Professional Documents

Culture Documents

Electrodeposition of Fe-Ni-Cr Alloy From Deep Eutectic

Uploaded by

Rahul VermaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrodeposition of Fe-Ni-Cr Alloy From Deep Eutectic

Uploaded by

Rahul VermaCopyright:

Available Formats

Int. J. Electrochem. Sci.

, 6 (2011) 1468 - 1478

International Journal of

ELECTROCHEMICAL

SCIENCE

www.electrochemsci.org

Electrodeposition of Fe-Ni-Cr alloy from Deep Eutectic

System containing Choline chloride and Ethylene Glycol

Gengan Saravanan, Subramanian Mohan*

Electroplating and Metal Finishing Technology division

CSIR-Central Electrochemical Research Institute

Karaikudi 630006, India

*

E-mail: sanjnamohan@yahoo.com

Received: 22 September 2010 / Accepted: 20 January 2011 / Published: 1 May 2011

A novel procedure for the electrochemical deposition of Fe-Ni-Cr alloy was investigated on mild steel

substrate. The alloy contains approximately 53-61% Fe, 34-41% Ni, and 4-15% Cr, our results show

that it is possible to produce a thick deposit of the alloy. The influence of electrodeposition potential

upon the Fe, Ni, and Cr composition were investigated. Surface morphology and composition of

deposits were analyzed using SEM with EDAX. The corrosion resistance of Fe54.62Ni30.87.Cr14.5

electrodeposited alloy on mild steel substrate were determined and compared with simulated data.

Keywords: Alloy (A), stainless steel (A), EIS (B), SEM (B), electrodeposited films (C).

1. INTRODUCTION

Fe-Ni-Cr alloy is a widely used in many areas due to its good corrosion resistance, magnetoresistive, and mechanical properties [1-4]. Resistance towards aggressive media and its

biocompatibility would make the alloy an excellent candidate for developing cheap biodevices, [5]

composition equivalent to stainless steel is reported by M.R. El-Sharif et al. [6-7] and it would allow

advantage to aforementioned properties and for fabrication of electroformed structures with complex

shapes. Electrodeposition of alloy such as Fe-Cr [8], Fe-Ni-Cr [7, 9], and Fe-Ni-Cr-Mo [10], has been

reported in the literature but were limited to producing thin layers in aqueous based electrolytes. Due

to the complexity of producing a ternary alloy by electrochemical means, the presence of Cr in high

quantity in the deposits is a challenge by itself [11]. First of all, Cr(III) aqua-species, Cr(H2O)63+, being

a very strong Lewis acid, undergoes a rapid olation reaction between unprotonated forms in aqueous

electrolyte, annihilating Cr deposition. To prevent this phenomenon, we will be investigating Cr

Int. J. Electrochem. Sci., Vol. 6, 2011

1469

electrodeposition from DES based on choline chloride without any complexing agent [12].

Additionally, the presence of Cr in the alloy decreases the quality of the structure by the formation of

cracks, low thickness, and increase of internal stress. In order to overcome this problem, the addition

of an organic additive such as saccharine [13] will reduce the stress and may help to get a better

deposits quality. On the other hand, these additives are known to prevent the formation of a passivated

oxide layer at the surface, thereby decreasing the corrosion resistance of the alloy [14]. In aqueous

based electrolyte, the reduction of water into hydrogen runs with very low overpotential on transition

metal [15] deposits and leads to free H2 and OH- anions. This reduction of water decreases the cathode

efficiency and the hydroxide increases the pH, which precipitates the iron and nickel as their insoluble

hydroxides. The precipitation of Cr(III) species into the deposits is also a problem [16].

In this study, a novel DES based electrolyte is developed allowing the deposition of Fe-Ni-Cr

alloys [17]. This work is very important in terms of free from aqueous electrolyte, complexing agent,

additive like saccharine and H2 reduction. Effect of electrodeposition potential on the composition,

structural morphology, and corrosion resistance properties of alloy deposits were investigated.

