Professional Documents

Culture Documents

ESR-2251 Trubolt Mar2009

Uploaded by

raydellrCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ESR-2251 Trubolt Mar2009

Uploaded by

raydellrCopyright:

Available Formats

ICC-ES Evaluation Report

ESR-2251*

Issued January1, 2007

This report is subject to re-examination in one year.

www.icc-es.org | (800) 423-6587 | (562) 699-0543

A Subsidiary of the International Code Council

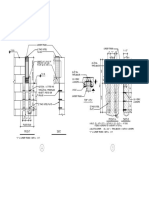

from Type 302 or Type 430 stainless steels. The standard

hexagonal nut conforms to ANSI B18.2.2-65, and the

washer conforms to ANSI/ASME B18.22.1 1965 (R1981).

The anchor stud is threaded throughout the majority of its

length and has a straight cylindrical section reduced in

diameter, around which the expansion clip is formed. The

expansion clip, consisting of a split-ring element with a

coined groove at each end, is shown in Figure 1. During

installation of the anchor, the expansion clip engages the

walls of the concrete as the wedge portion of the stud is

forced upward against the interior of the clip.

DIVISION: 03CONCRETE

Section: 03151Concrete Anchoring

REPORT HOLDER:

ITW RED HEAD

2171 EXECUTIVE DRIVE

SUITE 100

ADDISON, ILLINOIS 60101

(800) 899-7890

www.itw-redhead.com

techsupport@itw-redhead.com

4.0 DESIGN AND INSTALLATION

4.1 Strength Design:

EVALUATION SUBJECT:

ITW RED HEAD TRUBOLT CARBON STEEL WEDGE

ANCHORS IN CONCRETE

ADDITIONAL LISTEES:

ITW BRANDS

955 NATIONAL PARKWAY, SUITE 95500

SCHAUMBURG, ILLINOIS 60173

(877) 489-2726

www.itwbrands.com

Design strengths must be determined in accordance with

ACI 318-05 Appendix D as modified by IBC Section

1908.1.16 and this report. Design parameters are provided

in Table 3. Strength reduction factors (N) as given in ACI

318 Section D.4.4 must be used for load combinations

calculated in accordance with Section 1605.2 of the IBC.

Strength reduction factors (N) corresponding to ductile

steel elements may be used.

4.1.1 Requirements for Concrete Breakout Strength

in Tension: The nominal concrete breakout strength in

tension in regions where analysis indicates no cracking is

calculated in accordance with ACI 318 Section D.5.2.6.

See Section 4.1.3 in this report for limiting tension values

for a single anchor.

1.0 EVALUATION SCOPE

Compliance with the following codes:

2006 International Building Code (IBC)

2006 International Residential Code (IRC)

Property evaluated:

Structural

2.0 USES

The ITW RED HEAD TRUBOLT Wedge Anchor is used to

resist static and wind, tension and shear loads in

uncracked normal-weight concrete having a specified

compressive strength 2,500 psi fc 8,500 psi (17.2 MPa

fc 58.6 MPa). The anchoring system is an alternative to

cast-in-place anchors described in the IBC. The anchors

may also be used where an engineered design is

submitted in accordance with Section R301.1.2 of the IRC.

3.0 DESCRIPTION

The Trubolt wedge anchor is a zinc plated, torquecontrolled expansion anchor, available in 1/4-inch ,3/8-inch

1

and /2-inch diameters (6.4, 9.5 and 12.7 mm). The Trubolt

wedge anchor consists of a fully threaded stud, expansion

clip, nut and washer. The anchor stud is cold-formed from

carbon steel materials. The expansion clip is fabricated

4.1.2 Requirements for Critical Edge Distance: In

applications where c < ccr and supplemental reinforcement

to control splitting of the concrete is not present, the

concrete breakout strength in tension for uncracked

concrete, calculated according to ACI 318 Section D.5.2,

must be further multiplied by the factor edge as given by

the following equation:

c

c

edge = cr

(1)

where c cmin from Table 3

whereby the factor edge need not be taken as less than

1.5 h ef

c cr . For all other cases,

edge = 1.0. Values for the

critical edge distance ccr must be taken from Table 3.

