Professional Documents

Culture Documents

Sizing Heaters and Steam Requirements For Hotel

Uploaded by

antonpgmOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sizing Heaters and Steam Requirements For Hotel

Uploaded by

antonpgmCopyright:

Available Formats

ASTEG.

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

T H E

ALSTROM

C O R P O R A T I O N

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

An adequate supply of hot water is a must in motels, hotels and other types of multiple

dwellings. Improper sizing and design of hot water supply systems will invariably lead to

problems such as dissatisfaction of the customer due to undersized systems or wasteful

economics of oversized systems.

The report is based on recommendations of The ASHRAE Applications Handbook, good

practice of major USA manufacturers of the instantaneous, semi-instantaneous and storage

heaters, and the experience of the engineering staff of The Alstrom Corporation.

Although this report is limited to analysis of service, hot water supply at minimal initial

investment and maintenance cost. Hot water consumption depends on the hotel size, occupancy,

auxiliary services, and to a degree, the level of luxury provided by the hotel. While consumption

of hot water does not depend on the of water heater used, the rate of hourly energy consumption

will vary widely from one type of heater to another. The same building can get the necessary hot

water supply from a large boiler and a small instantaneous heat exchanger, or from a large

storage heater and a small boiler. A hot water storage heater will reduce the size of the boiler;

minimize hourly steam rate, gas, oil or electricity supply as opposed to an instantaneous and

semi-instantaneous water heater. Of course, the daily water and energy consumption does not

depend on the type of the heaters, but it will definitely affect the initial cost of the system and its

maintenance.

CM

MY

CY

CMY

The correct sizing of boilers and heat transfer equipment for hotels required the

understanding of the basic system design. This report provides a short review of the major

considerations for the end user and designer.

The review is restricted to guest room systems that utilize hot water for lavatories,

showers, bathtubs and basins. Although consumption patterns in guest rooms are subject o wide

variations, the general classification can be achieved depending on the type of hotel. Kitchens

and laundries vary greatly, and always re a subject to custom design. Fortunately, hot water

demand for kitchens and laundry rooms for a specific hotel can be estimated by the hot water

consumption of equipment utilized in these facilities.

In addition, the hotel engineering community prefers the separation of the kitchen and

laundry due to the severe impact of laundry start up demands that often coincide with the days

peak guest room consumption.

Temperature Regulators and Steam Traps

By definition, service water heaters are designed to heat cold water to desirable

temperature where demands are intermittent and are subject to frequent fluctuations. Selection

of the temperature regulator is important decisions that will affect the temperature expand during

the load variations, and, in to some degree, determines the size of the heating section. Indeed,

the size of the heat transfer equipment depends on the actual steam pressure that equals to

temperature regulating valve.

Down System shall be furnished with a NEMA I control system and all factory wired to a

single point 120 volt connection.

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

T H E

ALSTROM

C O R P O R A T I O N

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

There are three types of temperature regulating valves (TRV).

First: Self-contained vapor tension, Pilot-operated and Pneumatically-operated. Each has unique

advantages and disadvantages. Temperature regulator installations vary from systems with large

storage tanks that change temperature gradually as hot water is drawn off to instantaneous shell

and tube heat exchanges that require a fast temperature response time. Because the volume of

water in the tubes of the instantaneous heaters is small, variable flow causes uncertain

temperature fluctuations.

Self-contained (TRV) or pilots may require 10 to 80 seconds to respond to a temperature

change. This can cause momentary temperature fluctuations until the regulator is stabilized to a

changed condition. The use of a self-contained (TRV) with light spring decreases the

temperature span from a closed to an open position to approximately 6 deg. F. for valve, 10

deg. F to 1 1/14: valve and 13 deg. F to 2 valve. Actual span is determined by the fill fluid and

spring combination that varies with the adjustable temperature range selected. The short stroke

characteristic of the TRV design minimizes temperature span.

If self-operated (TRVs) must be used (air or electricity is not available) and a smaller

span is essential then further improvement may achieved by using a larger valve, half opened at

peak steam flow. Due to the linear characteristic of the sliding gate valves, the use of a larger

valve will reduce the differential temperature needed to achieve required steam flow when the

water flow is suddenly changed.

Pilot-operated regulators offer the advantage of higher flow rates and larger sizes,

however, are more expensive. In addition their control may be erratic if they are not sized

perfectly for flow rates and operating pressures. Please note that minimal differential pressure is

not required for proper operation of the pilot-operated self-contained temperature regulating

valve. The use of pilot-operated regulators should be reserved for use only where compressed

air or electrical supply is not available.

Pneumatically-operated Control Valves with temperature controller usually respond

faster to changed conditions and hold a closer set temperature. Pneumatic temperature

controllers with adjustable proportional band (span) and reset function can continuously maintain

the hot water temperature very close to the set point. Less expensive bi-metallic models are

available in accuracies similar to self-contained TRV, providing the advantage of quicker

response. These less sophisticated controllers are very popular due to reasonable cost.

Pneumatically-operated control valves with temperature controller, like the self-operated TRV,

do not require minimal differential pressure for proper operation.

All types of regulators do not have an immediate response. If the close temperature

control is required, the addition of a thermostatic mixing valve will temper the water temperature

within 2-3 deg. F., lower steam temperature that increases the size and cost of the heat transfer

equipment.

The following differential pressure psi may be recommended for self-contained and pneumatic

TRV.

Inlet Pressure

5

10

14.2

28.4

Outlet Pressure (psi)

1. 9

5

10

17.1

control valve and after main trap.

E. Unfired Steam Generator shall be furnished with two ASME Code Section I or Section

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

T H E

ALSTROM

C O R P O R A T I O N

42.7

49.8

71.1

99.5

144.2

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

27

29.9

46.9

64

106.7

Pilot-operated valves require a minimum differential pressure about 24.2psi.

The Float & Thermostatic Traps are commonly used to discharge air and condensate from

heat exchanges, preventing steam from entering return piping in steam heating systems. An

undersized steam trap will cause condensate to back into the heat exchanger and result in a steam

hammer. It is a good practice to oversize a steam trap 2(x) times the maximum capacity of the

temperature regulator. The steam trap selection is based on a differential pressure, which equals

to operational pressure in the heat exchanger less back pressure of the condensate line.

Instantaneous Hot Water Heaters

Instantaneous water heaters are selected to heat water during the peak momentary

consumption at the maximal temperature rise. A boiler, steam and condensate piping, TRV and

other accessories are selected to satisfy this maximal heat demand. With a drop in heat demand,

the TRV will reduce steam supply by controlling the hot water temperature.

The most common design of these heaters is shell and tube heat exchangers where the

water is heated as it flows through the tubes (Alstrom ECO-Pack Package). The tube side of the

instantaneous water heaters is constructed from stainless steel, copper or other nonferrous alloys.

Since steam is not corrosive fluid, the shell is constructed from carbon steel. The instantaneous

water heaters have relatively small size and can be easily installed, repaired or replaced in the

boiler room with limited access. Due to their small size and low cost of materials used,

instantaneous water heaters are inexpensive. The optimal heat exchanger will be one with

maximal permitted length because of its smaller diameter. High velocity of water improves heat

transfer rate and prevents scaling. This type of heaters requires the largest source of steam to

compare with other heaters.