2. EXPERIMENTAL SECTION

2.1. Preparation of Deep Eutectic Solvent and Electrochemical Deposition

The deep eutectic solvent (DES) was prepared by mixing choline chloride 4.4 g, CrCl36H2O

8.5 g, NiCl26H2O 3.8 g, FeSO47H2O - 0.33 g , KCl 1.5 g, ethylene glycol 44.4 g, at 65C until

a homogeneous, green liquid was formed [18]. Potentiostatic electrodeposition was carried out using

three electrode cell connected to a potentiostat/galvanostat PARSTAT 2273. Constant potential

deposition was carried out in an undivided cell at potential from -1.3 to -1.5 V. The working electrode

(area, 1cm2) was either copper or mild steel, counter and reference electrode were platinum foil and

saturated calomel electrode directly immersed in DES. The sample was degreased in acetone, electro

cleaned in alkaline solution, rinsed with 5%H2SO4 and finally rinsed with double distilled water.

2.2. Microchemical and Microstructural analyses

Structural morphology and elemental composition of deposits were carried out using scanning

electron microscopy energy dispersive X-ray spectroscopy (Hitachi, 3000H). X-ray diffraction pattern

of alloy phases were measured using a Phillips diffractometer, 2 from 20 to 100 using CuK, =

0.1540 nm.

2.3. Corrosion resistance studies

The electrochemical measurements were carried out using a PARSTAT 2273 advanced

electrochemical system (Princeton Applied Research Company, USA). A saturated calomel electrode

(SCE) was used as the reference electrode and a large platinum plate as the counter electrode. The mild

Int. J. Electrochem. Sci., Vol. 6, 2011

1470

steel (MS) and Fe-Ni-Cr alloy obtained at -1.5 V on MS were the working electrodes. The corrosive

medium in the test was 3.5% NaCl aqueous [19]. Potentiodynamic polarization curves were measured

for both substrate and electrodeposited alloy between -0.25 and 0.25V at scan rate of 5 mV/s. The

corrosion parameters were obtained with inbuilt software package (Power Suite). EIS were conducted

at open circuit potential over a frequency range from 105 to 10-2 Hz. The amplitude of potential

modulation was 5 mV. All the recorded impedance spectra were shown as Nyquist diagram.

ZSimpWin (3.21) software was used to fit the EIS experimental data.

3. RESULT AND DISCUSSION

3.1. X-ray diffraction analysis

Figure.1 shows a typical X-ray diffractogram for the electrodeposited alloy. As can be seen,

this alloy exhibits sharp lines characteristic for poly crystalline nature. The peaks were observed at

diffraction angle of 43.4, 50.4, 73.9, 89.8 and 94.9 corresponding to (111), (200), (220), (311) and

(222) crystal planes and Fe-Ni-Cr phases were polycrystalline. All peaks can be indexed as the Fe-NiCr face-centered cubic (FCC) phases based on the standard data of the JCPDS (Card no. 33-0945) file.

The average crystallite size was estimated at 35.5 nm using Scherer formula [20, 21].

(111)

Fe-Ni-Cr

600

(220)

200

(222)

400

(311)

(200)

Intensity (a.u)

800

40

50

60

70

80

90

100

2 (degrees)

Figure 1. XRD pattern of Fe-Ni-Cr alloy deposited at -1.5 V in deep eutectic solvent based on choline

chloride and ethylene glycol.

3.2. Microstructural characteristics and elemental composition

Deposition potential has an important effect on deposit brightness, microstructure and

composition of alloy deposits on copper substrate. In the present studies, the SEM images and EDAX

Int. J. Electrochem. Sci., Vol. 6, 2011

1471

patterns show differences on the samples obtained by potentiostatic deposition technique. Fig. 2A and

2B shows the morphology of alloy deposited at -1.3V and the corresponding EDAX pattern reveals the

presence of Fe-53.7% Ni- 41.7% and Cr-4.5%. Deposits were darker than one obtained at -1.4 and 1.5V, nodular grain sizes ranging from 0.3-0.7m with agglomeration of particles formed are seen.

