Professional Documents

Culture Documents

PVD Synthesis and High-Throughput

Uploaded by

Rahul VermaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PVD Synthesis and High-Throughput

Uploaded by

Rahul VermaCopyright:

Available Formats

INSTITUTE OF PHYSICS PUBLISHING

MEASUREMENT SCIENCE AND TECHNOLOGY

Meas. Sci. Technol. 16 (2005) 4653

doi:10.1088/0957-0233/16/1/007

PVD synthesis and high-throughput

property characterization of NiFeCr

alloy libraries

A Rar1,2, J J Frafjord1,2, Jason D Fowlkes2, E D Specht1,

P D Rack2, M L Santella1, H Bei1,2, E P George1,2

and G M Pharr1,2

1

Metals and Ceramics Division, Oak Ridge National Laboratory, Oak Ridge, TN 37831,

USA

2

Department of Materials Science and Engineering, The University of Tennessee, Knoxville,

TN 37996, USA

Received 15 April 2004, in final form 21 September 2004

Published 16 December 2004

Online at stacks.iop.org/MST/16/46

Abstract

Three methods of alloy library synthesis, thick-layer deposition followed by

interdiffusion, composition-spread codeposition and electron-beam melting

of thick deposited layers, have been applied to NiFeCr ternary and NiCr

binary alloys. Structural XRD mapping and mechanical characterization by

means of nanoindentation have been used to characterize the properties of

the libraries. The library synthesis methods are compared from the point of

view of the structural and mechanical information they can provide.

Keywords: combinatorial, alloy library, Ni, Fe, Cr, nanoindentation, XRD,

PVD, high throughput, x-ray diffraction, pulsed vapour deposition

(Some figures in this article are in colour only in the electronic version)

1. Introduction

The development of methods for high-throughput analysis of

binary and ternary alloy systems is a subject of great interest in

different areas of material science since combinatorial methods

were discovered in the 1970s [15]. Effective application of

combinatorial alloy library design first requires methods for

quick synthesis of alloy libraries covering a wide (or even

full) range of possible alloy compositions. Second, the library

must reproduce the relevant properties of the bulk materials

and allow for quick and effective measurements of important

properties. The properties of interest in this investigation

are phase composition and mechanical properties, including

the mechanical properties of non-equilibrium phases and thin

films that may be different from the equilibrium and bulk

material properties. These latter properties may be important

for MEMS device fabrication [6].

We investigate the applicability of three methods to Ni

FeCr ternary and NiCr binary library synthesis: deposition

of thick Cr, Fe and Ni layers followed by interdiffusion [7],

composition-spread codeposition [8] and a new method based

0957-0233/05/010046+08$30.00

on electron-beam melting of a thick Cr or Ni layer deposited

on a Ni or Cr substrate, respectively. NiFeCr was selected

as a model alloy system because it is the basis of a wide variety

of commercially important alloys such as stainless steels. As

such, this alloy system has been extensively studied, and its

structure and properties are well known [9].

2. Methods of alloy library synthesis

The synthesis of libraries by means of thick film deposition

and interdiffusion was described in detail in [7] and is shown

schematically in figure 1. Specimens of NiFeCr were

prepared by depositing films onto 50 mm diameter sapphire

substrates followed by annealing in vacuum to interdiffuse

the layers. Metal deposition was performed in an electronbeam evaporation system equipped with a sliding shutter and

a sample rotation stage. A typical background pressure was

about 106 Torr, and the deposition rate measured with a

quartz microbalance was approximately 3 nm s1 for Cr and

0.3 nm s1 for Fe and Ni. Layers of Cr, Fe and Ni were

sequentially deposited using the sliding shutter to create a

2005 IOP Publishing Ltd Printed in the UK

46

PVD synthesis and high-throughput property characterization of NiFeCr alloy libraries

sample rotation stage

resulting sample

deposited

films

shutter

deposition

sources

Figure 1. Schematic showing sample ternary alloy library preparation with thick film deposition and interdiffusion. A photo of the resulting

sample is shown at the left.

