Professional Documents

Culture Documents

Ball Mill Calculations

Uploaded by

vvijaybhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ball Mill Calculations

Uploaded by

vvijaybhanCopyright:

Available Formats

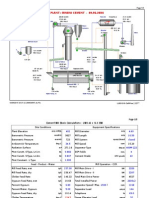

Ambuja Cement Rajasthan Limited

Ball Mill Performance & Efficiency

S.

Description

Symbol

Formula

Example

No.

1

Arm of gravity

0.666 * ( 1 - 4 * R2 )1.5

Torque factor matrix

TAN [ 0.5 / R * (1 - 4*R ) ] - [ 2*R * (1 - 4*R )

-1

2 0.5

0.583

Deff

4.18

Centre Distance (from mill centre to media top layer), mts

0.139

Deff

Mill effective diameter, mts

0.578

h/Deff, ratio of centre distance to mill effective diameter

Target

u

Material

Grinding

Coars e/Medium

Cem ent

&

Raw

Meal

Fine

Coal

Power consumption, net

2 0.5

Coars e/Medium

Medium

Pn

kW

Fitting

None

None

Danula

Sonex

None

None

Danula

Danula

None

Danula

Type

Balls

Rods

Balls

Balls

Balls

Cylpebs

Balls

Cylpebs

Balls/Cylpebs

Cylpebs

0.514 * F * u * n * Deff * a

Torque

0.73

0.55

0.75

0.66

0.69

0.73

0.71

0.75

0.69

0.71

175

Grinding media weight, tons

0.73

Torque factor

16

Mill speed, rpm

Deff

4.18

Deff

Mill effective diameter, mts

0.578

Arm of gravity, -

Pn

2538

Target

3

Power consumption, gross

New production rate

(Mill output Vs. Blaine)

Pg

Pn * 100 * 100

Pn

2450

kW

Em * Eg

Em

95

Em

Motor efficiency, %

Eg

95

Eg

Gearbox/girth gear efficiency, %

Pg

2715

Target

4

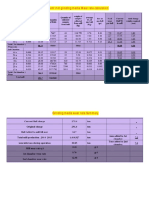

NPB

tph

Formula-1

OPB

OPB

OB

118

4000

Ambuja Cement Rajasthan Limited

Ball Mill Performance & Efficiency

S.

Description

Symbol

Formula

Example

No.

Exp ( ( NB - OB ) * 0.49 / 1000 )

NB

OPB

Old production rate, tph

NPB

OB

Old blaine, cm2/gm

Target

NB

New blaine, cm2/gm

Formula-2

OPB

OPB * ( OB / NB )

New production rate

(Mill output Vs. Residue)

OB

Old blaine, cm2/gm

NPB

NB

New blaine, cm2/gm

Target

( 2 - log ( NR ) )

OPR

150

OR

11.5

NR

9.5

OR

Old residue, %

NPR

138

NR

New residue, %

Target

Scem

2.1

Pu

90

21500 * ( Scem - Sclk )

(at weigh feeder)

tph

Pu * ( 100 - Fgyp )

Scem

Target SO3 content in cement, %

Sclk

0.3

Pu

Gypsum purity, %

Fgyp

4.8

Sclk

SO3 content in clinker, %

GSP

4.52

Fgyp

Free moisture in gypsum, %

MBS

%F

Old production rate, tph

GSP

%Filling

88

OPR

Gypsum set point

Maximum ball size

118

5000

NB

tph

4000

Old production rate, tph

OPR * ( 2 - log ( OR ) )

72

OB

OPB

NPR

mm

1.3

5000

36 * F

0.5

* { ( SG * Wi ) / ( %C * Deff

Target

0.5

)}

0.333

15

Feed size (sieve size in mm which retains 20% material), mm

SG

SG

Specific weight of feed material, gm/cm3

Wi

15

Wi

Bond's work index, kWh/t

%C

75

%C

Mill speed as %critical, %

Deff

5.1

Deff

Mill effective diameter, mts

MBS

90

Target

112.5 - ( 125 * h / Deff )

2.5

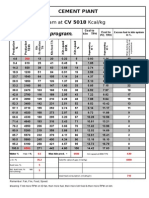

Ambuja Cement Rajasthan Limited

Ball Mill Performance & Efficiency

S.

