Professional Documents

Culture Documents

Mie Hse Jha 004 - Installation of Transformer

Uploaded by

Luqman OsmanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mie Hse Jha 004 - Installation of Transformer

Uploaded by

Luqman OsmanCopyright:

Available Formats

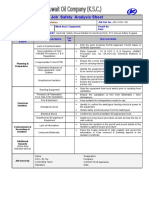

JOB HAZARD ANALYSIS

HOW TO USE THIS FORM :

1) Crew performing task reviews ALL generic JHA considerations.

2) Review previous JHA update(s) for useful information which will help this task.

3) Create new JHA update with generic form and ALL considerations for this task.

4) Carry out task as per plan. If any conditions change ---STOP & RE-ASSESS.

5) File JHA update for future reference.

Installation/Facility

Location

Associated Work Permit Type

Associated Work Permit Number

Electrical Isolation Certificate Number

Physical Isolation Certificate Number

WORK ACTIVITY

JHA Cross-Reference Number

Job

Step

INSTALLATION OF TRANSFORMER

Description of

Job Step

Potential

Impact

Potential

Hazards

Control

Measures

Recovery

Measures

MIE-HSE-JHA-004

Result

Preparation before task

- Lack in communication - Wrong information

& information

- Emergency event

- Permit application and valid

prior to work

- Safety briefing during toolbox

meeting or before starting

work as necessary

- Proper planning prior to work

- Workers are observed Rules &

Regulation on site through

HSE Induction

- Report to MIE

Management Rep.

- Report incident to

consortium

Acceptable

Installation of padding

(Chipping & Grouting)

- Flaying object

- Eye injury

- wear proper PPE (goggles/

Face shield)

Acceptable

- Dust

- Asthma

- work leader to ensure PPE

compliances (dust mask)

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Electrocution

- Electrical shock

- To ensure all equipment had

been inspected by consortium

Acceptable

- Sharp object

- Personal injury

- secure any sharp object

- wear proper PPE (hand gloves)

Acceptable

- Oil spillage / leakage

- Ensure generator had been

inspected by consortium

- provided drip pan

Acceptable

- Fire

- Fire extinguisher is always

available and fit to use

Acceptable

- Poor maintenance of

generator

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

JOB HAZARD ANALYSIS

3

Transportation of

equipment to work site

- Narrow road

- Collision

- Traffic obstruction

- Vehicle accident

- Property damage

- Physical injury

- Observe proper access way

- Assign flagman to control traffic

- Escort lorry crane movement on

site

- Ensure driver with valid driving

license

- Ensure that the lorry crane

has a valid PMA

- Comply to site traffic regulation

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Poor maintenance of

the transport

- Oil spillage / leakage

- To ensure the transport had

been inspected by consortium

personnel

Acceptable

- Equipment fall from

Transport

- Property damage/

personal injury

- Properly secure the equipment

by proper method

- Report to MIE

Management Rep.

-Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Protruding nails

- Physical injury

- Eliminated any sharp object

- Removed immediately the

wooden from work area

Acceptable

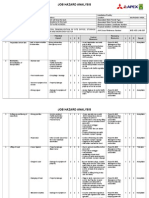

- Unpack equipment

Setting-up positioning of

crane/lorry

- Wrong position

- Vehicle accident

- Traffic obstruction

- Property damage

- Physical injury

- Crane operator has a valid

DOSH competency license

- Crane must have PMA

certificate

- Flagman to prevent

unauthorized entry during lifting

- Ensure ground condition before

work start

- Fully extend outrigger

- Pad provided

- Ensure all the tires are above

ground

- Cordon off working area with

barricade & proper signage

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Road close

- Other vehicle cannot

use the main road/road

obstruction

- Cordon off working area with

barricade & proper signage

- Flagman to fully standby

- Alternative road will be used

- Report to MIE

Management Rep.

- Report incident to

consortium

Acceptable

- Defective lifting

- Property damage

-Ensure that web slings, shackle

lifting gears and the crane block

safety latch in good condition.

- Riggers / Work supervisor must

ensure all loads to be properly

secured

- Follow work method statement

- Report to MIE

Management Rep.

