Professional Documents

Culture Documents

P 3

Uploaded by

Sairam Kumar ChowdaryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P 3

Uploaded by

Sairam Kumar ChowdaryCopyright:

Available Formats

3.

3 Classification of steam turbines

There are several ways in which a steam turbine may be classified. The most

common and important divisions are

1

According to the direction of steam flow

a

Axial turbines: In which steam flows in a direction parallel to the axis of

the turbine

Radial turbines: In which the steam flows in a direction perpendicular

to the axis of the turbine

Tangential turbines: In which the steam flows tangent to the axis of the

turbine.

According to the number of pressure stages

a

Single stage turbine: With one or more velocity stages usually of small

Power capacities

Multi stage turbine: These are made in wide range of power capacities

varying from small to large

3) According to the number of cylinders

a) Single Cylinder turbines

b) Double cylinder turbines

c) Three cylinder turbines

d) Four cylinder turbines

According to the method of governing

a

Turbines with throttle governing: Steam flow is controlled by opening

and closing of all the control valves simultaneously

Turbines with nozzle governing: Steam flow is controlled by sequential

opening and closing of the all the control valves allowing steam to flow

to associated to nozzle groups

Turbines with bypass governing: In which steam besides being fed to

the first stage is also directly led to one, Two or even three

intermediate stages of the turbine

According to steam conditions at inlet turbine

a

Low pressure turbines: Using steam at a pressure of 1.2 to 20atm.

Medium pressure turbines: Using steam at a pressure of 20 to 40atm.

High pressure turbines: Utilizing steam at a pressures above 40atm

and below 170atm

Turbines of very high pressures: Utilizing steam at pressure of 170atm

and higher and temperatures of 5500C and higher

Turbines of super critical pressures: Using steam at a pressures of

225atm and above

According to the shaft arrangement

a) Tandem compounded turbines: Here all the cylinders are arranged so

as to

Drive a single shaft

c

Cross compounded turbines: Here all the cylinders are arranged so as

to drive two or more shaft with separate generators with every shaft.

According to the principle of steam

a)

Impulse: In this the steam is expanded in fixed nozzles. The high

velocities

issuing from the nozzles does work on the moving blades which

causes

the shaft to rotate.

b)

Reaction: In which pressure is reduced in both fixed and moving

blades

these blades acts like nozzles and are of same shape. Work is done by

impulse effect due to the reverse of direction of the high velocity

steam

plus a reaction effect due to the expansion of steam through the

moving

blades.

d

Compounding: If the steam is expanded from the boiler pressure to

condenser pressure in one stage the speed of the rotor becomes

tremendously high which crops up practical compliances. There are

several methods of reducing speed to lower values; all these methods

utilize a multiple system of rotor in series, keyed on a common shaft

and the steam pressure is absorbed in stages as the steam flows over

the blades. This is known as Compounding.

Velocity compounded impulse turbine: Steam is expanded through a

stationary nozzles and the entire steam pressure drop takes place

there. The kinetic energy of high velocity steam issuing from nozzles is

utilized in a number of moving blades with fixed blades in between

them

Pressure compounded in impulse turbine: In this one the pressure drop

of the steam does not take place in the first nozzle ring, but is divided

equally between all them

Pressure-velocity compounded impulse turbine: It is a combination of

both the previous methods and has the advantage of allowing a more

pressure drop in each stage and less number of stages. Hence for a

given pressure drop the turbine will be shorter. But the diameter of the

turbine is increased at each stage to allow for the increasing at each

stage to allow for increasing volume of the steam.

WORKING PRINCIPLE OF STEAM TURBINE

When the steam is allowed to expand through a narrow orifice, it assumes

kinetic energy at the expense of enthalpy (heat energy). This kinetic energy of

steam is charged to mechanical (rotational) energy through the impact (impulse) a

reaction of steam against the blades. It should be realized that the blade of the

turbine obtains no moving force from the static pressure of the steam or from any

impact of the steam jet. The blades are designed in such a way, that the steam will

guide on and off the blade with out any tendency to strike it.

