Professional Documents

Culture Documents

ANCP0801 Mutual Coupling Measurements

Uploaded by

Insan AzizCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ANCP0801 Mutual Coupling Measurements

Uploaded by

Insan AzizCopyright:

Available Formats

AN CP0801

Application Note

MUTUAL COUPLING MEASUREMENTS

AN CP0801 Application Note

Manual Version: ANCP0801.AE.1

OMICRON electronics 2008. All rights reserved.

This Application Note is a publication of OMICRON electronics GmbH.

All rights including translation reserved. Reproduction of any kind, e.g., photocopying, microfilming or

storage in electronic data processing systems, requires the explicit consent of OMICRON electronics.

Reprinting, wholly or in part, is not permitted.

This Application Note represents the technical status at the time of printing. The product information,

specifications, and all technical data contained within this Application Note are not contractually

binding. OMICRON electronics reserves the right to make changes at any time to the technology and/or

configuration without announcement. OMICRON electronics is not to be held liable for statements and

declarations given in this Application Note. The user is responsible for every application described in

this Application Note and its results. OMICRON electronics explicitly exonerates itself from all liability

for mistakes in this document.

OMICRON electronics translates this manual from its source language English into a number of other

languages. Any translation of this manual is done for local requirements, and in the event of a dispute

between the English and any non-English versions, the English version of this manual shall govern.

Contents

Contents

1

Using This Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.1 Operator Qualifications and Safety Standards . . . . . . . . . . . . . . . . . . . . .4

1.2 Safety Measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3 Conventions and Symbols Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.4 Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Instructions for Connecting CP CU1 to Power Lines . . . . . . . . . . . .6

2.1 Before Starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.2 Recommended Current Range Settings . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.3 Estimating the Open-Line Voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.4 Connecting the Measurement Setup to Power Lines . . . . . . . . . . . . . . . .8

k Factor and Mutual Coupling Factor Measurement . . . . . . . . . . . . . . . . .10

3.1 Why k Factor Measurement? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.2 Mutual Coupling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.3 Performing Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.4 Interpretation of Measurement Results . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.4.1 Excel CPC 100 File Loader . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

AN CP0801 Application Note

1 Using This Document

Reading the AN CP0801 Application Note alone does not release you from the

duty of complying with all national and international safety regulations relevant

to working with the CPC 100 and the CP CU1. The regulation EN 50191 "The

Erection and Operation of Electrical Test Equipment" as well as all the

applicable regulations for accident prevention in the country and at the site of

operation has to be fulfilled.

1.1 Operator Qualifications and Safety Standards

Working on overhead lines is extremely dangerous. The mutual coupling

measurements described in this Application Note must be carried out only by

qualified, skilled and authorized personnel. Before starting to work, clearly

establish the responsibilities. Personnel receiving training, instructions,

directions, or education on the measurement setup must be under constant

supervision of an experienced operator while working with the equipment.

The measurements must comply with the relevant national and international

safety standards listed below:

EN 50191 (VDE 0104) "Erection and Operation of Electrical Equipment"

EN 50110-1 (VDE 0105 Part 100) "Operation of Electrical Installations"

IEEE 510 "IEEE Recommended Practices for Safety in High-Voltage and

High-Power Testing"

LAPG 1710.6 NASA "Electrical Safety"

Moreover, additional relevant laws and internal safety standards have to be

followed.

Using This Document

1.2 Safety Measures

Before starting a measurement, read the safety rules in the CPC 100 User and

Reference Manual and CP CU1 Reference Manual carefully and observe the

application specific safety instructions in this Application Note when performing

measurements to protect yourself from high-voltage hazards.

1.3 Conventions and Symbols Used

In this document, the following symbols indicate paragraphs with special safety

relevant meaning.

Symbol

Description

Equipment damage or loss of data possible.

Personal injury or severe damage to objects

possible.

1.4 Related Documents

The following documents complete the information covered in this Application

Note:

Title

Description

CPC 100 User Manual

Provides basic information on the CPC 100

test system and relevant safety instructions.

CPC 100 Reference Manual

Provides detailed hardware and software

information on the CPC 100 test system

including relevant safety instructions.

CP CU1 Reference Manual

Provides information on the CP CU1 coupling

unit and the CP GB1 grounding box including

typical application examples.

AN CP0801 Application Note

2 Safety Instructions for Connecting

CP CU1 to Power Lines

2.1 Before Starting

Caution: A lightning discharge to the line under test can cause injury or

possibly death of the operating staff. Do not connect the measurement

setup to overhead lines if there is a possibility of a thunderstorm over any

part of the lines to be measured.

