Professional Documents

Culture Documents

Tccs 01 2010 Tisco

Uploaded by

Vinh HiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tccs 01 2010 Tisco

Uploaded by

Vinh HiCopyright:

Available Formats

Tccs 01:2010/TISCo

tiu chun c s tcCS 01:2010/tisco

Thp ct b tng - thp thanh vn

1. Phm vi p dng:

Tiu chun ny qui nh cc yu cu k thut cho thp trn cn nng mt ngoi c gn, g dng

lm ct cho cc kt cu b tng, c sn xut ti cc my cn thp trong Cng ty c phn Gang

thp Thi Nguyn.

Qui nh cc mc thp dng sn xut thp vn:

- SD295A; BCT51; 20MnSi, CB300-V, CB400-V.

- SD390; 25Mn2Si, SD490,CB500-V v cc mc thp tng ng.

2. Tiu chun trch dn:

- TCVN 1651-2:2008; TCVN1765-75, TCVN 3104-79; JIS G3112:2004; JIS G3101-1987 cho

mc thp.

- JIS Z 2241 - 98 Cho phng php th bn.

- JIS Z 2248 - 96 Cho phng php th un.

3. nh ngha:

Thp ct b tng - thp thanh vn l thp trn cn nng c 2 ng gn chy dc v cc g xin

theo ng xon vt hai chiu ngc nhau ( Mt bn xon phi mt bn xon tri).

3.1 - Li: Phn mt ct ngang ca thanh thp khng cha cc gn dc cng nh cc g ngang

(ng knh d0).

3.2 - Gn dc: Gn lin tc u n song song vi trc ca thanh thp.

3.3 - G ngang: (vn ngang) L s li ln theo mt gc xin so vi trc dc ca thanh.

3.4 - Chiu cao ca gn (h): Khong cch t im cao nht ca gn, g (dc hoc ngang) n b

mt li c o trn mt ct vung gc vi trc ca thanh thp.

3.5 - Bc g (t): L khong cch gia cc tm ca hai g ngang k nhau c o song song

vi trc ca thanh.

3.6 - cho ca g ngang (a) : L gc gia g ngang v trc dc ca thanh.

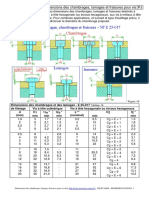

Hnh dng mt ngoi thp ct b tng cn nng (xem hnh 3).

4. Kch thc, khi lng v dung sai cho php:

4.1: Kch thc, khi lng v sai lch gii hn cho php: c nu trong bng 9.

Tccs 01:2010/TISCo

tcCS 01:2010/tisco Manufacturer basic standards.

HOT-ROLLED CONCRETE DEFORMED STEEL BAR

1. Scope:

This standard specifies technical specifications for deformed steel bar used for concrete

reinforcement and produced at TISCO mills. Symbols of grade used for producing

deformed steel as follows:

- SD295A; BCT51; 20MnSi, CB300-V, CB400-V.

- SD390; 25Mn2Si, SD490,CB500-V and other equal steel symbol grades.

2. Cited Standards:

- TCVN 1651-2:2008; TCVN1765-75, TCVN 3104-79; JIS G3112:2004; JIS G3101-1987

(Symbol of grade).

- JIS Z 2241-98; Method of tensile test.

- JIS Z 2248-96; Method of bend test.

3. Definition:

Concrete steel bar in a hot-rolled deformed steel bar with two ribs in axial direction and

spiral knots in oblique direction compared with axial direction.

3.1. Core: Part of section of steel bar without ribs and knots (diameter d0)

3.2. Rib: Continous protrucsions in axial direction.

3.3. Knot: Protrusions tilted an angle compared with axial direction.

3.4. Height of knot (h): Distance from highest point of knot (or rib) to surface of core. The

distance is determined by cross section of steel bar.

3.5. Interval between knots (t): Distance between two centered lines on two consecutive

knots. The distance is measured parallel with axial direction.

3.6. Obliquity of knot (a): is angle formed by knot and axial line. Shap of deformed steel

bar for concrete reinfoincement (fig.3)

Fig.3

4. Dimension, mass and tolerances.

4.1. Dimension, mass and allowable limits: Conformed to table 9.

Tccs 01:2010/TISCo

Bng 9: kch thc, khi lng v gii hn cho php

S

ng knh

Din tch danh

Khi lng

TT

danh ngha

ngha mt ct

1 m di

(d)

ngang

(mm)

(mm)

(kg/m)

D6

28,3

D8

Bc g max

Chiu cao g

Gc gia g

(mm)

v trc

min

max

(mm)

(mm)

(mm)

0,222

4,4

0,3

0,6

50,3

0,395

5,6

0,3

0,6

D9

60,1

0,47

6,20

0,35

0,70

D10

71,3

0,56

6,70

0,40

0,80

D12

109,0

0,86

8,30

0,50

1,00

D14

149,0

1,17

9,70

0,60

1,20

D16

198,6

1,56

11,10

0,70

1,40

D18

249,0

1,95

12,50

0,80

1,60

D20

311,0

2,44

14,00

1,00

2,00

10

D22

380,1

2,98

15,00

1,10

2,20

11

D25

491

3,85

17,50

1,25

2,50

12

D28

616

4,84

19,40

1,40

2,80

13

D32

794,2

6,23

22,30

1,60

3,20

14

D36

1017,9

7,99

25,00

1,80

3,60

15

D40

1257

9,86

27,80

2,00

4,00

16

D50

1964

15,42

34,70

2,50

5,00

(a)