Description

Symbol

Formula

Example

No.

%

Free height, mts

Deff

4.155

Deff

Mill effective diameter, mts

%F

37.3

Target

9

Circulation factor

Formula-1

F+G

F

F

Fresh feed rate, tph

Coarse return, tph

Formula-2

10 Circulation load

FF

150

CR

170

2.13

Target

2-3

Rg

54.92

Rg - Rf

Rf

3.52

Rg - Rm

Rm

34.16

Rg

Residue of coarse return, %

2.48

Rf

Residue of fines, %

Target

2-3

Rm

Residue of separator feed, %

C

2.48

CL

148

CL

%

( C - 1 ) * 100

C

Circulation factor, -

Target

11 Separator efficiency

SE

Formula-1

Ro

100

[log(Ro/Rf) - C * log[{Ro+(C-1)*Rg} / {Rf+(C-1)*Rg}]]*100

Rf

3.52

log(Ro/Rf) - C * log[{Ro+(C-1)*100} / {Rf+(C-1)*100}]

2.48

Ro

Residue of fresh feed, %

Rg

54.92

Rf

Residue of fines, %

SE

68.8

Circulation factor, -

Target

Rg

Residue of coarse return, %

Formula-2 (Fines Efficiency)

( 100 - Rf ) * 100

70-80

Rf

3.52

Rm

34.16

Ambuja Cement Rajasthan Limited

Ball Mill Performance & Efficiency

S.

Description

Symbol

Formula

Example

No.

( 100 - Rm ) * C

59.1

Residue of fines, %

SEf

Rm

Residue of separator feed, %

Target

70-80

Circulation factor, Rg

54.92

2.48

Rm

34.16

95.9

Rg * ( C - 1 ) * 100

C * Rm

Rg

Residue of coarse return, %

SEc

Circulation factor, -

Target

Rm

Residue of separator feed, %

nc

rpm

2.48

Rf

Formula-3 (Coarse Efficiency)

12 Critical speed

42.3 / Deff0.5

Deff

Mill effective diameter, mts

Deff

4.15

Pn

20.8

Target

New production rate

(Mill output Vs. Blaine)

NPR

Formula-1

OPB

tph

70-80

118

OPB

OB

4000

Exp ( ( NB - OB ) * 0.49 / 1000 )

NB

5000

OPB

Old production rate, tph

OB

Old blaine, cm2/gm

NB

New blaine, cm2/gm

Formula-2

OPB * ( OB / NB )

NPR

72

OPB

118

OB

4000

OPB

Old production rate, tph

NB

5000

OB

Old blaine, cm2/gm

NPR

NB

New blaine, cm2/gm

1.3

88

Ambuja Cement Rajasthan Limited

Ball Mill Performance & Efficiency

S.

Description

Symbol

Formula

Example

No.

2

New Specific power cons.

(sp. power Vs. Blaine)

Formula

NPR

E1

E (S1 / S)n

kWh/TC

1 New production rate

(Mill output Vs. Blaine)

NPR

New specific power

32.5

Old specific power

S1

5000

S1

New Blaine

4000

Old Blaine

1.3

Mill exponent for close ckt = 1.3

E1

43.44

OPB

118

Formula

tph

2 New Specific power cons.

(sp. power Vs. Blaine)

E1

OPB * ( OB / NB )1.3

4000

5000

OPB

Old production rate, tph

NB

OB

Old blaine, cm2/gm

NPR

NB

New blaine, cm2/gm

Formula

NPR

OB

E1

E (S1 / S)n

88

Ambuja Cement Rajasthan Limited

Ball Mill Performance & Efficiency

S.

