Professional Documents

Culture Documents

SPANDRELS at WALL1&3

Uploaded by

SanjithRNairOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SPANDRELS at WALL1&3

Uploaded by

SanjithRNairCopyright:

Available Formats

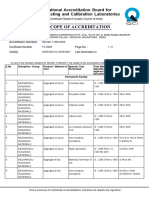

9th Ed.

AISC SECTION CHECK

3 Plate Beam-Column

Job No.

Page:

Date:

08/02/15

Prepare

Locatio

Rev. 14 (03-22-05)

DESCRIPTION of MEMBER & LOCATION

INPUT DATA

Axial Load =

X' Axis Moment =

"'Y' Axis Moment =

Shear Load =

1.00

151.92

0.00

2.53

kips

in-k

in-k

kips

Fy = 50 ksi

Fu = 65 ksi

Unsupported Lx =

Unsupported Ly =

Unsupported Lb =

Allowable Stress =

Cmx = 1.00

Cmy = 1.00

MEMBER DATA

20.00

10.00

10.00

Kx = 1.00

Ky = 1.00

feet

feet

feet

Cb = 1.00

MEMBER PROPERTIES

Area (in2) =

Full Ix (in4) =

6.61

Qs =

1.00

(Table B5.1)

174.3

Qa =

1.00

(Eq. A-B5-8 & 10)

Web Thickness = 0.1875 Inches

Eff. Ix (in ) =

174.3

rx =

5.14

Total Depth = 12 Inches

Eff. Sx (in ) =

29.06

ry =

1.43

Iy (in ) =

13.50

requiv =

1.77

Sy (in ) =

4.50

Flange Width = 6 Inches

Flange Thickness = 0.375 Inches

4

3

Flange to Web Weld = 1/8 in.

one side

RESULTS

ACTUAL STRESSES

fa =

0.15

ksi

fbx =

5.23

fby =

fv =

ALLOWABLE STRESSES

<-- AXIAL -->

Fa =

18.21

ksi (Eq. A-B5-11)

ksi

<--"X" BENDING-->

Fbx =

25.86

ksi (Eq. F1-6)

0.00

ksi

<--"Y" BENDING-->

Fby =

37.50

ksi (Eq. F2-1)

1.20

ksi

<-- SHEAR -->

Fv =

17.90

ksi (Eq. F4-2)

AISC SPECIFICATION CHECK

Combined Stress Ratio =

0.21

OK

(Chap. H, Eq. H1-3)

Shear Stress Ratio =

0.07

OK

Comb. Shear & Tension Stress =

0.00

<= 1.0

Member Weight =

MAX Slender Ratio =

No stiff's required.

22

84.0

lbs/ft.

< 200

SERVICABILITY DATA

LL: L/

(Chap. G, Eq. G5-1)

Flange to Web

D+L: L/

Weld Stress = 0.10

conc: L/

NOTE: No bolt holes were

calculated in flanges at point

of Max. stress.

278232005.xls

9th Ed. AISC SECTION CHECK

3 Plate Beam-Column

Job No.

Page:

Date:

08/02/15

Prepare

Locatio

Rev. 14 (03-22-05)

DESCRIPTION of MEMBER & LOCATION

INPUT DATA

Axial Load =

X' Axis Moment =

"'Y' Axis Moment =

Shear Load =

1.00

241.08

0.00

4.02

kips

in-k

in-k

kips

Fy = 50 ksi

Fu = 65 ksi

Unsupported Lx =

Unsupported Ly =

Unsupported Lb =

Allowable Stress =

Cmx = 1.00

Cmy = 1.00

MEMBER DATA

20.00

10.00

10.00

Kx = 1.00

Ky = 1.00

feet

feet

feet

Cb = 1.00

MEMBER PROPERTIES

Area (in2) =

Full Ix (in4) =

6.61

Qs =

1.00

(Table B5.1)

174.3

Qa =

1.00

(Eq. A-B5-8 & 10)

Web Thickness = 0.1875 Inches

Eff. Ix (in ) =

174.3

rx =

5.14

Total Depth = 12 Inches

Eff. Sx (in ) =

29.06

ry =

1.43

Iy (in ) =

13.50

requiv =

1.77

Sy (in ) =

4.50

Flange Width = 6 Inches

Flange Thickness = 0.375 Inches

4

3

Flange to Web Weld = 1/8 in.