Min 45

Ghi ch: Khi lng ring ca thp ly bng 7,85 g/cm

4.2. Cc quy nh v tr gp nhau ca cc gn dc v g ngang:

Tiu chun ny khng quy nh sai lch kch thc v x dch ca cc g xon vt theo cc

pha gii hn bi cc gn dc.

nhng v tr gp nhau ca cc g vi gn dc, cho php tng chiu rng ca g (tnh theo kch

thc bng 9):

- 1,0mm cho thanh thp c ng knh nh hn 10mm

- 1,5mm cho thanh thp c ng knh t 10 mm4 28mm

- 2,5mm cho thanh thp c ng knh t 29mm 4 50mm

4.3. Chiu di i vi thanh thp vn:

4.3.1. Chiu di quy c (m) theo bng 10.

BNG 10: chiu di tiu chun

CHIU DI THANH THP (m)

3,5

4,0

4,5

5,0

5,5

6,0

6,5

7,0

8,0

9,0

10

11

11,7

12

Tccs 01:2010/TISCo

table 9: dimension, mass and allowable limits

Nominal

Nominal

Unit Mass

Maximum

Heigth of Knots

Angle between

Diameter

Sectional

1 merter

Value of Mean

(mm)

Knots and

(d)

Area

(mm)

(mm)

D6

No

interval Between

min

max

Axial line

(kg/m)

Knots (mm)

(mm)

(mm)

(a)

28,3

0,222

4,4

0,3

0,6

D8

50,3

0,395

5,6

0,3

0,6

D9

60,1

0,47

6,20

0,35

0,70

D10

71,3

0,56

6,70

0,40

0,80

D12

109,0

0,86

8,30

0,50

1,00

D14

149,0

1,17

9,70

0,60

1,20

D16

198,6

1,56

11,10

0,70

1,40

D18

249,0

1,95

12,50

0,80

1,60

D20

311,0

2,44

14,00

1,00

2,00

10

D22

380,1

2,98

15,00

1,10

2,20

11

D25

491

3,85

17,50

1,25

2,50

12

D28

616

4,84

19,40

1,40

2,80

13

D32

794,2

6,23

22,30

1,60

3,20

14

D36

1017,9

7,99

25,00

1,80

3,60

15

D40

1257

9,86

27,80

2,00

4,00

16

D50

1964

15,42

34,70

2,50

5,00

Min 45

Note: Speccific weight of steel equals to 7,85g/cm

4.2. Specifications for meeting of knots and ribs:

This standard does not specify dimension tolerances and knot tolerances limited by ribs.

Allowable to increase width of knots at points of meeting between knots and ribs (calculated

on the dimension in Table 9.

- 1,0mm for bar with 10mm or below in nominal diameter.

- 1,5mm for bar with 10mm to 28mm in nominal diameter.

- 2,5mm for bar with 29mm to 50mm in nominal diameter.

4.3. Length for deformed steel bar:

4.3.1. The standard length for the deformed steel bar shall conform to table 10:

Table 10: standard length

LENGTH OF STEEL BAR (m)

3,5

4,0

4,5

5,0

5,5

6,0

6,5

7,0

8,0

9,0

10

11

11,7

12

Tccs 01:2010/TISCo

- Khi cung cp thanh thp vi chiu di khng quy c, c php c nhng thanh thp c

chiu di /2m mt lng khng ln hn 10% khi lng l hng.

- Theo tho thun vi khch hng, c php cung cp nhng thanh thp ngoi tiu chun v

c chiu di n 25m.

4.3.2. Sai lch gii hn v chiu di quy c ca thanh thp nh trong bng 11.

Bng 11: DUNG SAI CHIU Di Thanh Thp

Chiu di (m)

Dung sai (mm)

+ 40

-0

>7

C tng 1m chiu di th cng thm 5mm vo phn dung sai

nu trn. Tuy nhin gi tr cc i gii hn l 120mm.

Lu : Theo tho thun khch hng c th nh dung sai khc vi gi tr nu trn.

4.3.3. Dung sai khi lng cho 1 thanh thp vn theo bng 12.

Bng 12: Dung sai khi lng

Kch thc (mm)

Dung sai

D[8

8%

10 [ D < 14

6%

14 [ D < 22

5%

22 [ D < 50

4%

Ghi ch

Phng php ly mu th nghim

v tnh dung sai theo mc 6.2.

4.3.4. Dung sai khi lng cho mt b thp theo bng 13.

BNG 13: Dung sai khi lng cho mt b thp

Kch thc (mm)

Dung sai

Ghi ch

D < 10

7%

5%

Phng php ly mu th nghim

v tnh dung sai theo mc 6.2.

