Professional Documents

Culture Documents

VBM Seccionalizadores

Uploaded by

talaporriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VBM Seccionalizadores

Uploaded by

talaporriCopyright:

Available Formats

Joslyn_ProdGuide09_34&35:Joslyn_ProdGuide09_34&35

6/15/09

11:24 AM

Page 35

Capacitor Switches Single- & Three-Phase

VerSaVac Three-Phase Capacitor Switch

Now available with optional DC control

Includes operating handle for manual open and close

See I 750-272 Three-Phase VerSaVac Switch Installation

and Operating Procedure for complete details.

CAT. NO.

CAT. NO.

Porcelain

Epoxy

Grounded Systems

3148X0654G1

3148X0654G2

3148X0654G3

3148X0654G4

3148X0654G5

3148X0654G6

3148X0654G7

3148X0654G8

3148X0654G1

3148X0654G2

3148X0654G3

3148X0654G4

3148X0654G5

3148X0654G6

3148X0654G7

3148X0654G8

3148X1150G1

3148X1150G2

3148X1150G3

for Joslyn Hi-Voltage VerSaVac Three-Phase Distribution Capacitor Switch

Line-toMax. System

Ground/

Voltage (kV) Open-Gap BIL

Auxiliary

Contacts

No. of Pins

in Connector

Power Frequency

AC Withstand

Dry/Wet (kV RMS)

Control

Voltage (VAC)

3148X2154G1

3148X2154G2

3148X2154G3

3148X2154G4

3148X2154G5

3148X2154G6

3148X2154G7

3148X2154G8

3148X2154G1

3148X2154G2

3148X2154G3

3148X2154G4

3148X2154G5

3148X2154G6

3148X2154G7

3148X2154G8

3148X2161G1

3148X2161G2

3148X2161G3

15.5

15.5

15.5

15.5

15.5

15.5

15.5

15.5

27.5

27.5

27.5

27.5

27.5

27.5

27.5

27.5

38.0

38.0

38.0

95/95

95/95

95/95

95/95

125/95

125/95

125/95

125/95

95/95

95/95

95/95

95/95

125/95

125/95

125/95

125/95

125/125

150/125

150/125

1 (B)

1 (B)

2 (1A 1B)

2 (1A 1B)

1 (B)

1 (B)

2 (1A 1B)

2 (1A 1B)

1 (B)

1 (B)

2 (1A 1B)

2 (1A 1B)

1 (B)

1 (B)

2 (1A 1B)

2 (1A 1B)

1 (B)

1 (B)

1 (B)

5

5

6

6

5

5

6

6

5

5

6

6

5

5

6

6

5

5

5

36/30

36/30

36/30

36/30

60/50

60/50

60/50

60/50

36/30

36/30

36/30

36/30

60/50

60/50

60/50

60/50

60/50

70/60

70/60

120

240

120

240

120

240

120

240

120

240

120

240

120

240

120

240

120

120

240

3148X2154G1

3148X2154G2

3148X2154G3

3148X2154G4

3148X2154G5

3148X2154G6

3148X2154G7

3148X2154G8

3148X2161G1

3148X2161G2

3148X2161G3

15.5

15.5

15.5

15.5

15.5

15.5

15.5

15.5

27.5

27.5

27.5

95/95

95/95

95/95

95/95

125/95

125/95

125/95

125/95

125/125

150/125

150/125

1 (B)

1 (B)

2 (1A 1B)

2 (1A 1B)

1 (B)

1 (B)

2 (1A 1B)

2 (1A 1B)

1 (B)

1 (B)

1 (B)

5

5

6

6

5

5

6

6

5

5

5

36/30

36/30

36/30

36/30

60/50

60/50

60/50

60/50

60/50

70/60

70/60

120

240

120

240

120

240

120

240

120

120

240

Capacitor & Reactor

Switching

Ordering Information

Ungrounded Systems

3148X0654G1

3148X0654G2

3148X0654G3

3148X0654G4

3148X0654G5

3148X0654G6

3148X0654G7

3148X0654G8

3148X1150G1

3148X1150G2

3148X1150G3

Accessories

Junction Boxes, Cable Assemblies, Current Sensors, Mating Connectors, Animal Protectors, Undervoltage Trip Control, 125 DC Control Interface

For more information on capacitor controls, see our Fisher Pierce Product Selection Guide, PG-PC-FP-1008.

PG-PC-JOS-0509

utility.tnb.com

800.326.5282 8155 T&B Boulevard Memphis TN 38125

35

35

Joslyn_ProdGuide09_36&37:Joslyn_ProdGuide09_36&37

6/15/09

11:24 AM

Page 36

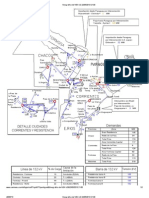

VBM Switching Systems

Joslyn Hi-Voltage Varmaster VBM Switching Systems

For substation capacitor

and reactor switching.

Joslyn Hi-Voltage Varmaster switching systems use VBM switches

that are completely sealed, breaker-class devices using a vacuum as

the interrupting dielectric. VBM switches offer high reliability with little

Capacitor & Reactor

Switching

or no maintenance and quiet, safe interruption with no external arcing.

