Professional Documents

Culture Documents

Procurement Purchasing Buyer Manager in Stockton NJ Resume Mardo Rob Hamilton

Uploaded by

Mardo Rob Hamilton0 ratings0% found this document useful (0 votes)

123 views2 pagesMardo Rob Hamilton has experience that includes purchasing management, supplier relationship and risk management, contract evaluation and negotiation, inventory control, coordination of purchasing, production planning, invoice processing and freight coordination.

Original Title

Procurement Purchasing Buyer Manager In Stockton NJ Resume Mardo Rob Hamilton

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMardo Rob Hamilton has experience that includes purchasing management, supplier relationship and risk management, contract evaluation and negotiation, inventory control, coordination of purchasing, production planning, invoice processing and freight coordination.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

123 views2 pagesProcurement Purchasing Buyer Manager in Stockton NJ Resume Mardo Rob Hamilton

Uploaded by

Mardo Rob HamiltonMardo Rob Hamilton has experience that includes purchasing management, supplier relationship and risk management, contract evaluation and negotiation, inventory control, coordination of purchasing, production planning, invoice processing and freight coordination.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

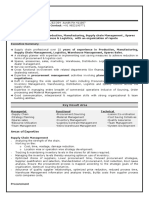

MARDO (ROB) HAMILTON

Stockton, New Jersey 08559

908-392-4033

robhamilton777@hotmail.com

Summary of Qualifications

Dependable and versatile professional with excellent interpersonal, problem solving and

communication skills. Experience includes purchasing, purchasing management, supplier

relationship and risk management, ISO-9001 purchasing policy implementation, contract

evaluation and negotiation, materials and inventory control, coordination of purchasing

production planning, invoice review and processing, freight coordination.

PURCHASING AND PURCHASING MANAGEMENT

Prepare and execute requisitions and purchase orders

High emphasis on supplier relationship and risk management

Research product availability and price trends to optimize sourcing opportunities

Develop and implement management cost reduction strategies and objectives

Resolve complex grievances and claims against suppliers

Intuitive negotiation of critical proposals and contracts

Establish broad based, reliable procurement network

Create transparency between purchasing and all other relevant departments

SUPPLIER MANAGEMENT

Manage suppliers as strategic, internal partners through considerate communication

Improve supplier effectiveness with defined expectations and ongoing performance evaluation

Eliminate supplier dependencies by expanding purchasing base and procurement options

Analyze and assess new value and reduce risks with key suppliers

Closely collaborate with all suppliers to increase profitability and improve quality

Establish and implement improvement goals and strategies to maximize supplier capacity

Identify and assist is elimination of supplier vulnerabilities

MATERIALS MANAGEMENT / INVENTORY CONTROL

Ensure accurate documentation of internal inventory control procedures

Oversee strategic and tactical projects aimed at operations cost reduction

Manage and participate in cycle count programs to maintain inventory accuracy

Research transaction history to resolve inventory discrepancies

Coordinate and maintain integrity of storeroom perpetual inventory

Implement and optimize chain of custody materials procedures

EMPLOYMENT HISTORY

Hitran Corporation: Flemington, NJ (2007 2015)

Purchasing/ Supplier Management for custom transformer manufacturer. Fast paced,

two shift purchasing environment. Responsibilities include: Supplier Relationship / Risk

Management. Evaluation of weekly component planning reports. Procurement of time

sensitive production materials. Resolution of vendor and incoming material issues. Invoice

review and processing. Negotiate and monitor material contracts. Detail oriented

environment, emphasizing strict adherence to ISO 9001 procedures and policies on every

manufacturing level. Implementation of Lean Manufacturing practices.

International Technidyne Corporation: Edison, NJ (2006 2007)

Production Supervisor for medical industry component manufacturer. Intensive, three

shift, GMP/ISO-9000, FDA regulated environment. Responsibilities include: execution of

weekly production schedule. Verification and monitoring of material usage. Resolution of

technical, quality and employee issues. Employee training. Highest importance placed on

employee safety and product quality. Ongoing analysis of processes and implementation of

Lean Manufacturing practices.

Caswell-Massey Corporation: Edison, NJ (2004 2006)

Purchasing Manager / Supplier Management for personal care products manufacturer.

Responsible for monitoring and maintaining Lean Inventory Levels of over 1,000 SKUs.

Supplier Relationship / Risk Management. Analyze monthly sales trends. Forecast future

product requirements. Schedule and manage internal/off-site production. Negotiate vendor

contracts. Approve all purchasing requests. Resolve invoice/receiving issues with vendors.