Steam consumption can be reduced by sub-cooling the condensate (Alstrom Steam Saver

Package). This method results in smaller diameter of piping and accessories, and it reduces heat

loss from the condensate line. By sub-cooling the condensate, heat loss from the flash steam,

occurring after the steam trap, is prevented, resulting in substantial energy savings and

preventing water hammer in the condensate line.

Semi-Instantaneous Water Heats without Storage Section

Several domestic manufacturers of Semi-instantaneous heaters use the shell as a storage

section for hot water. Since the ratio of storage capacity to recovery is measured in seconds,

they perform as instantaneous heaters. Therefore, their commercial name may result in certain

confusion.

The storage and heating sections of these heaters are constructed from corrosion resistant

materials, In addition, a circulating pump is provide in order to reduce temperature fluctuations

of the outgoing water. The manufactures of semi-instantaneous water heaters claim that outlet

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

T H E

ALSTROM

C O R P O R A T I O N

water temperature is maintained within 4 deg. F due to continuous circulation of water by the

pump. Unfortunately, there is no explanation whether this rang is maintained at steady flow rate

or is the temperature span from closed to open TRV.

Usually, hot water systems for hotels are designed to have hot water available

continuously at the fixtures by using return piping. In this case the circulation pump does not

provide any advantage, and the use of semi-instantaneous water heart with very small storage

section is hardly justified. High cost of materials, circulating pump, electrical panel and power

supply significantly increases the cost of these heater compared with instantaneous water heaters.

Compact Water Heaters

The Compact Water Heaters have storage section, designed by manufacturers to

accumulate heat in order to meet the surges of hot water demand for a limited period. Since

there is no need to satisfy momentary heat demand, these heaters require significantly smaller

source of steam than instantaneous water heaters.

C

The Compact Water Heaters have similar design to semi-instantaneous Water Heaters.

In this case, a circulating pump is useful to intensify heat transfer and prevent temperature

stratification of the stored water. As a result, 90% of the storage section is assumed to be useful.

CM

Sizing of Instantaneous and Semi-Instantaneous

Water Heaters without Storage Section

MY

CY

CMY

ASHRAE Fixture Units Method

The fixture Units are assigned to each fixture using hot water and totaled. The empirical

Modified Hunter Method, represented by curves for various building types, estimates the

required hot water flow rate (WFR). Since the reading of data fro the curve is inaccurate, the

following formulas were developed to interpolate the curve for hotels.

Fixture Units

0-75

75-400

More than 400

WFR = (36 + 1.280 x FU) x 0.264gpm

WFR = (107 + 0.333 x FU) x 0.264gpm

WFR = (156 + 0.210 x FU) x 0.264gpm

ASHRAE Applications Handbook recommends the following date.

Fixture Units (FU)

0.75

1

1.5

5/per 250 units

2

2.5

1.5

2.5

2.5

Basin, Private Lavatory

Basin, Private Lavatory

Tub & Shower

Dishwasher

Barber basin

Beauty parlor basin

Kitchen sinks

Pantry sinks

Service Sink

Down System shall be furnished with a NEMA I control system and all factory wired to a

single point 120 volt connection.

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

T H E

ALSTROM

C O R P O R A T I O N

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

Example: 200 Room Hotel

No. Fixture

200

10

20

186

6

4

Total

Type of Fixture

Private Lavatory

Public Lavatory

Private Shower

Tub & shower

Beauty parlor basin

Barber basin

200 x 0.75 =150

10 x 1= 10

20 x 1.5 = 30

186 x 1.5 = 279

6 x 2.5 = 15

4x2=8

492

Net Water Flow Rate

(156 + 0.21 x 492) x 0.264= 68.46gpm or 4107,6gph

Maximum Hourly Water Capacity per Unit (Room)

4107,6 / 200 = 20.54gph

Net Heater Capacity-Peak Heat Demand

4107,6 x 8.345 x 1 x (149-40) = 3,736,293 Btu/hr

Steam Rate

3770lbs/hr

To make preliminary estimates of hot water demand when the fixture count is not known, more

general recommendations may be used based on the type of building and number of customers.

The preliminary hot water demand for hotel or motes is 2.5 Fixture per room.

Estimated number of Fixture units:

FU = 2.5 x 200 = 500

Net Water Flow Rate

(156 + 0.21 x 500) x 60 x 0.264 = 4134.2gph

Comparisons of the flow based on actual fixture count to the flow obtained from the

preliminary estimate shows very close results. Please not, that there is a possibility of

preliminary estimate being twice as large then the actual fixture count.

Pressurized Hot Water Storage Heaters

Pressurized Hot Water Storage Heaters use vessels of certain volume. They consist of a

storage section and an immersed tube bundle. Steam or boiler water passes through the tubes of

the tube bundle. The incoming cold water enters the bottom of the storage section where it is

mixed with stored water and heated by a natural convention. Due to dilution by the cold water

entering the heater, only 60 to 80% of the storage section is assumed to be useful.

control valve and after main trap.

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

T H E

ALSTROM

C O R P O R A T I O N

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

During the day, flow rate of water entering the pressurized vessel, equal to the flow rate

of the water leaving the vessel. Although flow rate of the incoming water varies, the heating

section is selected for relatively steady average water rate called recovery. If water consumption

equals the recovery rate, than the average temperature of the stored water remains the same.

When the water demand is increased, the average temperature of the stored water is decreased.

And when the water demand is decreased, the average temperature of the stored water is again

increased. Since the recovery is significantly smaller than peak water demand, the use of storage

heaters requires smaller boilers, piping and accessories.

Storage heaters require the smallest source of steam in comparison with other heaters. At the

same time, they required large space in the boiler room. If the heating section or circulating

pump is damaged, the stored water has to be drained. In order to prevent corrosion, inner surface

of the storage section is line with epoxy, cement or other types of coatings. This protective layer

is prone to cracking and, therefore, requires periodical inspection. Due to thermal inertia of the

stored water temperature control is less problematic, and self-contained valves will provide

inexpensive and accurate result. Storage heaters are selected to maintain a reasonable constant

supply of steam or boiler water, but the actual water flow rate depends on hot water demand

during the day. An analysis of heat consumption patterns in hotels and other type of dwellings

shows that there are three heat consumption periods as follows: heat accumulating heat discharge

and standby.

Heat Accumulating

Heat Recovery is larger than Heat Consumption. The mean temperature of the stored

water is rising. The TRV is totally open to provide maximal supply of steam. When the set

temperature is achieved, the steam supply is reduced to minimum to compensate the heat loss.

Heat Discharging

Heat Consumption is larger than Heat Recovery. The mean temperature of the stored

water is dropping. Again, the TRV is totally open to provide maximal supply of steam.

Standby Period

When the stored water reaches the set temperature of TRV, steam consumption will be

reduced to compensate for the heat losses from the storage heater and the return price.