Manufactured for system voltages from 15kV to 69kV, VBM switches

are electrically connected in series to provide the necessary recovery

voltage characteristics for the specific application. They may also be

electrically connected in parallel for high continuous or momentary

current requirements. VBM switches ship completely factoryassembled, ready for fast, easy installation requiring no special

foundations or supports due to their compact, lightweight design.

Each vacuum interrupter is enclosed in a shatterproof, high-dielectric

housing to form a module designed with all solid insulation. The interrupter is surrounded by Joslyte high-dielectric, non-hydroscopic solid insulation

that does not absorb moisture, eliminates condensation and increases the impulse level on the outside of the vacuum interrupter. No gas, oil or other

material is required to maintain electrical properties.

One or two vacuum modules are mounted on each line-to-ground insulator and connected to the operating mechanism by a high-strength pull

rod. The operating mechanism is completely sealed in a housing that supports the line-to-ground insulators and the modules. An environmental

protection system in the housing, consisting of a breather chamber and desiccant, prevents moisture and contaminated air from entering the switch

operator, and an Open/Closed position indicator is directly coupled to the mechanism. The entire assembly can withstand a force of several Gs

without damage.

Stored-energy operating mechanisms, which can be operated manually or electrically, move the contacts at high speed and are unaffected by control

voltage fluctuation or manual operating speed. Each switch features an operation counter. A wide range of AC and DC voltage control package

options are available. All electrical control connections to the operating mechanism are made through a single environmental-control cable connector.

Benefits/Descriptions

Features

Vacuum Interruption and Solid

Dielectric Joslyte Insulation

No oil, no gas, no maintenance.

Long, Maintenance-Free Service Life

Depending on operating mechanism and control voltage selection, offers up to

100,000 maintenance-free operations.

15kV 69kV System Range

Substation or pole mounted installations.

Available with Vacstat Vacuum

Interrupter Monitor

Provides local/remote status of vacuum bottle and can block operation

if a problem is detected.

Zero Voltage Closing (ZVC)

Control Available

Mitigates the system overvoltages and high inrush currents typically associated with

bringing capacitor banks online to prevent resulting customer equipment damage

and stress on capacitors.

Compact and Lightweight

No special foundations or support required.

Completely Sealed Construction

Safe interruption with no external arcing; quiet yet high-speed operation.

Factory-Assembled

Fast, easy, low-cost installation.

Choice of Operating Mechanisms

and Controls

Solenoid or motor operating mechanism with AC or DC control voltage.

36

8155 T&B Boulevard Memphis TN 38125 800.326.5282

utility.tnb.com

PG-PC-JOS-0509

Joslyn_ProdGuide09_36&37:Joslyn_ProdGuide09_36&37

6/15/09

11:24 AM

Page 37

VBM Switching Systems

VBM Switch Construction

Control Cable

Connector

Line-To-Ground

Insulator

Upper

Module

Vacuum

Module Pair

Assembly

Single Vacuum

Module

Lower

Module

Position Indicator

Capacitor & Reactor

Switching

Mechanism

Housing

Breather

Bag Cover

Manual Operating

Handle

Mechanism Cover

The VBM switch is manufactured in voltage ratings from 15kV to 69kV with continuous current capabilities from 200A to 600A.

The mechanism may be operated manually, or electrically by solenoid or motor operators.

Single Vacuum Module Cutaway

Module Housing

Vacuum Contacts

High Voltage Terminals

Solid Dielectric

Joslyte Insulation

Dead Soft

Copper Shunts

Porcelain Insulator

Insulated Fiberglass Pull Rod

Cutaway of single-vacuum module mounted on 15kV line-to-ground insulator.

The assembly containing the vacuum interrupter is called a module. Each module has a vacuum

interrupter contact sealed in Joslyte solid dielectric insulation, which provides mechanical strength,

high dielectric strength and complete moisture sealing. The module housing is cycloaliphatic or EPR

rubber bonded to a fiberglass tube. One or two modules are mounted on each insulator and connect

to the mechanism by a high-strength pull rod.

PG-PC-JOS-0509

utility.tnb.com

800.326.5282 8155 T&B Boulevard Memphis TN 38125

37

Joslyn_ProdGuide09_38&39:Joslyn_ProdGuide09_38&39

6/15/09

11:24 AM

Page 38

VBM Switching Systems

Varmaster VBM Switch with Vacstat Vacuum Interrupter

Monitor alerts you immediately of loss of vacuum!

The Joslyn Hi-Voltage Vacstat Vacuum Interrupter Monitor provides you real-time status monitoring of your vacuum interrupters. This simple device

notifies you immediately of a loss of vacuum through a visual indicator located on the switch and via a contact in the switch control. Once the Vacstat

Vacuum Interrupter Monitor senses a loss of vacuum, all switch operations will be blocked until the switch has been serviced.

Capacitor & Reactor

Switching

How the Vacstat Vacuum Interrupter Monitor works.