Description

Symbol

Formula

Example

No.

kWh/TC

E1

New specific power

32.5

Old specific power

S1

5000

S1

New Blaine

4000

Old Blaine

1.3

Mill exponent for close ckt = 1.3

E1

43.44

Ambuja Cement Rajasthan Limited

Ambuja Cement Rajasthan Limited

Ambuja Cement Rajasthan Limited

Ambuja Cement Rajasthan Limited

100

3000

3500

1.221

Ambuja Cement Rajasthan Limited

Ambuja Cement Rajasthan Limited

You might also like

- TTLB 0079Document101 pagesTTLB 0079azharcattt88% (16)

- Capcosts 1998Document332 pagesCapcosts 1998gordonh90100% (5)

- JETFLEX Kiln Burner: Installation, Operation and Maintenance InstructionsDocument42 pagesJETFLEX Kiln Burner: Installation, Operation and Maintenance InstructionsJCSNo ratings yet

- 1 Ball Mills 1Document106 pages1 Ball Mills 1BharaniChirsabesan100% (3)

- Ball Mill Calculations PDFDocument2 pagesBall Mill Calculations PDFBùi Hắc Hải67% (3)

- Ball Mills & SeparatorsDocument91 pagesBall Mills & Separatorsvijay kumar100% (2)

- Factors Influencing Coal CombustionDocument38 pagesFactors Influencing Coal CombustionRajeevAgrawal100% (1)

- How to repair cement kiln tire and roller wearDocument8 pagesHow to repair cement kiln tire and roller wearmahreza18950% (2)

- Ball Mill Optimization PDFDocument82 pagesBall Mill Optimization PDFJackson Vu100% (2)

- HT Panel Preventive Maintenance SOPDocument9 pagesHT Panel Preventive Maintenance SOPPandu BirumakovelaNo ratings yet

- Pamantasan NG Lungsod NG Maynila: College of Engineering and Technology Chemical Engineering DepartmentDocument12 pagesPamantasan NG Lungsod NG Maynila: College of Engineering and Technology Chemical Engineering DepartmentKarl Raymundo100% (3)

- Ball Mill Testingjune99Document29 pagesBall Mill Testingjune99Shakil Ahmad83% (6)

- Recycling ConcreteDocument56 pagesRecycling ConcreteReshmita PallaNo ratings yet

- Ball Charge Design VDocument13 pagesBall Charge Design Vshani5573100% (1)

- Grinding Course: Ball Charge Design MethodsDocument12 pagesGrinding Course: Ball Charge Design MethodsVishnu Vardhan . C100% (12)

- Belt Selection CalculationDocument29 pagesBelt Selection CalculationElwathig BakhietNo ratings yet

- SDM Mill CalcsDocument10 pagesSDM Mill CalcsMohsen AghaeiNo ratings yet

- Ball Mill CalculationsDocument7 pagesBall Mill CalculationsSSAC PVT.LTD.100% (1)

- Cement Ball-Mill-Heat-BalanceDocument3 pagesCement Ball-Mill-Heat-Balanceanurag soni100% (1)

- Raw Materials Granulometry and Ball Charge DesignDocument11 pagesRaw Materials Granulometry and Ball Charge DesignKaran_Agarwal_4807100% (2)

- Ball MillDocument2 pagesBall Millsgupta_615796No ratings yet

- Finish Grinding by Roller PressDocument3 pagesFinish Grinding by Roller PressManish Verma100% (3)

- Clinker Production Kiln Surface Heat Loss FactorsDocument2 pagesClinker Production Kiln Surface Heat Loss FactorsvvijaybhanNo ratings yet

- Clinker Production Kiln Surface Heat Loss FactorsDocument2 pagesClinker Production Kiln Surface Heat Loss FactorsvvijaybhanNo ratings yet

- Clinker Production Kiln Surface Heat Loss FactorsDocument2 pagesClinker Production Kiln Surface Heat Loss FactorsvvijaybhanNo ratings yet

- 04 05 08Document55 pages04 05 08taghdirim100% (5)

- Ball Mill Volume LoadingDocument1 pageBall Mill Volume LoadingPieter100% (4)

- Cement Kiln Performance CalculationsDocument9 pagesCement Kiln Performance Calculationsvvijaybhan0% (2)

