilmxmenNo ratings yet

- Helmholtz EquationDocument7 pagesHelmholtz EquationscribdarunscribdNo ratings yet

- (Main) : Computer Based Test (CBT)Document12 pages(Main) : Computer Based Test (CBT)Resonance Eduventures100% (1)

- 0.the Water Vapour Permeability Mechanical Properties and Solubility of Fish Gelatin Chitosan Films Modified With Transglutaminase or 1 Ethyl 3 3 DimethDocument6 pages0.the Water Vapour Permeability Mechanical Properties and Solubility of Fish Gelatin Chitosan Films Modified With Transglutaminase or 1 Ethyl 3 3 DimethValentina RoznovNo ratings yet

- CS 2742 (Logic in Computer Science) - Fall 2011: Antonina KolokolovaDocument3 pagesCS 2742 (Logic in Computer Science) - Fall 2011: Antonina KolokolovaZhichaoWangNo ratings yet

- LZ96a Dist - Relay1Document40 pagesLZ96a Dist - Relay1RK K0% (1)

- 2011121503-3-Wannate 8221enDocument2 pages2011121503-3-Wannate 8221en8612106535No ratings yet

- ZondST2D Eng PDFDocument148 pagesZondST2D Eng PDFLilyOhhNo ratings yet

- A. Wipf - Path IntegralsDocument164 pagesA. Wipf - Path Integralsnom nomNo ratings yet

- Lecture Notes On Fluid Power Systems: Unit IDocument10 pagesLecture Notes On Fluid Power Systems: Unit ItadiwosNo ratings yet

- Apendice B - Transport Phenomena - Bird 2edDocument9 pagesApendice B - Transport Phenomena - Bird 2edarur007No ratings yet

- VV2230 - FERA - DR John Newnham - 22 Nov 06Document15 pagesVV2230 - FERA - DR John Newnham - 22 Nov 06breeeeezzzzzeNo ratings yet

- New Update LED Report Final ByXiaDocument99 pagesNew Update LED Report Final ByXiaapi-3703387100% (1)

- Biomechanical Analisys of Military BootsDocument42 pagesBiomechanical Analisys of Military Bootsbungureanu_6100% (1)

- Fluid Mechanics Lecture Week 6 Chapter 2 PPT With NotesDocument40 pagesFluid Mechanics Lecture Week 6 Chapter 2 PPT With NotesJake CanlasNo ratings yet

- P23-Gears Pumps Cataloque - v0.6 - NZDocument38 pagesP23-Gears Pumps Cataloque - v0.6 - NZRogerio DiasNo ratings yet