In conclusion, the method of hot water storage in the pressurized vessels is based on

1. Constant volume of stored water

2. Variable incoming and outgoing water flow rate

3. Variable temperature of stored water

Heat, stored in the Pressurized Storage Heater

Q (a) = M*Cp* (Ts-Tm) Btu

Where:

Ts-set temperature of the TRV that is maximal permitted temperature of the stored water

Tm-minimal permitted temperature of the stored water

M-Net Weight Storage Capacity of the Heater (lbs)

Cp-specific heat of water

As follows from this equation, heat stored in the Pressurized Storage Heater does not depend on

temperature of the incoming water.

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

T H E

ALSTROM

C O R P O R A T I O N

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

Example: calculate heat stored in 528gal Pressurized Storage Heater when the permitted

temperature variation Ts-Tm equals to 18 deg F.

Q(a) = 528 x 8.345 x 1 x 18 = 79311 Btu

Atmospheric Hot Water Storage Heaters

Atmospheric Hot Water Storage Heaters have similar design to Pressurized Storage

Heaters, but they are open to the atmosphere. This type of storage heater is commonly used in

several European countries and is used in the US for cold water storage.

The incoming cold water is heated to the requested temperature at a constant water flow

rate, usually, called recovery. The heating section is selected for recovery rate. If water

consumption equals the recovery rate, than the level of the stored water remains the same. When

the water demand is increased, the level of the stored water is decreased. And when the water

demand is decreased, the level of the stored water is again increased.

CM

MY

CY

CMY

The incoming water flow rate is constant during the day, while the flow rate of the

outgoing water depends on hot water demand during the day. Obviously, the flow rate of

outgoing water is equal or larger than flow rate of water entering the vessel. An analysis of

water consumption patterns in hotels and other type of dwellings shows that there are three water

consumption periods as follows: water accumulating, water discharge and standby.

Water Accumulating

When water demand is lower than hourly water supply, then the level of the stored water

is rising. The TRV is open to provide heating of the incoming water to the set temperature.

When the maximal level is achieved, the water supply is stopped by the liquid level control, and

steam supply is reduced to minimum to compensate the heat losses.

Water Discharging

When water demand is larger than hurly water supply, then the level of the stored water

drops. The steam supply remains the same as during the period of water accumulation.

Standby Period

When the stored water is not consumed, then steam consumption will be reduced to

compensate the heat loss from the heater and the return pipe. The water flow rate equals to the

flow rate of re-circulation.

In conclusion, the method of hot water storage in the Atmospheric vessels is based on:

1. Variable volume of stored water

2. Constant incoming and variable outgoing water flow rate

3. Constant temperature of stored water

Heat, Stored in the Atmospheric Storage Heater:

Q(a) = (Mf-Ma) * Cp * (Ts-Tc) Btu

Where:

Ts-required temperature of the stored water (deg. F)

Tc-the temperature of cold water (deg. F)

Mf=weight of water at maximal level (lbs)

Ma-weight of water at minimal level (lbs)

Cp-specific heat of water

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

T H E

ALSTROM

C O R P O R A T I O N

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

As follows from this equation, the heat stored in the Atmospheric Storage Heater, depends on

temperature of the incoming water.

Example: calculate heat stored in the 528gal Atmospheric Storage Heater

Q(a) = 528 x 8,345.1 (140-40) = 440,616 Btu

The Pressurized Storage Heater of the same size stores only 79311 Btu.

Alstrom Hot Water Generator

The Alstrom Corporation introduced a new, patented hot water heater that combines the

advantages of instantaneous and storage heaters (Alstrom Hot Water Generator ASH). The

Alstrom Hot Water Generator consists of storage section and built-in instantaneous shell and

tube heat exchanger. Steam or boiler water passes through the shell. At average recovery period

the incoming water enters the tubes of the tube bundle, where it is heated to the required storage

temperature. When the water consumption is lower than the recovery rate, the temperature

regulator reduces the supply of the heating media in order to prevent the overheating of the

stored water. And when the water demand is higher than the recovery rate, the temperature

regulator provided the maximal available steam.

CM

MY

CY

CMY

The immersed shell serves as an additional heat transfer area. Due to the natural

convection, water circulates from the bottom of the tank via tube bundle to the upper part of the

storage tank. If the heating section is damaged, the storage tank can be disconnected. The repair

or replacement of the heat transfer section can be performed without draining the tank. Hot

water already stored in the tank can provide uninterrupted minimal hot water demand (for

example, at night).

The heater is constructed from 316L stainless steel storage section and immersed heat

exchanger. Many manufacturers of 316L storage tanks provide up to 10 years guarantee against

material and workmanship failures.

Alstrom Combinational Hot Water Generator ASH can be sized as a Pressurized or

Atmospheric heater.

Sizing of Storage and Compact Heaters

ASHRAE Handbook recommends two different methods of sizing Pressurized Storage

and Compact Heaters without offering any analytical backup to their approach. Each offered

method yields a very different result when selecting a heater for the same set of data. The oldest

practice is to heat total tank volume of incoming cold water to set temperature within one hour.

Unfortunately, this method does not take into consideration the actual pattern of heat supply and

demand. Many manufacturers of heat transfer equipment recommend their methods with some

justification, but they usually recommend ASHRAE methods for government projects.

ASHRAE Fixture for Hot Water Demand (FD) Method

ASHRAE Application Handbook recommends the following data (at a final temperature of 140

deg. F.)

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

T H E

ALSTROM

C O R P O R A T I O N

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

Hot Water Demand per Fixture (gal/hr)

Basin, private lavatory

Basin, public lavatory

Tub & shower

Dishwasher

Barber basin

Beauty parlor basin

Kitchen sinks

Pantry sinks

Service sink

Demand factor

Storage capacity factor

2

8

20

50-200

12

12

30

10

30

0.25

0.8

Example: 200 Room Hotel:

No. Fixtures

200

10

20

186

6

4

Total

Type of Fixture

Private lavatory

Public lavatory

Private shower

Tub & shower

Beauty Parlor Basins

Barber basins

Maximal Water Demand (gal/hr)

200 x 2 = 400

10 x 8 = 80

20 x 20 = 400

186 x 20 = 3720

6 x 12 = 72

4 x 12 =48

4720gal/hr

The heating section should have a water heating capacity (Recovery) equal to Maximal

Water Demand multiplied by the Demand Factor. The storage section should have a capacity

equal to the Recovery Capacity multiplied by the Storage Capacity Factor.

Recovery capacity

Maximal daily water

capacity per unit

Storage capacity

Heat recovery

Heat recovery to peak heat

demand ratio

Steam rate

4720 x 0.25 = 1180gal/hr

24 x 1180/200 = 141.6gal/day

1180 x 0.8 = 944 gal

1180 x 8.345 x 1 (140-40) = 984710Btu/hr

984710/3,736,293 = 0.264

995lbs/hr

ASHRAE recovery Storage Capacity Ratio (RSR) Method

Volume of a storage section depends on recovery rate of the heating section. The higher

the recovery rate results in the smaller storage section. 1995 ASHRAE Application Handbook,

Chapter 45 provides the relationships between recovery and storage capacity for the various

building categories.