Figure 2. Sample preparation by codeposition from three sputtering

sources.

thickness gradient in each layer. The shutter was moved

at a constant rate such that the thickness of each layer

increased linearly with position to a maximum of about 1.7 m

at the thick end. After finishing a layer, the sample was rotated

by 120 about the substrate centre, and a layer of a different

alloying component was deposited. The total thickness of

the deposited layers was limited by the maximum thickness

measurable by the quartz microbalance (about 5 m).

After deposition, the layers were interdiffused by annealing.

The resulting sample is shown on the left side of figure 1.

This sample consisted of a triangular region with a constant

thickness of about 1.7 m and compositions spanning the

entire ternary phase diagram and binary regions with nonconstant thickness around the samples. Similar methods of

library fabrication based on multilayer deposition have been

used by others [10].

Composition-spread codeposition is probably the most

popular method of library synthesis. The experimental setup

used here corresponds to that used in an earlier publication

[11]. The alloy films were deposited using an RF magnetron

sputtering system onto 100 mm diameter sapphire substrates.

Figure 2 shows the three-source assembly illustrating the

source positions relative to the substrate. The sputtering

system has three 50 mm sources that were simultaneously

sputtered onto the fixed substrate. The iron and nickel sources

were oriented 180 apart in the chamber, and the chromium

target was oriented 90 from both the iron and nickel targets.

All the target centres were 16.5 cm from the substrate centre

and were tilted at 32 relative to the substrate normal to create

a composition gradient across the substrate.

For each deposition, the base pressure was nominally 7

107 Torr and the processing pressure was 103 Torr of argon.

The sputtering powers for the Fe, Cr and Ni targets were

160 W, 60 W and 60 W, respectively, and each film was

deposited for 3 h. Film thicknesses were about 2 m for each

film. No deliberate heating was applied to the substrate during

the deposition of the films; however the plasma produced

nominal heating of the substrate (about 100 C). A total of

five samples were sputter deposited, and all except one were

vacuum annealed for 2 h at temperatures of 200, 400, 600 and

800 C.

Library synthesis by means of electron-beam melting

was performed using a new technique. Nickel or chromium

substrates with a purity of 99.999% were polished with 6, 3 and

1 m diamond suspensions and cleaned in acetone and ethanol.

A Cr or Ni layer, with or without thickness gradients, was

deposited onto the nickel or chromium substrate, respectively,

by PVD. The deposition rate was about 1.21.6 nm s1, and the

total thickness of the deposited film varied from 0 to 10 m.

Electron-beam welding (EBW) was performed to alloy the

film with the substrate in a LeyboldHeraeus electron-beam

welder in vacuum (<3.2 104 Torr). For all the libraries, the

composition of the resulting alloy was analysed with energy

dispersive x-ray spectrometry (EDS). The libraries cover the

alloy composition from Ni to Cr. The region with high Cr

concentration was prepared by Ni deposition on Cr and vice

versa. The reference bulk samples were also prepared by arc

melting and casting.

An optical image of a typical cross section of a welded

sample is shown in figure 3. The alloyed area is easily

distinguished from the Ni matrix by the grain structure of

the region that was melted. The Cr composition on the cross

section within the alloyed region was found to be uniform by

means of EDS.

3. High-throughput library analysis

Among the parameters of interest for materials scientists are

structure and mechanical properties. The high-throughput

47

A Rar et al

Ni-Cr

Ni

Figure 3. Optical cross section of typical sample made by

electron-beam welding.

analysis of these properties of the alloy libraries is probably a

bigger challenge than the alloy library preparation. A number

of limitations on the methods of sample characterization

originate from the combinatorial nature of the sample and

the thin film or line form of the samples. The combinatorial

nature of the sample requires analysis of a few thousand points

to produce a map of the properties and quick analysis of the

properties at each point is essential. This made traditional

x-ray diffraction measurements impractical because the typical

time for data acquisition at each point is more than a minute.

The method of choice for mapping of the structure was

synchrotron-based x-ray diffraction.

The measurements of mechanical properties are also

strongly limited by the small sample size. We know of

only a few methods that can be used to measure mechanical

properties for such samples. Elastic modulus and hardness

may be measured by nanoindentation [12] and elastic modulus

by atomic force acoustic microscopy [13] and ultrasonic

microscopy [14]. Nanoindentation was selected because it

is a more conventional method, has a higher acquisition rate

and gave hardness measurements.