The Vacstat sensor is attached to the vacuum interrupter of a Varmaster

If a loss of vacuum occurs, the sensor blocks the optical signal to the

VBM Switch during the manufacturing process. The sensor then

control board, and the Vacstat status indicator automatically turns to red

continuously monitors the interrupter for the presence of vacuum.

to alert the operator to the problem. In addition, the remote status dry

contact provides a means to send an alarm signal to a remote location.

Once the capacitor switch is installed, the sensor generates an optical

The Vacstat monitor also blocks further electrical operation of the switch

signal that travels via a pair of fiber optic cables to a control board in the

to prevent possible damage to equipment or injury to personnel.

low-voltage section of the switch. As long as vacuum exists, the fiber

optic signal has a continuous path, and the Vacstat indicator remains in

the normal (unalarmed) state.

Vacuum Interrupter

Insulator

Vacuum

Interrupter

Monitor

Switch Position

Indicator & Counter

Vacuum Interrupter Status Indicator

Control Cable

Connector

Alarmed

Normal

Benefits/Descriptions

Features

38

38

Continuously Monitors Vacuum Interrupter

Status While the Switch Is Energized

and in Service

Reduces operating and maintenance costs by eliminating the need for routine off-line

vacuum interrupter inspections.

Blocks Switch Operation if Vacuum

Loss Is Detected

Protects your equipment and personnel from potential harm.

Provides Local and Remote Indication

of Vacuum Interrupter Status

Enables operating and maintenance personnel to take corrective action immediately in the

event of loss of vacuum, maximizing system reliability. SCADA notification available.

8155 T&B Boulevard Memphis TN 38125 800.326.5282

utility.tnb.com

PG-PC-JOS-0509

Joslyn_ProdGuide09_38&39:Joslyn_ProdGuide09_38&39

6/15/09

11:24 AM

Page 39

VBM Switching Systems

Varmaster VBM Switch Models

Three Phase

38kV 300A

One Pole*

48.5kV 300A

48.5kV 400A

* Three poles required for a three-phase installation.

PG-PC-JOS-0509

utility.tnb.com

Three Phase

25kV 200A

25kV 300A

25kV 400A

Capacitor & Reactor

Switching

Three Phase

15kV/25kV* 400A

15kV/25kV* 600A

* 25kV rating for solidly grounded capacitor bank configurations only.

One Pole*

38kV 400A

38kV 600A

48.5kV 200A**

* Three poles required for a three-phase installation.

** Solidly grounded capacitor bank configurations only.

One Pole*

72.5kV 300A

* Three poles required for a three-phase installation.

800.326.5282 8155 T&B Boulevard Memphis TN 38125

39

39

Joslyn_ProdGuide09_40&41:Joslyn_ProdGuide09_40&41

6/15/09

11:24 AM

Page 40

VBM Switching Systems

Varmaster VBM Switch Options and Accessories

Operating Mechanisms

A solenoid mechanism has an expected maintenance-free life of 100,000 operations on AC and 15,000 operations on DC. Controls

for solenoid operators are mounted in a separate enclosure.

A motor operator is only used on single-mechanism three-phase Varmaster VBM switches, such as 15kV, 400A and 600A models and 34.5kV,

Capacitor & Reactor

Switching

300A models. All controls are located inside the VBM mechanism housing. Inspection after 10,000 operations is recommended.

Solenoid Operator

Motor Operator

The completely sealed operating mechanism housing supports line-to-ground insulators and the modules. An expansion bag in the housing

prevents the intake of contaminants or moisture and contains a desiccant package to maintain dry air.

All electrical control connections to the mechanism are made through a single environmental control cable connector.

An open-closed position indicator is directly coupled to the mechanism. A separate operating crank enables manual operation of the switch.

The entire assembly can withstand several Gs without damage. Note that there may be one or more mechanisms for a three-phase Varmaster

VBM switch.

Operating Mechanism Options

Control

Voltage

AC 120V

AC 120V

AC 48V

AC 48V

DC 125V

DC 125V

DC 250V

Operating

Mechanism

5

Motor

3

Solenoid

5

Motor

3,8

Solenoid

5

Motor

3

Solenoid

3,8

Solenoid

Control Current per

Switch Mechanism

5A

7,8

60A

3A

6

60A

4A

7,8

60A

60A

1. Two A and two B mechanically operated contacts are standard. Six A and

six B contacts are available as an option. Contacts are rated at 10A,

125VDC or 115VAC.

Close

Time 4

3 sec.

6 cycles

5 sec.

6 cycles

3 sec.

6 cycles

6 cycles

Trip

Time 4

2 cycles

6 cycles

2 cycles

6 cycles

2 cycles

6 cycles

6 cycles

Auxiliary

Contacts

1

2 A and 2 B

2

4 A and 4 B

1

2 A and 2 B

2

4 A and 4 B

1

2 A and 2 B

2

4 A and 4 B

2

4 A and 4 A

5. Motor operating mechanisms are designed for single-mechanism threephase switches only.

6. Current is 60A peak for one-, two- or three-mechanism switch systems.

2. Four A and four B contacts available from auxiliary relay. Eight A and eight B

contacts are available as an option. Contacts are rated at 15A, 120VAC and

10A, 125VDC.