- Vertical Mill CalculationsDocument11 pagesVertical Mill CalculationsSai Sricharan Reddy84% (19)

- KHD Praesentation ZementDocument19 pagesKHD Praesentation ZementAnonymous Cxriyx9HIXNo ratings yet

- Screw Conveyor CalculationDocument14 pagesScrew Conveyor Calculationvvijaybhan100% (2)

- Mq45271 Ball Mill CalculationDocument130 pagesMq45271 Ball Mill CalculationAntonio Carlos de Angelis100% (1)

- All Cement Formulae PDFDocument163 pagesAll Cement Formulae PDFGanapathy SubramaniamNo ratings yet

- 16 Ball Filling Degree & Mill CalculationDocument2 pages16 Ball Filling Degree & Mill CalculationElwathig Bakhiet100% (4)

- BALL MILL - Ball Charge Composition Piece Weight & Specific SurfaceDocument1 pageBALL MILL - Ball Charge Composition Piece Weight & Specific Surfacevvijaybhan100% (1)

- BALL MILL - Ball Charge Composition Piece Weight & Specific SurfaceDocument1 pageBALL MILL - Ball Charge Composition Piece Weight & Specific Surfacevvijaybhan100% (1)

- 03 Ball Mill EDMDocument47 pages03 Ball Mill EDMVishnu Vardhan . C92% (13)

- Effect of Ball Size Distribution On Milling ParametersDocument103 pagesEffect of Ball Size Distribution On Milling ParametersHerwin NavarreteNo ratings yet

- Blaine Reference Blaine Required e KDocument4 pagesBlaine Reference Blaine Required e KNael100% (3)

- The Phosphates Processing HandbookDocument29 pagesThe Phosphates Processing HandbookweiningwuNo ratings yet

- Cement MillDocument28 pagesCement Millsaji kumar100% (2)

- 3 - Ball Mill GrindingDocument78 pages3 - Ball Mill GrindingMega Purnama Zainal91% (11)

- Ball MillDocument8 pagesBall MillHumbulaniNo ratings yet

- Raw Mix Design SoftwareDocument7 pagesRaw Mix Design Softwarevvijaybhan100% (9)

- Mill calculation analysisDocument3 pagesMill calculation analysisniladri.jagaty100% (2)

- Conversion Factor For NOx and SOx CalculationsDocument2 pagesConversion Factor For NOx and SOx CalculationsvvijaybhanNo ratings yet

- Ball Mill Heat Balance ExplanationDocument4 pagesBall Mill Heat Balance ExplanationVisnu Sankar67% (3)

- Mill Testing Optimisation and TargetingDocument134 pagesMill Testing Optimisation and TargetingArtemMirra90% (10)

- Cement Mill Gearbox Input & Output RatiosDocument1 pageCement Mill Gearbox Input & Output RatiosvvijaybhanNo ratings yet

- Van Hanh May Nghien Xi MangDocument212 pagesVan Hanh May Nghien Xi MangNguyen Thien Tung100% (4)

- Grinding Ball Performance Factors for Coarse and Fine GrindingDocument47 pagesGrinding Ball Performance Factors for Coarse and Fine Grindingmahreza189100% (3)

- Cement Mill Grinding Media Wear Rate CalculationDocument2 pagesCement Mill Grinding Media Wear Rate CalculationVijay Bhan100% (2)

- C 561Document2 pagesC 561Asep TheaNo ratings yet

- Rs 71 Ball Mill Sizng-1Document4 pagesRs 71 Ball Mill Sizng-1Dilnesa EjiguNo ratings yet

- Ball Mill Grinding Media Max Ball Size CalculationDocument2 pagesBall Mill Grinding Media Max Ball Size Calculationvvijaybhan100% (1)

- Ball Mill Grinding Media Max Ball Size CalculationDocument2 pagesBall Mill Grinding Media Max Ball Size Calculationvvijaybhan100% (1)

- Solid Fuel PreperationDocument1 pageSolid Fuel PreperationvvijaybhanNo ratings yet