Fig. 2C and 2D shows the SEM and EDAX results of alloy obtained at -1.4V, these deposits

were brighter than those obtained at -1.3V with grain sizes ranging from 0.2-0.5m. Deposits were

denser and compact layer containing spherical particles were formed as small clusters. The

compositions of alloy atomic percentage were Fe-60.9% Ni-34.3% and Cr-4.7% as shown by EDAX

analysis. SEM and EDAX results of alloy deposits obtained at -1.5V and these results were shown in

Fig. 2E and 2F. Deposits were brighter, homogeneous, dense and very small nodular grains with an

average size of 0.2m. Bright deposits could be due to increasing of Cr percentage in the alloy

composition, EDAX shows that the atomic percentages of alloy were Fe-54.6%, Ni-30.8% and Cr14.5%.

From the analysis of alloy deposits morphology and composition under different potentials, it

appears that the type of deposits and composition gradually changed from darker to bright and from

distorted [22] to close stainless steel [23] compositions [24].

Figure 2. (A) SEM

Figure 2. (B) EDAX

Int. J. Electrochem. Sci., Vol. 6, 2011

1472

Figure 2. (C) SEM

Figure 2. (D) EDAX

Figure 2. (E) SEM

Int. J. Electrochem. Sci., Vol. 6, 2011

1473

Figure 2. (F) EDAX

Figure 2. SEM images and EDAX patterns of Fe-Ni-Cr alloy deposits prepared under different

conditions: (2A and 2B) Fe53.74Ni41.73Cr4.52 electrodeposited alloy at -1.3 V; (2C and 2D)

Fe60.92Ni34.39Cr4.68 electrodeposited alloy at -1.4 V; (2E and 2F) Fe54.62Ni30.87.Cr14.5

electrodeposited alloy at -1.5 V.

The electrical double layer structure in DES may be expected to be different from that in the

conventional media containing molecular solvent dipole and supporting electrolyte, because DES is

composed of ions and they are directly in contact with the electrode surface. Compact-layer effect [25,

26] on the electrical double layer structure in DES would facilitate diffusion of ions.

3.3. Potentiodynamic polarization tests

The results from the potentiodynamic polarization measurements of the Fe54.62Ni30.87.Cr14.5 alloy

deposits on the mild steel substrate in 3.5% NaCl aqueous solution are shown in Fig. 3A. The curves

representing the mild steel (MS) and a Fe54.62Ni30.87.Cr14.5 electrodeposits obtained at -1.5V on mild

steel were shown for comparison. The earlier studies [27-29] indicate that transpassivation is always

accompanied by an increase in the anodic current density. In most cases, it is consider that the

indication of the onset of transpassivation is a sudden increase in the anodic current density with

increasing electrode potential. As Fig. 3A shows, the current density of the Fe-Ni-Cr deposits

increased rapidly when the potential reached -0.146 V (SCE), and there is no obvious localized

corrosion on the surface of alloy deposits. Therefore it is proposed that transpassivation of alloy

deposits occurs at this potential. In the whole transpassive region the current density of the alloy

deposits is much smaller than that of the mild steel substrate. It is clear from a comparison of the

corrosion potential (Ecorr) of the mild steel substrate -0.671 V (SCE) with the application of the

Fe54.62Ni30.87.Cr14.5 alloy deposits, reaching -0.385V (SCE). This increasing Ecorr indicates that after

applying an alloy deposits a better corrosion protection is obtained. Corrosion protection is normally

Int. J. Electrochem. Sci., Vol. 6, 2011

1474

proportional to the corrosion current density (Icorr) measured via polarization. The very lower (Icorr)

values for the Fe54.62Ni30.87.Cr14.5 /mild steel (1.1X10-5) [23] than that of bare mild steel (71X10-5) could

indicate that the Fe54.62Ni30.87.Cr14.5 alloy electrodeposits is more protective than the mild steel

substrate. Corrosion rate in mmpy was estimated from the polarization curves, and is given in Table.1.

