Professional Documents

Culture Documents

Coples G

Uploaded by

José Luis PalizaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coples G

Uploaded by

José Luis PalizaCopyright:

Available Formats

2

-INTRODUCTION

(

\

The steel tape red grid coupling is similar in nature to a steel gear coupling, except the connecting sleeve is replaced by a flexible chrome-vanadium alloy leaf spring grid. The steel hbs are

cut with profiled slots, llowing the grid to engage circumferentially. The grid "springs" deflect

under trque, distributing the peak torque load over a large angle of rotation. The inherent property of torsional softness allows the coupling to absorb shock loads.

Vibration& Shock

INPUT

m

..J5d=.

OUTPUT-

LightLoad

The grid contacts near the outer

edges of the hub teeth: A long

span between the points of contact remains free to flex under

_Ioad.

ADVANTAGES

. Overload conditions cause the

..,

"

grid element to shear,

like-a

mechanical fuse.

. Grid can be changed "in-place",

-00

saving time.

Normal Load

11

-

(g)

CID

J:ib=

. Low maintenance

As the load increases, the distance between the contact

points on the hub teeth is short-

. Quiet operation

ened, but a fre_espan still

remains to cushion the load.

--

Allows for parallel/angular mis.,.

alignment and permits end float

Torsional.flexibility

Shock Load

The coupling isflexible within

its rated capacity. Under

extremeoverloads,

the grid

bears fully on the hub teeth and

transmits fullload directly.

. Competitively priced

(j)

::.'v

STYLE "TG" GRID COUPLING

HORIZONTAL SPLIT COVER

(Vertical Split Cover Available Upon Request)

GUARDEXTM

COVER PROFILES

Aluminum

Split Cover

(Horizontal

Shown)

Rubber Gasket

1020

Steel

Hubs

(2)

1140

1150

SIB1170

Grid Assy

"TG" TAPERED GRID

DIMENSIONAL

1020

0.68

1030

1.93

1040

DATA

4,500

422

4,500

.1,200

1.38

.47 . 4.33

3.86

3.22

4,500

2,000

1.70

.47

4.63

4.12

1050

5.63

4,500

3,500

1.97

.47

5.43

1060

8.85

4,350

5,500

2.17

.75

1070

13

4,125

8,000

2-;56/

1080,

27

3,600

16,500

1090

48

3,600

30,000

1100

81

1110

.....121

1120

l..

2,400

1.18

50,510

.

.47

4.00

3.86

1.56

2.62

.060

1.94

2.69

.060

,.177

2.00

2.25

2.75

.060

.177

4.87'

2.37

2.63

3.13

'.060

.177

12

5.93

5.12

2.50

3.00

3.62

.060

.177

16

.75

6.37

6.12

3.00

3.44 ~. 3.74

.060

.177

22

3~07

1.06

7.64

7.12.

3.50

4.13

4.57

.060

.177

40

3.75

1.06

8.39,

7.87

4.87

4.80

.060

.236

55

5.59

6.12

.060

.236

93

1.87

."

1.87

3.87

.177

4

'.'

4.21

1.61

9.84

9.67,

4.75

4.61

1.61

10.63

10.18

5.00

6.31

6.36

.060

.375

119

'.

2,250

75,014

177

2,025

110,020

5.35

2.36

12.13

11.98

5.87

7.06

7.54

.060

.375

1130

257

1,800

160,030

6.50

2.64

13.62

12.98

6.37

8.56

7.68

.060

.500

,179

.

267

1140

370

1,650

230,043

7.25

2.64

15.12

14.63

7.20

10.00

7.91

.060

.500

393

1150

515

1,500

320,060

8.00

4.25

17.84

14.64

7.20

10.60

10.68

.060

.500

'

..'

516

. .

1160

724

1,350

450,084

8.98

4.75

19.74

15.83

7.80

12.00

10.98

.060

.500

1170

965

1,225

600,112

10.98

5.25

22.30

700

'. .

17.24

8.50

14.00

11.98

.060

.500

988

. ..I-'. ,..:-'-,

~

.-':;-.,',. , ',.:.,:

--'--'

'--' '-.

GUARDEXTM "TG" TAPERED GRID COUPLING

~~

INSTAlLATION

INSTRUCTIONS

<V

Clean all metal parts using nonflarruabl~ 501vent. Lightly coat seals whh'grease and place on

shaft before mour;1tinghubo Mount hubsnthe

shafts.

"-'-"'1...

@ Align so that a straightedge

rests squarely on

both hubs as shown as well as ate-90? inteNa!.