- Report incident to

consortium

Acceptable

To set up lifting gears

JOB HAZARD ANALYSIS

Lifting of Load

- Sharp edges

- Personal injury

- Eliminated sharp edges

- Wear proper PPE

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Knocking and

damaging equipment

- Property damage to

equipment

- Competent signal man must

guide vehicle during movement

- Make clear off the access way

- Cordon off working area with

barricade & proper signage

- Tagline to be used during lifting

- Ensure proper communication

hand signal

- All tools must be inspected

Acceptable

- Falling from height

- Personal injury

- practice buddy system when

using ladder

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Crane toppled

- Property damage

- Ensure ground condition before

work start

- Fully extend outrigger

- Pad provided

- Follow actual lifting chart

- Cordon off radius working area

with barricade & proper signage

- Report to MIE

Management Rep.

- Report incident to

consortium

Acceptable

- Dropped Load

- Damage to equipment/

property

-Ensure that web slings, shackle

lifting gears and the crane block

safety latch in good condition.

- Riggers / Work supervisor must

ensure all loads to be properly

secured

- Strictly no lifting during heavy

rain and windy

- Report to MIE

Management Rep.

- Report incident to

consortium

Acceptable

- Swinging of load

- Property damage

- Riggers /work supervisor must

ensure that Tag line in good

condition and adequate in

length and must be used to

control the swinging of the load.

- Stay clear of suspended load

swing radius

- Report to MIE

Management Rep.

- Report incident to

consortium

Acceptable

JOB HAZARD ANALYSIS

- Miscommunication

- Damage to equipment

- Only the authorized signalman

should give signals to the crane

operator

- Ensure proper communication

hand signal, walkie-talkie or

whistle

- Report to MIE

Management Rep.

- Report incident to

consortium

Acceptable

- Vehicles and other

personnel moving in

and around the lifting

area

- Vehicle accident

- Personnel injury

- Display front and back warning

signages and barricade the

area to notify other personnel of

the activities going on

- Flagman to prevent

unauthorized entry during lifting

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

Transformer Installation

Work

- Slip, Trip & Fall

- Physical injury

- Maintain good housekeeping at

all time

- Clear any obstruction at work

area

- Do proper planning &

arrangement for the task

- Barricade / covered any open

hole

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Visual inspection

- Sharp edges

- Personal injury

- secured/covered any sharp

edges

- wear proper PPE

Acceptable

- Transformer alignment

work

- Transformer topple/

hit people

- Property damage

- Personal injury

- Proper planning & follow work

method for installation work

- experience manpower to carry

out the task

- Enough manpower for activity

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Concrete hole

- Electrocution

- Electrical shock

- All tools must be inspected

- wear proper PPE

Acceptable

- Flaying object

- Eye injury

- wear proper PPE (goggles/

face shield)

- Report to MIE

Management Rep.

- Report incident to

consortium

- To contact nearest

first aider on site

Acceptable

- Dust

- Asthma

- work leader to ensure PPE

compliances (dust mask)

Acceptable

JOB HAZARD ANALYSIS

8

Daily job completion /

Housekeeping

-Walkway obstruction

- Slip and fall

- Tripping hazard

- Remove all material from

access way

- Ensure work area is kept clean

- Waste material should be

disposed at designated place

- Properly stacking and secure

the materials

- Report to MIE

Management Rep.

-Report incident to

consortium

-To contact nearest

first aider on site

Acceptable

- Ergonomics

- Physical injury

- Proper body positioning

- Practice buddy system during

activity

- Use safe method to lift material

Acceptable

- Sharp object

- Physical injury

- Eliminate/secure any sharp

object

- Wear proper PPE

- Report to MIE

Management Rep.

-Report incident to

consortium

-To contact nearest

first aider on site

- Report to MIE

Management Rep.

-Report incident to

consortium

-To contact nearest

first aider on site

Acceptable

L - LIKELIHOOD

CATEGORY

DEFINITION

CATEGORY

LOW

Remote

LOW

MEDIUM

Possible

MEDIU

M

HIGH

Probable

HIGH

IS THERE A SAFER WAY TO COMPLETE THE JOB?

ARE THERE ALTERNATIVES WITH LESS RISK?