Very lower corrosion rate is obtained for alloy deposits than that of bare substrate.

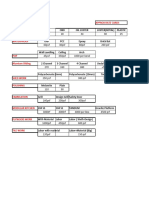

Table 1. Corrosion parameters obtained from potentiodynamic polarization and electrochemical

impedance measurements by Nyquist plot in 3.5% NaCl solution.

Sample

Ecorr V

(SCE)

MS substrate

-0.671

FeNiCr/mild

steel

-0.384

ba

bc

(V/decade) (V/decade)

0.373

0.228

Icorr

(A/cm2)

-0.061

7.1X10-4

-0.260

-5

1.1X10

Corrosion

rate

(mmpy)

8.42

0.1213

Rct

(/cm2)

Zw

(/cm2)

Cdl

(F/cm2)

Porosity

(%)

116

1.0 X10-3

3053

287

1.7 X10

-3

0.2237

3.4. Electrochemical impedance spectroscopy measurements

The polarization resistance and double layer capacitance of Fe-Ni-Cr deposits in a corrosive

medium could provide information regarding the ongoing corrosion reaction process. EIS data

provides additional information about the deposits/solution and substrate/solution interface. The simple

RC combination can be used to model several components of an electrochemical cell. For example, the

bulk electrolyte and a deposits on the electrode surface each has an associated resistance and

capacitance. However, it should be noted that the semi-circle for the bulk electrolyte is often not seen

since it typically occurs at higher frequencies than those that can be used in an impedance experiment.

Therefore, only the low frequency limit can be measured. This parallel combination can also be used to

model the interfacial region; C is double-layer capacitance (Cdl) and R is the charge transfer resistance

(Rct). The rationale for representing the charge-transfer reaction as a resistance is derived from the

small overpotential limit of the Butler-Volmer equation [30, 31]

Where

It should be stressed that this linear relationship only applies at low overpotentials between 5 to

10 mV. Hence, the A.C. amplitude used in electrochemical impedance experiments is limited to 5 to

10 mV. The other fundamental component of an electrochemical cell that must be considered is masstransport. Semi-infinite diffusion can be modeled using the Warburg impedance Zw, which is given by

the following equation.

Int. J. Electrochem. Sci., Vol. 6, 2011

1475

This element has a constant phase angle and yields a strait line in the Nyquist plot at an angle

of 45. The equivalent circuit for an electrochemical cell, in which solution species involved in the

charge-transfer reaction can be constructed from the components discussed above, is shown as insert in

Fig. 3B and 3C. The semi-circle at high frequencies indicates charge-transfer control; however, at

lower frequencies, the rate of mass-transfer become the rate limiting factor and is reflected by the

transition from a semi-circle to a straight line.

Fig. 3B and 3C shows the experimental and simulated impedance response of bare mild

steel and Fe-Ni-Cr alloy deposits on mild steel substrates in a Nyquist representation. At low

frequencies the interception with the real axis was ascribed to the charge transfer resistance Rct at the

corrosion potential. The Rct value of Fe54.62Ni30.87.Cr14.5/mild steel was several order magnitude higher

than that of bare mild steel substrate. The value of fitted parameters of the equivalent circuit, together

with the corrosion potentials Ecorr as a function of Fe54.62Ni30.87.Cr14.5 alloy electrodeposits on mild steel

substrate were presented in Table.1. Porosity of Fe54.62Ni30.87.Cr14.5 alloy electrodeposits on mild steel

substrate were calculated based on our previous studies [32, 33]. Table 1 shows that the diffusion