The clearance must not exc:eed"the lim-its'specified on page 3.;

@ After greasing the tooth groove hub, fix thEfGRID

in the same direction. Remember! A~eql;iate

lubrication is 'essential for .satisfaet6ry op.~tion

andlongevity of'co'plirtg. We\JE?commet1di'fhe

."

following

lubric:ant$,:

.(",)''''

Gl)lfcrown #2 (G~lf Oil) M4rfak#g;~(T~~~o}

..;,

Alvania!#2

1

@ Pack the spaces

-.-,

.. Mobilux4f2

.:"'~

(Shell Oil)

".,

,'"

",_.,

~..

(MQ'tpUe)

",

/"'';''

betweri'" and ., ~t(:>f1d

,

'

ithe grid with..fiS much lubric~:mt,aS"pq$ible gnd positlon gaske!~ 0r"ass~~'~J.~d

lower cover so that tbe'~atch' nlitk$,~'q.re

on the sam~ side~New'greas~"~hOl;Jld

b'e applied ever,y 3 months or250 hot:i'rs

.

GUARDIAN Industries"

32010hio Street, P.O. Box 478, Michigan City, IN 46361

219/874-5248.

FAX 219/879-6643.

www.guardiancouplings.com'

".

. ~

'.

J,"Gopyrighf!!' Guardian

Industries

1999

of.operation,

whJchev~r

i~.long'e~~~.;[f~~'

FEATURES OF THE GUARDEXCOUPLING

DOUBLE CROWNED TOOTH

I

Large contact area to provide low contact pressure and to reduce stress of shaft misalignment.

Load distributed near the center of the tooth for maximum strength.

~

Low frition for a smooth flow of power withoutthe need for lubrication-maintenance

free.

Free axial movement of the coupling parts to compensate for shaft thermal changes and future alignment problems.

ALlGNIVIENTTOLERANCES

AXIAL DISPLACEMENT

*Kupplungstechnik

GmbH

P ARALLEL

OFFSET

ANGULAR MISALlGNMENT

GUARDEX

COUPLlNG

M-STYLE

SELECTION

llJl/aid

iCcip

N'I1(

\;

86

138

173

390

520

694

868

1,215

3,298

6,000

10,600

M-14

M-19

M-24

M-28

M-32

M-38

M-42

M-48

M-65

M-80

M-100

173

277

347

781

1,041

1,388

1,736

2,430

6,596

12,000

21,000

2.5

3.7

4.5

10.5

14.5

22.0

24.0

30.0

90.0

165.0

294.0

14,000

11,800

10,600

8,500

7,500

6,700

6,000

5,600

4,000

3,150

3,000

1.5

2.5

3.2

7.0

9.5

12.5

16.0

22.0

60.0

110.0

191.0

1. Nominal torque ratings allow tor 180F ambient, tull misalignment

and/or maximum RPM.

2. Starting torque and braking loads should not exceed listed maximum

torque.

3. Intermittent,

transient peak loads should not exceed three times

nominal torque.

4. Applications

with unitorm loading, well-aligned

shafts, and low speeds

will allow tor operation at maximum torque levels.

M-STYLE COUPLlNG

Nylon'Sleeve, Steel Hubs

Three-Piece Construction

NYLON SLEEVE

.1

3/a to 112

5/a to 71a

15/16 to 11/4

15/16 to 13/a

1'/16 to 13/4

113/16 to 21/4

25/16 to 23/4

213/16 to 31/4

35/16 to 33/4

313/16 to 41/2.

STEEL HUBS

1/a X

3/16 X

1/4 X

5/16 X

3/a X

112 X

5/a X

3/4 X

71a X

2MM.

3MM

4MM

5MM

6MM

8MM

10MryI

12 MM

14 MM

16 MM

18MM

20MM

22MM

25MM

6-7-8

9-10

11-12

13 thru 17

18 thru 22

23 thru 30

31 thru 38

39 thru 44

45 thru 50

51 thru 58

"59 thru 65

66 thru 75

76 thru 85

86 thru 95

1/16

3/32

1/a

5/32

3/16

1/4

5/16

3/a

7/16

1 x 112

Woodruff and special keyways available.