3. For capacitor or reactor switching, a low-energy control is available.

See Options and Accessories.

7. Current is 120A for the 34.5kV, 300A Varmaster VBM switch.

8. Current for three-mechanism switch systems is approximately 180A peak

for three cycles.

4. Close or Trip Times are measured from applying of close or trip signals.

Vacuum contact travel time is six milliseconds. All Varmaster VBM switches

have built-in anti-pump controls.

40

8155 T&B Boulevard Memphis TN 38125 800.326.5282

utility.tnb.com

PG-PC-JOS-0509

Joslyn_ProdGuide09_40&41:Joslyn_ProdGuide09_40&41

6/15/09

11:24 AM

Page 41

VBM Switching Systems

Varmaster VBM Switch Clearance Requirements

For Varmaster VBM switches with multiple vacuum interrupters in series, a 32" (813mm) clearance must be maintained from all switch line

parts to adjacent equipment, such as buses, reactors, CTs, transformers or frames. Adjacent equipment also includes high-voltage

conductors, which must run horizontally for at least 32" before bending upward.

Failure to meet this clearance requirement will adversely affect the electrical voltage distribution and electromagnetic field within the interrupters

during opening and closing operations. This insufficient clearance can prevent proper interruption within the vacuum switch interrupters,

resulting in undesirable restrikes during opening operations for some application parameters.

Incorrect

High-Voltage Conductor is

within 32-Inch Area

32"

32"

32"

Capacitor & Reactor

Switching

32" Clearance around 38kV Single-Phase Interrupters, Front View

Correct

High-Voltage Conductor

is outside 32-Inch Area

Two Interrupters in

Series with Bus Bar

32"

32"

32" Clearance around 38kV Single-Phase Interrupters, Side View

32"

32"

PG-PC-JOS-0509

utility.tnb.com

32"

800.326.5282 8155 T&B Boulevard Memphis TN 38125

41

Joslyn_ProdGuide09_42&43:Joslyn_ProdGuide09_42&43

6/15/09

11:24 AM

Page 42

VBM Switching Systems

Capacitor & Reactor

Switching

One Interrupter per Phase, 32" (813mm) Clearance Not Required

Three Phase

15kV/25kV

NOTE: The 32" (813mm) clearance requirement does not apply to Varmaster VBM switches with only one interrupter per phase, as shown above.

All other configurations shown must maintain the 32" (813mm) clearance.

Two or More Interrupters per Phase, 32" (813mm) Clearance Required

Three Phase

38kV

Single Phase

48.5kV

Single Phase

69kV

42

Double-Stack Interrupters

8155 T&B Boulevard Memphis TN 38125 800.326.5282

Three Phase

25kV

utility.tnb.com

PG-PC-JOS-0509

Joslyn_ProdGuide09_42&43:Joslyn_ProdGuide09_42&43

6/15/09

11:24 AM

Page 43

VBM Switching Systems

Varmaster VBM Terminal Pad Orientation Options

for Single-Mechanism Switches

Standard

Alternate A

Alternate B

Alternate C

Capacitor & Reactor

Switching

Trip Lever &

Position Indicator

High-Voltage Connections

Varmaster VBM switches have terminal pads made of aluminum alloy with standard NEMA two-hole drilling. The electrical connection at the terminal

pad must be treated with Alcoa No. 2 joint compound or equivalent. Remove the brown paper from the terminal pad before making electrical

connections. Wire brushing through the compound will improve the connection.

Terminal Pad

134"

(44mm)

1

2"

(13mm)

PG-PC-JOS-0509

utility.tnb.com

800.326.5282 8155 T&B Boulevard Memphis TN 38125

43

Joslyn_ProdGuide09_44&45:Joslyn_ProdGuide09_44&45

6/15/09

11:25 AM

Page 44

VBM Switching Systems

Dimensions for Three-Phase Switch, 15kV/25kV* Grounded 400A, 15kV/25kV* Grounded 600A

1512"

(394mm)

1512"

(394mm)

2 F1 + F2 100lb.

F1 (50lb. max.)

3738" (949mm)

28316" (716mm)

Control

Cable

Socket

F2

31516"

(100mm)

16 16" (408mm)

1

6 2"

(165mm)

1

Capacitor & Reactor

Switching

81516"

(227mm)

1716"

(37mm)

2514" (641mm)

738"

(187mm)

878" (225mm)

834"

(223mm)

39 8" (994mm)

1

Clear Space Required

for Removal of

Mechanism Cover

44" (1,118mm)

42" (1,067mm)

Side View

* Solid grounded systems and capacitor bank only.

3

4" (19mm) Dia. for

Mounting (3 Holes)

134" (44mm)

Weight: 148lb. (67kg) maximum.

Dimensions for Three-Phase Switch, 25kV 200A, 25kV 300A, 25kV 400A

1512"

(394mm)

1512"

(394mm)

F ( 50lb. max.)

Control

Cable

Socket

40716"

(1,028mm)

100lb. max.