impedance value (Zw = 287 /cm2 ) of the deposited alloy is higher than the chargetransfer resistance

of mild steel substrate (Rct = 116 /cm2). This shows that diffusion process can dominate the whole

corrosion process for the deposited alloy and also means that the uncoated mild steel substrate easily

suffers from attack by aggressive substance like CO2 and chloride ions. Both Rct and Zw values of the

deposited alloy are much larger than those of the bare mild steel substrate. This suggests that

electrochemical reaction is difficult on the deposited electrode surface and Fe-Ni-Cr alloy deposits

presents better corrosion resistance.

Figure 3. (A)

Int. J. Electrochem. Sci., Vol. 6, 2011

1476

Figure 3. (B)

Figure 3. (C)

Figure 3. (A) Typical Potentiodynamic polarization curves of electrodeposited alloy and bare

substrate in 3.5% NaCl solution. (B and C) Electrochemical impedance spectroscopy both ( )

experimental and ( ) simulated Nyquist plot for mild steel (MS) and Fe54.62Ni30.87.Cr14.5 alloy

on mild steel (Fe54.62Ni30.87.Cr14.5 / MS) (insert Equivalent circuit diagrams for impedance

spectra).

Int. J. Electrochem. Sci., Vol. 6, 2011

1477

The lower the porosity values the better is corrosion protection and the less defects are in the

alloy electrodeposits. The double layer capacitance parameter Cdl was another parameter that could

provide information about the polarity and the amount of charge at the alloy deposits/solution

interface. Higher Ecorr, Rct, Zw and lower Icorr, Cdl values of Fe54.62Ni30.87.Cr14.5 alloy electrodeposited on

mild steel substrate showed better corrosion resistance properties than that of bare substrates.

4. CONCLUSIONS

We developed a novel DES for the electrodeposition of Fe-Ni-Cr alloy without H2 evolution.

The major advantages of DES are free from Cr-complexing agent, brightener and stress reducer. The

effect of electrodeposition potential on the structural morphology and composition of Fe-Ni-Cr alloy

was successfully studied by SEM and EDAX techniques. From these results potential for

electrodeposition of Fe-Ni-Cr alloy compositions is optimized. We obtained higher Cr% in alloy

composition without Cr-complexing agent at -1.5V; whose structural morphology is fine grained dense

nodular deposit. The Potentiodynamic polarization and Electrochemical Impedance Spectroscopy

results showed Fe54.62Ni30.87.Cr14.5 alloy deposited at -1.5V is having very high Rct, Zw and lower Icorr

than that of bare mild steel substrate.

ACKNOWLEDGMENT

Authors thank the Department of Science and Technology New Delhi for a research grant under SERC

(Engineering Sciences) scheme no. SR/S3/ME/ 0030/2009.We thank the Director, (CSIR)-CECRI to

carryout the research work and Mr. R. Ravishanker CECRI for SEM and EDAX measurement.

References

E. Oberg, Machinerys Handbook, 25th ed.; Industrial Press Inc: New York, 1996, p. 411.

T.E. Harris, G.M. Whitney and I.M. Croll, J. Electrochem. Soc. 142 (1995) 1031.

P.C. Andricacos and N. Robertson, IBM. J. Res. Dev. 42 (1998) 671.

M.A. Ameer, A.M. Fekry, A.A.Ghoneim and F.A.Attaby, Int. J. Electrochem. Sci. 5 (2010)

1847.

5. L.T. Romankiw, Electrochim. Acta. 42 (1997) 2985.

6. M.R. El-Sharif, A. Watson and C.U. Chisholm, Trans. IMF. 66 (1988) 34.

7. M.R. El-Sharif, J. MacDougall and C.U. Chisholm, Trans. IMF. 77 (4) (1999) 139.

8. F. Wang and T. Watanabe, Mater. Sci. Eng. A. 349 (2003) 183.

9. H.Adelkhani and MR Arshadi, J. Alloys and Compounds. 476 (2009) 234.

10. A.G. Dolati, M. Ghorbani and A. Afshar, Surf. Coat. Technol. 166 (2003) 105.

11. BM. In, E. Akiyama, H. Habazaki, A. Kawashima, K. Asami and K. Hashimoto. Corros. Sci.

37 (1995) 709.