RESULT

R - RATING

S - SEVERITY

DEFINITIONS

No Injury

No Damage

No Pollution

First Aid

Injury

Lost Time

Injury

Minor

Damage

Major

Damage

Minor

Pollution

Major

Pollution

6-9

UNACCEPTABLE

3-4

TOLERABLE

1-2

ACCEPTABLE

LIKELIHOOD

You might also like

- JHA - General Electrical WorkDocument7 pagesJHA - General Electrical WorkEL Mer96% (49)

- Jha - Transformer Installation PDFDocument6 pagesJha - Transformer Installation PDFperquino oasan0% (1)

- JSA Transformer Installations, Testing, Commissioning.Document6 pagesJSA Transformer Installations, Testing, Commissioning.Kiran Bhatt75% (4)

- Job Safety Analysis Sheet: Electrical IsolationDocument1 pageJob Safety Analysis Sheet: Electrical IsolationLal Dhwoj100% (2)

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteDocument5 pagesJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANNo ratings yet

- JSA E&I 4.earthing Bonding InstallationDocument3 pagesJSA E&I 4.earthing Bonding InstallationAmyNo ratings yet

- JSA Cable Pulling and Laying WorksDocument6 pagesJSA Cable Pulling and Laying Workskabir100% (1)

- JSA FOR Shakthi ElectricalDocument8 pagesJSA FOR Shakthi Electricalwahyu nugroho100% (1)

- Jsa Cable TerminationDocument4 pagesJsa Cable TerminationSyed Yousuf Ali100% (1)

- JSA Transformer InstallationDocument1 pageJSA Transformer Installationpushpanath reddyNo ratings yet

- Grounding System Jsa 2008Document4 pagesGrounding System Jsa 2008Aldrin100% (5)

- JOB HAZARD ANALYSIS - Cable TrayDocument10 pagesJOB HAZARD ANALYSIS - Cable TrayJayson Escamillan100% (1)

- JSA Cable DisconnectedDocument4 pagesJSA Cable Disconnectedwendypost730% (1)

- Jsa forOperatingAForkliftDocument2 pagesJsa forOperatingAForkliftsupahing supahingNo ratings yet

- JSA E&I 10.electrical Instrument Panels RemovalDocument3 pagesJSA E&I 10.electrical Instrument Panels RemovalAmyNo ratings yet

- JSA For DuctDocument14 pagesJSA For DuctRakeshkasarla100% (3)

- JSA For Hydro Test Activites (Generic)Document4 pagesJSA For Hydro Test Activites (Generic)Khaled Ismail88% (25)

- JSA For HVAC WorkDocument8 pagesJSA For HVAC Worksathakathulla100% (3)

- Electrical InstallationDocument3 pagesElectrical InstallationWalid KhelfaNo ratings yet

- Petrofac: Job Safety AnalysisDocument3 pagesPetrofac: Job Safety AnalysisMon Trang Nguyễn100% (5)

- JHA PlumberDocument3 pagesJHA PlumberEko Susanto100% (1)

- 004 Annexure D Job Safety SAnalysis JSADocument3 pages004 Annexure D Job Safety SAnalysis JSAAvoor Khan75% (4)

- JSA For Electrical TestingDocument5 pagesJSA For Electrical TestingAchmad Djadjang0% (1)

- JSA Cable Laying PDFDocument2 pagesJSA Cable Laying PDFManoj WaskelNo ratings yet

- JSA For Cable Tray Installation-Reviewed by CBREDocument10 pagesJSA For Cable Tray Installation-Reviewed by CBREPrakash Tiwari88% (8)

- Demolition PDFDocument2 pagesDemolition PDFvinothNo ratings yet

- Jsa-Jha For Using of Hand ToolsDocument2 pagesJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdNo ratings yet

- JHA For Electrical Works - Rev. 01.Document16 pagesJHA For Electrical Works - Rev. 01.SreekumarNo ratings yet

- Job Safety Analysis Worksheet: Yes NoDocument8 pagesJob Safety Analysis Worksheet: Yes NoBorislav VulićNo ratings yet

- Fire Fighting JSADocument14 pagesFire Fighting JSANikhil Manjrekar83% (6)

- JSA Earthpit Construction GeneralDocument4 pagesJSA Earthpit Construction Generalmukka88No ratings yet