DIMENSIONS

~p

./

M-14

M-19

M.24

M-28

M-32

--M-38

M-42

M-48

M-65

M-80

M-100

Notes:

1.77"

1.96"

2.07"

3.17"

3.15"

3.15"

3.36"

3.91"

5.51"

7.g2"

8.98"

1.57"

1.90"

2.05"

2.58"

3.00"

3.25"

3.63"

3.88"

5.58"

6.89"

8.26"

.14"

.25"

.25"

.69"

.63"

.65"

.73"

1.20"

1.38"

1.8-3"

2.48"

1.30"

1.53"

1.76"

2.12"

2.47"

2.70"

3.06"

3.06"

4.33"

5.70"

6.93"

.78"

.86"

.84"

1.40"

1.40"

1.40"

1.50"

1.80"

2.76"

3.54"

4.33"

1.45"

1.45"

1.60"

1.80"

1.92"

1.90"

1.97"

1.93"

2.83"

3.66"

4.02"

.19"

.28"

.39"

.37"

.35"

.35"

.36"

.31

"

.48"

N/A

N/A

20

24

28

34

40

44

50

50

42

46

48

10-24

1/4.20

1/4-20

1/4-20

5/16-18

5/16-18

5/16-8

3/8-16

3/8-16

3/8-16

112-13

.4

.6

,8

1.8

3.2

4.0..

4.4

5.4

15

25

45

.187"/.625"

.375" 1.750"

.375"/.945"

.250"/1.125"

.437" /1 .26"

c._437.. /-1-.50'"

.437"/1.65"

.437" /1.89"

.500" /2.56"

.98"/3.15"

1.38"/3.94"

1/4,3/8,7/16,1/2,5/8

7/16,1/2,5/8,3/4

1/2,5/8,3/4,7/8,11/8

7/16.1/2

7/16,1/2

1/2,5/8,3/4,7/8,11/8,11/4

~.1/2,5/8,3/4,7/8,11/8,13/8,11/2

5/8,3/4,7/8,11/8,13/8,11/2,15/8

5/8,3/4,7/8,11/8,13/8,11/2,15/8,13/4

1,11/8,13/8,15/8,17/8,21/8,23/8

17/8,21/8,23/8,27/8,31/8

As Requested

1. Dimension "A" is "fully compressed", For best misalignment characteristics, 1116" gap per hub is recommended.

2. M-80/M-100 sleeves have internal snap ring provisions.

'$

d)

6)

.. ~ >

CoupIIng'has-"additional

axialtraveIJ9r

-..,~~

.-~._..

"".

'{'r:",<o'~'~'i.-rt't'",

:~1f":

.'

DEMAG brake m,otors.. ". < . ..\<.!!:'""

>77,;'

Sleeve held to O(le 'hub with!?"mip ffr.igs.t+:Z.:<.

Opposite hub ha~ free a)<ialtr~v~1 ofl!p!",.

to .500".

;/1: .,~

"

Special'hub lngfll5a'(,ailable.(s'~~,L:-,'~~c5,~';,~=~,::

.'

and

"..

L2)

k.

'/.

f.i:::'

~:(:~<:,;,~

~..~,'

'

_e, .,

d..~,.~:

"'"

55.6;38

"~.19

1.50

M8

5/16-18

'55.538"

'M8

2;J9

-1,~9 5116-18

).

70'~ M10

.2]5' . 3/8-16

.,70,M10

2.76 :3/8-16

.

.

ASSEMBlV NOTE~:

Dimensions A, E, & F aremea~ur~Q

.'

""

fUlly'com":ji,e,ssed:

...'.

_

For best misalignmentcharacte~istics,'aV16"g~'p

Hubs should be mountedflush

with the enQ ofth.~ s'~ati wlien p()~$ibl.

P.O. Box 478, Michigan City, IN 46361

Fax 219/879-6643"

,~~.-~-

. .."....

Sleeve should move freely inan:axial dir~ctioriafter&ssmbly.

'.'

"'..,

GUARDIANlndustries;~~'

3201' Ohio Street,

219/874-5248

.,-

. _.

per hbisrecomnlenoed.

,

"''-

_'

.'_'

Copy.rjght@'Guardrn~astries

"

..

p::.....

1,'.....

'

-

1998

~-

.-:::;'\

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Diagrama PLCDocument1 pageDiagrama PLCJosé Luis PalizaNo ratings yet

- Diagrama PLCDocument1 pageDiagrama PLCJosé Luis PalizaNo ratings yet

- Limp Bizkit - (Behind Blue Eyes Tab)Document5 pagesLimp Bizkit - (Behind Blue Eyes Tab)José Luis PalizaNo ratings yet

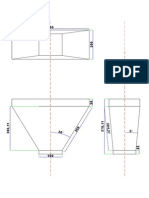

- Tolva ModelDocument1 pageTolva ModelJosé Luis PalizaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Behavior of Geogrid Reinforced Sand and Effect of Reinfor - 2014 - Geotextiles A PDFDocument15 pagesBehavior of Geogrid Reinforced Sand and Effect of Reinfor - 2014 - Geotextiles A PDFRsmoothNo ratings yet

- Popcorn: Critical Temperature, Jump and Sound: ResearchDocument6 pagesPopcorn: Critical Temperature, Jump and Sound: ResearchAngga PratamaNo ratings yet