Caution: Connecting the measurement setup to overhead lines with a life

parallel system brings about high-voltage hazards. It is strongly

recommended to take all parallel lines out of service before proceeding.

Before connecting CP CU1 to overhead lines or power cables (further on

referred to as power lines), you must estimate the open-line voltage as

described in 2.3 "Estimating the Open-Line Voltage". Follow the instructions

below exactly and sequentially to protect yourself from high-voltage hazards. In

addition to the following safety instructions, observe "Safety Rules" on page 7 of

the CP CU1 Reference Manual V1.4.

2.2 Recommended Current Range Settings

The highest current range allowed by the open-line voltage (see

2.4 "Connecting the Measurement Setup to Power Lines" on page 8) provides

the best measurement accuracy. However, depending on the length of the

power line under test, this setting may result in CPC 100 overload due to low

driving voltage. As a rule of thumb, the current range required for the power line

length is given in Table 2-1: "Recommended Current Range Settings" below.

Set the current range switch of CP CU1 to the value according to the table.

Table 2-1:

Recommended Current

Range Settings

Line Impedance

Line Length

Current

Range

Compliance

Voltage

01.6

02 km/01.5 miles

100 A

50 V

0.88

110 km/0.55 miles

50 A

100 V

4.040

550 km/330 miles

20 A

250 V

> 16

> 20 km/15 miles

10 A

500 V

Safety Instructions for Connecting CP CU1 to Power Lines

2.3 Estimating the Open-Line Voltage

To estimate the open-line voltage:

1. Switch off, short-circuit and ground the power line on both sides using an

installed grounding switch or, if no grounding switch is available on site, using

grounding cables (further on, the grounding switch or these extra grounding

cables are referred to as grounding switch).

2. Make sure that the connection to ground at the far end of the power line is

not removed during the complete test procedure.

3. In addition to the grounding switch, ground the line at the near end using a

grounding set consisting of three cables rated for the maximum short-circuit

current possible on the line (further on, this connection is called working

ground).

4. Open the grounding switch at the near end of the power line and measure the

current through the working ground using a clamp-on ammeter on all three

phases.

5. Close the grounding switch.

6. Calculate the estimated open-line voltage after removal of the grounding

cables as follows:

Vest [V] = meas [A] 0.4 [/km] 2 lline [km]

(Eq. 2-1)

or

Vest [V] = meas [A] 0.64 [/mile] 2 lline [miles]

(Eq. 2-2)

where Vest [V] is the estimated open-loop voltage in volts,

meas is the highest measured current in ampers,

0.4 [/km] = 0.64 [/mile] is the constant of a typical overhead line per wire

and lline [km] and lline [miles] is the length of the line in km and miles respectively.

Caution: If the estimated open-line voltage is

> 500 V, stop. The measurement is not possible due to high-voltage

hazard. Try to take parallel lines out of service.

250500 V, the measurement is possible only in the 10 A range.

100250 V, the measurement is possible in the 10 A or 20 A range.

50100 V, the measurement is possible in the 10 A, 20 A or 50 A range.

< 50 V, the measurement is possible in all current ranges.

7. If the current range allowed by the estimated open-line-voltage is lower as

the current range set according to Table 2-1: "Recommended Current Range

Settings" on page 6, set the current range switch of CP CU1 to the value

allowed by the open-line voltage.

AN CP0801 Application Note

Caution: While the grounding switch at the near end of the power line is

open, the area around CP GB1 in the range of 5 m/15 ft and around CP CU1

in the range of 2 m/5 ft is a dangerous zone due to high-voltage and

mechanical hazards. Do not enter the dangerous zone. Keep the

grounding switch open for a time as short as possible.

Caution: If you see or hear anything uncommon in the test equipment, for

example noise of electrical discharge or lightening of surge arrestors,

close the grounding switch before touching the measurement setup.

2.4 Connecting the Measurement Setup to Power

Lines

If the estimated open-line voltage (see "Estimating the Open-Line Voltage" on

page 7) allows measurement in the current range you want to use, connect the

measurement setup to the power line as follows:

1. Make sure that the grounding switch is closed.

2. Connect CP GB1 to ground using the delivered cable near the place where

the connection to the line is made. Make sure that the grounding stud is in

good condition, clean and free of oxidation.

Caution: Depending on the type of grounding points in the substation, the

appropriate connection set and socket clamp have to be used. Connecting

socket clamps of one type to a grounding point of another system is highly

dangerous on both the connection of the grounding set to CP GB1 and the

connection of CP GB1 to the grounding point in the substation. The 16 to

20 mm socket clamps are designed and tested for fault currents up to

26.5 kA, the 25 mm (1 inch) socket clamp for fault currents up to 30 kA,

both for a maximum duration of 100 ms. On locations where higher fault

currents are possible, CP CU1 and CP GB1 must not be used.