one side

RESULTS

ACTUAL STRESSES

fa =

0.15

ksi

fbx =

8.30

fby =

fv =

ALLOWABLE STRESSES

<-- AXIAL -->

Fa =

18.21

ksi (Eq. A-B5-11)

ksi

<--"X" BENDING-->

Fbx =

25.86

ksi (Eq. F1-6)

0.00

ksi

<--"Y" BENDING-->

Fby =

37.50

ksi (Eq. F2-1)

1.90

ksi

<-- SHEAR -->

Fv =

17.90

ksi (Eq. F4-2)

AISC SPECIFICATION CHECK

Combined Stress Ratio =

0.33

OK

(Chap. H, Eq. H1-3)

Shear Stress Ratio =

0.11

OK

Comb. Shear & Tension Stress =

0.00

<= 1.0

Member Weight =

MAX Slender Ratio =

No stiff's required.

22

84.0

lbs/ft.

< 200

SERVICABILITY DATA

LL: L/

(Chap. G, Eq. G5-1)

Flange to Web

D+L: L/

Weld Stress = 0.16

conc: L/

NOTE: No bolt holes were

calculated in flanges at point

of Max. stress.

278232005.xls

Design of Spandrel beams: End Wall 1 & 3

Calculation design loads:

Seismic case:

referring SBC 97 page 244,

Fp

=

Av*cC*P*Wc

Av

=

0.05

Cc

=

3 (wall elements)

P

=

1.5

Wc

=

82.5 psf

Fp

18.6 psf

Wind case:

Min tributary area

Span

trib height

trib area

Wind coefficient

Wind pressure

design wind pressure

Governing load case

10

16.7

167

1.2

12.397

14.88

ft

ft

ft2

( as per table. 1606.2c)

psf

psf

18.6 psf ( for Spandrel)

Design of spandrel at End wall 1 & 3

34.67 ft

Spandrel reaction from staad

( spandrel 2)

253.2

33.33 ft

plf

18.6 psf

13 ft

Spandrel reaction from staad

( spandrel 1)

401.8

plf

Spandrel 2 at elevation :

33.33 ft

Span

=

20

ft

BM

( wl2/8)

=

151.92

k-"

Shear

=

2.532

k

Axial

=

1

stress increase

1

refer attached stress check for member design.

Combined Stress ratio

Shear stress ratio

=

=

Deflection check:

Ixx

Iyy

0.21

0.07

174.333252 inch4

13.50 inch4

Major axis:

= 5/356*(wl4/EIxx)

=

Minor axis: = 5/356*(wl4/EIyy)

( only for self weight)

=

Major axis deflection

0.19

"

0.22

"

safe

Minor axis deflection

safe

combined stress ratio

Shear stress ratio

:

:

ok

ok

Lx

20 ft

ly

10 ft

lb

10 ft

Provide SFB at 10 ft spacing.

Member size:

Flange width

Flange wthk

web thk

over all depth

6

0.375

0.188

12

"

"

"

"

inch4

Allowable

L/

Allowable

L/

240

1 "

360

0.6667 "

Design of spandrel at End wall 1 & 3

34.67 ft

Spandrel reaction from staad

( Ledger angle)

178.5

33.33 ft

plf

18.6 psf

13 ft

Spandrel reaction from staad

( spandrel )

401.8

plf

Spandrel at elevation :

13 ft

Span

=

20

ft

BM

( wl2/8)

=

241.08

k-"

Shear

=

4.018

k-"

Axial

=

1

stress incress

1

refer attached stress check for member design.

Combined Stress ratio

Shear stress ratio

=

=

Deflection check:

Ixx

Iyy

0.33

0.11

174.333252 inch4

13.50 inch4

Major axis:

= 5/356*(wl4/EIxx)

=

Minor axis: = 5/356*(wl4/EIyy)

( only for self weight)

=

Major axis deflection

0.14

"

0.00

"

safe

Minor axis deflection

safe

combined stress ratio

Shear stress ratio

:

:

ok

ok

Lx

20 ft

ly

10 ft

lb

10 ft

Provide SFB at 10 ft spacing.