12. A.P. Abbott, G. Capper, D.L. Davies and R.K. Rasheed, Chem. Eur. J. 10 (2004) 3769.

13. A.M. El Sherik and U. J. Erb, Mater. Soc. 30 (1995) 5743.

14. S-H. Deng and Z-Q. Gong, Anti-Corrosi on Methods and Materials. 50(4) (2003) 267.

15. S. N. Srimathi and S. M. Mayanna, Mater. Chem. Phys. 11 (1984) 351.

1.

2.

3.

4.

Int. J. Electrochem. Sci., Vol. 6, 2011

1478

16. S. Surviliene, A. Lisowska-Oleksiak, A. Selskis and A. Cesuniene, Trans. IMF. 86 (5) (2006)

241.

17. A.P. Abbott, G. Capper, K.J. McKenzie and K.S. Ryder. J. Electroanal. Chem. 599 (2007) 288.

18. A.P. Abbott, J.C. Barron, K.S. Ryder and D. Wilson. Chem. Eur. J. 13 (2007) 6495.

19. M.V. Cardoso, S.T. Amaral and E.M.A. Martn, Corros. Sci. 50 (2008) 2429.

20. Y.P. Liu, Y. J. Zhu, Y.H. Zhang et al, J Mater Chem. 7(5) (1997) 787.

21. L. Xu, J. Du, S. Ge, N. He and S. Li, J Appl Electrochem. 39(5) (2009) 713.

22. L. Sziraki, E. Kuzmann, M. El-Sharif, C.U. Chisholm, G. Principi, C. Tosello and A. Vertes,

Electrochem. Commun. 2 (2000) 619.

23. L. Philippe and C. Heiss, J. Michler, Chem. Mater. 20 (2008) 3377.

24. S. Abd El rehim, M. Ibrahim and M. Dankeria, Trans.IMF. 80 (2002) 29.

25. A.A. Kornyshev and M.A. Vorotyntsev, J. Electroanal. Chem. 167 (1984) 1.

26. A.A. Kornyshev, Electrochim. Acta. 12 (1989) 1829.

27. M. Bojinov, I. Betova and R. Raicheff, J.Electroanal. Chem. 430 (1997) 169.

28. N. Sato, J. Electrochem.Soc. 129 (1982) 255.

29. A.Y. Musa, A.A. H. Kadhum, A.B. Mohamad, A. R. Daud, M.S.Takriff,

S. K.Kamarudin and N. Muhamad, Int. J. Electrochem. Sci. 4 (2009) 707.

30. Zaki Ahmad, Principles of Corrosion Engineering and Corrosion Control,

Elsevier Science & Technology, 2006 (Chapter-4), p. 73.

31. J.R. MacDonald (Ed). Impedance Spectroscopy, Wiley, New York, 1987.

32. G. Saravanan and S. Mohan, Corros. Sci. 51 (2009) 197.

33. G. Saravanan and S. Mohan, J Appl Electrochem. 39 (2009) 1393.

2011 by ESG (www.electrochemsci.org)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- BMG-5000 High Strength Soft Magnetic Iron-Based Bulk Metallic GlassDocument12 pagesBMG-5000 High Strength Soft Magnetic Iron-Based Bulk Metallic GlassRahul VermaNo ratings yet

- VSM IIT Madras - Sample RequirementsDocument2 pagesVSM IIT Madras - Sample RequirementsPrasad DNo ratings yet