3. Disconnect the grounding cables from the ground (the grounding switch is

closed!) and connect them to the CP GB1s line studs.

4. Position CP CU1 at a minimum distance of 5 m/15 ft from CP GB1.

5. Position CPC 100 at a minimum distance of 5 m/15 ft from CP CU1 and

10 m/30 ft from CP GB1.

6. Ground CP CU1 using a cable of at least 6 mm2 cross-section close to

CPC 100 and the position of the operator.

7. Connect CP CU1 with CP GB1 as shown in Figure 2-1: "Wiring the

Measurement Setup" on page 9.

Safety Instructions for Connecting CP CU1 to Power Lines

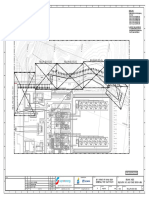

Figure 2-1:

Wiring the

Measurement Setup

Connection using

grounding sets on site

L3/C L2/B L1/A

8. Ground CPC 100 using a cable of at least 6 mm2 cross-section close to the

position of the operator.

9. Connect CP CU1 with CPC 100 as shown in Figure 2-1: "Wiring the

Measurement Setup" above.

10.Mark the area around CP GB1 in the range of at least 5 m/15 ft and around

CP CU1 in the range of at least 2 m/5 ft as dangerous zone.

11.Open the grounding switch and read the voltmeter on the CP CU1s front

panel from outside of the dangerous zone.

Caution: If the voltmeters reading is

> 500 V, stop. The measurement is not possible due to high-voltage

hazard.

250500 V, the measurement is possible only in the 10 A range.

100250 V, the measurement is possible in the 10 A or 20 A range.

50100 V, the measurement is possible in the 10 A, 20 A or 50 A range.

< 50 V, the measurement is possible in all current ranges.

If the open-line voltage allows measurement, proceed as described in

"Performing Measurements" on page 13.

Make sure that the grounding switch is always closed when no

measurement is performed and especially when the wiring is modified or

the current range switch of CP CU1 is set.

AN CP0801 Application Note

3 k Factor and Mutual Coupling Factor

Measurement

3.1 Why k Factor Measurement?

On most modern secondary distance protection relays, the value of the positivesequence (line) and zero-sequence (line-to-ground) impedance or the ground

impedance matching factor (k factor) is required to make the relay settings. The

line impedance can be readily calculated but the chosen values for the ground

impedance often do not match the actual conditions. This is because that nearby

parallel systems have an influence on the measurement and thus discrepancies

between the calculated and actual values are generated. Therefore, the mutual

coupling factor between two systems has to be determined to consider these

influences for the evaluation of the measurement results. The accuracy of these

settings is crucial to the operation of the relay because they directly affect the

reach of the different protection zones, for example in case of a line-to-ground

fault. Measurements show that in a significant number of cases the k factor of

the measured lines is set more than 20% from its actual value. This can result in

zone under- or overreach and consequently, the selectivity is lost. This situation

is particularly relevant to underground power cables.

The k factors are line parameters independent of the fault location describing the

ratio of the line and ground impedances. The following k factor definitions are

commonly used:

The complex ratio of the ground impedance Z E and the line impedance Z L

Z

-----0 1

ZE Z1

k L = ------ = -------------------- ,

ZL

3

(Eq. 3-1)

Note: Z1 = Z L

the complex ratio of the zero-sequence impedance Z 0 and the positivesequence impedance Z 1 (see Figure 3-1: "Zero-Sequence Impedance

Definition" below)

Z0

k 0 = ----Z1

and a couple of real values

10

(Eq. 3-2)

k Factor and Mutual Coupling Factor Measurement

RE

-----RL

(Eq. 3-3)

XE

-----XL

(Eq. 3-4)

where R E and X E are the real and imaginary parts respectively of the ground

impedance and R L and X L are the real and imaginary parts respectively of the

line impedance.

Figure 3-1:

Zero-Sequence

Impedance Definition

The single-phase zero-sequence impedance corresponds to a serial connection

from the line impedance Z 1 and the triple ground impedance Z E . The k factor is

an important setting of distance protection relays. The precision of this setting

affects the accuracy of distance protection relays dramatically. The k factor can

be calculated, but the calculation results give only a rough estimate of the actual

value. As a wrong k factor setting can cause worse power quality, higher risk to

lose the system stability and loss of power supply, k factor measurements are

essential for fast, selective and reliable distance protection.