Member size:

Flange width

Flange wthk

web thk

over all depth

6

0.375

0.188

12

"

"

"

"

inch4

Allowable

L/

Allowable

L/

240

1 "

360

0.6667 "

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Mentoring Record Mentoring Record: BranchDocument4 pagesMentoring Record Mentoring Record: BranchSanjithRNairNo ratings yet

- Naac Self Study Report PDFDocument469 pagesNaac Self Study Report PDFSanjithRNairNo ratings yet

- Slab Schedule: Sla B Thickness Reinforcement in Short Direction Reinforcement in Long DirectionDocument1 pageSlab Schedule: Sla B Thickness Reinforcement in Short Direction Reinforcement in Long DirectionSanjithRNairNo ratings yet

- Quiz FileDocument11 pagesQuiz FileSanjithRNairNo ratings yet

- Course Title: Computer Application Lab Course Code: 5019 Course Category: P Periods/Week: 6 Periods/Semester: 78 Credits: 3Document2 pagesCourse Title: Computer Application Lab Course Code: 5019 Course Category: P Periods/Week: 6 Periods/Semester: 78 Credits: 3SanjithRNairNo ratings yet

- Mission VisionDocument5 pagesMission VisionSanjithRNairNo ratings yet

- Government Polytechnic College Muttom, IdukkiDocument1 pageGovernment Polytechnic College Muttom, IdukkiSanjithRNairNo ratings yet

- Survey 3Document22 pagesSurvey 3SanjithRNairNo ratings yet

- Staad ProDocument48 pagesStaad ProSanjithRNairNo ratings yet

- CE II 2016 Admin Result Analysis 2017 April ExamDocument33 pagesCE II 2016 Admin Result Analysis 2017 April ExamSanjithRNairNo ratings yet

- (GATE IES PSU) IES MASTER Environmental Engineering - 1 (Water Supply Engineering) Study Material For GATE, PSU, IES, GOVT Exams PDFDocument194 pages(GATE IES PSU) IES MASTER Environmental Engineering - 1 (Water Supply Engineering) Study Material For GATE, PSU, IES, GOVT Exams PDFSanjithRNair100% (1)

- Government Polytechnic College, Muttom: Time Table For Practical Examination April-2019Document1 pageGovernment Polytechnic College, Muttom: Time Table For Practical Examination April-2019SanjithRNairNo ratings yet

- Government Polytechnic College Muttom, IdukkiDocument1 pageGovernment Polytechnic College Muttom, IdukkiSanjithRNairNo ratings yet

- Corrected Cad Lab ManualDocument42 pagesCorrected Cad Lab ManualSanjithRNairNo ratings yet

- Govt. Polytechnic College Muttom FSI/FAR Statement: SL No Name of Building Builtup Area in m2Document2 pagesGovt. Polytechnic College Muttom FSI/FAR Statement: SL No Name of Building Builtup Area in m2SanjithRNairNo ratings yet

- Government Polytechnic College Muttom, Idukki: MASTERPLAN FOR 2019-2029Document1 pageGovernment Polytechnic College Muttom, Idukki: MASTERPLAN FOR 2019-2029SanjithRNairNo ratings yet

- Government Polytechnic College Muttom: Laboratory Manual Survey Practical-IiDocument38 pagesGovernment Polytechnic College Muttom: Laboratory Manual Survey Practical-IiSanjithRNairNo ratings yet

- Floor Floor Area (m2) Carpet Area (m2) Basement 498 325.8 Ground 857.1 551.2 First 857.1 551.2 Terrace Floor 34.55 0Document1 pageFloor Floor Area (m2) Carpet Area (m2) Basement 498 325.8 Ground 857.1 551.2 First 857.1 551.2 Terrace Floor 34.55 0SanjithRNairNo ratings yet

- Spreadsheets For RC Design: N. PrabhakarDocument1 pageSpreadsheets For RC Design: N. PrabhakarSanjithRNair0% (1)

- Weight Calculation Sn-5845-B01: Item Estimated Obtained Savings (KG) Unit NO TOTAL (KG) Unit NO TOTAL (KG) - 354 191 191Document1 pageWeight Calculation Sn-5845-B01: Item Estimated Obtained Savings (KG) Unit NO TOTAL (KG) Unit NO TOTAL (KG) - 354 191 191SanjithRNairNo ratings yet

- Excel Slab ProgramsDocument18 pagesExcel Slab ProgramsSanjithRNair100% (1)

- Is 802 Recommendations On Wind Load On TransmissionDocument57 pagesIs 802 Recommendations On Wind Load On TransmissionSanjithRNairNo ratings yet

- Testing & Modeling of Fresh Conc.Document71 pagesTesting & Modeling of Fresh Conc.SanjithRNairNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- AIPL-Scope 1 TC-8469Document6 pagesAIPL-Scope 1 TC-8469Saurav KumarNo ratings yet