4938"

(1,254mm)

31516"

(100mm)

1616"

(408mm)

F2

81516"

(227mm)

612"

(165mm)

1716"

(37mm)

878"

(225mm)

2514" (641mm)

39 8" (994mm)

738"

(187mm)

44" (1,118mm)

Clear Space Required for

Removal of Mechanism Cover

834"

(223mm)

42" (1,067mm)

Side View

4" (19mm) Dia. for Mounting (3 Holes)

134" (44mm)

Weight: 225lb. (102kg) maximum.

44

8155 T&B Boulevard Memphis TN 38125 800.326.5282

utility.tnb.com

PG-PC-JOS-0509

Joslyn_ProdGuide09_44&45:Joslyn_ProdGuide09_44&45

6/15/09

11:25 AM

Page 45

VBM Switching Systems

Dimensions for Three-Phase Switch, 38kV 300A

6734" (1,721mm)

738"

738"

(187mm) (187mm)

16" (14mm)

Dia. Holes

6138" (1,159mm)

CL Terminal Pads

301116" (779mm)

441116" (1,135mm)

2238"

(568mm)

F1 (40lb. max.)

2" (13mm)

134" (44mm)

Control

Cable

Socket

4512"

(1,156mm)

214"

(57mm)

5578"

(1,419mm)

22916"

(573mm)

2514" (641mm)

Capacitor & Reactor

Switching

F2 (90lb. max.)

834" (223mm)

738" (187mm)

3918" (994mm)

878" (225mm)

44" (1,118mm)

4" (19mm) Dia. for

Mounting (3 Holes)

Side View

42" (1,067mm)

Clear Space

Required for

Removal of

Mechanism

Cover

134" (44mm)

NOTE: Other insulation ratings are available

for extra creepage.

Front View

Weight: 225lb. (102kg) maximum.

Dimensions for One-Pole* Switch, 38kV 400A, 38kV 600A, 48.5kV 200A**

31" (787mm)

36716"

(926mm)

(50lb. max.)

F1

24516"

(618mm)

Control Cable

Socket

4514"

(1,150mm)

20716"

(516mm)

4"

(102mm)

81516"

(227mm)

612"

(165mm)

1716" (37mm)

4" (19mm)

Dia. for

Mounting

(3 Holes)

738"

(187mm)

878" (225mm)

2514" (641mm)

3

834"

(223mm)

3918" (994mm)

44" (1,118mm)

Clear Space Required for

Removal of Mechanism Cover

42" (1,067mm)

Front View

Side View

134" (44mm)

Weight: 180lb. (82kg) maximum.

* Three poles are required for a three-phase installation.

**Solidly grounded 46kV capacitor bank confiuration.

PG-PC-JOS-0509

utility.tnb.com

800.326.5282 8155 T&B Boulevard Memphis TN 38125

45

You might also like

- Manual Estabilizador SVC y Svc-33Document12 pagesManual Estabilizador SVC y Svc-33Ner Amiel Montes LazaroNo ratings yet

- Instrucciones Seccionadores de Apertura LateralDocument23 pagesInstrucciones Seccionadores de Apertura Lateralchamp2006No ratings yet

- PROYECTO FINAL Electronica IndustrialDocument18 pagesPROYECTO FINAL Electronica IndustrialLeonardo Alejandro Vargas TorrezNo ratings yet

- IAPE E2 Rodrigo RoblesDocument7 pagesIAPE E2 Rodrigo RoblesRodrigoNo ratings yet

- Manual Regulador de VoltajeDocument26 pagesManual Regulador de Voltajecarl evens jeanNo ratings yet

- Manual Regulador de VoltajeDocument26 pagesManual Regulador de Voltajecarl evens jeanNo ratings yet

- Catalogo Del Recloser en EspañolDocument9 pagesCatalogo Del Recloser en EspañolHillary Mcgowan50% (2)

- VLT® 6000 HVAC Instrucción VARIADOR DE VELOCIDADDocument28 pagesVLT® 6000 HVAC Instrucción VARIADOR DE VELOCIDADWilliam RaicoNo ratings yet

- Siemens Catálogo Reconectador 3AD 2008Document36 pagesSiemens Catálogo Reconectador 3AD 2008Christopher DavisNo ratings yet

- Conceptos PastillaDocument3 pagesConceptos PastillaEduardo S CossúNo ratings yet

- CT Excelinepro V1catalogo ExcelineDocument23 pagesCT Excelinepro V1catalogo Excelinesergio58No ratings yet

- Mantenimiento de circuitos eléctricos y protecciónDocument8 pagesMantenimiento de circuitos eléctricos y protecciónJojan Veraz50% (2)

- Bticino MegatikerDocument65 pagesBticino MegatikerXholo Ono100% (1)

- Sarel WL It-Fr 022013Document28 pagesSarel WL It-Fr 022013Elias Ulises Manriquez FuentealbaNo ratings yet

- Manual de usuario cuadros monofásicos PROMet AKO-1750x-1755xDocument28 pagesManual de usuario cuadros monofásicos PROMet AKO-1750x-1755xjoaquin42100% (1)