4.1.3 Requirements for Pullout Strength in Tension:

The pullout strength for a single anchor in uncracked

concrete must not exceed the values given in Table 4.

4.1.4 Requirements for Static Shear Capacity Vs: In

lieu of the values of Vs as given in ACI 318 Section

*Corrected March 2009

ICC-ES Evaluation Reports are not to be construed as representing aesthetics or any other attributes not specifically addressed, nor are they to be construed

as an endorsement of the subject of the report or a recommendation for its use. There is no warranty by ICC Evaluation Service, Inc., express or implied, as

to any finding or other matter in this report, or as to any product covered by the report.

Copyright 2007

Page 1 of 6

ESR-2251 | Most Widely Accepted and Trusted

Page 2 of 6

D.6.1.2(c), the shear values given in Table 3 of this report

must be used.

specified compressive strength, fc, of 2,500 psi to

8,500 psi (17.2 MPa to 58.6 MPa).

4.1.5 Requirements

for

Minimum

Member

Thickness, Minimum Anchor Spacing and Minimum

Edge Distance: In lieu of ACI 318 Section D.8.3, values of

cmin and smin as given in Table 3 of this report must be

used. Additional combinations for minimum edge distance

cmin and spacing smin may be derived by linear interpolation

between the given boundary values.

5.3 The values of fc used for calculation purposes must

not exceed 8,000 psi (55.1 MPa).

5.4 Loads applied to the anchors must be adjusted in

accordance with Section 1605.2 of the IBC for

strength design, and in accordance with Section

1605.3 of the IBC for allowable stress design.

4.2 Allowable Stress Design:

5.5 Strength design values must be established in

accordance with Section 4.1 of this report.

Design resistances for use with allowable stress design

load combinations calculated in accordance with Section

1605.3 of the IBC, must be established as follows:

5.6 Allowable design values are established

accordance with Section 4.2 of this report.

Rallow, ASD = NNn/1.4

(3)

Where Nn represents the limiting design strength in

tension (Np,unc) or shear (Ns) as noted in Table 3 in this

report. Allowable stress design values for static shear and

tension are noted in Tables 5 and 6. Limits on edge

distance, anchor spacing and member thickness, as given

in Table 3 of this report, must apply. The appropriate

strength reduction factors N are noted in Table 3.

In lieu of ACI 318 Sections D.7.1, D.7.2 and D.7.3,

interaction must be calculated as follows:

For shear loads V0.2 @ Vallow, ASD, the full allowable load

in tension Tallow, ASD may be taken.

For tension loads T 0.2 @ Tallow, ASD, the full allowable

load in shear Vallow, ASD may be taken.

For all other cases:

T

Tallow,ASD

5.7 Anchor spacing and edge distance, as well as

minimum member thickness, must comply with Table

3.

5.8 Prior to installation, calculations justifying that the

design loads comply with this report, and are less

than or equal to the applied loads, must be submitted

to the building official for approval.

5.9 Since an ICC-ES acceptance criteria for evaluating

data to determine the performance of expansion

anchors subjected to fatigue or shock loading is

unavailable at this time, the use of these anchors

under such conditions is beyond the scope of this

report.

5.10 Anchors used to resist seismic loads are limited to

locations designated as Seismic Design Categories A

and B.

5.11 Anchors may be used to resist short-term loading due

to wind forces, subject to the conditions of this report.

V

Vallow,ASD

in

1.2

(4)

4.3 Installation:

The anchors must be installed in accordance with the

manufacturers installation instructions and this report.

Embedment, spacing, edge distance, and concrete

thickness are shown in Tables 2 and 3. Holes must be

predrilled in concrete with a compressive strength from

2,500 to 8,500 psi (17.2 to 58.6 MPa), using carbide-tipped

masonry drill bits complying with ANSI B212.15-1994. The

nominal drill bit diameter must be equal to the anchor

diameter. The drilled hole must exceed the required

embedment in concrete as noted in Table 2. The hole must

be cleaned with pressurized air prior to installation of the

anchor. A standard hexagonal nut and washer must be

used over the material being fastened and the nut

tightened (three to five turns) until the minimum installation

torque, as specified in Table 2, is reached.

