Professional Documents

Culture Documents

Prokon - Circular Column

Uploaded by

Masaba SolomonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prokon - Circular Column

Uploaded by

Masaba SolomonCopyright:

Available Formats

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Date

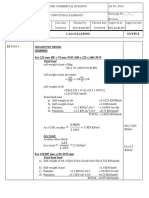

Example: Braced slender column with bi-axial moment

C12

Circular column design by PROKON. (CirCol Ver W2.5.06 - 01 Sep 2011)

Design code : BS8110 - 1997

Input tables

General design parameters and loads:

Load

Case

Ultimate Limit State Design Loads

Description

P (kN)

1 DL+LL

(mm)

300

d'

(mm)

41

(m)

Lo

20

My top (kNm)

10

Mx bot (kNm)

10

25

fcu (MPa)

fy

Mx top (kNm)

460

(MPa)

General design parameters:

Given:

d = 300 mm

d' = 41 mm

Lo = 6.000 m

fcu = 25 MPa

fy = 460 MPa

Y

300

200

100

Therefore:

0

p300 2

4

= 70.69103 mm

diax' = dia - d'

= 300 - 41

= 259.000 mm

diay' = dia - d'

= 300 - 41

= 259.000 mm

Assumptions:

(1) The general conditions of clause 3.8.1 are applicable.

(2) The section is symmetrically reinforced.

(3) The specified design axial loads include the self-weight of the column.

(4) The design axial loads are taken constant over the height of the column.

300

200

100

Y

0

p. d 2

Ac =

4

My bot (kNm)

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Date

Design approach:

The column is designed using an iterative procedure:

(1) The column design charts are constructed.

(2) An area steel is chosen.

(3) The corresponding slenderness moments are calculated.

(4) The design axis and design ultimate moment is determined .

(5) The steel required for the design axial force and moment is read from

the relevant design chart.

(6) The procedure is repeated until the convergence of the area steel

about the design axis.

(7) The area steel perpendicular to the design axis is read from the relevant

design chart.

Check column slenderness:

End fixity and bracing for bending about the X-X axis:

At the top end: Condition 2 (partially fixed).

At the bottom end: Condition 3 (pinned).

The column is braced.

\ x = 0.95

Table 3.21

End fixity and bracing for bending about the Y-Y axis:

At the top end: Condition 2 (partially fixed).

At the bottom end: Condition 3 (pinned).

The column is braced.

\ y = 0.95

Table 3.21

Effective column height:

lex = x. Lo

= .95 6

= 5.700 m

ley = y. Lo

= .95 6

= 5.700 m

Column slenderness about both axes:

lx =

lex

dia

5.7

.3

= 19.000

ly =

ley

dia

5.7

.3

= 19.000

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Date

Minimum Moments for Design:

Check for mininum eccentricity:

For bi-axial bending, it is only necessary to ensure that the eccentricity

exceeds the minimum about one axis at a time.

3.8.2.4

For the worst effect, apply the minimum eccentricity about the minor axis:

emin = 0.05 . d

= 0.05 .3

= 0.0150 m

Mmin = emin. N

= .015 20

= 0.3000 kNm

Check if the column is slender:

3.8.1.3

lx = 19.0 > 15

ly = 19.0 > 15

\ The column is slender.

Check slenderness limit:

3.8.1.7

Lo = 6.000 m < 60dia' = 18.000 m

\ Slenderness limit not exceeded.

Initial moments:

The initial end moments about the X-X axis:

M1 = Smaller initial end moment = 0.0 kNm

M2 = Larger initial end moment = 10.0 kNm

The initial moment near mid-height of the column :

Mi = - 0.4 . M1 + 0.6 . M2

= - 0.4 0 + 0.6 10

= 6.000 kNm

Mi2 = 0.4 . M2

= 0.4 10

= 4.000 kNm

\ Mi 0.4M2 = 6.0 kNm

3.8.3.2

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Date

The initial end moments about the Y-Y axis:

M1 = Smaller initial end moment = 0.0 kNm

M2 = Larger initial end moment = 10.0 kNm

The initial moment near mid-height of the column :

3.8.3.2

Mi = - 0.4 . M1 + 0.6 . M2

= - 0.4 0 + 0.6 10

= 6.000 kNm

Mi2 = 0.4 . M2

= 0.4 10

= 4.000 kNm

\ Mi 0.4M2 = 6.0 kNm

Deflection induced moments:

Design ultimate capacity of section under axial load only:

Nuz = 0.4444 . f cu. Ac + 0.95 . f y. Asc

= 0.4444 25000 .07069 + 0.95 460000 .0003

= 916.466 kN

Maximum allowable stress and strain:

Allowable compression stress in steel

f sc = 0.95 . f y

= 0.95 460

= 437.000 MPa

Allowable tensile stress in steel

f st = 0.95 . f y

= 0.95 460

= 437.000 MPa

Allowable tensile strain in steel

ey =

=

f st

Es

438.1

200000

= 0.0022

3.8.3.1

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Allowable compressive strain in concrete

ec = 0.0035

For bending about the X-X axis:

Balanced neutral axis depth

xbal =

dia - dcx

ey

1+

cstrain

.3 - .041

.00219

1+

.0035

= 0.1593 mm

Nbal calculated from basic principles using x = xbal = 368.3 kN

K=

=

Nuz - N

Nuz - Nbal

756.77 - 20

756.77 - 368.34

= 1.897

a =

1 . lex 2

2000 dia

1

5.7 2

2000 .3

= 0.1805

Therefore:

Madd = N . a. K. dia

= 20 .1805 1 .3

= 1.083

For bending about the Y-Y axis:

Balanced neutral axis depth

Date

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

xbal =

Client

Calcs by

Checked by

Date

dia - dc

ey

1+

cstrain

.3 - .041

.00219

1+

.0035

= 0.1593 mm

Nbal calculated from basic principles using x = xbal = 368.3 kN

K=

=

Nuz - N

Nuz - Nbal

756.77 - 20

756.77 - 368.34

= 1.897

a =

1 . ley 2

2000 dia

1

5.7 2

2000 .3

= 0.1805

Therefore:

Madd = N . a. K. dia

= 20 .1805 1 .3

= 1.083

Design ultimate load and moment:

Design axial load:

Pu = 20.0 kN

For bending about the X-X axis, the maximum design moment is the greatest of:

(a)

3.8.3.2

3.8.3.2

M2 = 10.0 kNm

(b)

3.8.3.2

M = Mi + Madd

= 6 + 1.083

= 7.083 kNm

(c)

3.8.3.2

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

M = M1 +

=0 +

Client

Calcs by

Checked by

Date

Madd

2

1.083

2

= 0.5415 kNm

(d)

3.8.3.2

M = emin. N

= .015 20

= 0.3000 kNm

Thus

3.8.3.2

M = 10.0 kNm

Moment distribution along the height of the column for bending about the X-X:

At the top, Mx = 10.0 kNm

Near mid-height, Mx = 7.1 kNm

At the bottom, Mx = 0.0 kNm

Moments about X-X axis( kNm)

Initial

Mx=10.0 kNm

Mxmin=0.3 kNm

Madd/2=0.5 kNm

Mxadd/2=1.1 kNm

Mxtop=10.0 kNm

Additional

For bending about the Y-Y axis, the maximum design moment is the greatest of:

(a)

Design

3.8.3.2

3.8.3.2

M2 = 10.0 kNm

(b)

3.8.3.2

M = Mi + Madd

= 6 + 1.083

= 7.083 kNm

(c)

3.8.3.2

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

M = M1 +

=0 +

Client

Calcs by

Checked by

Date

Madd

2

1.083

2

= 0.5415 kNm

(d)

3.8.3.2

M = emin. N

= .015 20

= 0.3000 kNm

Thus

3.8.3.2

M = 10.0 kNm

Moment distribution along the height of the column for bending about the Y-Y:

At the top, My = 10.0 kNm

Near mid-height, My = 7.1 kNm

At the bottom, My = 0.3 kNm

Moments about Y-Y axis( kNm)

My=10.0 kNm

Mymin=0.3 kNm

Madd/2=0.5 kNm

Initial

Myadd/2=1.1 kNm

Mytop=10.0 kNm

Additional

Design of column section for ULS:

Through inspection:

The critical section lies at the top end of the column.