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham75% (4)

- Ultratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSADocument5 pagesUltratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSATFattah100% (1)

- JSA Manual Excavation and Cable LayingDocument3 pagesJSA Manual Excavation and Cable Layingimran100% (1)

- Area Hard Barrication JsaDocument7 pagesArea Hard Barrication JsaJanakiramanNo ratings yet

- JHA For Installation of Boiler AccessoriesDocument2 pagesJHA For Installation of Boiler Accessoriesperquino oasan100% (3)

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 pagesJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNo ratings yet

- Installation of Pannel JSADocument6 pagesInstallation of Pannel JSAOFFSHORE OFFSITENo ratings yet

- 01 JSA For Earthworks at Corridor ADocument32 pages01 JSA For Earthworks at Corridor AHilbrecht De Pedro100% (1)

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- Jsa For Mechanical Activity: H/M/L H/M/LDocument1 pageJsa For Mechanical Activity: H/M/L H/M/Ljithin shankarNo ratings yet

- Jsa - Cable TerminationDocument4 pagesJsa - Cable TerminationD FiransyahNo ratings yet

- Job Safety Analysis: Cable Jointing & Termination in Wind TurbinesDocument1 pageJob Safety Analysis: Cable Jointing & Termination in Wind TurbinesPerwez2186% (7)

- PTW JHA Installation of New Control Panel at WWTPDocument2 pagesPTW JHA Installation of New Control Panel at WWTPPHH9834100% (1)

- JSA FOR HT LT Panel - Transformer InstallationDocument2 pagesJSA FOR HT LT Panel - Transformer Installationwahyu nugroho83% (6)

- Jsa ExcavatorDocument1 pageJsa Excavatorbladeliger220% (1)

- Tie in Hot Work JHADocument4 pagesTie in Hot Work JHAmalik jahan100% (2)

- JSA For HILTIDocument3 pagesJSA For HILTIMohammed Minhaj100% (1)

- 013 JSA For Earthwork at Receiving BasinDocument4 pages013 JSA For Earthwork at Receiving BasinHilbrecht De Pedro100% (1)

- JSA For MEP Work FormatDocument3 pagesJSA For MEP Work FormatmohdNo ratings yet

- Draft JSA Levelling & GradingDocument9 pagesDraft JSA Levelling & GradingAzeem Khan33% (3)

- Mie-Hse-Jha-001 - Mobilization, Demobilization of Site Office, Storage Container and Workshop SetupDocument5 pagesMie-Hse-Jha-001 - Mobilization, Demobilization of Site Office, Storage Container and Workshop SetupLuqman Osman100% (4)

- Mie Hse Jha 002 - Welding, Cutting, Fabrication WorkDocument4 pagesMie Hse Jha 002 - Welding, Cutting, Fabrication WorkLuqman Osman100% (1)

- Mie-Hse-Jha-007 - Cable Pulling, Laying, Dressing Work, TerminationDocument6 pagesMie-Hse-Jha-007 - Cable Pulling, Laying, Dressing Work, TerminationLuqman Osman100% (3)

- Method Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksDocument3 pagesMethod Statement: Company: Naseem & Son Project: Date: 21/05/2022 1. Description of WorksSagar SharmaNo ratings yet

- Qd0002 Adm Tem Hse 00018 Lessons Learned Rev 0aDocument2 pagesQd0002 Adm Tem Hse 00018 Lessons Learned Rev 0ashah fahadNo ratings yet

- Risk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Document14 pagesRisk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Pang Lee ChingNo ratings yet

- BGS-MOS Redevelopment of BHS at T2-R2Document33 pagesBGS-MOS Redevelopment of BHS at T2-R2LOURLINE TANGZONo ratings yet

- Your Electronic Ticket-EMD Receipt PDFDocument2 pagesYour Electronic Ticket-EMD Receipt PDFLuqman OsmanNo ratings yet

- PEP Suriname 2018 - 2DMTCSEM18 - Atlantic Guardian - V1.0 MSDocument51 pagesPEP Suriname 2018 - 2DMTCSEM18 - Atlantic Guardian - V1.0 MSLuqman OsmanNo ratings yet