4.4 Special Inspection:

Special inspection is required, in accordance with Section

1704.13 of the IBC. The special inspector must be on the

jobsite continuously during anchor installation to verify

anchor type, anchor dimensions, concrete type, concrete

compressive strength, hole dimensions, anchor spacing,

slab thickness, anchor embedment and tightening torque.

5.0 CONDITIONS OF USE

The ITW Red Head Trubolt Wedge Anchors described in

this report comply with the codes listed in Section 1.0 of

this report, subject to the following conditions:

5.1 Anchor sizes, dimensions, and installation are as set

forth in this report.

5.2 The anchors must be installed in accordance with the

manufacturers published instructions and this report

in uncracked normal-weight concrete having a

5.12 Where not otherwise prohibited in the code, Trubolt

wedge anchors are permitted for use with fireresistance-rated construction provided that at least

one of the following conditions is fulfilled:

Anchors are used to resist wind forces only.

Anchors that support a fire-resistance-rated

envelope or a fire-resistance-rated membrane are

protected

by

approved

fire-resistance-rated

materials, or have been evaluated for resistance to

fire exposure in accordance with recognized

standards.

Anchors are

elements.

used

to

support

nonstructural

5.13 Use of zinc-coated carbon steel anchors is limited to

dry, interior locations.

5.14 Anchors are manufactured under an approved quality

control program with inspections by PFS Corporation

(AA-652).

6.0 EVIDENCE SUBMITTED

6.1 Data complying with the ICC-ES Acceptance Criteria

for Expansion Anchors in Concrete and Masonry

Elements (AC193), dated October 2005 (ACI 355.2)

for use in uncracked concrete.

6.2 A quality control manual.

7.0 IDENTIFICATION

The concrete anchors are identified by their dimensional

characteristics, the anchor size, and by the length code

stamped on the anchor, as indicated in Table 1. Packages

are identified with the anchor type and size, the

manufacturers name and address, and the name of the

quality control agency (PFS Corporation).

ESR-2251 | Most Widely Accepted and Trusted

Page 3 of 6

FIGURE 1ITW RED HEAD TRUBOLT WEDGE ANCHOR

TABLE 1LENGTH IDENTIFICATION SYSTEM

LENGTH ID MARKING ON

ANCHOR HEAD

Length of

anchor, lanch

(inches)

UNITS

inches

(mm)

1 /2

(38.1)

2

(50.8)

2 /2

(63.5)

3

(76.2)

3 /2

(88.9)

4

(101.6)

4 /2

(114.3)

5

(127.0)

From

5 /2

(139.7)

6

(152.4)

Up to, but

not including

inches

(mm)

2

(50.8)

2 /2

(63.5)

3

(76.2)

3 /2

(88.9)

4

(101.6)

4 /2

(114.3)

5

(127.0)

5 /2

(139.7)

6

(152.4)

6 /2

(165.1)

ESR-2251 | Most Widely Accepted and Trusted

Page 4 of 6

FIGURE 2ITW RED HEAD TRUBOLT WEDGE ANCHOR (INSTALLED)

TABLE 2INSTALLATION INFORMATION

SYMBOL

NOMINAL ANCHOR DIAMETER (in.)

UNITS

/4

/8

0.25

(6.4)

/2

Anchor outer diameter

do

inches

(mm)

0.375

(9.5)

Nominal carbide bit diameter

dbit

Inches

(mm)

hef

inches

(mm)

1 /2

(38)

2

(51)

1 /4

(44)

2 /8

(67)

Embedment depth

1 /8

(48)

3 /8

(86)

ho

inches

(mm)

2

(51)

2 /2

(64)

2 /2

(64)

3 /8

(86)

Min hole depth

2 /4

(70)

4 /4

(108)

Min slab thickness

hmin

inches

(mm)

4

(102)

4

(102)

5

(127)

5

(127)

6

(152)

Installation torque

Tinst

ft-lb

(N-m)

4

(5)

Reference hole diameter

dh

inches

(mm)

/16

(7.9)

/4

0.5

(12.7)

1

/8

25

(34)

7

/16

(11.1)

/2

3

55

(75)

9

/16

(14.3)

ESR-2251 | Most Widely Accepted and Trusted

Page 5 of 6

TABLE 3CITW TRUBOLT WEDGE ANCHOR, DESIGN INFORMATION

DESIGN INFORMATION

Anchor O.D.