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

T H E

ALSTROM

C O R P O R A T I O N

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

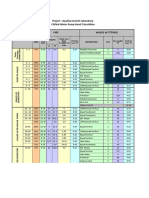

The following data was extracted from the curves of the ASHRAE Handbook; p.45.13,

fig 16.

Hotel/Motel

20 units or less

Usable Storage

Capacity per unit (gal)

16 8

Recovery Capacity per unit (gph)

1.5 2.8 5

Storage/Recovery Ratio(hours)

10.67 2.86 0.4

60 units

16 8

100 units or more

16 8

1.25 2.1 3.9

1. 1.4

3.2

12.8 3.8 0.51

16 5.71 0.625

The usable storage capacities are net usable requirements. Due to temperature

stratification the average temperature of the stored water is lower than the desirable outlet

temperature. Assuming that 70% of the hot water in a storage tank is usable, the actual storage

tank should be increased by 43% in order to compensate for unusable hot water.

Option 1: Water Recovery Capacity for 200 units:

M

CM

MY

CY

CMY

Maximal daily water capacity per unit

Net storage capacity

Actual storage capacity

Heating section capacity

Heat recovery to peak heat

Demand ratio

Steam rate

200 x 1 = 200gph

24 x 200/200 = 24gph

200 x 16 = 3200gal

3200 x 1.43 = 4576gal

200 x 8.345 x 1 x (140-40) = 166900Btu/hr

166900/3,736,293 =0.0447

169lbs/hr

Option 2: Water Recovery Capacity for 200 units:

Maximal daily water capacity per unit

Net storage capacity

Actual storage capacity

Heating section capacity

Heat recovery to peak heat

Demand ratio

Steam rate

200 x 1.4 = 280gph

24 x 280/200 = 33.6gph

200 x 8 = 1600gal

1600 x 1.43 = 2288gal

280 x 8.345 x 1 x (140-40) = 233660Btu/hr

233660/3736293 = 0.0625

239.6 lbs/hr

Option 3: Water Recovery Capacity for 200 units:

Maximal daily water capacity per unit

Net storage capacity

Actual storage capacity

Heating section capacity

Heat recovery to peak heat

Demand ratio

Steam rate

200 x 3.2 = 640gph

24 x 640/200 = 76.8gph

200 x 2 = 400gal

400 x 1.43 = 572gal

640 x 8.345 x (140-40) = 534080Btu/hr

534080/3736293 = 0.143

530 lbs/hr

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

T H E

ALSTROM

C O R P O R A T I O N

Recovery Capacity

Maximal daily water capacity

Capacity per unit

gal/hr

gal/day

RSR

Method

640

76.8

Heat recovery

Steam rate

Actual storage capacity

Btu/hr

lbs/hr

gal

534080

530

572

FD

Method

1180

141.6

984710

995

944

The comparison of the tabulated data shows that the ASHRAE methods result in

significant difference of the storage section size and heat recovery without any explanation.

The previous calculations are based on consumption of 140 deg. F hot water using 40

deg. F cold water to obtain 100 deg. F. mixed water at the fixture. Any variation of these

standard temperatures will affect the hot water consumption. The Correction Factor from the

following formula should multiply the calculated standard Hot Water Demand: CF = [ (Tm-Tc) /

(Tm-40)] x [Th-Tc) / (140-40)]

CM

MY

CY

CMY

For example, if the heater is sized for 792.0gal/hr recovery and 1321gal storage section, but

actual cold-water temperature is 68 deg. F and hot water temperature is 176 dg F, then:

CF = [(100-68) / (100-40)] x [(176-68) / (140-40)] = 0.576

The recovery of hot water at 176 deg F.

792 x 0.576 = 456gal/hr and storage section 1321 x 0.576 =761gal

The Alstrom method of Sizing Hot Water Storage Heaters

The Alstrom method of sizing storage heaters is based on comparison of integrated heat

supply and demand during the periods of accumulation and discharge. It utilizes the more

general concept of storing energy by heat recovery rather than water recovery.

This method was developed by Russian scientist Dr. Hludov with modifications made by

the Alstrom President, Dr. Ari Nir. The similar ideas and useful recommendation are provided

by the paper of Valentine A. Lehr, PE, A Hot Water Requirements for Hotels in Heating,

Piping Air Conditioning Magazine.

The Alstrom method utilizes statistical data of daily hot water consumption per unit. This

data may be extracted from ASHRAE handbook, but the most accurate information can be

established from the measured hot water demand pattern of comparable buildings.

The Average Hourly Heat Recovery equals:

Q = a * n*Cp (Ts-Tc) /24

Where:

a: hot water demand at maximal day water recovery per one unit gal/day.

n: number of units.

ASHRAE Applications handbook recommends the following Hot Water Demand at maximal

day(gal/hotel unit):

Number of units

<=20

60

ASHRAE Hot

35

25

Water Demand at maximum day (gal/hotel unit)

>=100

15

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

T H E

ALSTROM

C O R P O R A T I O N

The typical pattern of heat demand throughout the 24 hour period is presented by the

following table.

Hours

0-2

2-7

7-12

12-18

18-22

22-24

Total

Relative Heat

Demand

0.8

0.2

2.2

0.8

1.4

1.2

Relative Hours

Period

0.8 * 2 = 1.6

0.2 8 5 = 1.0

5 * 2.2 = 11

6 * 0.8 = 4.8

4 * 1.4 = 5.6

2 * 1.2 = 2.4

= 26.4

Accumulation

Accumulation

Discharge

Accumulation

Discharge

Discharge

The ratio of total relative hours to 24 hour period may be called as a Coefficient of Thermal

Storage irregularity CTR.

In this case:

CTR = 26.4/24 = 1.1

C

Example: estimated size of the heaters and heat demand for 200 units hotel with hot water

temperature 140 deg. F and cold water temperature 40 deg. F.

CM

Estimated Hourly Heat Demand:

Q(d) = 15 x 8.345 x 1 x (140-40) /24 = 104312Btu/hr

MY

CY

Estimated Hourly Heat recovery:

Q(a) = 104312 x 26.4/24 = 114743Btu/hr

CMY

Hours

0-2

2-7

7-12

12-18

18-22

22-24

Relative

Heat

Demand

0.8

0.2

2.2

0.8

1.4

1.2

Integrated

Integrated

Heat

Heat Demand

Heat Demand,

Supply, Btu

Btu

104312 x 0.8 x 2 = 166,899

166,899

229,341

104312 x 0.2 x 5 = 104,312

271,211

802,694

104312 x 2.2 x 5 = 1,147,432

1,418,643

1,376,048

104312 x 0.8 x 6 = 500,698

1,919,341

2,064,071

104312 x 1.4 x 4 = 584,147

2,503,488

2,522,754

104312 x 1.2 x 2 = 250,348

2,753,837

2,753,837

Stored

Heat,

Btu

41,698

458,683

41,698

145,944

20,849

Since Total Heat Supply should be equal or greater than Total Heat Demand at any period

of the day, the further correction is required until Accumulated Heat becomes positive.