Because there are usually strong disturbances by other lines in service,

measurement at the mains frequency is not feasible. All measurements running

according to the templates are done below and above the mains frequency and

the results are interpolated. From these results the positive- and zero-sequence

impedances as well as the k factor in various formats are calculated.

11

AN CP0801 Application Note

3.2 Mutual Coupling

Basically, mutual coupling is nothing but a voltage induced in the parallel

system II, which is caused by a current in system I. Due to the voltage induced

in system II, a current also flows in the parallel system, which in turn induces a

voltage in system I. This relation is shown in the following figure.

Figure 3-2:

Mutual Coupling

Between Two Wires

For measuring the coupling impedance Z M , the template requires two

measurements. The advantage of this measurement is that no measurement is

required on system II. Rather, all measurements are conducted on system I. In

the first measurement, system II is separated from the ground on at least one

end. Consequently, no current can flow through system II. The result is the zerosequence impedance Z 01 for the case that no current can flow in system II. For

the second measurement, both ends of the line have to be grounded to ensure

a flow of current. However, the voltage in system II becomes zero. The result of

this measurement is the zero-sequence impedance Z 02 . The coupling

impedance Z M is now calculated from Z 01 and Z 02 :

1

Z = --- ( Z 01 Z 02 ) Z 01

3

(Eq. 3-5)

The coupling factor can be presented in two versions. The following equation

shows the complex coupling factor kM.

ZM

k M = ------Z1

(Eq. 3-6)

In the two equations below, the real and imaginary components are split.

RM

XM

------- and ------RL

XL

12

(Eq. 3-7)

k Factor and Mutual Coupling Factor Measurement

3.3 Performing Measurements

Connect the measurement setup to the overhead lines or power cables under

test following 2 "Safety Instructions for Connecting CP CU1 to Power Lines" on

page 6.

Note: For line length below 5 km/3 miles it is recommended to connect the

V SENSE input of CP CU1 as close as possible to the VT of the line to

reduce the additional impedance of the current feed in the path. For longer

lines, you can connect the V SENSE input with the Kelvin clamps directly

on CP GB1.

13

AN CP0801 Application Note

In the course of the k factor test procedure, the following measurements are

performed:

Line-to-line impedance measurements: L1-L2, L1-L3, L2-L3 (Figure

3-3: "Line-to-Line Impedance Measurements" below shows the L1-L2

measurement as example.)

Figure 3-3:

Line-to-Line Impedance

Measurements

Far end

Overhead line

Near end

V1 AC

I AC

CPC 100

EXT. BOOSTER

14

I AC V1 AC I OUT

CP CU1

BOOSTER V SENSE

CP GB1

k Factor and Mutual Coupling Factor Measurement

Line-to-ground impedance measurements: L1-E, L2-E, L3-E (Figure

3-5: "Zero-Sequence Impedance Measurement - System II is in operation"

below shows the L1-E measurement as example.)

Figure 3-4:Line-toGround Impedance

Measurements

Far end

Overhead line

Near end

V1 AC

I AC

CPC 100

EXT. BOOSTER

I AC V1 AC I OUT

CP CU1

BOOSTER V SENSE

CP GB1

Zero-sequence impedance measurements: L1||L2||L3-E (see Figure

3-5: "Zero-Sequence Impedance Measurement - System II is in operation",

Figure 3-6: "Zero-Sequence Impedance Measurement - System II is off and

disconnected from the ground on at least one end", and Figure 3-7: "ZeroSequence Impedance Measurement - System II is off and connected to the

ground on both ends" below).

15

AN CP0801 Application Note

Short the three phases with the delivered three-lead cable as shown in

"Shorting the Phases" on page 17 of the CP CU1 Reference Manual V1.4.

Figure 3-5:

Zero-Sequence

Impedance

Measurement System II is in operation

Far end

Overhead line

Near end

V1 AC

I AC

CPC 100

EXT. BOOSTER

16

I AC V1 AC I OUT

CP CU1

BOOSTER V SENSE

CP GB1

k Factor and Mutual Coupling Factor Measurement

Figure 3-6:

Zero-Sequence

Impedance

Measurement System II is off and

disconnected from the

ground on at least one

end

Far end

Overhead line

Near end

V1 AC

I AC

CPC 100

EXT. BOOSTER

I AC V1 AC I OUT

CP CU1

BOOSTER

V SENSE

CP GB1

17

AN CP0801 Application Note

Figure 3-7:

Zero-Sequence

Impedance

Measurement System II is off and

connected to the ground

on both ends

Far end

Overhead line

Near end

V1 AC

I AC

CPC 100

EXT. BOOSTER

I AC V1 AC I OUT

CP CU1

BOOSTER

V SENSE

CP GB1

The test procedure is controlled by templates available on the CPC Explorer

CD-ROM shipped with your CP CU1 or in the customer area of www.omicron.at.