The x-ray diffraction measurements were described in

detail in [15]. The experimental setup is outlined in figure 4.

Diffraction and fluorescence data were collected using the

bending magnet beamline X33-BM at the Advanced Photon

Source (APS). The focused beam size with energy 12 keV was

1.0 mm 0.25 mm in size, providing a 1.0 mm 1.0 mm

footprint on the sample when incident at a 15 glancing angle.

The sample was mapped by rastering in 1 and 2 mm steps

for the 50 and 100 mm diameter samples, respectively. The

composition range of elements within one spot was about

2 at% for diffused samples and about 1 at% for codeposited

samples. Data were collected for 12 s at each point.

Fluorescence spectra were acquired using a Si drift

detector with a resolution of 165 eV at 6.4 keV. The detector

viewed the sample at a 15 glancing angle, the angle of the

incident x-rays. The integrated counts in the Cr, Fe and Ni K

lines were measured by least-squares fitting to Gaussian line

shapes and recalculated to obtain composition. The corners of

the ternary diagram were used as internal standards.

48

Diffraction patterns were taken using a 1024 1024 pixel

CCD detector. A typical diffraction pattern formed on the

CCD is shown in the inset in figure 4. The CCD image was

converted to a standard diffraction pattern which is shown in

the right panel together with the measured composition. This

set of data was used for identification of the phase location on

the ternary phase diagram.

Nanoindentation experiments were performed using a

commercial nanoindentation system with a Berkovich indenter

in the continuous stiffness mode [12].

4. Experimental results for composition and phase

distribution

The interdiffused samples easily covered all possible ternary

and binary compositional spreads with an almost linear

composition dependence on position [15]. The resulting phase

distribution for a sample interdiffused by annealing at 875 C

is shown in figure 5 along with a calculated ternary phase

diagram at the same temperature. The diagram was calculated

using the PANDATTM Software Package [16] and SSOL2SGTE Solutions Database [17]. The phase diagram measured

from the experimental library is in reasonable agreement with

the theoretical prediction. The possible sources of discrepancy

are changes during the sample cooling and accuracy

of the measurements, as have been discussed elsewhere

[7, 15, 18].

For the codeposited samples the composition spread

is smaller, and the phase distribution is complicated by

a non-equilibrium phase observed after annealing at low

temperatures. The measured locations of phases in the

codeposited samples are shown in figure 6: (a) before

annealing, and for 2 h post-deposition annealing temperatures

of (b) 200 C, (c) 400 C, (d ) 600 C and (e) 800 C. The area of

the non-equilibrium phase is indicated by grey shading. This

phase was identified as having the -Mn structure [19], but it

must be mentioned that another structure for this metastable

phase is the -brass structure with a bcc cell containing

52 atoms [20]. The diffraction pattern of -brass structure

is similar to -Mn. We have not yet acquired enough data

to determine which structure was observed. Other phase

boundaries are indicated by the heavy lines. The light lines

indicate the edge of the wafer.

Figure 6(f ) shows for comparison the measured phase

diagram for a smaller 50 mm wafer without annealing as

was reported in [11]. Increasing the sample size from 50

to 100 mm, which is the maximum possible size for this PVD

apparatus, significantly increases the observed composition

range of the ternary diagram. However, only about 30% of the

possible compositions may be prepared on one substrate. This

will not be a significant disadvantage for the practical usage

of this method, if investigations are devoted to improvements

of the properties of known alloy systems for which only small

composition variations are required. Such an application

will additionally benefit from good reproducibility of the

sample preparation provided by this method. The composition

spanned by the film varies by only a few atomic per cent

from run to run, indicating consistency of both deposition and

analysis.

PVD synthesis and high-throughput property characterization of NiFeCr alloy libraries

Counts (arb. units)

1250

Fe52Cr41Ni6

S phase

1000

750

500

250

0

20

25

30

35

40

2-Theta ()

composition

12 keV

0.25x1 mm

CCD

Detector

Silicon drift detector

Figure 4. Schematic of XRD scanning experiment and data processing.