- Aplicaciones de Los TiristoresDocument5 pagesAplicaciones de Los TiristoresAdam Smith77% (13)

- Instrumentacion Unidad 3 Actuadores EléctricosDocument10 pagesInstrumentacion Unidad 3 Actuadores Eléctricosjose armando mijares garciaNo ratings yet

- S 200 SpanishDocument23 pagesS 200 SpanishErnesto Hc0% (1)

- Control DAS con función ALADocument25 pagesControl DAS con función ALAAna FariñaNo ratings yet

- Manual de Operación SEHDocument17 pagesManual de Operación SEHPatricio Eduardo Segura FuentealbaNo ratings yet

- Exposicion Riesgo ElectricoDocument17 pagesExposicion Riesgo ElectricoHernando Jose Fuentes RomeroNo ratings yet

- Arranque motor monofásicoDocument5 pagesArranque motor monofásicoAsesor Manandes Wilson GudiñoNo ratings yet

- Practico 1 InstrumentacionDocument14 pagesPractico 1 InstrumentacionFatima TeranNo ratings yet

- Reconectador EPR - Control ETR-300R - ETIMS - ENTECDocument59 pagesReconectador EPR - Control ETR-300R - ETIMS - ENTECMiguel Angel RamirezNo ratings yet

- Regulador de voltaje 220v trifásico manual de instalaciónDocument1 pageRegulador de voltaje 220v trifásico manual de instalaciónmrocha6305No ratings yet

- Celdas SarelDocument8 pagesCeldas SarelALARCONISTANo ratings yet

- Load Transfer Panel ES 1211Document6 pagesLoad Transfer Panel ES 1211maesemarcoNo ratings yet

- Seccionadores bajo carga 17,5-36kV 400-630ADocument4 pagesSeccionadores bajo carga 17,5-36kV 400-630AJorge LeanizNo ratings yet

- Sacar Narrativa Al Final Controles Principios Generales Sobre Control de Motores EléctricosDocument20 pagesSacar Narrativa Al Final Controles Principios Generales Sobre Control de Motores EléctricosAnonymous xMmMAFnNo ratings yet

- Subestacioncompacta Zetrac y Tabla de Cap de Fusibles Segun Pot y TensionDocument4 pagesSubestacioncompacta Zetrac y Tabla de Cap de Fusibles Segun Pot y TensionJL AguilarNo ratings yet

- Con5000mp PDocument28 pagesCon5000mp PManelNo ratings yet

- Accionamientos y ElectricosDocument8 pagesAccionamientos y Electricosyerson marquezNo ratings yet

- Mantenimiento Industrial Clase 7 03-11-22Document27 pagesMantenimiento Industrial Clase 7 03-11-22marcos basilio mamaniNo ratings yet

- ScompactaDocument4 pagesScompactalaglossyNo ratings yet

- 2-El Reconectador en Los Sistemas de Distribucion ElectricaDocument13 pages2-El Reconectador en Los Sistemas de Distribucion ElectricaVane Oñate100% (3)

- Investigacion de Operación y Diagnostico A Sub Estaciones ElectricasDocument10 pagesInvestigacion de Operación y Diagnostico A Sub Estaciones ElectricasBrandon LedezmaNo ratings yet

- Cálculos de TransformadoresDocument9 pagesCálculos de TransformadoresWilliam Magaña100% (1)

- Exposicion Diagnostico Del Sistema Electrico Sede de La CorteDocument32 pagesExposicion Diagnostico Del Sistema Electrico Sede de La CorteDarcy Acuña RomanNo ratings yet

- Manual de operación y mantención de sistema solar conectado a la redDocument13 pagesManual de operación y mantención de sistema solar conectado a la redjose leivaNo ratings yet

- Manual de Servicio y Mantto A Minisplit Trane PDFDocument23 pagesManual de Servicio y Mantto A Minisplit Trane PDFElias Landz60% (5)

- Aislamiento Del Devanado Del GeneradorDocument4 pagesAislamiento Del Devanado Del Generadordamian_pelonNo ratings yet

- Proyecto SImarisDocument15 pagesProyecto SImarisPablo MazariegosNo ratings yet

- Seccionamiento, Protección Contra Los Cortocircuitos y SobrecargasDocument15 pagesSeccionamiento, Protección Contra Los Cortocircuitos y Sobrecargasaldrako4No ratings yet

- Mantenimiento A Seccionadores de PotenciaDocument4 pagesMantenimiento A Seccionadores de PotenciaolveraNo ratings yet

- grupo 3Document10 pagesgrupo 3FERNANDO SARIO GARCIANo ratings yet

- LGPG 111Document418 pagesLGPG 111jjcanoolivaresNo ratings yet

- Transferencia Automatica Con ContactoresDocument6 pagesTransferencia Automatica Con ContactoresAlexSoraNo ratings yet

- Controles Eléctricos IndustrialesDocument8 pagesControles Eléctricos Industrialeswjhon456No ratings yet