As the steam moves over the blade, its direction is continuously changing

and centrifugal pressure exerted as the result is normal to the blade surface at all

points. The total motive force acting on the blades is thus the resultant of all the

centrifugal forces plus change of momentum. This causes the rotational motion of

blades.

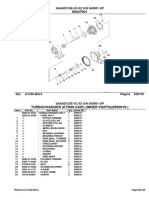

CONSTUCTIONAL DETAILS:The constructional details of the turbine includes the HP, IP, and LP turbines

You might also like

- Robotics Is The Branch of Mechanical Engineering, Electrical Engineering, ElectronicDocument1 pageRobotics Is The Branch of Mechanical Engineering, Electrical Engineering, ElectronicSairam Kumar ChowdaryNo ratings yet

- Apfc SyllabusDocument1 pageApfc SyllabusgreggtldivisionNo ratings yet

- Legd 1 PsDocument11 pagesLegd 1 PsnirdharNo ratings yet

- Heat Rate Calculation: Ms Es6 HPT GlandDocument1 pageHeat Rate Calculation: Ms Es6 HPT GlandSairam Kumar ChowdaryNo ratings yet

- Engineering drawings and technical concepts explainedDocument2 pagesEngineering drawings and technical concepts explainedSairam Kumar ChowdaryNo ratings yet

- P 3Document1 pageP 3Sairam Kumar ChowdaryNo ratings yet

- TetDocument23 pagesTetSairam Kumar ChowdaryNo ratings yet

- Engineering DrawingDocument30 pagesEngineering DrawingDeepak MmechNo ratings yet

- At Temperature T 207.4 C (Consider Temperature) From Steam Tables, Enthalpy H 897.5 KJ / KGDocument1 pageAt Temperature T 207.4 C (Consider Temperature) From Steam Tables, Enthalpy H 897.5 KJ / KGSairam Kumar ChowdaryNo ratings yet

- Steam Turbine Extraction Points & PressuresDocument3 pagesSteam Turbine Extraction Points & PressuresSairam Kumar ChowdaryNo ratings yet

- Ip Turbine OutletDocument2 pagesIp Turbine OutletSairam Kumar ChowdaryNo ratings yet

- 6 Components of Steam TurbineDocument3 pages6 Components of Steam TurbineSairam Kumar ChowdaryNo ratings yet

- Performance Calculation: Actual Values of Unit - I at Full LoadDocument2 pagesPerformance Calculation: Actual Values of Unit - I at Full LoadSairam Kumar ChowdaryNo ratings yet

- Operational DataDocument4 pagesOperational DataSairam Kumar ChowdaryNo ratings yet

- AcknowledgementDocument5 pagesAcknowledgementSairam Kumar ChowdaryNo ratings yet

- SpecificationDocument3 pagesSpecificationSairam Kumar ChowdaryNo ratings yet

- Introduction To R.T.P.P: 1.1 GeneralDocument12 pagesIntroduction To R.T.P.P: 1.1 GeneralSairam Kumar ChowdaryNo ratings yet

- Introduction To R.T.P.P: 1.1 GeneralDocument12 pagesIntroduction To R.T.P.P: 1.1 GeneralSairam Kumar ChowdaryNo ratings yet

- Heat Rate and Efficiency of Steam TurbinesDocument11 pagesHeat Rate and Efficiency of Steam TurbinesSairam Kumar ChowdaryNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Gas Power Cycles: Mehmet KanogluDocument29 pagesGas Power Cycles: Mehmet KanogluFiras Abu talebNo ratings yet

- TFE 731 Chap 79Document24 pagesTFE 731 Chap 79Egor8550% (2)

- Centrifugal Compressors: Petroskills CourseDocument23 pagesCentrifugal Compressors: Petroskills CoursedeepikaNo ratings yet

- Tabel Dimensi Pipa Besi: Project TeamDocument3 pagesTabel Dimensi Pipa Besi: Project TeamYhonni IrwanNo ratings yet

- NPSH - An Introduction For Pump Users: 1. General FormulationDocument4 pagesNPSH - An Introduction For Pump Users: 1. General FormulationTravis SkinnerNo ratings yet