Assume Q(a) = 114743 + (41698/12) = 118219 Btu/hr

Hours

0-2

2-7

7-12

Relative

Heat

Demand

0.8

0.2

2.2

Integrated Heat

Demand, Btu

166,899

271,211

1,418,643

Integrated Heat

Supply, Btu

236,286

827,000

1,417,746

Stored Heat,

Btu

69,492

555,960

0

Period

Accumulation

Accumulation

Discharge

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

T H E

ALSTROM

C O R P O R A T I O N

12-18

18-22

22-24

0.8

1.4

1.2

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel1,919,341

2,503,488

2,753,837

2,126,571

2,599,000

2,835,429

288,444

97,095

83,333

Accumulation

Discharge

Discharge

Due to heat loss in return pipe the temperature of the hot water at the far end may be 18

deg F., lower than the temperature of water, leaving the heater. In order to keep the average

temperature 140 deg. F at the fixture assume the set temperature of the Pressurized storage heater

equals 149 deg F.

Maximal Stored Heat = 555960 = 30887lbs

149- 131

18

The size of the storage section can be reduced by using higher set temperature with

further tempering of stored water with cold water in the mixing valve. For example, if the set

temperature of water is 180 deg. F, then

Net Storage Section Capacity of the Pressurized Vessel equals:

Maximal Stored Heat = 555960 = 11346lbs

180-131

49

M

If set temperature of the Atmospheric storage heater equals 149 deg. F then

Net Storage Section Capacity of the Atmospheric Vessel:

CM

MY

CY

Maximal Stored Heat = 555960 = 6864lbs

149-68

81

CMY

The size of the Storage Section can be reduced by using higher set temperature with

further tempering of stored water with cold water in the mixing valve.

If set temperature of water is 180 deg. F, then

Net Storage Section Capacity of the Atmospheric Vessel:

Maximal Stored Heat = 555960 = 4964lbs

180-68

112

These selections provides the size of the storage section for a system with minimalpractically steady steam combustion.

When the space in the boiler room is limited or there is a large source of steam, then a

smaller Pressurized Compact Heaters can be used. The selected heating element provides

practically constant heat rate, as long as the temperature of the stored water below the set

temperature of the TRV.

Indeed, heat exchanged

Q(a) = A x U x LMTD

Where:

Q(a)- heat exchanged (Btu/hr

A- heat transfer area (sq.feet)

U- overall heat transfer coefficient (Btu/sq.feet x hr x deg. F)

LMTD- log mean temperature difference (deg. F)

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

T H E

ALSTROM

C O R P O R A T I O N

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

For storage and compact heaters heat exchanged depends mostly on the difference

between steam temperature and cold water temperature that may be assumed constant during the

day. The following heat balance equation can be used:

Q(dm) = M x (Ts -Tm) x Cp + Q(h) x DP or

Q(h) = [Q(dm) M x (Ts Tm) x Cp] / DP

Where:

Q(dm)- heat demand during discharge period (Btu)

Q(a)- heat recovery (Btu/hr)

DP- discharge period (hr)

M- weight of the stored water (gal)

For the discussed case, maximal Accumulated Heat during the day equals 555960 Btu.

This heat will be discharge within period from 7a.m. to 12 a.m.

Therefore:

Q(d) = 555960 + 118143 x 5 = 1,146,674Btu

CM

In order to compare this method with ASHRAE AARSSR@ Curve Method, the volume

of the storage tank is taken from the previous example:

Option 1: Assume Net Storage Section equals 3200 gal

O(h) = (1,146,674 3200 x 8.345 x 18) / 5 = 133200Btu/hr

MY

CY

CMY

ASHRAE AARSR @ method requires 166900 Btu/hr

In this case, discharge period equals:

DP = (1,146,674 3200 x 8.345 x 18) / 166900 = 4 hours or

delta t = (1,146,674 166900 x 5) / (3200 x 8.345) = 11.7deg F.

Option 2: Assume Net Storage equals 1600gal

Q(h) = (1,146,674 - 1600 x 8.345 x18) / 5 = 181268Btu/hr

ASHRAE AARSR @ method requires 233660 Btu/hr

In this case, discharge period equals:

DP = (1,146,674 1600 x 8.345 x 18) / 233660 = 3.88 hours or

delta t = (1,146,674 - 233660 x 5) / (1600 x 8.345) = 1.62deg F.

Option 3: Assume Net Storage Section equals 400 gal

Q(h) = (1,146,674 - 400 x 8.345 x18) / 5 = 217318Btu/hr

ASHRAE AARSR @ method requires 534080 Btu/hr

In this case, discharge period equals:

DP = (1,146,674 400 x 8.345 x 18) / 534080 = 2.03 hours

ASHRAE AFD @ method requires 984710 Btu/hr

In this case, discharge period equals:

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

T H E

ALSTROM

C O R P O R A T I O N

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

DP = (1,146,674 400 x 8.345 x 18) / 984710 = 1.1 hours

Selection of heaters described above by The Alstrom Method is based on 5 hours reheat

time. Heat demand for other reheat times can be also calculated. The following table shows

Heat Recovery as function of the size of Storage Section and Discharge Period.

Storage Section (gal)

3200

1600

400

Discharge Period (hours)

5

4

3

133200

166500

222000

181268

226585

302113

217318

271647

362197

2

333000

453170

543295

1

666000

906340

1086590

The calculations show that the sizing of a compact heater and, as result, heat recovery

depends on the permitted temperature fluctuation within the storage section and hours of

discharge period. There are many options for size selection of the storage heart and,

consequently, steam demand.

The pressurized Hot Water Heaters selected by ASHRAE Methods provide

quicker reheat time, and obviously, need more available steam. Further decrease of the storage

section may result in insufficient storage capacity and drastic increase in steam peak demand.

The A.O. Smith & Company recommends the following minimal storage Capacity for

Hot Water Hotel Systems.

Number of Units

10

30

75

150

200

300 and more

Storage Capacity (gal)

106

158

264

357

423

602

Return Piping

Usually, hot water systems for hotels are designed to have hot water available

continuously at the fixtures by using return piping. When the designer selects Heat Recovery

Section, the amount and temperature of return water should be taken in consideration.

Return Water Flow Rate = Heat Loss / Cp x (Th Tr)

Re-circulation Ratio R = Return Water Flow Rate

Net Water Flow Rate

The actual Hot Water Flow Rate via the heater

WFR(h) = Net Water Flow Rate* (1 + R)

The actual Cold Water Temperature entering heater

T(ac) = (Tc + R * Tr) / (1 + R)

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

T H E

ALSTROM

C O R P O R A T I O N

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

The actual Heat Exchanged Capacity

Q(h) = Net Heat Capacity + Net Water Flow Rate * R * Cp * (Th Tr)

For the previously considered instantaneous heater assume

R = 0.1, Tc = 40 deg. F, Th = 149 deg. F, Tr = 131 deg. F

WFR(a) = 4107.6 * (1 + 0.1) = 4518.4 gph

T(ac) = 40 + 0.1 * 131 = 48.3 deg. F

1 + 0.1

Q(h) = 3,736,293 + 4107.6 x 8.345 x 0.1 x 1 x (149-131) =3,797,993 Btu/hr or

Q(a) = 4518.4 x 8.345 x 1 x (149 48.3) = 3,796,999 Btu/hr

Of Course, similar calculations are valid for storage and compact heaters.