- MCQ Unit I Phy110Document28 pagesMCQ Unit I Phy110Ansh ThakurNo ratings yet

- Nonlinear Analysis of Cable Structures by PDFDocument7 pagesNonlinear Analysis of Cable Structures by PDFmorteza90No ratings yet

- Pump DesignDocument10 pagesPump DesignashokrangasamyNo ratings yet

- GOVPUB C13 96aDocument216 pagesGOVPUB C13 96aQLPGNo ratings yet

- Seismic Design of Reinforced Concrete Buildings To EC8 With Reference To The 2nd Generaton of The Code - Singapore - 22 July 2022Document58 pagesSeismic Design of Reinforced Concrete Buildings To EC8 With Reference To The 2nd Generaton of The Code - Singapore - 22 July 2022thusiyanthanpNo ratings yet

- CAMENEN LARSON 2005 A General Formula For Non-Cohesive Bed Load SedimentDocument12 pagesCAMENEN LARSON 2005 A General Formula For Non-Cohesive Bed Load SedimentFelipe AzevedoNo ratings yet

- Handbook of Fluid Dynamics and Fluid Machinery - Vol-1 - Fundamentals of Fluid Dynamics - J.A.Schetz - A.E.Fuhs - 1996 - Wiley - 958pg PDFDocument958 pagesHandbook of Fluid Dynamics and Fluid Machinery - Vol-1 - Fundamentals of Fluid Dynamics - J.A.Schetz - A.E.Fuhs - 1996 - Wiley - 958pg PDFEDWAR CAMILO FLOREZ100% (1)

- Flow Meter Orifice CalculationDocument27 pagesFlow Meter Orifice CalculationLaksono BudiNo ratings yet

- TOS II Prev Year QPsDocument16 pagesTOS II Prev Year QPsEesha NairNo ratings yet

- Simulation Final ProjectDocument10 pagesSimulation Final ProjectSalman SheikhNo ratings yet

- Moulding Design GuideDocument6 pagesMoulding Design Guideharisson316No ratings yet

- Physics Projectile Motion NotesDocument6 pagesPhysics Projectile Motion Notessohamdey100% (1)

- Effect of Grain Size On Mechanical Properties of MetalsDocument7 pagesEffect of Grain Size On Mechanical Properties of MetalsMuhannad MohammedNo ratings yet

- A Comprehensive Comparison of Two-Fluid Model, Discrete ElementDocument23 pagesA Comprehensive Comparison of Two-Fluid Model, Discrete Elementเดชา อินทร์โท่โล่No ratings yet

- ES224 01 Spring 2018 CourseContentDocument1 pageES224 01 Spring 2018 CourseContentIskandar IskandarovNo ratings yet

- Open Channel FlowDocument68 pagesOpen Channel FlowhaasnNo ratings yet

- Bab-05a-Sifat Fluida-2008Document59 pagesBab-05a-Sifat Fluida-2008Indah ChairunisaNo ratings yet

- Basic Automobile DesignDocument3 pagesBasic Automobile Designraumil1237590No ratings yet

- Mechanical Engineering Science 1: Fluid Mechanics: Tutorial 7 - Hydrostatic ForcesDocument7 pagesMechanical Engineering Science 1: Fluid Mechanics: Tutorial 7 - Hydrostatic ForcesSabah MazoodNo ratings yet

- The Effects of Addendum Modification Coefficient On Tooth Stresses of Spur GearDocument8 pagesThe Effects of Addendum Modification Coefficient On Tooth Stresses of Spur GearSezgin BayrakNo ratings yet

- Elastic Inelastic CollisionsDocument3 pagesElastic Inelastic Collisionssaud ahmedNo ratings yet

- ProblemsDocument11 pagesProblemsVOJNo ratings yet

- Mode ShapeDocument2 pagesMode ShapezcvzxNo ratings yet

- Best Practice Srs Menter 2015Document75 pagesBest Practice Srs Menter 2015ohpmynNo ratings yet

- Design LocomotionDocument36 pagesDesign LocomotionsherlockmsNo ratings yet

- CFD Analysis of Missile Shroud Separation PDFDocument108 pagesCFD Analysis of Missile Shroud Separation PDFPhạm Công ÁnhNo ratings yet

- Researchers in An Entropy Wonderland: A Review of The Entropy ConceptDocument29 pagesResearchers in An Entropy Wonderland: A Review of The Entropy ConceptBis ChemNo ratings yet

- Computer Aided Analysis and Design of Building Structures PDFDocument145 pagesComputer Aided Analysis and Design of Building Structures PDFUmer WaheedNo ratings yet