It is recommended to use the same test current for all measurements. To find

out the highest test current possible, start the test procedure with the

measurement featuring the highest impedance, that is the L1-L3 measurement

on power cables and the L1-E measurement on overhead lines.

After wiring the measurement setup to the line under test proceed as follows:

1. Configure CPC 100 as described in 2.3 "Configuring CPC 100" on page 22

of the CP CU1 Reference Manual V1.4 for the CP CU1s current range set

by the current range switch.

Caution: The configured current range must not exceed the limit by the

open-line voltage.

18

k Factor and Mutual Coupling Factor Measurement

2. Choose the XML template for the mains frequency

(e.g. "Line Imp CU1 60Hz.xmt" for the 60 Hz mains frequency) and open the

template.

Caution: Open the grounding switch at the near end before making the test

and keep it open only during the measurement. Close the grounding

switch after the test and before reconnecting the measurement setup.

3. Run the test procedure.

The following measurements are performed:

Line-to-line measurements: L1-L2, L1-L3, L2-L3

For each measurement, connect the I OUT and V SENSE inputs of

CP CU1 to the corresponding CP GB1s line studs.

Line-to-ground measurements: L1-E, L2-E, L3-E

For each measurement, connect the I OUT and V SENSE inputs of

CP CU1 to the corresponding CP GB1s line studs.

Zero-sequence impedance measurements: L1||L2||L3-E

4. If an overload of CPC 100 occurs, reduce the test current or set a lower

current range and run the test procedure once again.

Lower test currents at the two highest frequencies are recommended.

5. Save the test procedure as a file on CPC 100.

6. Download the test file from CPC 100 to the PC using CPC Explorer.

Load the test file into the Microsoft Excel template.

The measurement results are displayed.

3.4 Interpretation of Measurement Results

To interpret the results of line impedance measurements correctly, you have to

know details about the overhead line or power cable under test. You will find

below some useful notes about how to interpret the measurement results.

Usually, the resistive part of the line impedance is relatively constant over the

L1-L2, L1-L3 and L2-L3 as well as L1-E, L2-E and L3-E measurements. If the

measurement results differ considerably, typically contact problems are the

reason. In some cases, the grounding switches at the far end of the line are not

as good as necessary for the measurement. Additional grounding cables could

help to avoid the contact problems. For the lines under test shorter than

5 km/3 miles, do not connect the V SENSE input of CP CU1 with the Kelvin

clamps, but rather use additional clamps directly on the wires of the power line.

The inductive part of the line impedance increases with the distance between

the lines. This is documented by the measurement results stored in an example

file delivered with the line impedance templates (see the marked results in

19

AN CP0801 Application Note

Figure 3-8: "Measurement Results" on page 21). The measured overhead line

with the shortest distance between the lines L1 and L3 is shown in Figure

3-9: "Measured Overhead Line" on page 22.

Note: For each line of measurement results there is a separate overload

indication top right on the CPC 100s screen (or in the report) explained

below.

No overload indication means no overload during that step of the measurement

sequence.

Dotted overload indication means that there was an overload during that step of

the measurement sequence but not all the time.

Solid overload indication means a permanent overload during that step of the

measurement sequence.

3.4.1

Excel CPC 100 File Loader

Excel CPC 100 File Loader allows loading XML files generated with CPC 100

into Microsoft Excel templates for post-processing. Excel CPC 100 File Loader

is installed with CPC Explorer. After the installation, a shortcut to start Excel

CPC 100 File Loader appears on your desktop. Templates are pairs of XML

documents and Microsoft Excel templates designed by OMICRON electronics

or end users for designated applications. The XML templates are predefined test

procedures, often with comments, that run on CPC 100 and guide the user

through the test. Once completed, the XML file is saved, downloaded to the PC

using CPC Explorer and then loaded with CPC 100 File Loader into the

corresponding Microsoft Excel template. There the results are post-processed

and a final test report is generated. The template pairs facilitate and speed

testing with CPC 100 and the evaluation of results.

20

k Factor and Mutual Coupling Factor Measurement

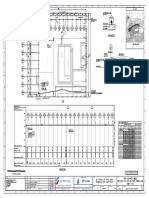

Figure 3-8:

Measurement Results

Click the button "Load XML-File" to open the browse menu to load the desired

data to the template. Click "Print Report" to print the calculated data. Under

"Measurements", the results of the impedances of the nine conducted

21

AN CP0801 Application Note

measurements are shown in Cartesian and Eulerian form. The relevant

calculated impedances are listed under "Impedance Results". Z 1 is the

arithmetic mean value of the first three measurements. Z 0 is the triple value of

the measured three-phase zero-sequence impedance and thus refers to one

phase (see Figure 3-1: "Zero-Sequence Impedance Definition"). The coupling

impedance Z M is calculated according to (Eq. 3-5) on page 12. The coupling

zero-sequence impedance Z M0 corresponds to the triple value of the coupling

impedance Z M .