(bcc)

Cr

(intermetallic)

(bcc)

Cr

(fcc)

Fe

Ni

(a)

++

+

+

(b)

Fe

(bcc)

(fcc)

Ni

Figure 5. (a) Calculated ternary diagram of NiFeCr system at 875 C and (b) measured ternary diagram for sample interdiffused at

875 C for 3 h and 20 min.

The experimentally measured phase distribution at an

annealing temperature of 800 C corresponds well to the

equilibrium diagram calculated for the same temperature,

indicating that equilibrium has been achieved. In addition,

diffusion mobility is high at 600 C as confirmed by the

disappearance of the metastable phase and by the temperature

dependence of the grain sizes, as shown in figure 7.

The Scherer particle size equation [21] was used to calculate

the grain size from the most intense peak of each phase with no

corrections for instrumental resolution. Grain growth begins

at 600 C, which is also the temperature at which the -Mn

phase disappears. At 400 C and below, the samples are clearly

not in equilibrium, since a significant portion of the observed

composition spread is occupied by the metastable -Mn

phase, thus providing options to study the phase properties.

The great mobility at 600 C opens the possibility of full

49

A Rar et al

(a)

(d )

(b)

(e)

-Mn (shaded)

(c)

(f)

Figure 6. Ternary phase diagram for codeposited sample (a) as-deposited, and after 2 h annealing in vacuum at (b) 200 C, (c) 400 C,

(d ) 600 C, (e) 800 C. (f ) Ternary phase diagram for as-deposited sample on a 50 mm substrate from [4].

alloying at a lower temperature than for the thick interdiffusion

layer method, where annealing temperatures in the range of

825875 C were required [7].

50

The e-beam welding methods are still in development.

The film thickness and e-beam parameters are far from optimal

and may limit the obtained composition spread. For example,

PVD synthesis and high-throughput property characterization of NiFeCr alloy libraries

(a) 350

45

300

-Mn

bcc

fcc

35

30

Modulus (GPa)

mean grain size nm

40

25

250

200

150

20

100

15

10

(b)

20

20

40

60

80

Chromium Concentration (atomic %)

100

14

200

400

600

800

annealing temperature C

Figure 7. Diffraction particle size for observed phases versus

annealing temperature as measured by x-ray technique.

one typical weld used for nanoindentation only had a Cr

composition range of 525 at%. Increasing the e-beam

current provided a deeper and larger weld and alloy

region with smaller Cr concentration, but also produced

significant surface roughness that made the nanoindentation

measurements difficult. Preparation of samples with a higher

Cr concentration by means of a thicker Cr layer may prove

difficult because the Cr does not adhere well to the Ni substrate

past a certain thickness. Instead, samples with higher Cr

concentration were prepared by Ni films on Cr substrates. This

EBW method may also be useful for ternary alloy preparation

by using, for example, Cr- and Fe-deposited films wedged in

different directions on the nickel substrate.

5. Testing of mechanical properties by

nanoindentation

The libraries prepared by electron-beam welding were found

to be best for nanoindentation measurements because the depth

and width of the region to be tested were greater than typical

sizes needed for nanoindentation experiments. The measured

elastic modulus, E, and hardness, H, versus Cr concentration

for five samples are shown in figure 8 by circles together with

the data for bulk samples shown by triangles.

The results for the different libraries for the same

composition are similar (within the experimental scatter),

indicating that the properties of the alloy libraries depend only

on the resulting alloy composition and are not sensitive to

differences in the procedures used for library preparation, i.e.,

power setting of the welding e-beam, thickness of the deposited

layer, which material (Ni or Cr) was used as substrate and

which as deposited film. The scatter in the library data is

related to sample roughness and the presence of multi-phase

regions at some compositions. The last factor also contributes

to scatter in the measurements of the bulk samples. The

results for Cr concentration above 85 at% were found to be too

scattered and will not be shown and discussed in this paper.

The measured moduli for bulk samples agree well with the

results obtained for the library. The composition dependence

Hardness (GPa)

12

10

8

6

4

2

0

40

60

80

100

Chromium Concentration (atomic %)

Figure 8. Nanoindentation measurements of (a) modulus and

(b) hardness of EBW samples (open circles) and bulk standard

(triangles) versus Cr composition. The line shows the expected

modulus from the rule of mixtures.

of modulus is not trivial. The solid line through the data

indicates the modulus expected from a simple rule of mixing

by using moduli for Ni and Cr, of 200 and 270 GPa,

respectively [22]. For Cr concentrations below 30 at%

the measured modulus follows the tendency expected from

the mixing law, but is slightly lower than predicted. This

may indicate problems with the accuracy of nanoindentation

measurements, and some sample problems due to surface voids

or contamination. The measured moduli are almost constant

for Cr compositions from 30 to 60 at% but increase rapidly

thereafter.