- Your Electronic Ticket-EMD Receipt PDFDocument2 pagesYour Electronic Ticket-EMD Receipt PDFLuqman OsmanNo ratings yet

- GF-OGF4-X-PR-0522 - Hazardous Material Management Procedure - Rev A PDFDocument12 pagesGF-OGF4-X-PR-0522 - Hazardous Material Management Procedure - Rev A PDFLuqman OsmanNo ratings yet

- Shanghai Youlong LRDocument16 pagesShanghai Youlong LRLuqman Osman100% (1)

- Hac BasicDocument3 pagesHac BasicLuqman OsmanNo ratings yet

- Management of Inert Confined Space EntryDocument4 pagesManagement of Inert Confined Space EntryLuqman OsmanNo ratings yet

- Simplified LOTO ProcedureDocument8 pagesSimplified LOTO ProcedureLuqman OsmanNo ratings yet

- Management of Inert Confined Space EntryDocument4 pagesManagement of Inert Confined Space EntryLuqman OsmanNo ratings yet

- 6419RJ510-10006 Blinds Management ProcedureDocument14 pages6419RJ510-10006 Blinds Management ProcedureLuqman Osman100% (1)

- Overview CHRA 3rd Ed-Taklimat Pusat PengajarDocument31 pagesOverview CHRA 3rd Ed-Taklimat Pusat PengajarLuqman Osman100% (3)

- Risk Profile PrecommissioningDocument5 pagesRisk Profile PrecommissioningLuqman OsmanNo ratings yet

- Bow Tie Pneumatic 2nd TrialDocument1 pageBow Tie Pneumatic 2nd TrialLuqman OsmanNo ratings yet

- Att I - Commissioning ChecklistDocument2 pagesAtt I - Commissioning ChecklistLuqman OsmanNo ratings yet

- Att III - Log Sheet MRTDocument1 pageAtt III - Log Sheet MRTLuqman OsmanNo ratings yet

- Attendance Sheet:: Dr. MD Mizanur Rahman: Research Methodology: KOG 11603Document1 pageAttendance Sheet:: Dr. MD Mizanur Rahman: Research Methodology: KOG 11603Luqman OsmanNo ratings yet

- Hse Close Out Report PresentationDocument31 pagesHse Close Out Report PresentationLuqman Osman100% (10)

- Case Study SogtDocument4 pagesCase Study SogtLuqman OsmanNo ratings yet

- Jurnal Project Management Norasiah Mk1512008t Norfaizah Mk1512009tDocument23 pagesJurnal Project Management Norasiah Mk1512008t Norfaizah Mk1512009tLuqman OsmanNo ratings yet

- PRD Risk Register - Att 1Document1 pagePRD Risk Register - Att 1Luqman OsmanNo ratings yet

- JHA Scaffolding - ApprovedDocument15 pagesJHA Scaffolding - ApprovedLuqman OsmanNo ratings yet

- Welfield Services SDN BHD: Implementation of Consequence Management System Due To Hse Violation To ContractorDocument2 pagesWelfield Services SDN BHD: Implementation of Consequence Management System Due To Hse Violation To ContractorLuqman OsmanNo ratings yet

- Mk1622030t Journal Writing Rev 1Document23 pagesMk1622030t Journal Writing Rev 1Luqman OsmanNo ratings yet

- Assignment CaseStudy SOGT CHALLENGES PRD and WBS KOG11203 Project ManagementDocument26 pagesAssignment CaseStudy SOGT CHALLENGES PRD and WBS KOG11203 Project ManagementLuqman OsmanNo ratings yet

- MarkingGuideline For Journal PublicationDocument3 pagesMarkingGuideline For Journal PublicationLuqman OsmanNo ratings yet

- Project Hse Execution PlanDocument15 pagesProject Hse Execution PlanLuqman Osman25% (4)

- Psoter Soshea Osh SeminarDocument1 pagePsoter Soshea Osh SeminarLuqman OsmanNo ratings yet

- Work Breakdown Structure For Bimp Pipeline Project: Luqman Bin OsmanDocument3 pagesWork Breakdown Structure For Bimp Pipeline Project: Luqman Bin OsmanLuqman OsmanNo ratings yet