The "Residual Compensation Factor" is the k factor calculated from the

determined data for setting the relays. Under "Residual Compensation Factor

Format", one of the three manufacturer-dependent formats can be selected.

Under "Mutual Coupling Factor", the mutual coupling factor is indicated. Like for

the k factor, three different display formats are available.

Figure 3-9:

Measured Overhead

Line

L2

L1

L3

The L2-E measurement features the lowest X component because the line is

very close to the ground wire. The X component of the L3-E measurement is

decreased by a parallel system taking course close to L3 on the other side of the

22

k Factor and Mutual Coupling Factor Measurement

tower. Short-circuiting of the parallel system during the measurement would

have increased the effect and would have lead to erroneous results because this

is not the normal operating condition.

Another interesting effect can be observed when measuring power cables. If the

screen or shield is very close to the conductors but the conductors are relatively

wide from each other, the inductive part of the line-to-line measurements is

higher than the inductive part of the line-to-ground measurements, resulting in a

negative X component of the calculated impedance Z E . This seemingly strange

result is explained as follows. Recalling (see 3.1 "Why k Factor Measurement?"

on page 10) that the zero-sequence impedance is given by

Z 0 = Z 1 + 3Z E

(Eq. 3-8)

and hence

( Z0 Z1 )

Z E = ---------------------3

(Eq. 3-9)

where Z 1 is the positive-sequence impedance and Z E is defined as a difference

between the line-to-ground loop measurement and a half of the line-to-line loop

measurement, the X component of Z E can become negative.

23

You might also like

- RD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CDocument2 pagesRD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CInsan Aziz100% (1)

- RD P WW P00 1022 - Rev.3 - P&ID Waste Water Treatment SystemDocument2 pagesRD P WW P00 1022 - Rev.3 - P&ID Waste Water Treatment SystemInsan AzizNo ratings yet

- RD-P-WA-P07-2002 - Rev.4 - Piping & Instrumentation Diagram HP & LP Steam Scrubbing (UNIT2)Document1 pageRD-P-WA-P07-2002 - Rev.4 - Piping & Instrumentation Diagram HP & LP Steam Scrubbing (UNIT2)Insan Aziz100% (2)

- RD-I-CI-G00-1018-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-BDocument3 pagesRD-I-CI-G00-1018-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-BInsan Aziz100% (1)

- RD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CDocument2 pagesRD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CInsan Aziz100% (1)

- RD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CDocument2 pagesRD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CInsan Aziz100% (1)

- RD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CDocument2 pagesRD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CInsan Aziz100% (1)

- RD-I-CI-G00-1015-17 - Rev.0 - Typical Drawing For Instrument Installation Cable Installation Detail (1 of 3)Document1 pageRD-I-CI-G00-1015-17 - Rev.0 - Typical Drawing For Instrument Installation Cable Installation Detail (1 of 3)Insan AzizNo ratings yet

- RD-PRD01-EnG-CSPC-2076 - Rev.0 - Piping Material Class For Lube Oil, Control Oil, Gland Steam SystemDocument3 pagesRD-PRD01-EnG-CSPC-2076 - Rev.0 - Piping Material Class For Lube Oil, Control Oil, Gland Steam SystemInsan AzizNo ratings yet

- RD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CDocument2 pagesRD-I-CI-G00-1024-02 - Rev.1 - Layout of Instrument Plot Plan, Wiring & Grounding For Well Pad RD-CInsan Aziz100% (1)

- RD-I-CI-G00-1018-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-BDocument3 pagesRD-I-CI-G00-1018-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-BInsan Aziz100% (1)

- RD-I-CI-G00-1020-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-MDocument3 pagesRD-I-CI-G00-1020-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-MInsan Aziz100% (1)

- RD-I-CI-G00-1020-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-MDocument3 pagesRD-I-CI-G00-1020-02 - Rev.1 - Layout of Instrument Plot Plan Wiring & Grounding For Well PAD RD-MInsan Aziz100% (1)

- RD-I-CI-G00-1017-01 - Rev.1 - Layout of Instrument J Main Cable Way and Cable Way For SeparatorDocument2 pagesRD-I-CI-G00-1017-01 - Rev.1 - Layout of Instrument J Main Cable Way and Cable Way For SeparatorInsan AzizNo ratings yet