The hardness measurements also show good correlation

between the EBW library and bulk samples. The hardness

increase with Cr concentration correlates well with the

modulus increase, i.e., hardness increases for Cr compositions

below 30 at%, remains roughly constant from 30 to 50 at%,

and then increases by a factor of 3 when the Cr concentration

increases from 50 to 75 at%.

The nanoindentation

measurements have been confirmed by microhardness

measurements which have been carried out on the same

bulk samples. These measurements reproduce well the

nanoindentation results.

The complicated dependences of modulus and hardness of

the alloy on the composition are probably due to formation of

a binary phase at chromium concentration between 40 and

85 at%. This preliminary assumption is based upon the

formation of binary phase around a chromium concentration

of about 40 at% according to the phase diagram as shown in

figure 5(a).

A careful characterization of the alloy

microstructure will be performed in the future to understand

the hardness and modulus dependence on Cr concentration.

51

A Rar et al

30000

much easier. The preliminary experiments performed for

the libraries prepared by codeposition show little scatter,

indicating no problems due to roughness and significant

contact depth region where the influence of substrate is not

important or can be taken into account [24]. This made the

future investigations of the mechanical properties of the -Mn

phase possible.

Ni

20000

10000

-10000

-20000

Fe

Cr

-30000

-30000 -20000 -10000

10000

20000

30000

1.9E5

2.5E5

1.9E5

1.9E5

Figure 9. Boundary map for a ternary alloy library made by

thick-layer interdiffusion. The location of the phase is shown by

the dashed line, by the solid line and by closed squares. The

triangle indicates the location of the ternary library; the rectangle

indicates the area where the nanoindentation mapping was

performed. The contact stiffness map in N m1 for this area for load

2.7 mN is shown in a separate panel as a contour map. The border

of the ternary diagram for the map is shown by the diagonal line.

In general, nanoindentation measurements of the thin

films on substrate have two problems: data scatter due to

surface roughness [23] and influence of substrate on the

measured modulus and hardness [24, 25]. These factors were

significant in measurements of the alloy libraries made by

interdiffusion and codeposition.

Nanoindentation measurements proved most difficult for

the libraries prepared by interdiffusion. This complication was

due to the relatively thin layer of FeCrNi alloy produced, and

also due to the surface becoming rough during annealing as

a result of grain growth. Surface roughness produces scatter

in nanoindentation measurements [23]. For these samples,

the mechanical properties were screened to determine relative

variations within the sample. Some of the screening results

have been discussed in [18]. In figure 9, the results of 2D

mapping of 15 15 contact stiffness measurements at a fixed

load of 2.7 mN is shown for the region around the phase. The

contact stiffness at fixed load is not very sensitive to surface

roughness. The measured contact stiffness decreases in the

phase from about 2.5 105 to 1.6 105 N m1 relative to the

nearby phase. Assuming from the rule of mixing that the

changes in modulus are negligibly small, this corresponds to

an increase in hardness of about 2.5 times, which is similar to

earlier results [18] and agrees with the tendency observed in

bulk samples [26].

The codeposited samples were only about 2 m thick, but

the flat surface made standard nanoindentation measurements

52

6. Conclusion: benefits and limitations of the

methods

The examples of combinatorial alloy development presented

here show that there is some tradeoff between easy

structural/chemical characterization over a wide area of

the phase diagram and easy mechanical measurements.

Mechanical measurements were easier to obtain for the

codeposited samples than for annealed multilayer deposited

samples, and they were easiest for the electron-beam-welded

samples. Surface polishing may be additionally applied

to EBW samples and should reduce roughness-related data

scatter and possible effects of surface contamination.

Structural mapping of the full ternary diagram is easiest

for samples made by interdiffusion, but more difficult for

codeposited samples due to the limited range of composition

that can be achieved. The additional benefit of codeposited

libraries is the option of studying the non-equilibrium phases.