Provide quarterly production/inventory analysis reports. Visit vendor sites to maintain high

visibility quality control presence. Materials management.

Sissco-Permadur Industries: Somerville, NJ (1996 2004)

Purchasing / Production Supervisor for materials handling, custom overhead crane

manufacturer. Broad scope of responsibility. Purchased all components for manufacturing

processes. Supplier Relationship / Risk Management. Negotiate vendor contracts. Manage

and participate in yearly cycle counting initiatives. Inventory control and materials

discrepancy resolution. Concurrent coordination of up to 25 customer jobs. Direct the

activities of production, engineering and subcontracting personnel. Coordinate domestic and

international shipment of machinery.

EDUCATION : BACHELOR OF ARTS

TRENTON STATE COLLEGE

SPECIALIZED EDUCATION :

Lean Manufacturing Certification

Contract Negotiation and Mediation

You might also like

- Supplier Quality ManagerDocument7 pagesSupplier Quality ManagersaravanakumarpalaniNo ratings yet

- Director Procurement or Manager Procurement or Director CustomerDocument3 pagesDirector Procurement or Manager Procurement or Director Customerapi-121647647No ratings yet

- ProcurementDocument31 pagesProcurementfeteneNo ratings yet

- Avneet Kaur 4299521 ADMN 1100 AssignmentDocument2 pagesAvneet Kaur 4299521 ADMN 1100 Assignmentjashandeep kaurNo ratings yet

- Senior Buyer Generic JDDocument3 pagesSenior Buyer Generic JDtasfaye wakoNo ratings yet

- Supply Chain Operations Management in New York City Resume Anthony DittaDocument2 pagesSupply Chain Operations Management in New York City Resume Anthony DittaAnthonyDittaNo ratings yet

- The Accredited Supply Chain ProfessionalFrom EverandThe Accredited Supply Chain ProfessionalRating: 5 out of 5 stars5/5 (1)

- Director Quality Regulatory Compliance in United States Resume David TickerDocument3 pagesDirector Quality Regulatory Compliance in United States Resume David TickerDavidTickerNo ratings yet

- CEER - Direct Proc Assist ManagerDocument3 pagesCEER - Direct Proc Assist ManagerAdam HeitzNo ratings yet

- Director Purchasing Procurement Manager in Oklahoma City OK Resume Jeff AmendDocument3 pagesDirector Purchasing Procurement Manager in Oklahoma City OK Resume Jeff AmendJeffAmendNo ratings yet

- Quality Assurance & Systems Manager - NairobiDocument2 pagesQuality Assurance & Systems Manager - NairobiAm BRENKANo ratings yet

- CH 2 ProcurementDocument60 pagesCH 2 Procurementahsanzia62No ratings yet

- Resume - MingYin 2013 CTCDocument2 pagesResume - MingYin 2013 CTCpepeNo ratings yet

- Minh Soumitta v1Document5 pagesMinh Soumitta v1soumitta elisabeth minhNo ratings yet

- Resume B.Document3 pagesResume B.杨鹏No ratings yet

- Manager Supplier Development HeadofficeDocument2 pagesManager Supplier Development HeadofficeRajeshPatilNo ratings yet

- Contigency PlanDocument20 pagesContigency PlanジョcleaveジョNo ratings yet

- SCM ch05Document84 pagesSCM ch05Hasan RazaNo ratings yet

- Job Purpose: Knowledge/SkillsDocument2 pagesJob Purpose: Knowledge/Skillsaryan4ever05No ratings yet

- VP Purchasing Supply Chain Pharmaceutical in NJ Resume Syed Farrukh YousufDocument2 pagesVP Purchasing Supply Chain Pharmaceutical in NJ Resume Syed Farrukh YousufSyedFarrukhYousufNo ratings yet

- Senior Analyst Manager Strategic Sourcing in Irvine Orange County CA Resume Vivienne StrettenDocument2 pagesSenior Analyst Manager Strategic Sourcing in Irvine Orange County CA Resume Vivienne StrettenVivienne StrettenNo ratings yet

- 2007 07 10 MaterialsManagerDocument2 pages2007 07 10 MaterialsManagerSunil BmNo ratings yet

- Supplier Development Engineer Generic JDDocument4 pagesSupplier Development Engineer Generic JDPatrick BelenNo ratings yet

- Chapter 5-Supplier SelectionDocument35 pagesChapter 5-Supplier SelectionPortia Shilenge40% (5)

- Supply Chain Procurement Operations in Atlanta GA Resume Donald LuxDocument3 pagesSupply Chain Procurement Operations in Atlanta GA Resume Donald LuxDonaldLux100% (1)