Sizing of heat recovery section without taken into consideration, the amount and temperature of

return water results in under sizing of the heater. It also causes increase in pressure drop.

For this example, this increase approximately equals to 4518.4 x 4518.4 = 1.21

4107.6 4107.6

Major Problems Scale Formation, Corrosion & Water Hammer

CM

MY

CY

CMY

The common problems that occur in the heat exchanges are: scale formation, corrosion,

and water hammer. Indeed, the rate of scaling increase with temperature rise and prolonged

usage because calcium carbonate and other solids lose solubility at high temperature from hard

water. Scaling results in poor performance of the heater and increased pressure drop. Scaling

can be reduced by selecting a heater with high water velocity to generate turbulent flow that

prevents the precipitation of scales on the surface. The Alstrom Corporation recommends water

velocity in the 5-8 ft/s that may be achieved in the water heaters with a pressure droop of 3 7.5

psi.

Corrosion problems increase with temperature because corrosive oxygen and carbon

dioxide gases are release from the water. The Alstrom Corporation recommends the use of 316L

stainless steel that has superior corrosion resistance. The concentration of chlorides should be

maintained at the minimal recommended level in order to prevent stress corrosion.

Steam hammer can cause serious damage to the tubes of any heat exchanger. A vacuum

breaker and/or air vent should be used in accordance with the type of steam system installed.

The proper steam trap should be selected for the total capacity of the temperature

regulator (not the capacity of heat exchanger!) for the pressure at the trap. A careful

consideration of the above-mentioned points, before installation is done, could prevent costly

repairs that may be caused by steam hammer. In addition, a properly sized relief valve must be

installed on the heated waterside to protect heat exchanges from possible damage due to

volumetric expansion.

The weakest point in the heat exchange is tube-to-tube-sheet joints. Tube expansion and

further seal welding tubes to the tube-sheet achieve the most efficient joins.

ASTEG.pdf

1/18/05

12:37:12 PM

1408 Seabury Ave. Bronx, NY 10461 tel 718.824.4901 fax 718.409.3605 alstromcorp.com

T H E

ALSTROM

C O R P O R A T I O N

Sizing Heaters and Steam Requirements for

Domestic Hot Water Systems

-Hotel-

Conclusions

Instantaneous and Semi-instantaneous Heaters require minimal space and very large

steam supply. They may be recommended for applications where unlimited or inexpensive

steam is available. Self-contained TRV can be used if there are no momentary changes in hot

water consumption. Otherwise, pneumatically operated TRV should be used.

Storage heaters require minimal and steady supply of steam, but they have the largest size

of storage section as opposed to compact heaters that require smaller size of the storage section,

but they need more hourly steam supply. The major factor in sizing of compact heaters is the

duration of the discharge period that depends on the type and location of the hotel. Surprisingly,

size of the storage section has limited effect on the requested heat recovery. Self-contained TRV

provides sufficient temperature control.

In comparison with empirical ASHRAE Methods, The Alstrom Method provides

analytical approach for sizing of storage section, steam requirement calculation, and prediction

of temperature variations of the mean stored water temperature during the periods of heat

accumulation and discharge. All of the discussed methods provide legitimate result that may be

considered by a designer, depending on specifics of the particular project.

Atmospheric Hot Water Storage Heaters have minimal sizes and require minimal amount

of heat. The usage of these heaters should be considered.

All mentioned above methods can be used for the sizing of storage heaters and boilers.

Economical analysis, space limitations, hot water demand for kitchens, laundries, swimming

pools, as well as, other factors may affect the decision of the designer to select heaters and

boilers.

It should be taken in consideration, that design calculations are based on heating cold

water, entering at minimal temperature during the year. In reality, this temperature will be

higher during most of the seasons and, consequently, heat demand will be reduced. The TRV

will reduce the steam supply and, as a result, boilers and heaters will not be used for their full

capacity.

Over sizing of boilers and heaters increases the initial cost of the system, but he under

sizing of the heating capacity may result in sever shortage of hot water during the coldest periods

of the year. The systems designer shall establish the delicate balance between the investment in

the system and its reliability.

You might also like

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Swimming Pool Heater SizingDocument1 pageSwimming Pool Heater SizingAmeer AbbasNo ratings yet

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Supersedes Bulletin # 006/2000Document15 pagesSupersedes Bulletin # 006/2000almig200100% (2)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- ASPE PSD - Building Storm Water SystemsDocument1 pageASPE PSD - Building Storm Water SystemsNiong DavidNo ratings yet

- Hot Water Calculation PDFDocument22 pagesHot Water Calculation PDFChamara Chinthaka Ranasinghe0% (1)

- Calorifier ManualDocument27 pagesCalorifier ManualPaul KwongNo ratings yet

- Ishrae Variable Volume Pumping SystemDocument14 pagesIshrae Variable Volume Pumping SystemAidrus AliNo ratings yet

- Ozone Treatment of Cooling Tower WaterDocument26 pagesOzone Treatment of Cooling Tower WaterLh KooNo ratings yet

- Improving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringDocument7 pagesImproving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringminiongskyNo ratings yet

- Domestic Water Pipe Sizing Ib P Pc2014 009Document20 pagesDomestic Water Pipe Sizing Ib P Pc2014 00963ragtopNo ratings yet

- Sprinkler System SchematicsDocument1 pageSprinkler System SchematicsAvk Sanjeevan100% (1)

- 01-Pressurization Fan Calculation Sheet - Rev-01Document4 pages01-Pressurization Fan Calculation Sheet - Rev-01Hamdy AdelNo ratings yet

- Comparison VRF Vs Aircooled Chiller: Rec-Unitech Philippines Design Review and Proposal From: Engr Beng Rosales, MsmeDocument6 pagesComparison VRF Vs Aircooled Chiller: Rec-Unitech Philippines Design Review and Proposal From: Engr Beng Rosales, MsmeBeng RosalesNo ratings yet

- World Highest Building (Burj Kalifa) Air DisruptionDocument40 pagesWorld Highest Building (Burj Kalifa) Air DisruptionPrabu RajaNo ratings yet

- Carrier Recommended Minimum CW Fluid Loop VolumeDocument1 pageCarrier Recommended Minimum CW Fluid Loop VolumeRyan Carter100% (2)

- Calorifier Data SheetDocument4 pagesCalorifier Data SheetgksakthiNo ratings yet

- Project CalculationsDocument3 pagesProject CalculationsVenkata Subramanyam KotaNo ratings yet

- ORC Working Fluids Comparison ECOS PresentationDocument16 pagesORC Working Fluids Comparison ECOS Presentationoverlord5555No ratings yet