- RD-I-CI-G00-1017-02 - Rev.1 - Layout of Instrument J Main Cable Way and Cable Way For SeparatorDocument2 pagesRD-I-CI-G00-1017-02 - Rev.1 - Layout of Instrument J Main Cable Way and Cable Way For SeparatorInsan AzizNo ratings yet

- RD M PO P00 1030 - Rev.0 - Welding Map Overhead CranesDocument7 pagesRD M PO P00 1030 - Rev.0 - Welding Map Overhead CranesInsan AzizNo ratings yet

- 33 File 20210813-135348 PRODUCT CATALOGUE 2021 PDFDocument20 pages33 File 20210813-135348 PRODUCT CATALOGUE 2021 PDFInsan AzizNo ratings yet

- RD-PRD01-EnG-CTEN-2003 - Rev.6 - Setting Value List For STG & AuxiliariesDocument24 pagesRD-PRD01-EnG-CTEN-2003 - Rev.6 - Setting Value List For STG & AuxiliariesInsan AzizNo ratings yet

- RD P WW P00 1022 - Rev.3 - P&ID Waste Water Treatment SystemDocument2 pagesRD P WW P00 1022 - Rev.3 - P&ID Waste Water Treatment SystemInsan AzizNo ratings yet

- RD-L-PO-G00-1003-005 - Rev.0 - PA Sheet Relocation SWS Line at PWR Station SHT 5Document1 pageRD-L-PO-G00-1003-005 - Rev.0 - PA Sheet Relocation SWS Line at PWR Station SHT 5Insan AzizNo ratings yet

- RD-PRD01-EnG-CDAT-1602 - Rev.1 Special Motorized Control Valve (MOV) For SGSDocument17 pagesRD-PRD01-EnG-CDAT-1602 - Rev.1 Special Motorized Control Valve (MOV) For SGSInsan AzizNo ratings yet

- RD I PC p00 2002 - Rev.3 - Dcs I o ListDocument87 pagesRD I PC p00 2002 - Rev.3 - Dcs I o ListInsan AzizNo ratings yet

- RD L Po g00 1005 0009 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ghd10 Drain Wastafel Dn50 120a)Document1 pageRD L Po g00 1005 0009 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ghd10 Drain Wastafel Dn50 120a)Insan AzizNo ratings yet

- RD L Po g00 1005 0003 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ghd10 Ven Dn50 120a)Document1 pageRD L Po g00 1005 0003 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ghd10 Ven Dn50 120a)Insan AzizNo ratings yet

- RD-L-PO-G00-1003-003 - Rev.0 - Piping Alignment Sheet Relocation SWS Sheet 3 of 6Document1 pageRD-L-PO-G00-1003-003 - Rev.0 - Piping Alignment Sheet Relocation SWS Sheet 3 of 6Insan AzizNo ratings yet

- RD-L-PO-G00-1003 - Rev.0 - DWG Index Relocation SWS Line PWR Station AreaDocument2 pagesRD-L-PO-G00-1003 - Rev.0 - DWG Index Relocation SWS Line PWR Station AreaInsan AzizNo ratings yet

- RD L PO G00 1005 0004 - Rev.0 - Isometric Drawing For DW (Line No. RD00 GHD10 BR005 DN50 120A)Document1 pageRD L PO G00 1005 0004 - Rev.0 - Isometric Drawing For DW (Line No. RD00 GHD10 BR005 DN50 120A)Insan AzizNo ratings yet

- RD-L-PO-G00-1003-004 - Rev.0 - Piping Alignment Sheet Relocation SWS Sheet 4 of 6Document1 pageRD-L-PO-G00-1003-004 - Rev.0 - Piping Alignment Sheet Relocation SWS Sheet 4 of 6Insan AzizNo ratings yet

- RD L Po g00 1005 0001 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ggdb10 Li Cl501 Dn50 120a) Rd00 Gdb10 Li Cl501 Dn50 120a - sht1 001Document1 pageRD L Po g00 1005 0001 - Rev.0 - Isometric Drawing For DW (Line No. Rd00 Ggdb10 Li Cl501 Dn50 120a) Rd00 Gdb10 Li Cl501 Dn50 120a - sht1 001Insan AzizNo ratings yet

- RD-L-PO-G00-1003-001 - Rev.0 - PA Sheet Relocation SWS Line at PWR Station SHT 1Document2 pagesRD-L-PO-G00-1003-001 - Rev.0 - PA Sheet Relocation SWS Line at PWR Station SHT 1Insan AzizNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Mlpower: R S T N Pe Outx-P:2-Cr:10ADocument14 pagesMlpower: R S T N Pe Outx-P:2-Cr:10AJavier MartínezNo ratings yet