- Spot Learning (Autosaved) (Autosaved) PDFDocument159 pagesSpot Learning (Autosaved) (Autosaved) PDFaraz_1985No ratings yet

- CBBT CablesDocument1 pageCBBT CablesKristaNo ratings yet

- Astm C1399Document5 pagesAstm C1399Alexa CepedaNo ratings yet

- Airframe and Aero Engine Lab FinalDocument25 pagesAirframe and Aero Engine Lab FinalAravind Phoenix50% (2)

- Chiller Plant Calculation & Raw Data RequiredDocument1 pageChiller Plant Calculation & Raw Data RequiredBudi IswahyudiNo ratings yet

- Technical Folder Filtercel Cfa-W: SpecificationsDocument1 pageTechnical Folder Filtercel Cfa-W: SpecificationsmehrezNo ratings yet

- Servicies DWG - of HotelDocument1 pageServicies DWG - of HotelShreyash ShindeNo ratings yet

- Metallization Processes: Polymer Processing Assignment BY-ANJANEYA MISHRA (BE/10684/15) JITESH KUMAR (BE/10688/14)Document13 pagesMetallization Processes: Polymer Processing Assignment BY-ANJANEYA MISHRA (BE/10684/15) JITESH KUMAR (BE/10688/14)anjaneya mishraNo ratings yet

- Applied Mechanics Ii: M N A P Area Orload ForceDocument57 pagesApplied Mechanics Ii: M N A P Area Orload ForceMutiu Toheeb OpeyemiNo ratings yet

- Design Calculation-Inia-Pergola 1Document10 pagesDesign Calculation-Inia-Pergola 1Glastal EngineersNo ratings yet

- Schedule of Rates 2011 Rev1Document144 pagesSchedule of Rates 2011 Rev1Screen BiruNo ratings yet

- Rectangular Pile Cap Shear Check: 1-Input DataDocument11 pagesRectangular Pile Cap Shear Check: 1-Input DataPhilip RichNo ratings yet

- DPA110DHA1CP - Product SpecificationsDocument1 pageDPA110DHA1CP - Product SpecificationsJohn Luke LinharesNo ratings yet

- Girth Gear WearDocument6 pagesGirth Gear Wearho-fa100% (2)

- Sika PDS - E - Sika Pocket Grout PDFDocument2 pagesSika PDS - E - Sika Pocket Grout PDFlwin_oo2435No ratings yet

- Rock Mechanics 988Document69 pagesRock Mechanics 988Sheshu BabuNo ratings yet

- Project Final Repord 2076 PDFDocument106 pagesProject Final Repord 2076 PDFPawan Kumar Karki100% (1)

- Co-Polyamide - PA - Polymers - Detail - FixattiDocument4 pagesCo-Polyamide - PA - Polymers - Detail - FixattiRitesh TiwariNo ratings yet

- Strength of MaterialsDocument6 pagesStrength of MaterialsSheryll de GuzmanNo ratings yet

- BucoDocument3 pagesBucoYvala Zamora PercyNo ratings yet

- General Sections Rule 093A: 093. Grounding Conductor and Means of ConnectionDocument11 pagesGeneral Sections Rule 093A: 093. Grounding Conductor and Means of ConnectionrvasilevaNo ratings yet

- ModDT IOM 12 2015Document36 pagesModDT IOM 12 2015Last Juan StandingNo ratings yet

- Specification: Filter Regulator+LubricatorDocument2 pagesSpecification: Filter Regulator+LubricatorLuiggi Javier Juliano BarraNo ratings yet

- Excelite Plastic Limited: Choose Excelite, Make You The Best in Your Local Market!Document40 pagesExcelite Plastic Limited: Choose Excelite, Make You The Best in Your Local Market!onikith1751100% (1)

- Hollow Core Slab MachineDocument17 pagesHollow Core Slab MachineprensolandNo ratings yet

- Prefabrication of FormworkDocument18 pagesPrefabrication of Formworkyrdgcgf5664No ratings yet

- New Insert Enter Into Market: SeriesDocument1 pageNew Insert Enter Into Market: SeriesJanaka ChathurangaNo ratings yet

- No199 (1999 Eurosteel Conference)Document719 pagesNo199 (1999 Eurosteel Conference)FourHorsemenNo ratings yet

- Method Statement For Batching/Mixing of ConcreteDocument4 pagesMethod Statement For Batching/Mixing of ConcreteNorendro KangjamNo ratings yet