The column is bi-axially bent: the moments are therefore added vectorially

to obtain the final design moment:

M' = Mx2 + My2

= 10 2 + 10 2

= 14.142

Design

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Date

Design axial load:

Pu = 20.0

For bending about the design axis:

160

170

160

170

-200

-400

-600

-800

-1000

-1200

-1400

-1600

-1800

Moment max = 141.5kNm @ 315 kN

150

150

140

130

120

110

100

90.0

6%

5%

4%

3%

80.0

2%

70.0

60.0

1%

50.0

40.0

0%

30.0

20.0

10.0

Axial Load (kN)

Column design chart

2600

2400

2200

2000

1800

1600

1400

1200

1000

800

600

400

200

Bending Moment (kNm)

From the design chart, Asc = 299 = 0.42%

Design chart for bending about any axis:

Bending Moment (kNm)

140

130

Moment max = 141.5kNm @ 315 kN

-200

-400

-600

-800

-1000

-1200

-1400

-1600

-1800

120

110

100

90.0

6%

5%

4%

3%

80.0

2%

70.0

60.0

1%

50.0

40.0

0%

30.0

20.0

10.0

Axial Load (kN)

Column design chart

2600

2400

2200

2000

1800

1600

1400

1200

1000

800

600

400

200

Job Number

Sheet

Job Title

Software Consultants (Pty) Ltd

Internet: http://www.prokon.com

E-Mail : mail@prokon.com

Client

Calcs by

Checked by

Date

Summary of design calculations:

Design results for all load cases:

Load case

Axis

X-X

Y-Y

N (kN)

20.0

M1 (kNm) M2 (kNm) Mi (kNm) Madd (kNm) Design

0.0

0.0

10.0

10.0

6.0

6.0

1.1

1.1

X-X

Top

M (kNm)

10.0

10.0

M' (kNm)

14.1

Asc (mm)

299 (0.42%)

You might also like

- Column Base Design:: Input DataDocument3 pagesColumn Base Design:: Input DataEng HatemNo ratings yet

- General Purpose Structural Analysis, Design and Detailing SoftwareDocument17 pagesGeneral Purpose Structural Analysis, Design and Detailing SoftwareNana AmoakoNo ratings yet

- Example 1: Simply Supported Rectangular Beam: Referent Calculation ResultDocument5 pagesExample 1: Simply Supported Rectangular Beam: Referent Calculation ResultMohd NazwalNo ratings yet

- SP-23 Vertical Curves For HighwaysDocument28 pagesSP-23 Vertical Curves For Highwaysimranmax13100% (5)

- Monolithic Staircase DesignDocument5 pagesMonolithic Staircase DesignAzraiAzizNo ratings yet

- Steady Pipe Flows: Single and Branched Lines: M.S. Ghidaoui (Spring 2006)Document16 pagesSteady Pipe Flows: Single and Branched Lines: M.S. Ghidaoui (Spring 2006)khalidh20100% (1)

- 04 Machine Design & DesignDocument22 pages04 Machine Design & DesignCholan PillaiNo ratings yet

- Experiment Atterberg Limits: PurposeDocument8 pagesExperiment Atterberg Limits: PurposefoidsNo ratings yet

- Esteem 9 Roof Beam ResultDocument6 pagesEsteem 9 Roof Beam Resultmysteryman2960No ratings yet

- Advanced Structural DesignDocument2 pagesAdvanced Structural DesignAnonymous zwnFXURJNo ratings yet

- BS-5950-90 Example 001Document7 pagesBS-5950-90 Example 001Win ThanNo ratings yet

- Rectangular Water Tank DesignDocument61 pagesRectangular Water Tank DesignChinkuNo ratings yet

- Analysis of Ribbed SlabDocument12 pagesAnalysis of Ribbed Slabmickymat100% (1)

- DU Calculation For House ConnectionDocument17 pagesDU Calculation For House Connectionhychauhan1No ratings yet

- Traffic Characterization MethodsDocument11 pagesTraffic Characterization MethodsAlejandro GonzalezNo ratings yet

- Water Tank DesignDocument7 pagesWater Tank DesignMilan LamsalNo ratings yet

- Industrial Training ReportDocument20 pagesIndustrial Training Reportch umairNo ratings yet

- Presentation On Analysis and Design of Small Reinforced Concrete BuildingsDocument29 pagesPresentation On Analysis and Design of Small Reinforced Concrete BuildingsPuneeth H GowdaNo ratings yet

- Water Reticulation Design Calculation AnalysisDocument4 pagesWater Reticulation Design Calculation AnalysisGan Chin PhangNo ratings yet