- Fe - (CR, Mo) - (C, B) - TM Bulk Metallic Glasses With High Strength and High Glass-Forming AbilityDocument4 pagesFe - (CR, Mo) - (C, B) - TM Bulk Metallic Glasses With High Strength and High Glass-Forming AbilityRahul VermaNo ratings yet

- Superalloy 2011Document41 pagesSuperalloy 2011Rahul VermaNo ratings yet

- Four Probe MethodDocument1 pageFour Probe MethodVita Efellina100% (3)

- High Performance of Low Cost Soft Magnetic MaterialsDocument7 pagesHigh Performance of Low Cost Soft Magnetic MaterialsRahul VermaNo ratings yet

- Al 1Document4 pagesAl 1Rahul VermaNo ratings yet

- PRB - Domain Structure of A Nd60Al10Fe20Co10 Bulk Metallic GlassDocument4 pagesPRB - Domain Structure of A Nd60Al10Fe20Co10 Bulk Metallic GlassRahul VermaNo ratings yet

- The European Physical Journal B - Condensed Matter and Complex Systems Volume 34 Issue 2 2003 (Doi 10.1140/epjb/e2003-00207-3) O. Crisan J. M. Grenèche J. M. Le Breton A. D. Crisan Y. La - MaDocument8 pagesThe European Physical Journal B - Condensed Matter and Complex Systems Volume 34 Issue 2 2003 (Doi 10.1140/epjb/e2003-00207-3) O. Crisan J. M. Grenèche J. M. Le Breton A. D. Crisan Y. La - MaRahul VermaNo ratings yet

- Effect of Composition On The Solidification Behavior of SeveralDocument14 pagesEffect of Composition On The Solidification Behavior of SeveralRahul VermaNo ratings yet

- Calculation of Phase Equilibria in The Fe-Ni-Cr System BasedDocument15 pagesCalculation of Phase Equilibria in The Fe-Ni-Cr System BasedRahul VermaNo ratings yet

- Magnetic Cluster Expansion Model For Random and OrderedDocument26 pagesMagnetic Cluster Expansion Model For Random and OrderedRahul VermaNo ratings yet

- PVD Synthesis and High-ThroughputDocument8 pagesPVD Synthesis and High-ThroughputRahul VermaNo ratings yet

- The Influence of NB and C On The SolidificationDocument6 pagesThe Influence of NB and C On The SolidificationRahul VermaNo ratings yet

- Ni-Cr-Fe 1Document3 pagesNi-Cr-Fe 1Rahul VermaNo ratings yet

- Fe-Ni-Cr 2Document16 pagesFe-Ni-Cr 2Rahul VermaNo ratings yet

- Ni-Cr-Fe 1Document3 pagesNi-Cr-Fe 1Rahul VermaNo ratings yet

- Fe-Ni-Cr 2Document16 pagesFe-Ni-Cr 2Rahul VermaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Studies On Regenerated Protein Fibers. Production Regenerated Fibroin Fiber by The Self-Dialyzing Wet Spinning MethodDocument9 pagesStudies On Regenerated Protein Fibers. Production Regenerated Fibroin Fiber by The Self-Dialyzing Wet Spinning Methodapi-3733260No ratings yet

- US20220162497A1Document14 pagesUS20220162497A1Seyedeh Maryam MousaviNo ratings yet

- Mil DTL 81706BDocument20 pagesMil DTL 81706BwcwtnuiNo ratings yet

- Mott - HyPulse Element FilterDocument12 pagesMott - HyPulse Element FilterCristhian CuevaNo ratings yet

- European Patent Application C07F 7/08: Method For Preparation of Organohydrogen PolysiloxanesDocument5 pagesEuropean Patent Application C07F 7/08: Method For Preparation of Organohydrogen Polysiloxanesswaroop_exlncNo ratings yet

- Disolutions PDFDocument28 pagesDisolutions PDFarcilalilianaNo ratings yet

- Chemical Properties of Soil: pH, CEC & PZCDocument17 pagesChemical Properties of Soil: pH, CEC & PZCHasnat QureshiNo ratings yet