- Multiflo W: Horizontal Multistage PumpsDocument14 pagesMultiflo W: Horizontal Multistage Pumpsbayu enasoraNo ratings yet

- Tssa Tender AplyDocument3 pagesTssa Tender AplyCorrosion FactoryNo ratings yet

- Hydraulic/Hydrostatic Schematic With SJC and High Flow Option S175 (S/N 525215000 AND ABOVE) (S/N 525315000 AND ABOVE) S185 (S/N 525015000 AND ABOVE) (S/N 525115000 AND ABOVE)Document2 pagesHydraulic/Hydrostatic Schematic With SJC and High Flow Option S175 (S/N 525215000 AND ABOVE) (S/N 525315000 AND ABOVE) S185 (S/N 525015000 AND ABOVE) (S/N 525115000 AND ABOVE)alexandrNo ratings yet

- Body Valve PicantoDocument7 pagesBody Valve PicantoadinxNo ratings yet

- Manufacturers of Vibration Control Products and Pipe Accessories Data SheetDocument2 pagesManufacturers of Vibration Control Products and Pipe Accessories Data Sheetbman0051401No ratings yet

- Catalog enDocument154 pagesCatalog enabdulhakimNo ratings yet

- KSB - Etanorm FXV - TSB Pompe KSBDocument44 pagesKSB - Etanorm FXV - TSB Pompe KSBioan cristian cotorobai100% (1)

- EW145B Service InformationDocument373 pagesEW145B Service Informationxzen.urlNo ratings yet

- Topic 4b Turbulent Flow - Major Loses 2020Document24 pagesTopic 4b Turbulent Flow - Major Loses 2020Nor SyamimiNo ratings yet

- Fire Sprinkler Product BrochureDocument8 pagesFire Sprinkler Product Brochurecvolkan1No ratings yet

- Fire Protection SysytemDocument5 pagesFire Protection SysytemphilipyapNo ratings yet

- 06 Final Drive & Tandem PDFDocument4 pages06 Final Drive & Tandem PDFYerson Genovez RamosNo ratings yet

- Duocheck SBMDocument1 pageDuocheck SBMNicolás FriasNo ratings yet

- Coverpage To Material/Test CertificateDocument7 pagesCoverpage To Material/Test CertificateAhmed Abd ElmegeedNo ratings yet

- 5c3319910a969 - Komatsu PC750-7, PC800-7 LC-SE - Section 90 - Hyd and Elect DiagramDocument9 pages5c3319910a969 - Komatsu PC750-7, PC800-7 LC-SE - Section 90 - Hyd and Elect DiagramGeorge ZormpasNo ratings yet

- Valvula Asiento Inclinado Serie E290 AscoDocument3 pagesValvula Asiento Inclinado Serie E290 AscoBase SistemasNo ratings yet

- Turbocharger KTR90 232e Inne PDFDocument1 pageTurbocharger KTR90 232e Inne PDFWilheam MamaniNo ratings yet

- Basic AtlasCopcoDocument6 pagesBasic AtlasCopcosgupta_615796No ratings yet

- Steady Incompressible Flow in Pressure ConduitsDocument32 pagesSteady Incompressible Flow in Pressure ConduitsRas AmiraNo ratings yet

- Spectacle Blind FlangeDocument3 pagesSpectacle Blind Flangemaniastur365No ratings yet

- H and P Unit I II III MQCDocument36 pagesH and P Unit I II III MQCSuryakant LadNo ratings yet

- MeasureMaster Dual Chamber Orifice FittingDocument6 pagesMeasureMaster Dual Chamber Orifice FittingirfanNo ratings yet

- 0299 249 2 Sys Hy en 144Document64 pages0299 249 2 Sys Hy en 144api-19483250100% (1)

- Two Phase Separation Process OverviewDocument25 pagesTwo Phase Separation Process OverviewSafwan NasirNo ratings yet

- Topaire Air Cooled Split Unit AG3 Series Catalgoue 2023Document5 pagesTopaire Air Cooled Split Unit AG3 Series Catalgoue 2023bitalohNo ratings yet