- Pivotell Advance GSM Instruction Book 130418Document16 pagesPivotell Advance GSM Instruction Book 130418Eira HammondNo ratings yet

- Magnetic Levitation - WorkbookDocument35 pagesMagnetic Levitation - Workbooktusharmali990% (2)

- Filtro Fir En: Mikroc Pro For Dspic Tomado y Modificado de Filter Design ToolDocument3 pagesFiltro Fir En: Mikroc Pro For Dspic Tomado y Modificado de Filter Design ToolBrahian AguilarNo ratings yet

- EEE314 TestDocument1 pageEEE314 TestAde Precious100% (1)

- Vol07 Tab01Document372 pagesVol07 Tab01Adrian M FahriNo ratings yet

- Session 2 Wiring and Setting - LATAMDocument58 pagesSession 2 Wiring and Setting - LATAMPaulo Augusto GarayNo ratings yet

- Operation Manual: Rinnai Commercial ControllerDocument12 pagesOperation Manual: Rinnai Commercial ControllerRhizhailNo ratings yet

- Circuit Safari HandbookDocument21 pagesCircuit Safari Handbooky lNo ratings yet

- Esl Cep 3.a.9Document23 pagesEsl Cep 3.a.9DanielNo ratings yet

- Technical Notification: Saturn BM, Mkii Antenna Functionality and AdjustmentDocument6 pagesTechnical Notification: Saturn BM, Mkii Antenna Functionality and AdjustmentJon CornishNo ratings yet

- manualEMC 1Document27 pagesmanualEMC 1Parmeshwar Nath Tripathi25% (4)

- CBSE X Science Board Paper: (Time Allowed: 2 Hours) (Maximum Marks:60)Document11 pagesCBSE X Science Board Paper: (Time Allowed: 2 Hours) (Maximum Marks:60)Jince JacobNo ratings yet

- Electronics Cooling With Nanofluids A Critical ReviewDocument19 pagesElectronics Cooling With Nanofluids A Critical ReviewPralay laskarNo ratings yet

- Sierra Wireless AirLink Fastrack Xtend User Guide Rev001Document124 pagesSierra Wireless AirLink Fastrack Xtend User Guide Rev001mataNo ratings yet

- Electromagnetic Spectrum WorksheetDocument3 pagesElectromagnetic Spectrum Worksheettijil100% (1)

- Unit 25 Selecting and Using Programmable Controllers PDFDocument12 pagesUnit 25 Selecting and Using Programmable Controllers PDFahmed357No ratings yet

- Phase Locked LoopDocument4 pagesPhase Locked LoopsagarduttaNo ratings yet

- Pa0klt ManualDocument21 pagesPa0klt ManualIan McNairNo ratings yet

- CH 21. Nonmetals, Metalloids, Metals, and Metal Complexes: Brady & Senese, 5th EdDocument58 pagesCH 21. Nonmetals, Metalloids, Metals, and Metal Complexes: Brady & Senese, 5th EdZenonissya GalwanNo ratings yet

- 0111 SunSwitch - OFFER FOR - 1 KVA TO 8 KVA Solar Hybrid PCUDocument8 pages0111 SunSwitch - OFFER FOR - 1 KVA TO 8 KVA Solar Hybrid PCUGaurav KhannaNo ratings yet

- HFT500 Service Manual Rev2.0 20171208Document48 pagesHFT500 Service Manual Rev2.0 20171208alex obregon100% (3)

- Transfer Fundtion of DC GeneratorDocument5 pagesTransfer Fundtion of DC GeneratorMohammad Haris MNo ratings yet

- Power Transistor ( 40V, 2A) : 2SB1183 / 2SB1239Document1 pagePower Transistor ( 40V, 2A) : 2SB1183 / 2SB1239Angel Simo MoralesNo ratings yet

- XA Manual-V1.2Document72 pagesXA Manual-V1.2Mohamed Elsayed100% (1)

- Bta08 600c PDFDocument18 pagesBta08 600c PDFsidhom saidNo ratings yet

- Fault Finding For Charging System Diagnostic/TroubleshootingDocument4 pagesFault Finding For Charging System Diagnostic/TroubleshootingMinibikeTechNo ratings yet

- Series 9180/ 9270 Power AmplifierDocument20 pagesSeries 9180/ 9270 Power AmplifierCouger ForuNo ratings yet

- The CEO's Plain English Guide ToDocument36 pagesThe CEO's Plain English Guide ToadinankaleemNo ratings yet

- Datasheet lm337Document8 pagesDatasheet lm337eduardo1011No ratings yet