- Bio Polishing EnzymeDocument3 pagesBio Polishing Enzymefebry_yulindraNo ratings yet

- Alloys & Strengthening: Lecture 10. Introduction & The Equilibrium Phase DiagramDocument23 pagesAlloys & Strengthening: Lecture 10. Introduction & The Equilibrium Phase DiagramHenry HarrodNo ratings yet

- Capitolo 15Document20 pagesCapitolo 15Juan Pablo CorreaNo ratings yet

- Shape Memory AlloysDocument16 pagesShape Memory AlloysginejonathanNo ratings yet

- Reactive Intermediates - LecturesDocument24 pagesReactive Intermediates - Lecturesapi-3771395100% (1)

- Testing Liquids For PolarityDocument17 pagesTesting Liquids For PolarityRaniaKaliNo ratings yet

- NCSE 2013 Integrated ScienceDocument22 pagesNCSE 2013 Integrated ScienceMicahNo ratings yet

- TDS SHELL CATENEX SNR ARIZONAmotorsDocument2 pagesTDS SHELL CATENEX SNR ARIZONAmotorsİbrahim MutafogluNo ratings yet

- Is 2932 2003 PDFDocument22 pagesIs 2932 2003 PDFSuyambu100% (1)

- Comparing Characteristics of Elastomeric and Thermoplastic Insulation MaterialsDocument1 pageComparing Characteristics of Elastomeric and Thermoplastic Insulation MaterialskapilNo ratings yet

- Grade 7 Learning Module Prototype 1Document9 pagesGrade 7 Learning Module Prototype 1Espie Rose DumalagNo ratings yet

- Jiacheng Yang, Tianbo Tang, Yu Jiang, Georgios Karavalakis, Thomas D. Durbin, J. Wayne Miller, David R. Cocker III, Kent C. JohnsonDocument9 pagesJiacheng Yang, Tianbo Tang, Yu Jiang, Georgios Karavalakis, Thomas D. Durbin, J. Wayne Miller, David R. Cocker III, Kent C. JohnsonMohamed TaalbiNo ratings yet

- Evaluation of In-Vitro Antioxidant Potential On Ethanolic Extract of Root of Smilax ChinaDocument6 pagesEvaluation of In-Vitro Antioxidant Potential On Ethanolic Extract of Root of Smilax ChinaRAPPORTS DE PHARMACIE100% (1)

- 3.2.2 Reaction Rates QPDocument17 pages3.2.2 Reaction Rates QPjasmeet kahlonNo ratings yet

- Formulation Development of Albendazole-Loaded Self PDFDocument20 pagesFormulation Development of Albendazole-Loaded Self PDFDiah100% (1)

- New Sample Prep and Data Analysis For Analyzing Pesticides in FoodsDocument42 pagesNew Sample Prep and Data Analysis For Analyzing Pesticides in FoodsdonkixNo ratings yet

- Determine nutrients with lab testsDocument5 pagesDetermine nutrients with lab testsDevi RambaranNo ratings yet

- Project Topics For CL 10Document8 pagesProject Topics For CL 10Nihaas Reddy KoppulaNo ratings yet

- Organic DerivativesDocument24 pagesOrganic Derivativesami tiu100% (1)

- Rate CardDocument6 pagesRate CardRavi SrivastavaNo ratings yet

- Chemolube H - Product DescriptionDocument6 pagesChemolube H - Product DescriptionJulio VargasNo ratings yet

- Acrylic AcidDocument5 pagesAcrylic AcidMohit YaduwanshiNo ratings yet

- Benzene Quiz Questions - Footprints-Science GCSE Science Animations and Quizzes GCSE Science RevisionDocument1 pageBenzene Quiz Questions - Footprints-Science GCSE Science Animations and Quizzes GCSE Science RevisionlollNo ratings yet