Effective min. embedment

SYMBOL

do

hef

Minimum member thickness

hmin

Installation Torque

Tinst

Critcial edge distance

ccr

Minimum edge distance

Minimum anchor spacing

Min. hole depth in concrete

Min. Specified Yield Strength

Min. Specified Ultimate Strength

Effective tensile stress area

Effective shear stress area

Steel strength in tension

Steel strength in shear

Pullout strength, uncracked concrete

cmin

smin

ho

fy

fu

Ase

Ase

NOMINAL ANCHOR DIAMETER

UNITS

/4

in

0.250

mm

6.4

0.500

9.5

12.7

in

1 /2

1 /4

2 /8

1 /8

3 /8

mm

38

51

44

67

48

86

in

mm

102

102

102

127

127

152

ft-lb

25

55

N-m

34

75

in

2 /8

2 /8

5 /4

3 /4

6 /4

mm

67

76

67

133

95

171

in

1 /4

1 /2

2 /4

3 /4

3 /4

mm

44

38

57

51

95

95

in

1 /4

1 /2

2 /4

3 /4

3 /4

mm

44

38

57

51

95

95

in

2 /2

2 /2

3 /8

2 /4

4 /4

51

64

64

86

70

108

mm

lb/in

N/mm

lb/in

in

in

379

517

mm

lb

Vs

0.032

0.078

0.142

20.5

50.0

91.5

0.032

0.078

0.142

20.5

50.0

91.5

2385

5815

10645

kN

10.6

lb

1430

2975

25.9

3490

4450

6385

kN

6.4

13.2

15.5

19.8

28.4

lb

Np,uncr

75,000

mm

55,000

N/mm

Ns

47.3

See Table 4

kN

Effectiveness factor kuncr uncracked concrete

24

/2

0.375

Anchor Category

Axial stiffness in service load range

/8

lb/in

14,651

9,385

17,515

26,424

32,483

26,136

kN/mm

2.6

1.6

3.1

4.6

5.7

4.6

34

47

28

45

17

33

Coefficient for variation for axial stiffness in service load range

Strength reduction factor N for tension, steel failure modes

0.75

Strength reduction factor N for shear, steel failure modes

0.65

Strength reduction factor N for tension, concrete failure modes,

Condition B

0.65

Strength reduction factor N for shear, concrete failure modes,

Condition B

0.70

For SI: 1 inch = 25.4 mm, 1 lbf = 4.45 N, 1 psi = 0.006895 Mpa. For pound-inch units: 1 mm = 0.03937 inch.

All anchors are classified as ductile in accordance with D1 of ACI 318.

ESR-2251 | Most Widely Accepted and Trusted

Page 6 of 6

1,2

TABLE 4ITW TRUBOLT WEDGE PULLOUT STRENGTH (Np, unc) (pounds)

NOMINAL ANCHOR DIAMETER (in.) EMBEDMENT DEPTH (in.)

1

/4

/8

/2

CONCRETE COMPRESSIVE STRENGTH

f'c = 2,500 psi

f'c = 3,000 psi

f'c = 4,000 psi

1 /2

1,392

1,525

1,610

1,822

1,706

1,869

1,947

2,151

1 /4

2,198

2,408

2,621

3,153

2 /8

3,469

3,800

3,936

4,275

1 /8

2,400

2,629

3,172

4,520

4,168

4,520

4,520

4,520

3 /8

f'c = 6,500 psi

For SI: 1 inch = 25.4 mm, 1 lbf = 4.45 N, 1 psi = 0.006895 MPa.

1

Values are for single anchors with no edge distance or spacing reduction.

Condition B applies where supplementary reinforcement in conformance with ACI318-02 Section D.4.4 is not provided, or where product

pullout or pryout strength governs. For cases where the presence of supplementary reinforcement can be verified, the strength reduction

factors associated with Condition A may be used.

2

TABLE 5ITW TRUBOLT WEDGE ANCHOR ALLOWABLE STATIC TENSION (ASD), NORMAL-WEIGHT

1,2

UNCRACKED CONCRETE, CONDITION B (pounds)

NOMINAL ANCHOR DIAMETER (in.) EMBEDMENT DEPTH (in.)