- M 389 ContentDocument52 pagesM 389 ContentokahertaberNo ratings yet

- Fixture Units Sizing ChartDocument4 pagesFixture Units Sizing ChartAfrooz Momeni100% (1)

- Hot Water Circulating Pump Cal2Document2 pagesHot Water Circulating Pump Cal2Nghia100% (1)

- Project: Quality Control Laboratory Chilled Water Pump Head Calculation Pipe Valves & FittingsDocument15 pagesProject: Quality Control Laboratory Chilled Water Pump Head Calculation Pipe Valves & FittingsZain ShariffNo ratings yet

- Sound Attenuator Selection Path Report: Total Air Flow (M3/sec) Source Sound Power LevelDocument1 pageSound Attenuator Selection Path Report: Total Air Flow (M3/sec) Source Sound Power Levelmefaisal75No ratings yet

- Rules and Rules of Thumb For Duct SystemsDocument1 pageRules and Rules of Thumb For Duct SystemsNguyễn Xuân ĐiệpNo ratings yet

- Refrigeration and Air-Conditioning (Meng 4711) : PsychrometryDocument58 pagesRefrigeration and Air-Conditioning (Meng 4711) : PsychrometryaddisudagneNo ratings yet

- Boiler Feed Water Treatment & BlowdownDocument6 pagesBoiler Feed Water Treatment & BlowdownnurulNo ratings yet

- Hot Water CalculationDocument2 pagesHot Water CalculationNghiaNo ratings yet

- Hot Water Heater Sizing Guidelines: I. DefinitionsDocument8 pagesHot Water Heater Sizing Guidelines: I. DefinitionsMac ShaikNo ratings yet

- Water Heater SpreadsheetDocument17 pagesWater Heater SpreadsheetHgagselim SelimNo ratings yet

- Hot Water-Plumbing Lect - 2015 BAUDocument60 pagesHot Water-Plumbing Lect - 2015 BAUAbed BaayounNo ratings yet

- Grease Interceptor Sizing Guide 94200870413PMDocument2 pagesGrease Interceptor Sizing Guide 94200870413PMShady B. ZoghbyNo ratings yet

- Design of Centralized Hot Water Supply SystemDocument36 pagesDesign of Centralized Hot Water Supply SystemAbhik BhattacharjeeNo ratings yet

- Selection Sheet - 30XA452 Screw ChillerDocument1 pageSelection Sheet - 30XA452 Screw Chillercalvin.bloodaxe4478No ratings yet

- ASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorDocument6 pagesASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorsajuhereNo ratings yet

- ClimateMaster Pool SizingDocument5 pagesClimateMaster Pool SizingNghiaNo ratings yet

- Proper Engine Room VentilationDocument2 pagesProper Engine Room VentilationAsok AyyappanNo ratings yet

- Potable Water Pumps: Lamah EstDocument18 pagesPotable Water Pumps: Lamah Estفتحى أحمدNo ratings yet

- Hot Water Circulation Pump Capacity CalculationDocument2 pagesHot Water Circulation Pump Capacity CalculationKarthy GanesanNo ratings yet

- Water Cooled PackageDocument37 pagesWater Cooled PackageLeed EN100% (1)

- Exhaust Fan SelectionDocument81 pagesExhaust Fan Selectionprabhuselva22100% (1)

- Expansion Tank CalculationsDocument5 pagesExpansion Tank Calculationspsjjoshi0% (1)

- Calorifier - Heat Recovery Time EtcDocument5 pagesCalorifier - Heat Recovery Time Etcmahmed111No ratings yet

- Swimming Pool Evaporation Loss Calculation VERY IMPORTANTDocument5 pagesSwimming Pool Evaporation Loss Calculation VERY IMPORTANTonspsnonsNo ratings yet

- 1715-DD-M004 Water Booster Pump Demand CalculationDocument5 pages1715-DD-M004 Water Booster Pump Demand CalculationMUBASHIRNo ratings yet

- Sample Calculations of Boiler Pumps and IDDocument5 pagesSample Calculations of Boiler Pumps and IDMasih BelajarNo ratings yet

- Project Standard Specification: Jacuzzi 15491 - Page 1/5Document5 pagesProject Standard Specification: Jacuzzi 15491 - Page 1/5adel rihanaNo ratings yet

- FAHUDocument4 pagesFAHUSundar DAACNo ratings yet

- Tutorial - Cold Water SupplyDocument7 pagesTutorial - Cold Water SupplyyugerajdNo ratings yet

- CHW Pipe Straight Pressure DropDocument2 pagesCHW Pipe Straight Pressure DropDesigner ForeverNo ratings yet

- 1-Sanitary Drainage SystemsDocument20 pages1-Sanitary Drainage Systemsraja bharathiNo ratings yet

- Swimming Pools PDFDocument75 pagesSwimming Pools PDFYazNo ratings yet

- 19.5 Plumbing - Hot Water StorageDocument11 pages19.5 Plumbing - Hot Water StorageNadeesha BandaraNo ratings yet

- Rycroft HT BreezeDocument16 pagesRycroft HT BreezesatejNo ratings yet

- Heating and Cooling Generation and Distribution Systems: Central Vs Decentralized SystemsDocument15 pagesHeating and Cooling Generation and Distribution Systems: Central Vs Decentralized SystemsRakesh RanjanNo ratings yet

- Hot Water Circulation - Designers GuideDocument3 pagesHot Water Circulation - Designers GuideAntonio LebrunNo ratings yet

- I3 Steam Systems 16 20Document5 pagesI3 Steam Systems 16 20qayoom5629No ratings yet

- r557 Mixing ManifoldDocument12 pagesr557 Mixing Manifolddejanoski_aNo ratings yet

- ASHRAE Journal - How To Design & Control Waterside Economizers-TaylorDocument7 pagesASHRAE Journal - How To Design & Control Waterside Economizers-TaylorsajuhereNo ratings yet

- Sony Ericsson-Java Docs and Tools PDFDocument3 pagesSony Ericsson-Java Docs and Tools PDFantonpgmNo ratings yet

- Well Known IP PortsDocument19 pagesWell Known IP PortsantonpgmNo ratings yet

- Sony Ericsson-Java Docs and Tools PDFDocument3 pagesSony Ericsson-Java Docs and Tools PDFantonpgmNo ratings yet

- Visual Mobile Designer Custom ComponentsDocument4 pagesVisual Mobile Designer Custom ComponentsantonpgmNo ratings yet

- SonyEricsson Java Adapting R2ADocument23 pagesSonyEricsson Java Adapting R2AantonpgmNo ratings yet

- Fatro Catalog Downlight E27 Series PDFDocument9 pagesFatro Catalog Downlight E27 Series PDFantonpgmNo ratings yet

- Modena CatalogDocument99 pagesModena CatalogantonpgmNo ratings yet

- Introducing JavaFX - Sun's New Family of Java-Based Products - Programming and Development - TechRepublicDocument9 pagesIntroducing JavaFX - Sun's New Family of Java-Based Products - Programming and Development - TechRepublicantonpgmNo ratings yet