- Cooler Design and Operation CriteriaDocument19 pagesCooler Design and Operation Criteriatricky777100% (1)

- Ball Mill Audit and OptimizationDocument82 pagesBall Mill Audit and Optimizationanrulo100% (4)

- How To Align The Kiln Burner v1-1 PDFDocument2 pagesHow To Align The Kiln Burner v1-1 PDFMustafa Ramadan100% (1)

- Horizontal Sand Mill RTSM-AD Lab Mill User ManualDocument24 pagesHorizontal Sand Mill RTSM-AD Lab Mill User ManualTom TraviNo ratings yet

- Max ball size by feed size and mill diameterDocument3 pagesMax ball size by feed size and mill diametervvijaybhan100% (1)

- Max ball size by feed size and mill diameterDocument3 pagesMax ball size by feed size and mill diametervvijaybhan100% (1)

- Modeling and Analysis of Rotor Shaft Assembly of Hammer Mill CrusherDocument46 pagesModeling and Analysis of Rotor Shaft Assembly of Hammer Mill CrusherPrudhvi VasagiriNo ratings yet

- Ball Mill Degree of Filling CalculationDocument4 pagesBall Mill Degree of Filling Calculationvvijaybhan100% (1)

- Ball Mill Degree of Filling CalculationDocument4 pagesBall Mill Degree of Filling Calculationvvijaybhan100% (1)

- GRINDINGDocument45 pagesGRINDINGTOULASSI-ANANI Yves Lolo100% (3)

- Process Train Ball MillDocument28 pagesProcess Train Ball MillvvijaybhanNo ratings yet

- Ball Mill DesignDocument6 pagesBall Mill DesignElwathig Bakhiet100% (2)

- Clinker Production Caliculation ProgramDocument3 pagesClinker Production Caliculation Programvvijaybhan100% (1)

- Tromp Curve CalculationDocument6 pagesTromp Curve Calculationvvijaybhan80% (5)

- Fan Flow CalculationDocument1 pageFan Flow CalculationvvijaybhanNo ratings yet

- Fan Flow CalculationDocument1 pageFan Flow CalculationvvijaybhanNo ratings yet

- Kiln Cooler Heat Mass BalanceDocument84 pagesKiln Cooler Heat Mass BalancePrabhakar Reddy PeramNo ratings yet

- Circulating Load: in The Crushing and Milling CircuitDocument17 pagesCirculating Load: in The Crushing and Milling Circuitaghilif100% (1)

- Circulating Load: in The Crushing and Milling CircuitDocument17 pagesCirculating Load: in The Crushing and Milling Circuitaghilif100% (1)

- Cement MillDocument19 pagesCement MillBùi Hắc HảiNo ratings yet

- S. Description Symbol Unit No.: F.L. Smidth's ATOX Vertical Roller MillDocument2 pagesS. Description Symbol Unit No.: F.L. Smidth's ATOX Vertical Roller Millvvijaybhan0% (1)

- Fuel and Combustion CalculationsDocument6 pagesFuel and Combustion Calculationsvvijaybhan100% (2)

- VITRO S5 Technical ManualDocument35 pagesVITRO S5 Technical ManualOliver AlfaroNo ratings yet

- Ball Mill Grinding Process HandbookDocument26 pagesBall Mill Grinding Process HandbookPavel Parfenov100% (4)

- Sulfur Dioxide Control: The Babcock & Wilcox CompanyDocument20 pagesSulfur Dioxide Control: The Babcock & Wilcox CompanyAnith kumar ReddyNo ratings yet

- Blaine Apparatus CalibrationDocument1 pageBlaine Apparatus Calibrationvvijaybhan50% (2)

- Rotary Kilns: Transport Phenomena and Transport ProcessesFrom EverandRotary Kilns: Transport Phenomena and Transport ProcessesRating: 4.5 out of 5 stars4.5/5 (4)

- METSIM Brochure2 2009 PDFDocument40 pagesMETSIM Brochure2 2009 PDFjaja_5430% (1)