1

/4

/8

/2

CONCRETE COMPRESSIVE STRENGTH

f'c = 2,500 psi

f'c = 3,000 psi

f'c = 4,000 psi

1 /2

646

708

747

846

792

868

905

999

1 /4

1,021

1,118

1,217

1,464

2 /8

1,611

1,764

1,827

1,985

1 /8

1,114

1,221

1,473

2,100

1,935

2,100

2,100

2,100

3 /8

f'c = 6,500 psi

For SI: 1 inch = 25.4 mm, 1 lbf = 4.45 N, 1 psi = 0.006895 MPa.

1

Values are for single anchors with no edge distance or spacing reduction.

Condition B applies where supplementary reinforcement in conformance with ACI318-02 Section D.4.4 is not provided, or where product

pullout or pryout strength governs. For cases where the presence of supplementary reinforcement can be verified, the strength reduction

factors associated with Condition A may be used.

2

TABLE 6ITW TRUBOLT WEDGE ANCHOR ALLOWABLE STATIC SHEAR (ASD) (pounds)

NOMINAL ANCHOR DIAMETER (in.)

EMBEDMENT DEPTH (in.)

/4

/8

/2

For SI: 1 inch = 25.4 mm, 1 lbf = 4.45 N.

1

Values are for single anchors with no edge distance or spacing reduction.

ALLOWABLE LOAD

1 /2

2

664

1 /4

1,382

2 /8

1,619

1 /8

2,067

2,965

3 /8

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- WMB05Document1 pageWMB05raydellrNo ratings yet

- Truss Saddle Detail 2Document1 pageTruss Saddle Detail 2raydellrNo ratings yet

- Helical Piles in Tropical SoilsDocument9 pagesHelical Piles in Tropical SoilsraydellrNo ratings yet

- Numerical Simulation of Installation of Driven Piles in Sand Using MPMDocument16 pagesNumerical Simulation of Installation of Driven Piles in Sand Using MPMraydellrNo ratings yet

- Highlight of Qualifications: Raydel Lorenzo ReinaldoDocument2 pagesHighlight of Qualifications: Raydel Lorenzo ReinaldoraydellrNo ratings yet

- 200 Questions and Answers On Practical Civil Engineering Works 2008Document84 pages200 Questions and Answers On Practical Civil Engineering Works 2008ramdj100% (4)

- Effect of Anisotropy and Destructuration On The Behavior of Murro Test EmbankmentDocument11 pagesEffect of Anisotropy and Destructuration On The Behavior of Murro Test EmbankmentraydellrNo ratings yet

- Pan2015 Argetina 9781614996033-0961Document8 pagesPan2015 Argetina 9781614996033-0961raydellrNo ratings yet

- Ecuaciones en Latex - Santisi PDFDocument34 pagesEcuaciones en Latex - Santisi PDFMolestia AparteNo ratings yet

- Diagnostic of The Colonial Structure "Palacio Del Segundo Cabo" in Havana, CubaDocument9 pagesDiagnostic of The Colonial Structure "Palacio Del Segundo Cabo" in Havana, CubaraydellrNo ratings yet

- CPT k0Document8 pagesCPT k0raydellrNo ratings yet

- Diagnostic of The Colonial Structure "Palacio Del Segundo Cabo" in Havana, CubaDocument9 pagesDiagnostic of The Colonial Structure "Palacio Del Segundo Cabo" in Havana, CubaraydellrNo ratings yet

- Material Point Method For Geotechnical Problems Involving Large DeformationDocument1 pageMaterial Point Method For Geotechnical Problems Involving Large DeformationraydellrNo ratings yet

- Diagnostic of The Colonial Structure "Palacio Del Segundo Cabo" in Havana, CubaDocument9 pagesDiagnostic of The Colonial Structure "Palacio Del Segundo Cabo" in Havana, CubaraydellrNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Rethinking Classroom Assessment With Purpose in MindDocument112 pagesRethinking Classroom Assessment With Purpose in MindlykkhaiNo ratings yet