- Sanjeev Taras: Key Result AreaDocument3 pagesSanjeev Taras: Key Result AreaANUJ TarasNo ratings yet

- VP Director Strategic Sourcing Operations in Philadelphia PA Resume Richard StoyDocument2 pagesVP Director Strategic Sourcing Operations in Philadelphia PA Resume Richard StoyRichardStoyNo ratings yet

- Senior Purchasing Manager Director in San Antonio TX Resume Edward RiveraDocument3 pagesSenior Purchasing Manager Director in San Antonio TX Resume Edward RiveraEdwardRiveraNo ratings yet

- 04 - Ethical & Sustainable SourcingDocument32 pages04 - Ethical & Sustainable SourcingJohnny RamonNo ratings yet

- Senior Supplier Quality Engineer Generic JDDocument4 pagesSenior Supplier Quality Engineer Generic JDKhtb AshrafNo ratings yet

- Weele 5th Ed - Chapter 03Document17 pagesWeele 5th Ed - Chapter 03Neha SharmaNo ratings yet

- Supply Chain Management OverviewDocument104 pagesSupply Chain Management OverviewPiyush GuptaNo ratings yet

- Procurement: EIN 5346 Logistics EngineeringDocument65 pagesProcurement: EIN 5346 Logistics EngineeringGayatri NaiduNo ratings yet

- Vendor Management in FMCG CompaniesDocument25 pagesVendor Management in FMCG CompaniesParas Nath VermaNo ratings yet

- Strategic Sourcing & Vendor MGMTDocument25 pagesStrategic Sourcing & Vendor MGMTrgandotraNo ratings yet

- Supply Chain Integration and ManagementDocument2 pagesSupply Chain Integration and ManagementOpindra Kumar SinghNo ratings yet

- Procurement Specialist Senior Buyer in Sacramento CA Resume Harriet KingDocument2 pagesProcurement Specialist Senior Buyer in Sacramento CA Resume Harriet KingHarrietKingNo ratings yet

- Procurement Team: ResponsibilitiesDocument8 pagesProcurement Team: Responsibilitiesclyde dsouza100% (1)

- Supply Chain Procurement Director in Los Angeles CA Resume Roy ToddDocument2 pagesSupply Chain Procurement Director in Los Angeles CA Resume Roy ToddRoyTodd3100% (1)

- Senior Director Operations Procurement Management in Santa Rosa CA Resume Terry MerrillDocument2 pagesSenior Director Operations Procurement Management in Santa Rosa CA Resume Terry MerrillTerryMerrillNo ratings yet

- Purchasing Manager Supply Base Commodity in San Jose CA Resume Susan BoettcherDocument2 pagesPurchasing Manager Supply Base Commodity in San Jose CA Resume Susan BoettcherSusanBoettcherNo ratings yet

- Mobile 09821114616 E-Mail:: Rama R. BelagaliDocument3 pagesMobile 09821114616 E-Mail:: Rama R. BelagaliNityaNo ratings yet

- TQM Sunum 1Document23 pagesTQM Sunum 1an7l7aNo ratings yet

- BD JobsDocument2 pagesBD Jobsnipaprocurement2No ratings yet

- Seyedeh Fashandi Executive Resume FINALDocument2 pagesSeyedeh Fashandi Executive Resume FINALsfashandi123No ratings yet

- HRM NestleDocument7 pagesHRM NestleAbdulahad MemonNo ratings yet

- Strategic Buyer JSS-Job DescriptionDocument2 pagesStrategic Buyer JSS-Job Descriptionanca.l.radaNo ratings yet

- JAINABAFAALResumeDocument5 pagesJAINABAFAALResumeArun YadavNo ratings yet

- Midterm OPS Man ReviewerDocument31 pagesMidterm OPS Man ReviewerKristal Alain AgraoNo ratings yet

- Supplier RelationDocument28 pagesSupplier RelationkamellukuniNo ratings yet

- Purchasing Manager or Materials Manager or Supply Chain ManagerDocument3 pagesPurchasing Manager or Materials Manager or Supply Chain Managerapi-78792797No ratings yet

- Delivery Performance Improvement GuidelinesDocument6 pagesDelivery Performance Improvement GuidelinesParag HadkeNo ratings yet

- Lec 7 TQM Supplier RelationshipDocument17 pagesLec 7 TQM Supplier Relationshipshasan247100% (1)

- Materials Management PURCHASINGDocument14 pagesMaterials Management PURCHASINGCecil YankahNo ratings yet