- Estabilizador - UpsDocument7 pagesEstabilizador - UpsccanavalnNo ratings yet

- Resumen Generalidades Acometidas EléctricasDocument3 pagesResumen Generalidades Acometidas EléctricasAlejandro Rodriguez LeytonNo ratings yet

- Procedimiento de Trabajos A EjecutarDocument34 pagesProcedimiento de Trabajos A EjecutarFelipe PeñaililloNo ratings yet

- Seccionadores Schneider PDFDocument24 pagesSeccionadores Schneider PDFFrancisco Mendoza SaldarriagaNo ratings yet

- 2014 SECCIONADORESv02Document64 pages2014 SECCIONADORESv02JUAN PABLONo ratings yet

- ¿Que Es Un SeccionadorDocument4 pages¿Que Es Un SeccionadorAndro PixelNo ratings yet

- Control de PotenciaDocument37 pagesControl de PotenciaabbadonaNo ratings yet

- Montaje de redes eléctricas subterráneas de alta tensión. ELEE0209From EverandMontaje de redes eléctricas subterráneas de alta tensión. ELEE0209No ratings yet

- Montaje y mantenimiento de instalaciones eléctricas de interior. ELEE0109From EverandMontaje y mantenimiento de instalaciones eléctricas de interior. ELEE0109No ratings yet

- UF1445 - Realización de las intervenciones necesarias para el mantenimiento de las instalaciones eléctricas en el entorno de edificios y con fines especialesFrom EverandUF1445 - Realización de las intervenciones necesarias para el mantenimiento de las instalaciones eléctricas en el entorno de edificios y con fines especialesNo ratings yet

- Montaje y mantenimiento de instalaciones eléctricas de baja tensión en edificios de viviendas. ELEE0109From EverandMontaje y mantenimiento de instalaciones eléctricas de baja tensión en edificios de viviendas. ELEE0109No ratings yet

- Montaje de instalaciones eléctricas de enlace en edificios. ELEE0109From EverandMontaje de instalaciones eléctricas de enlace en edificios. ELEE0109No ratings yet

- TemarioDocument1 pageTemariotalaporriNo ratings yet

- 1 HK Ge 13 Es LR PDFDocument892 pages1 HK Ge 13 Es LR PDFMarco Antonio Romero AcostaNo ratings yet

- Cable - FL CAT5 HEAVY - 2744814: Datos MercantilesDocument2 pagesCable - FL CAT5 HEAVY - 2744814: Datos MercantilestalaporriNo ratings yet

- Cómo Sabría AmarteDocument1 pageCómo Sabría AmartetalaporriNo ratings yet

- Triste Soledad Que AmargaDocument1 pageTriste Soledad Que AmargatalaporriNo ratings yet

- Convertidor de Fibra Óptica - FL MC 2000E SM40 LC - 2891156: Datos MercantilesDocument4 pagesConvertidor de Fibra Óptica - FL MC 2000E SM40 LC - 2891156: Datos MercantilestalaporriNo ratings yet

- Tensiones y Flujos de Potencia 23-12-2014 21 - 00Document2 pagesTensiones y Flujos de Potencia 23-12-2014 21 - 00talaporriNo ratings yet

- Me Abrasaban Tus OjosDocument1 pageMe Abrasaban Tus OjostalaporriNo ratings yet

- Geografico de NEA V2 22 - 05 - 2013 21 - 00 PDFDocument2 pagesGeografico de NEA V2 22 - 05 - 2013 21 - 00 PDFtalaporriNo ratings yet

- Relé Direccional de TierraDocument6 pagesRelé Direccional de TierratalaporriNo ratings yet

- Dime Amor MioDocument1 pageDime Amor MiotalaporriNo ratings yet

- SueñaDocument1 pageSueñacurisos85No ratings yet

- Me Gustas Cuando Callas Porque Estás Como AusenteDocument1 pageMe Gustas Cuando Callas Porque Estás Como AusentetalaporriNo ratings yet

- Quisiera Ser El Fuego Que Avivara Tus CenizasDocument1 pageQuisiera Ser El Fuego Que Avivara Tus CenizastalaporriNo ratings yet

- Hoy Vuelvo Nuevamente...Document1 pageHoy Vuelvo Nuevamente...curisos85No ratings yet

- Costos y Presupuestos (FRSF)Document9 pagesCostos y Presupuestos (FRSF)talaporriNo ratings yet

- Niña de Ojos Azules PreciososDocument1 pageNiña de Ojos Azules PreciososRey David Montes MartinezNo ratings yet

- Mi SentirDocument1 pageMi Sentircurisos85No ratings yet

- SELECCION DE PIPING Model PDFDocument1 pageSELECCION DE PIPING Model PDFtalaporriNo ratings yet

- Borges IIDocument1 pageBorges IIKristopher PaulNo ratings yet

- Poesias de AmorDocument2 pagesPoesias de AmortalaporriNo ratings yet

- Borges IIDocument1 pageBorges IIKristopher PaulNo ratings yet

- Cuadro Tarifario A Enero 2014Document3 pagesCuadro Tarifario A Enero 2014talaporriNo ratings yet