The structural mapping of EBW samples is difficult because of

limited composition spread in a single sample. Five samples

were used to cover all possible binary compositions in these

investigations, and the number of the samples will not be

smaller than 2 with 23 welds on each sample even in perfect

conditions. This amount will increase significantly for ternary

library preparation by EBW.

Acknowledgments

Work sponsored by the US Department of Energy (US

DOE), Division of Materials Sciences and Office of Industrial

Technologies, Industrial Materials for the Future Program,

under grant no DE-FC07-02ID14251. Oak Ridge National

Laboratory (ORNL) is operated by UT-Battelle LLC, for the

US DOE under contract no DE-AC05-00OR22725. The

UNICAT facility at the Advanced Photon Source (APS) is

supported by the University of Illinois at Urbana-Champaign,

Materials Research Laboratory (US DOE, the State of

Illinois-IBHE-HECA and the NSF), the Oak Ridge National

Laboratory (US DOE under contract with UT-Battelle LLC),

the National Institute of Standards and Technology (United

States Department of Commerce) and UOP LLC. The APS is

supported by the US DOE, Basic Energy Sciences, Office of

Science under contract no W-31-109-ENG-38.

References

[1]

[2]

[3]

[4]

Hanek J J 2004 Appl. Surf. Sci. 223 1

Adams E J, Xiang X D and Zhao J C 2002 MRS Bull. 27 295

Xiang X D 2004 Appl. Surf. Sci. 223 54

Collins P C, Banerjee R, Banerjee S and Fraser H L 2003

Mater. Sci. Eng. A 352 118

[5] Cohen-Adad M Th, Gharbi M, Goutaudier C and

Cohen-Adad R 1999 J. Alloys Compounds 289 185

[6] Obermeier E 1997 Mater. Res. Soc. Symp. Proc. 39

PVD synthesis and high-throughput property characterization of NiFeCr alloy libraries

[7] Rar A, Specht E D, George E P, Santella M L and Pharr G M

2004 J. Vac. Sci. Technol. A 22 1788

[8] Christen H M, Silliman S D and Harshavardhan K S 2002

Appl. Surf. Sci. 189 216

[9] Lula R A and Parr J G 1986 Stainless Steel (Metals Park, OH:

American Society for Metals)

[10] Yamamoto Y, Takahashi R, Matsumoto Y, Chikyow T and

Koinuma H 2004 Appl. Surf. Sci. 223 9

[11] Specht E D, Rack P D, Rar A, Pharr G M, George E P and

Hong H 2004 Mater. Res. Soc. Symp. Proc. 804 45

[12] Oliver W C and Pharr G M 1992 J. Mater. Res. 7 1564

[13] Rabe U, Amelio S, Kopycinska M, Hirsekorn S, Kempf M,

Goken M and Arnold W 2002 Surf. Interface Anal. 33 65

[14] Hurley D C, Tewary V K and Richards A J 2001 Meas. Sci.

Technol. 12 1486

[15] Specht E D, Rar A, Pharr G M, George E P, Zschack P,

Hong H and Ilavsky J 2003 J. Mater. Res. 18 2522

[16] Chen S L, Daniel S, Zhang F, Chang Y A, Yan X Y, Xie F Y,

Schmid-Fetzer R and Oates W A 2002 Calphad 26 175

[17] Hack K (ed) 1996 The SGTE Casebook: Thermodynamics at

Work (London: The Institute of Materials) p 227

[18] Rar A, Specht E D, Meyer H M III, Santella M L, George E P

and Pharr G M 2004 Mater. Res. Soc. Symp. Proc.

804 63

[19] Simmonds M C, Newman R C, Fujimoto S and Colligon J S

1996 Thin Solid Films 279 4

[20] Brandon J K, Brizard R Y, Chieh P C, McMillan R K and

Pearson W B 1974 Acta Crystallogr. B 30 1412

[21] Warren B E (ed) 1990 X-Ray Diffraction (New York: Dover)

p 253

[22] Simmons G and Wang H 1971 Single Crystal Elastic

Constants and Calculated Aggregate Properties

(Cambridge, MA: MIT Press)

[23] Mencik J and Swain M V 1995 J. Mater. Res. 10 1491

[24] Rar A, Song H and Pharr G M 2002 Mater. Res. Soc. Symp.