- 9 - The Relationship Between CEO Characteristics and Leverage - The Role of Independent CommissionersDocument10 pages9 - The Relationship Between CEO Characteristics and Leverage - The Role of Independent Commissionerscristina.llaneza02100% (1)

- Final Research Dossier - Joey KassenoffDocument11 pagesFinal Research Dossier - Joey Kassenoffapi-438481986No ratings yet

- The Effect of Online Game Addiction To TheDocument5 pagesThe Effect of Online Game Addiction To TheRafuell Amper CablasNo ratings yet

- Bai TapDocument6 pagesBai TapChi VominhNo ratings yet

- Edu Mphil SyllabusDocument27 pagesEdu Mphil Syllabussollu786_889163149No ratings yet

- Complete Notes On 9th Physics by Asif RasheedDocument82 pagesComplete Notes On 9th Physics by Asif RasheedAsif Rasheed Rajput75% (28)

- Kenya Dieticians License ApplicationDocument5 pagesKenya Dieticians License ApplicationGrace NdutaNo ratings yet

- 1 HeterogenitasDocument46 pages1 HeterogenitasRani JuliariniNo ratings yet

- Three Phase Traffic Theory PDFDocument11 pagesThree Phase Traffic Theory PDFKocic GradnjaNo ratings yet

- Why I Am Not A Primitivist - Jason McQuinnDocument9 pagesWhy I Am Not A Primitivist - Jason McQuinnfabio.coltroNo ratings yet

- Appendix A. Second QuantizationDocument24 pagesAppendix A. Second QuantizationAgtc TandayNo ratings yet

- English AssignmentDocument79 pagesEnglish AssignmentAnime TubeNo ratings yet

- DS - 20190709 - E2 - E2 198S-264S Datasheet - V10 - ENDocument13 pagesDS - 20190709 - E2 - E2 198S-264S Datasheet - V10 - ENCristina CorfaNo ratings yet

- Unit4 Dbms PDFDocument66 pagesUnit4 Dbms PDFRS GamerNo ratings yet

- B2 - PlatoDocument1 pageB2 - PlatoVeda Leigh SyNo ratings yet

- A2 Unit 4 Academic Skills Plus LessonDocument2 pagesA2 Unit 4 Academic Skills Plus LessonJanaNo ratings yet

- House (Sometimes Known As House, M.D.) Is An American TelevisionDocument17 pagesHouse (Sometimes Known As House, M.D.) Is An American Televisionpichi94No ratings yet

- Reflection Paper IIDocument1 pageReflection Paper IIHazel Marie Echavez100% (1)

- 3D Solar System With Opengl and C#Document4 pages3D Solar System With Opengl and C#Shylaja GNo ratings yet

- RGB PDFDocument35 pagesRGB PDFGestion Medios Zamba ColorsNo ratings yet

- Respiratory Protection RequirementsDocument35 pagesRespiratory Protection RequirementsNehemiah Cervantes100% (3)

- OSTEOARTHRITISDocument53 pagesOSTEOARTHRITISRiza Umami100% (1)

- Overcoming ChallengesDocument28 pagesOvercoming ChallengesDeutsche Mark CuynoNo ratings yet

- Structural Analysis of Mn(phen)3(CF3SO3)2 ComplexDocument7 pagesStructural Analysis of Mn(phen)3(CF3SO3)2 ComplexAnonymous 8pSaum8qNo ratings yet

- 200+ Selenium Interview QuestionsDocument40 pages200+ Selenium Interview QuestionsdhanaNo ratings yet

- General Dynamics F-16 Fighting Falcon - Wikipedia, The Free EncyclopediaDocument28 pagesGeneral Dynamics F-16 Fighting Falcon - Wikipedia, The Free EncyclopediaJulie MerrillNo ratings yet

- KF2.5-200 - With-M-C - GB - 03-15 KRACHT Bomba PDFDocument8 pagesKF2.5-200 - With-M-C - GB - 03-15 KRACHT Bomba PDFJairo Andrés FA100% (1)

- SPEC 2 - Module 1Document21 pagesSPEC 2 - Module 1Margie Anne ClaudNo ratings yet

- Band Theory of Soids5!1!13Document20 pagesBand Theory of Soids5!1!13Ravi Kumar BanalaNo ratings yet