- Nadia Karima Izzaty 1306369466 Dept. Teknik Sipil: Time Ordinate Effective Rainfall OutputDocument9 pagesNadia Karima Izzaty 1306369466 Dept. Teknik Sipil: Time Ordinate Effective Rainfall OutputNadia Karima100% (1)

- Proposed 100 PE Small Sewerage Treatment SystemDocument1 pageProposed 100 PE Small Sewerage Treatment SystemArman ManNo ratings yet

- BEC 304 Steel and Timber DesignDocument18 pagesBEC 304 Steel and Timber DesignSeng Suen100% (1)

- Structural Analysis GuideDocument115 pagesStructural Analysis GuideMohamed Raffik Bagha100% (1)

- Chapter - 1 in Elastic Moment RedistributionDocument8 pagesChapter - 1 in Elastic Moment RedistributionHelen NegashNo ratings yet

- ProkonDocument7 pagesProkonmark7301158No ratings yet

- Loading To Box-CulvertsDocument20 pagesLoading To Box-CulvertsLjubomir JocicNo ratings yet

- Design Guidelines For Timber Ceiling Structures With Asbestos Cement Sheets or Light Timber Planks by Prof. S.R. de S. Chandrakeerthy 2005Document8 pagesDesign Guidelines For Timber Ceiling Structures With Asbestos Cement Sheets or Light Timber Planks by Prof. S.R. de S. Chandrakeerthy 2005ishanNo ratings yet

- Report Project EsteemDocument5 pagesReport Project EsteemKavi MaranNo ratings yet

- Utilization of Compact Discs in Concrete Masonry Unit (Hollow Block) ProductionDocument7 pagesUtilization of Compact Discs in Concrete Masonry Unit (Hollow Block) ProductionAlexander Vaugn VillasisNo ratings yet

- Design of A Steel Roof TrussDocument49 pagesDesign of A Steel Roof TrusseseemNo ratings yet

- PROKON Structural Analysis and DesignDocument9 pagesPROKON Structural Analysis and Designmanhal alnoaimy100% (1)

- Design of Square FoundationDocument5 pagesDesign of Square FoundationLAgoonNo ratings yet

- Hollow Pot Design WorksheetDocument7 pagesHollow Pot Design Worksheetpatrick chegeNo ratings yet

- Drainage DesignDocument16 pagesDrainage DesignChaerudin Imam100% (1)

- One Way Slab ExampleDocument18 pagesOne Way Slab Examplegizachewgirma551No ratings yet

- Ahe QBDocument20 pagesAhe QBNivedhitha CNo ratings yet

- Water RecDocument22 pagesWater RecKavi MaranNo ratings yet

- Design of Water Tank Using SAP2000 - Structural Analysis of Water TankDocument2 pagesDesign of Water Tank Using SAP2000 - Structural Analysis of Water TankSushil Dhungana100% (1)

- GEO3701 Assessment 6 2021Document7 pagesGEO3701 Assessment 6 2021Tyburg R DhliwayoNo ratings yet

- PROKON - Plane Frame - Analysis - Example - BeamDocument44 pagesPROKON - Plane Frame - Analysis - Example - BeamJames RamNo ratings yet

- Canal Outlets&Modules Worked Out ExampesDocument34 pagesCanal Outlets&Modules Worked Out ExampesrsherazNo ratings yet

- Water TankDocument5 pagesWater TankHari RamNo ratings yet

- Footing Design CalculationDocument45 pagesFooting Design Calculationsam_antony20050% (1)

- StaircaseDocument9 pagesStaircaseNNo ratings yet

- Example 6.2 - Slab-Continuous (One-Way)Document7 pagesExample 6.2 - Slab-Continuous (One-Way)nnsNo ratings yet

- Example Flange Beam PDFDocument17 pagesExample Flange Beam PDFFarhana HussinNo ratings yet

- THE HONG KONG POLYTECHNIC UNIVERSITY CBR TESTDocument6 pagesTHE HONG KONG POLYTECHNIC UNIVERSITY CBR TESTKaLeung ChungNo ratings yet

- Load Calculation in A BuildingDocument7 pagesLoad Calculation in A BuildingBaharulHussainNo ratings yet

- Moving Loads Vehicles Creation by Database EditingDocument9 pagesMoving Loads Vehicles Creation by Database Editingauriga2008No ratings yet

- 06 Reinforced Concrete StaircasesDocument30 pages06 Reinforced Concrete StaircasesGerhard vd WesthuizenNo ratings yet