Proc. 695 431

[25] Nix W D 1997 Mater. Sci. Eng. A 234236 37

[26] Bain E C and Griffiths W E 1927 Trans. AIME 75 166

53

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Four Probe MethodDocument1 pageFour Probe MethodVita Efellina100% (3)

- Dr. Rajat Kumar Roy (Magnetics Department NML) Rahul VermaDocument12 pagesDr. Rajat Kumar Roy (Magnetics Department NML) Rahul VermaRahul VermaNo ratings yet

- Al 1Document4 pagesAl 1Rahul VermaNo ratings yet

- VSM IIT Madras - Sample RequirementsDocument2 pagesVSM IIT Madras - Sample RequirementsPrasad DNo ratings yet

- Fe - (CR, Mo) - (C, B) - TM Bulk Metallic Glasses With High Strength and High Glass-Forming AbilityDocument4 pagesFe - (CR, Mo) - (C, B) - TM Bulk Metallic Glasses With High Strength and High Glass-Forming AbilityRahul VermaNo ratings yet

- PRB - Domain Structure of A Nd60Al10Fe20Co10 Bulk Metallic GlassDocument4 pagesPRB - Domain Structure of A Nd60Al10Fe20Co10 Bulk Metallic GlassRahul VermaNo ratings yet

- Magnetic Cluster Expansion Model For Random and OrderedDocument26 pagesMagnetic Cluster Expansion Model For Random and OrderedRahul VermaNo ratings yet

- Superalloy 2011Document41 pagesSuperalloy 2011Rahul VermaNo ratings yet

- The European Physical Journal B - Condensed Matter and Complex Systems Volume 34 Issue 2 2003 (Doi 10.1140/epjb/e2003-00207-3) O. Crisan J. M. Grenèche J. M. Le Breton A. D. Crisan Y. La - MaDocument8 pagesThe European Physical Journal B - Condensed Matter and Complex Systems Volume 34 Issue 2 2003 (Doi 10.1140/epjb/e2003-00207-3) O. Crisan J. M. Grenèche J. M. Le Breton A. D. Crisan Y. La - MaRahul VermaNo ratings yet

- Effect of Composition On The Solidification Behavior of SeveralDocument14 pagesEffect of Composition On The Solidification Behavior of SeveralRahul VermaNo ratings yet

- High Performance of Low Cost Soft Magnetic MaterialsDocument7 pagesHigh Performance of Low Cost Soft Magnetic MaterialsRahul VermaNo ratings yet

- Fe-Ni-Cr 2Document16 pagesFe-Ni-Cr 2Rahul VermaNo ratings yet

- Calculation of Phase Equilibria in The Fe-Ni-Cr System BasedDocument15 pagesCalculation of Phase Equilibria in The Fe-Ni-Cr System BasedRahul VermaNo ratings yet

- Electrodeposition of Fe-Ni-Cr Alloy From Deep EutecticDocument11 pagesElectrodeposition of Fe-Ni-Cr Alloy From Deep EutecticRahul VermaNo ratings yet

- Ni-Cr-Fe 1Document3 pagesNi-Cr-Fe 1Rahul VermaNo ratings yet

- The Influence of NB and C On The SolidificationDocument6 pagesThe Influence of NB and C On The SolidificationRahul VermaNo ratings yet

- Fe-Ni-Cr 2Document16 pagesFe-Ni-Cr 2Rahul VermaNo ratings yet

- Ni-Cr-Fe 1Document3 pagesNi-Cr-Fe 1Rahul VermaNo ratings yet

- Cytology Book?: (Based On Bethesda Form)Document22 pagesCytology Book?: (Based On Bethesda Form)Khairatul AyyunNo ratings yet

- Animal Slide Preparation TechniqueDocument10 pagesAnimal Slide Preparation Techniqueraja nur aimiNo ratings yet

- PT1 Data Sheet Cell Structure - Examining Plant and Animal CellsDocument8 pagesPT1 Data Sheet Cell Structure - Examining Plant and Animal CellsAsuka ChanNo ratings yet