- EE03103CDocument25 pagesEE03103CyaropelNo ratings yet

- Catalogo General de Joslyn Proteccion y ControlDocument4 pagesCatalogo General de Joslyn Proteccion y ControltalaporriNo ratings yet

- Just in TimeDocument12 pagesJust in TimetalaporriNo ratings yet

- Arteche CT RC Es 2012 ADocument7 pagesArteche CT RC Es 2012 AtalaporriNo ratings yet

- Oi - (Iet Oit) - Desplazam de Los Trabajadores PDFDocument8 pagesOi - (Iet Oit) - Desplazam de Los Trabajadores PDFtalaporriNo ratings yet

- OrgESO Mapa 04 PDFDocument1 pageOrgESO Mapa 04 PDFcristian41historiaNo ratings yet

- Herramientas de Manejo ManualDocument24 pagesHerramientas de Manejo ManualWilliam Hernan Valero TorresNo ratings yet

- Ejercicio MedallasDocument3 pagesEjercicio MedallasEstebanPinedaVelasquezNo ratings yet

- Diagrama de Gantt Practica ProfesionalDocument2 pagesDiagrama de Gantt Practica ProfesionalAle C MoncadaNo ratings yet

- Sistemas Operativos CuestionarioDocument5 pagesSistemas Operativos CuestionarioJULIO CESAR FERNANDEZNo ratings yet

- Act 3. Auditoria de SistemasDocument18 pagesAct 3. Auditoria de SistemasEsteban Ospina lunaNo ratings yet

- TORNO PARALELO CONVENCIONAL Roscado exteriorDocument24 pagesTORNO PARALELO CONVENCIONAL Roscado exteriorBelthor QNo ratings yet

- Ejemplo SPSSDocument28 pagesEjemplo SPSSMAR26VID67% (3)

- Examen ComputacionDocument9 pagesExamen Computacionanon_869390812No ratings yet

- Practica 1 y 2 de RedesDocument5 pagesPractica 1 y 2 de Redesmigo1375No ratings yet

- Lista ImagenworldDocument5 pagesLista ImagenworldEdward RodriguezNo ratings yet

- Alumbrado PALAMIS LED Clever GroupDocument10 pagesAlumbrado PALAMIS LED Clever GroupJosue CastroNo ratings yet

- Lab 4.aplicaion de SecuenciadorDocument11 pagesLab 4.aplicaion de SecuenciadorAlex Chuctaya100% (2)

- ListaDocument11 pagesListaDon Leo ValerioNo ratings yet

- Fuente ConmutadaDocument20 pagesFuente ConmutadaESTIVENNo ratings yet

- Contador AnilloDocument7 pagesContador AnilloJhonatan Santa Cruz ChiloNo ratings yet

- 2.1.4.4 Packet Tracer - Configure VLANs, VTP, and DTP PDFDocument7 pages2.1.4.4 Packet Tracer - Configure VLANs, VTP, and DTP PDFjulian guayaraNo ratings yet

- Tipos interrupcionesDocument3 pagesTipos interrupcionesJacke801JeevasNo ratings yet

- Instalar Repositorios de Fedora 19Document34 pagesInstalar Repositorios de Fedora 19Alberto HernándezNo ratings yet

- Manual Usuario Perkins Serie 2800 Mod. 2806a-E18 y 2806c-E18Document64 pagesManual Usuario Perkins Serie 2800 Mod. 2806a-E18 y 2806c-E18Miguel Angel Pavon Carbonell67% (3)

- Tarea S11 Dirección de Mercadotecnia y VentasDocument6 pagesTarea S11 Dirección de Mercadotecnia y VentasCarlos MagdalenoNo ratings yet

- Conexià N Labview MySQLDocument7 pagesConexià N Labview MySQLSaad Nayib Bittar MonterrozaNo ratings yet

- Crea USB Arranque Windows 7-10Document2 pagesCrea USB Arranque Windows 7-10Daniel Sosa ArriondoNo ratings yet

- DS - TECNO - ListaGral 18 11 2016Document604 pagesDS - TECNO - ListaGral 18 11 2016rammau11No ratings yet

- PaginaDocument5 pagesPaginaRobPNo ratings yet

- Desarrollo Arduino en Proteus para Manejar Un Display de 7 Segmentos.Document15 pagesDesarrollo Arduino en Proteus para Manejar Un Display de 7 Segmentos.Hector Leon TorresNo ratings yet

- Foro Semana 1 y 2 Creatividad e Innovacion para Las OrganizacionesDocument3 pagesForo Semana 1 y 2 Creatividad e Innovacion para Las OrganizacionesPatricia JimenezNo ratings yet

- Archivos ExeDocument4 pagesArchivos ExepaoloNo ratings yet

- Breve Historia de WordDocument1 pageBreve Historia de WordEneNo ratings yet

- VLSMDocument40 pagesVLSMJeanette Minerva HuanquilNo ratings yet

- Registro Oficinas Económicas y ComercialesDocument25 pagesRegistro Oficinas Económicas y ComercialesMonica BerenguerNo ratings yet