- Culvert Design Write UpDocument8 pagesCulvert Design Write UpifylasyNo ratings yet

- Grid Method Contour LineDocument6 pagesGrid Method Contour LineMherlieNo ratings yet

- Chapter 1B Mat FoundationsDocument17 pagesChapter 1B Mat Foundationsmohamed hassan adenNo ratings yet

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985From EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985No ratings yet

- ColumnsDocument12 pagesColumnsHesbon Moriasi100% (1)

- Design of a Circular Reinforced Concrete ColumnDocument9 pagesDesign of a Circular Reinforced Concrete ColumnBenjamin SalinasNo ratings yet

- Circular Column CalculationDocument6 pagesCircular Column CalculationKwan Hau LeeNo ratings yet

- 15A-W9-2ND-ATTIC: Input TablesDocument5 pages15A-W9-2ND-ATTIC: Input TablesJONHCENA13No ratings yet

- Column - C1-400mm: General Design ParametersDocument4 pagesColumn - C1-400mm: General Design ParametersSravan KumarNo ratings yet

- Harvard Referencing 2010Document40 pagesHarvard Referencing 2010ivkenavarchNo ratings yet

- Historic Building Structural Assessment Report GuidelinesDocument2 pagesHistoric Building Structural Assessment Report GuidelinesMasaba SolomonNo ratings yet

- DCP Soil TestsDocument1 pageDCP Soil TestsMasaba SolomonNo ratings yet

- Prokon Out PutDocument7 pagesProkon Out PutMasaba SolomonNo ratings yet

- Column footing detailsDocument1 pageColumn footing detailsMasaba SolomonNo ratings yet

- Periodic Structural Inspection of Existing BuildingDocument14 pagesPeriodic Structural Inspection of Existing BuildingSarah SullivanNo ratings yet

- Tedds Foundation DesignDocument7 pagesTedds Foundation DesignMasaba SolomonNo ratings yet

- Sample BOQDocument1 pageSample BOQMasaba SolomonNo ratings yet

- Prokon Out PutDocument7 pagesProkon Out PutMasaba SolomonNo ratings yet

- Prokon Out PutDocument7 pagesProkon Out PutMasaba SolomonNo ratings yet

- Orion 16 ActivationDocument1 pageOrion 16 ActivationMasaba SolomonNo ratings yet

- Shear Wall Modelling PresentationDocument86 pagesShear Wall Modelling PresentationMasaba SolomonNo ratings yet

- Column Load CalculationsDocument50 pagesColumn Load CalculationsMasaba SolomonNo ratings yet

- Column Load ExampleDocument3 pagesColumn Load ExampleMasaba SolomonNo ratings yet

- Standard Training Manual: CSC OrionDocument245 pagesStandard Training Manual: CSC OrionMasaba Solomon63% (8)

- Sacred Heart StrengtheningDocument1 pageSacred Heart StrengtheningMasaba SolomonNo ratings yet

- Column Load CalculationsDocument50 pagesColumn Load CalculationsMasaba SolomonNo ratings yet

- Column Load CalculationsDocument50 pagesColumn Load CalculationsMasaba SolomonNo ratings yet

- Opthamology FDNSDocument1 pageOpthamology FDNSMasaba SolomonNo ratings yet

- Column Load Calculation Excel Sheet Examples.Document96 pagesColumn Load Calculation Excel Sheet Examples.Masaba SolomonNo ratings yet

- Column Load CalculationsDocument50 pagesColumn Load CalculationsMasaba SolomonNo ratings yet

- Column Load CalculationsDocument50 pagesColumn Load CalculationsMasaba SolomonNo ratings yet

- ChecksDocument1 pageChecksMasaba SolomonNo ratings yet

- TP16-2-Appearance of Embellishment & Trims After A Durability Wash TestDocument4 pagesTP16-2-Appearance of Embellishment & Trims After A Durability Wash TestSazzad Hossain Hossain100% (1)

- Load Rejection Test (LRT) and Reliability Running Test (RRT) - My Little WorldDocument3 pagesLoad Rejection Test (LRT) and Reliability Running Test (RRT) - My Little WorldLudka BelicovaNo ratings yet

- Computer Parts Vendors in Western RegionDocument9 pagesComputer Parts Vendors in Western RegionJohn SmithNo ratings yet