- 1 Question Bank For Unit 1Document11 pages1 Question Bank For Unit 1Ajay KareNo ratings yet

- Construction Planning and SchedulingDocument11 pagesConstruction Planning and SchedulingAWAKSEORANGNo ratings yet

- Artificial Intelligence: Three Domains of AIDocument4 pagesArtificial Intelligence: Three Domains of AIRIYA ARORA34 IX-CNo ratings yet

- A Brief Introduction To UnixDocument13 pagesA Brief Introduction To UnixLeyang LiuNo ratings yet

- Help CenterDocument4 pagesHelp CenterShivali VermaNo ratings yet

- Lc1f2254 Datasheet WW En-WwDocument3 pagesLc1f2254 Datasheet WW En-Wwramiz razaNo ratings yet

- HE - FOS - GR7-9 - Q1 - MODULE-2 For TeacherDocument27 pagesHE - FOS - GR7-9 - Q1 - MODULE-2 For TeacherVicente VicenteNo ratings yet

- Proposal - Axis BankDocument51 pagesProposal - Axis BankRahul S DevNo ratings yet

- Iso 3834 3 2021Document10 pagesIso 3834 3 2021Dulce Tlanilli Dionisio AmadoNo ratings yet

- SAP CloudDocument512 pagesSAP CloudyabbaNo ratings yet

- Recent Trends in AutomobilesDocument23 pagesRecent Trends in AutomobilesVivekanand ChockalingamNo ratings yet

- جدول كميات كهرباDocument3 pagesجدول كميات كهرباhany mohamed100% (1)

- Jntuh 4-1 AttendanceDocument15 pagesJntuh 4-1 Attendancedodda12345No ratings yet

- Product Highlights: All Gigabit PortsDocument5 pagesProduct Highlights: All Gigabit Portssaumal20No ratings yet

- XS 500 - 3000W R50 Users Manual Version 3Document49 pagesXS 500 - 3000W R50 Users Manual Version 3Mario Armelao100% (1)

- Federal Communications Commission 90.35: 90.33 General EligibilityDocument40 pagesFederal Communications Commission 90.35: 90.33 General EligibilityAl_CodaNo ratings yet

- Integrating Microsoft Access With Autocad VbaDocument19 pagesIntegrating Microsoft Access With Autocad VbaLuiz Paulo Cruz JrNo ratings yet

- CalderaDocument56 pagesCalderaEsteban TapiaNo ratings yet

- Carpool App Case StudyDocument2 pagesCarpool App Case StudyLuh CheeseNo ratings yet

- M1 Section 1. Assignment 1 Metacognitive Reading ReportDocument2 pagesM1 Section 1. Assignment 1 Metacognitive Reading ReportLandThere100% (1)

- Case Study NasariaDocument20 pagesCase Study NasariaHarsh SinhaNo ratings yet

- Traffic Light Detection and Recognition For Self Driving Cars Using Deep Learning SurveyDocument4 pagesTraffic Light Detection and Recognition For Self Driving Cars Using Deep Learning SurveyEditor IJTSRDNo ratings yet

- CyberOps Skills Assessment - Student TRNG - ExamDocument4 pagesCyberOps Skills Assessment - Student TRNG - ExamIsabella Leon67% (3)

- 8a. Scratch-3.0-for-Inclusive-LearningDocument31 pages8a. Scratch-3.0-for-Inclusive-LearningAvram MarianNo ratings yet

- Columbus Europe's Laboratory On The International Space StationDocument39 pagesColumbus Europe's Laboratory On The International Space StationBob AndrepontNo ratings yet

- UM HDL Buspro Setup Tool 2 (2020!05!23)Document32 pagesUM HDL Buspro Setup Tool 2 (2020!05!23)crisma tariNo ratings yet

- HTML FormDocument5 pagesHTML Formshivam ashishNo ratings yet

- U6csa18 Data Communication and Computer Networksl T P c3 0 0 3Document2 pagesU6csa18 Data Communication and Computer Networksl T P c3 0 0 3Vinoth KumarNo ratings yet

- Mitsubishi RobotDocument48 pagesMitsubishi RobotdanielNo ratings yet

- Vessel Technical BrochureDocument26 pagesVessel Technical BrochureMonica IorgulescuNo ratings yet