- Normal Skin Microbiota Is Altered in Pre-Clinical Hidradenitis SuppurativaDocument6 pagesNormal Skin Microbiota Is Altered in Pre-Clinical Hidradenitis SuppurativaŠišmišova DevojkaNo ratings yet

- Inter Metallic Compounds, Volume 2, Basic Mechanical Properties and Lattice DefectsDocument211 pagesInter Metallic Compounds, Volume 2, Basic Mechanical Properties and Lattice Defectssril35100% (2)

- Chapter 6 WordDocument13 pagesChapter 6 WordXyrelle SantiagoNo ratings yet

- MICP - Introduction and Bacterial Growth and RequirementsDocument85 pagesMICP - Introduction and Bacterial Growth and RequirementsKYLE ANDREW SAWITNo ratings yet

- The Encyclopedia of Microscopy (1961) by ClarkDocument716 pagesThe Encyclopedia of Microscopy (1961) by ClarkDan JohnsonNo ratings yet

- 8 - Chun - J. Appl. Phys - 1999Document10 pages8 - Chun - J. Appl. Phys - 1999Gustavo MartinezNo ratings yet

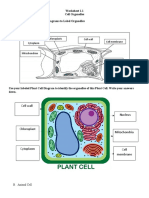

- Worksheet 1.1 Cell OrganelleDocument2 pagesWorksheet 1.1 Cell OrganelleCyndel TindoyNo ratings yet

- Connective Tissue ProperDocument27 pagesConnective Tissue Properapi-19641337No ratings yet

- Estimation of Time Since Death Ba PDFDocument6 pagesEstimation of Time Since Death Ba PDFCesar Augusto Rojas MachucaNo ratings yet

- 11th BioBotany Important Questions English Medium PDFDocument6 pages11th BioBotany Important Questions English Medium PDFSilva scary sv75% (4)

- FEI Quanta 400 FEG - FEI CompanyDocument2 pagesFEI Quanta 400 FEG - FEI CompanyGrégory PezzattiNo ratings yet

- 01 Bio IX ICSE Cell PDFDocument6 pages01 Bio IX ICSE Cell PDFthe lillyNo ratings yet

- Mechanical Testing and Structure AnalysisDocument6 pagesMechanical Testing and Structure AnalysisAbdullah AlkalaliNo ratings yet

- Laboratory Activity 3Document4 pagesLaboratory Activity 3Sabrina MascardoNo ratings yet

- Prokaryotic and Eukaryotic CellDocument19 pagesProkaryotic and Eukaryotic CellReanne MeregildoNo ratings yet

- Antibiotics and Antimicrobial Susceptibility LabDocument4 pagesAntibiotics and Antimicrobial Susceptibility LabjosephNo ratings yet

- Microstructure Analysis Metallography Mechanical TestingDocument6 pagesMicrostructure Analysis Metallography Mechanical TestingMosso MartinNo ratings yet

- Quiz 7 CellDocument16 pagesQuiz 7 CellNOVEIA CLOWIE TRUGILLONo ratings yet

- Kuliah 1 - Sejarah Dan Ruang Lingkup MikrobiologiDocument42 pagesKuliah 1 - Sejarah Dan Ruang Lingkup MikrobiologiGandis IndahNo ratings yet

- Lab Report Bacteria CountDocument5 pagesLab Report Bacteria Countsarahyahaya67% (3)

- Acid-Fast StainDocument12 pagesAcid-Fast StainDragoș Mălăescu100% (1)

- 2020 - Subvisible Particulate Contamination in Cell TherapyDocument4 pages2020 - Subvisible Particulate Contamination in Cell Therapypascal candillonNo ratings yet

- 1 SM PDFDocument205 pages1 SM PDFTaniaNo ratings yet

- Cell Biology Chapter 1Document16 pagesCell Biology Chapter 1Molly511100% (1)

- Laboratory Manual: Fundamentals of Plant PathologyDocument63 pagesLaboratory Manual: Fundamentals of Plant PathologyCh Dheeraj RaoNo ratings yet

- Effects of Alloying Elements On SteelDocument6 pagesEffects of Alloying Elements On SteelSalem GarrabNo ratings yet

- Areolar Connective Tissue LPOMPODocument7 pagesAreolar Connective Tissue LPOMPOWinard WantogNo ratings yet