- Materials Management PURCHASINGDocument14 pagesMaterials Management PURCHASINGE-Lie NarteyNo ratings yet

- Success in Supply Chain ManagementDocument21 pagesSuccess in Supply Chain Managementfachri.yusuf0701No ratings yet

- MODULE-II Sourcing ManagementDocument14 pagesMODULE-II Sourcing ManagementumeshNo ratings yet

- 5.3.1 & 5.3.2 - Responsibilities AuthoritiesDocument5 pages5.3.1 & 5.3.2 - Responsibilities Authoritiesrc2834338No ratings yet

- Himalaya Drug CompanyyyyyDocument44 pagesHimalaya Drug CompanyyyyyShalemRajNo ratings yet

- Rules 2014 68 UE ENDocument72 pagesRules 2014 68 UE ENEduardo Depiatti100% (1)

- Internal Audit Checklist Iatf 16949Document54 pagesInternal Audit Checklist Iatf 16949Puspavathi S Rama NaiduNo ratings yet

- Quality ManualDocument17 pagesQuality Manualعصمت ضيف اللهNo ratings yet

- Company Profile PDFDocument17 pagesCompany Profile PDFranjithjoyNo ratings yet

- Cepex Plastic ValvesDocument160 pagesCepex Plastic ValvesAlee CastroNo ratings yet

- M&E NoteDocument358 pagesM&E NoteAlex Choong100% (2)

- QHSE002 QHSE Manual Rev 0.0 PDFDocument41 pagesQHSE002 QHSE Manual Rev 0.0 PDFRafeeq rahman100% (1)

- ISO 3834 Enquiry FormDocument2 pagesISO 3834 Enquiry FormscandalthegoodNo ratings yet

- Pharmaceutical Industry Deviation Management Case StudyDocument8 pagesPharmaceutical Industry Deviation Management Case StudytrinhtreeNo ratings yet

- Tran Ho Van TienDocument2 pagesTran Ho Van TienTiếnTrầnHồVănNo ratings yet

- BU4505 OQM - Coursework - 012023 - RevisedDocument10 pagesBU4505 OQM - Coursework - 012023 - Revisedyang liuNo ratings yet

- Fresh Air Louver PDFDocument9 pagesFresh Air Louver PDFMUHAMMED SHAFEEQNo ratings yet

- HESCO ConcertainerDocument36 pagesHESCO ConcertainerThinkDefence100% (1)

- The Role of The Stakeholder in The Quality Improvement of An OrganizationDocument11 pagesThe Role of The Stakeholder in The Quality Improvement of An OrganizationAyame KusuragiNo ratings yet

- A Report ShikharDocument38 pagesA Report ShikharShikharNo ratings yet

- The Seven Most Important ISO 9001Document4 pagesThe Seven Most Important ISO 9001Lourdes Marianne Meneses100% (1)

- CONF 785 DMP Titrino ENDocument2 pagesCONF 785 DMP Titrino ENNghịch Ngợm Rồng ConNo ratings yet

- ISO 9000 Marketing Procedures Process StreetDocument34 pagesISO 9000 Marketing Procedures Process StreetOliver Peterson100% (1)

- FrenosDocument18 pagesFrenosLuisEdgarOrellanaLopezNo ratings yet

- Janani Suraksha Yojana (JSY)Document23 pagesJanani Suraksha Yojana (JSY)vkb_99996326No ratings yet

- Quality PlanDocument23 pagesQuality PlanArun Kumar88% (8)

- Asq 13485Document32 pagesAsq 13485Darren TanNo ratings yet

- Key Performance Indicator For Measuring and Improving Quality of Construction ProjectsDocument7 pagesKey Performance Indicator For Measuring and Improving Quality of Construction ProjectsGokul KrishnanNo ratings yet

- ISO 9001 QMS Internal AuditDocument2 pagesISO 9001 QMS Internal AuditNurul AfizaNo ratings yet

- BS en 10021-2006Document20 pagesBS en 10021-2006peymanNo ratings yet

- Technical Specification For Street Lighting Pole - OctagonalDocument2 pagesTechnical Specification For Street Lighting Pole - OctagonalSIVA NAGA SUDHEER SIDDANINo ratings yet

- Voluntary Food LawsDocument9 pagesVoluntary Food LawsSomya Mehndiratta100% (1)

- Guidance For The Transitioning From ISO 9001:2008 TO ISO 9001:2015Document10 pagesGuidance For The Transitioning From ISO 9001:2008 TO ISO 9001:2015Sead ZejnilovicNo ratings yet

- Redbook Vol1part4Document76 pagesRedbook Vol1part4vulkans014No ratings yet