- Ball Classification Calculation Results by Diameter and Mill LengthDocument9 pagesBall Classification Calculation Results by Diameter and Mill Lengthshani5573No ratings yet

- Material Transfer in Rotary KilnsDocument3 pagesMaterial Transfer in Rotary KilnsMehrdad AminkazemiNo ratings yet

- Tromp Curve VDocument10 pagesTromp Curve VAdelezzat OmranNo ratings yet

- LN Electrical DataDocument7 pagesLN Electrical DataBen MusimaneNo ratings yet

- Bell Pipe, One-Stage Diffuser: /difusor de Una EtapaDocument8 pagesBell Pipe, One-Stage Diffuser: /difusor de Una EtapaLuciano MelacheNo ratings yet

- Tromp CurveDocument10 pagesTromp CurveAdelezzat OmranNo ratings yet

- 2170Document9 pages2170ForteLubNo ratings yet

- Daihatsu Charade G100 Data BookDocument1 pageDaihatsu Charade G100 Data BookZain Akhtar100% (3)

- Construction - Hammer MillDocument1 pageConstruction - Hammer MillvvijaybhanNo ratings yet

- Thermal Equivalents of Fuels in kcal and BtuDocument1 pageThermal Equivalents of Fuels in kcal and BtuvvijaybhanNo ratings yet

- Mill CIRCUIT SAMPLESDocument2 pagesMill CIRCUIT SAMPLESvvijaybhanNo ratings yet

- Hammer Mill OperationDocument1 pageHammer Mill OperationvvijaybhanNo ratings yet

- Gyratory Screen - LimestoneDocument1 pageGyratory Screen - LimestonevvijaybhanNo ratings yet

- Cement Kiln StartupDocument1 pageCement Kiln StartupvvijaybhanNo ratings yet

- Lime Stone Stock Pile CalculationDocument1 pageLime Stone Stock Pile CalculationvvijaybhanNo ratings yet

- Gera Box CalculationDocument1 pageGera Box CalculationvvijaybhanNo ratings yet

- Blaine Vs OutputDocument2 pagesBlaine Vs Outputvvijaybhan100% (1)

- Gera Box CalculationDocument1 pageGera Box CalculationvvijaybhanNo ratings yet

- Laws of Crushing and Grinding ExperimentDocument2 pagesLaws of Crushing and Grinding ExperimentdivNo ratings yet

- Oec-3027-R1 Ti 1291Document16 pagesOec-3027-R1 Ti 1291mehdi_palangiNo ratings yet

- Theme Based Safety Discussion (TBT) For Manual Grinding OperationDocument3 pagesTheme Based Safety Discussion (TBT) For Manual Grinding OperationMr. XNo ratings yet

- Career Episode 3 Design and Analysis of An Electrical Grinding MachineDocument6 pagesCareer Episode 3 Design and Analysis of An Electrical Grinding MachineNishar Alam Khan 19MCD0042No ratings yet

- Parte IIDocument27 pagesParte IIRodrigues RodriguesNo ratings yet

- Manufacturing wholewheat AttaDocument3 pagesManufacturing wholewheat AttaPramod Chamaria67% (6)

- Amendments Nov 2011Document93 pagesAmendments Nov 2011Tharun RajNo ratings yet

- Food Engineering MCQDocument56 pagesFood Engineering MCQNamra0% (1)

- HACCP Exercise Assignment Wheat Flour MatterhornDocument10 pagesHACCP Exercise Assignment Wheat Flour MatterhornZigiju ZelekeNo ratings yet

- SAG Mill StoppageDocument4 pagesSAG Mill StoppageJob MateusNo ratings yet

- Kdidi 24621Document9 pagesKdidi 24621Abi NikilNo ratings yet

- Home OfficeDocument14 pagesHome OfficeLet it beNo ratings yet

- Aminpro FK TestDocument9 pagesAminpro FK TestpeilinlanNo ratings yet

- Primary Size Reduction With Jaw CrushersDocument8 pagesPrimary Size Reduction With Jaw CrushersSebastian SalNo ratings yet