- General Catalogue PanasonicDocument49 pagesGeneral Catalogue Panasonicantonpgm50% (4)

- Discovering Processes From Event LogsDocument58 pagesDiscovering Processes From Event LogsantonpgmNo ratings yet

- Catalog Belanko LegrandDocument24 pagesCatalog Belanko LegrandjefriNo ratings yet

- Legrand Plexo Catalogue 02Document20 pagesLegrand Plexo Catalogue 02antonpgmNo ratings yet

- Schneider EE WhitePaper1Document16 pagesSchneider EE WhitePaper1antonpgmNo ratings yet

- Legrand - Niloe - CatalogueDocument12 pagesLegrand - Niloe - CatalogueantonpgmNo ratings yet

- Legrand - Mallia CatalogueDocument20 pagesLegrand - Mallia CatalogueantonpgmNo ratings yet

- Schneider Electric M9GT13BEN Lighting Circuits GuideDocument76 pagesSchneider Electric M9GT13BEN Lighting Circuits GuideantonpgmNo ratings yet

- Vakmanschap Buizenlegger Kunststof - Ind en EngDocument97 pagesVakmanschap Buizenlegger Kunststof - Ind en EngTri YuniartoNo ratings yet

- Disorders of The Endocrine System and Dental ManagementDocument63 pagesDisorders of The Endocrine System and Dental ManagementSanni FatimaNo ratings yet

- The Heart: Dr. Silvia BoyajianDocument44 pagesThe Heart: Dr. Silvia BoyajianAsem YousefNo ratings yet

- Ncs University System Department of Health Sciences: Discipline (MLT-04) (VIROLOGY &MYCOLOGY)Document5 pagesNcs University System Department of Health Sciences: Discipline (MLT-04) (VIROLOGY &MYCOLOGY)Habib UllahNo ratings yet

- LightsDocument33 pagesLightsEduardo Almeida SilvaNo ratings yet

- Glass Standards PDFDocument4 pagesGlass Standards PDFCristian TofanNo ratings yet

- How To Make FireworksDocument14 pagesHow To Make FireworksLeonardo BiancoNo ratings yet

- FutbolistaDocument18 pagesFutbolistaKaren Osses50% (2)

- Cleavage in MammalsDocument51 pagesCleavage in MammalsIrfan Azram100% (4)

- Action Plan Gulayan Sa PaaralanDocument2 pagesAction Plan Gulayan Sa PaaralanAntonio ArienzaNo ratings yet

- Pipe Support Span CalculationDocument14 pagesPipe Support Span Calculationrajeevfa100% (3)

- Trucks Fin Eu PCDocument117 pagesTrucks Fin Eu PCjeanpienaarNo ratings yet

- 100 Câu Viết Lại Câu Ôn Thi Vào Lóp 6Document10 pages100 Câu Viết Lại Câu Ôn Thi Vào Lóp 6Nguyễn Thanh PhươngNo ratings yet

- Iso 3932 1976Document8 pagesIso 3932 1976NaveedNo ratings yet

- MCQ Unit 3Document15 pagesMCQ Unit 3gaur1234No ratings yet

- Markov Interest Rate Models - Hagan and WoodwardDocument28 pagesMarkov Interest Rate Models - Hagan and WoodwardlucaliberaceNo ratings yet

- Gummetal Zastosowania Kliniczne 0Document8 pagesGummetal Zastosowania Kliniczne 0ΑΛΕΞΑΝΔΡΟΣ ΣΤΕΦΑΝΗΣNo ratings yet

- SpiralsDocument12 pagesSpiralskkglobalNo ratings yet

- GirishDocument7 pagesGirishgsalunkhe241287No ratings yet

- Asms 02 0033Document6 pagesAsms 02 0033Delfia AkiharyNo ratings yet

- AsasDocument2 pagesAsasbuntu2003No ratings yet

- ISNGI 2017 ProgrammeDocument6 pagesISNGI 2017 ProgrammeJoanna JohnsonNo ratings yet

- MEAMTA2-Assignment 2Document5 pagesMEAMTA2-Assignment 2pfukanisibuyi7No ratings yet

- Geo-Technical Investigation On Black Cotton Soils: GeotechnicalinvestigationonblackcottonsoilsDocument5 pagesGeo-Technical Investigation On Black Cotton Soils: GeotechnicalinvestigationonblackcottonsoilsDevendrasinh PadhiyarNo ratings yet

- Agriculture Mcqs PDFDocument4 pagesAgriculture Mcqs PDFAbdul QudoosNo ratings yet

- TNB Ar2011Document334 pagesTNB Ar2011Duncan LeeNo ratings yet

- Module Letter 1Document2 pagesModule Letter 1eeroleNo ratings yet

- BOQ For Softscape and Hardscape Bendungan Karian-3Document23 pagesBOQ For Softscape and Hardscape Bendungan Karian-3greenorchidresidenceNo ratings yet

- Da13 DDR N1 14000305 254 0Document3 pagesDa13 DDR N1 14000305 254 0Hamed NazariNo ratings yet

- Think Before Buying: ReadingDocument1 pageThink Before Buying: ReadingadrianmaiarotaNo ratings yet

- S120 Technical Specifications - 23 Dec 21Document17 pagesS120 Technical Specifications - 23 Dec 21jayraj jadejaNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceFrom EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceNo ratings yet

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingFrom EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingNo ratings yet

- Renewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningFrom EverandRenewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningRating: 5 out of 5 stars5/5 (4)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Renewable Energy Finance: Theory and PracticeFrom EverandRenewable Energy Finance: Theory and PracticeRating: 4 out of 5 stars4/5 (1)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Electric Motor Control: DC, AC, and BLDC MotorsFrom EverandElectric Motor Control: DC, AC, and BLDC MotorsRating: 4.5 out of 5 stars4.5/5 (19)

- Oil: An Overview of the Petroleum IndustryFrom EverandOil: An Overview of the Petroleum IndustryRating: 4.5 out of 5 stars4.5/5 (3)

- The Homeowner's DIY Guide to Electrical WiringFrom EverandThe Homeowner's DIY Guide to Electrical WiringRating: 5 out of 5 stars5/5 (2)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Oil companies and the energy transitionFrom EverandOil companies and the energy transitionNo ratings yet

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Electric Motors and Drives: Fundamentals, Types and ApplicationsFrom EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsRating: 4.5 out of 5 stars4.5/5 (12)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Handbook of Offshore Oil and Gas OperationsFrom EverandHandbook of Offshore Oil and Gas OperationsRating: 4.5 out of 5 stars4.5/5 (4)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Global Landscape of Renewable Energy FinanceFrom EverandGlobal Landscape of Renewable Energy FinanceNo ratings yet

- Natural Gas Processing: Technology and Engineering DesignFrom EverandNatural Gas Processing: Technology and Engineering DesignRating: 5 out of 5 stars5/5 (8)

- Thermal Power Plant: Design and OperationFrom EverandThermal Power Plant: Design and OperationRating: 4.5 out of 5 stars4.5/5 (23)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)