- When D2 Doesnt WorkDocument64 pagesWhen D2 Doesnt WorkSmilindNo ratings yet

- Aalco Metals LTD Aluminium AlloyDocument2 pagesAalco Metals LTD Aluminium Alloyanwarali1975No ratings yet

- ConductivityDocument36 pagesConductivityThangadurai Senthil Ram PrabhuNo ratings yet

- Ah 14526Document4 pagesAh 14526Lucio Valderrama PeredaNo ratings yet

- IO - 20190107 - ABB MV Switchgear 36kV - Installation and Operating Instructions - V20 - ENDocument24 pagesIO - 20190107 - ABB MV Switchgear 36kV - Installation and Operating Instructions - V20 - ENFranco MolinaNo ratings yet

- STRING WOUND CPPW Cartridge ContinentalDocument1 pageSTRING WOUND CPPW Cartridge ContinentalIndoarthawa FilterNo ratings yet

- Benefit of Axial Design Waterjet Propulsion - Wartsila PDFDocument20 pagesBenefit of Axial Design Waterjet Propulsion - Wartsila PDFPandega PutraNo ratings yet

- Steam Trap LossDocument12 pagesSteam Trap LossVikas SinglaNo ratings yet

- Efficient Molasses Mixer for Optimum Massecuite BlendingDocument1 pageEfficient Molasses Mixer for Optimum Massecuite BlendingRio Fransen AruanNo ratings yet

- GenSet Wattage WorksheetDocument2 pagesGenSet Wattage Worksheetjdc_1811654No ratings yet

- Duraband Information Vs 300XTDocument4 pagesDuraband Information Vs 300XTanhlhNo ratings yet

- Centralized Suply of Gas SystemDocument43 pagesCentralized Suply of Gas SystemAmir ChakaNo ratings yet

- Sample SowDocument41 pagesSample Sowamir11601No ratings yet

- Green University of Bangladesh: Department of Textile EngineeringDocument9 pagesGreen University of Bangladesh: Department of Textile EngineeringGreen University TextileNo ratings yet

- Powder Metallurgy: Dr. Chaitanya Sharma Phd. Iit RoorkeeDocument46 pagesPowder Metallurgy: Dr. Chaitanya Sharma Phd. Iit RoorkeeShivam DixitNo ratings yet

- MSE Wall Shop Drawing Checklist (Rev 3)Document3 pagesMSE Wall Shop Drawing Checklist (Rev 3)lcruz117No ratings yet

- METHOD STATEMENT FOR INSTALLATION of PVC Conduits and Accessories in The Concrete Slabs, Columns, Block Works and Concrete Walls PDFDocument6 pagesMETHOD STATEMENT FOR INSTALLATION of PVC Conduits and Accessories in The Concrete Slabs, Columns, Block Works and Concrete Walls PDFselvamejia0% (1)

- Glamox Lamparas Mariteam - CatalogDocument87 pagesGlamox Lamparas Mariteam - CatalogFarihna JoseNo ratings yet

- Cold Soak Testing & Filter Blocking TendencyDocument2 pagesCold Soak Testing & Filter Blocking TendencyGISELLENo ratings yet

- RES6-EnG Rules For Pleasure Yachts Part C 2018Document241 pagesRES6-EnG Rules For Pleasure Yachts Part C 2018Baris AkgülNo ratings yet

- Winsurf QX-9: Tech Data SheetDocument16 pagesWinsurf QX-9: Tech Data SheetFloraNo ratings yet

- Sewing Machine Needles For Leather and Technical TextilesDocument16 pagesSewing Machine Needles For Leather and Technical TextilesstansracingNo ratings yet

- TRseries Repair Manual2ENG SmallDocument42 pagesTRseries Repair Manual2ENG SmallKabi RockNo ratings yet

- Sika Hydrotite CJ-Type 2012-01-1Document5 pagesSika Hydrotite CJ-Type 2012-01-1pandavision76No ratings yet

- Differential CaseDocument5 pagesDifferential CaseOmar Jayson Siao VallejeraNo ratings yet

- IGM No. 204 Container DetailsDocument16 pagesIGM No. 204 Container DetailsMuhammad Shahzad100% (1)

- CBSE Sample Paper Class 8 Science SA1 Set 2: General InstructionsDocument4 pagesCBSE Sample Paper Class 8 Science SA1 Set 2: General InstructionsVijayalakshmi SenthilNo ratings yet