10 [ D < 14

14 [ D < 29

D 29

4%

3,5%

Ghi ch: Bng ny ch c p dng khi c tho thun trc vi khch hng.

Tccs 01:2010/TISCo

- When supply steel bar with length different from above specified length, allowable to have

steel bars 2m or more in length but the amount shall be 10% or below of lot total mass.

- According to agreement between purchaser and producer, allowable to supply steel bars out

of the range and up to 25m in length.

4.3.2. The tolerances on length for deformed steel bar shall conform to table 11.

Table 11: tolerances on length

Length (m)

Tolerances (mm)

+ 40

-0

>7

For each increase of 1m in length, further 5mm shall be added

to the tolerances on the plus side given above. The maximum

value, however, shall be limited to 120mm.

Note: According to agreement, the Purchaser may designate the tolerances other than given above.

4.3.3. The tolerances on mass for one piece of the deformed steel bar shall conform to table 12.

Talbe 12: tolerances on mass of one piece

Dimension (mm)

Tolerance

D[8

8%

10 [ D < 14

6%

14 [ D < 22

5%

22 [ D < 50

4%

Remarks

The sampling methods of specimen

and calculation of tolerances shall

be in accordance with 6.2. of this

standard.

4.3.4. The tolerances on mass of one set.

The tolerances of one set of the feformed steel bar shall conform to table 13.

TALBE 13: TOLERANCES ON MASS OF ONE SET

Dimension (mm)

D < 10

10 [ D < 14

14 [ D < 29

D 29

Tolerance

7%

5%

4%

3,5%

Remarks

The sampling methods of specimen

and calculation of tolerances shall

be in accordance with 6.2. of this

standard.

Note: This table shall be applied only when specified by the purchaser in advance.

Tccs 01:2010/TISCo

5. Yu cu k thut

5.1. Thnh phn ho hc mc thp

Thnh phn ho hc ca cc mc thp phi ph hp vi bng 14.

Bng 14: Thnh Phn ho hc

Thnh phn ho hc (%)

Nhm mc thp

Nhm

SD 295A

v tng

ng

Nhm

SD 390

v tng

ng

Nhm

SD 490 v

tng ng

C + Mn/6

Si

Mn

SD295A

SD295B

[ 0,27

[ 0,55

[ 1,5

0,04

0,04

SS540

[ 0,3

[ 1,6

0,04

0,04

Q295

[ 0,16

[ 0,55

0,8 1,5

0,045

0,045

Q345

[ 0,2

[ 0,55

1 1,6

0,045

0,045

SD345

0,27 max

0,55 max

1,60 max

BCT51

0,28 0,37

0,15 0,35

0,50 0,80

0,040 max 0,050 max

20MnSi

0,17 0,25

0,40 0,8

1,20 1,60

0,045 max 0,045 max

CB300-V

0,050 max 0,050 max

SD390

0,29 max

0,55 max

1,80 max

0,040 max 0,040 max 0,55 max

25Mn2Si

0,2 0,29

0,6 0,9

1,2 1,6

0,040 max 0,045 max

Q390

[ 0,2

[ 0,05

1 1,6

0,045

0,045

Q420

[ 0,2

[ 0,05

1 1,7

0,045

0,045

CB400-V

0,29 max

0,55 max

1,80 max

0,040 max 0,040 max 0,56 max

SD490

0,32 max

0,55 max

1,80 max

0,040 max 0,040 max 0,60 max

0,32 max

0,55 max

1,80 max

0,04 max

CB500-V

0,050 max 0,050 max

0,040 max 0,040 max 0,50 max

0,04 max

0,61 max

5.2. Tnh cht c l ca thp thanh vn theo tiu chun ny:

Gii hn chy, bn tc thi ( bn ko); gin di tng i c xc nh bng phng php th

ko, th un trng thi ngui v phi ph hp vi bng 15.

Bng 15: tnh cht c l

Nhm mc thp

ng knh

danh ngha

d (mm)

6 16

Nhm

SD 295A

v tng

ng

SD 295A

SD 295B

17 50

6 16

17 50

Gii hn

chy

bn

ko

dn di

tng i

(N/mm )

(N/mm )

(%)

295min

440 600

16 min

440 min

16 min

295390

Th un ngui

C l dy trc un

d l ng knh danh

ngha ca sn phm

Gc un

C = 1,5d

180

C = 2,0d

180

C = 1,5d

C = 2,0d

Tccs 01:2010/TISCo

5. Technical Specification

5.1. Chemical Composition

Chemical composition shall conform to table 14.

TABLE 14: CHEMICAL COMPOSITION (%)

Chemical Composition (%)

Symbol of Grade

C + Mn/6

Si

Mn

SD295A

SD295B

[ 0,27

[ 0,55

[ 1,5

0,04

0,04

SS540

[ 0,3

[ 1,6

0,04

0,04

Q295

[ 0,16

[ 0,55

0,8 1,5

0,045

0,045

Q345

[ 0,2

[ 0,55

1 1,6

0,045

0,045

SD345

0,27 max

0,55 max

1,60 max

BCT51

0,28 0,37

0,15 0,35

0,50 0,80

0,040 max 0,050 max

20MnSi

0,17 0,25

0,40 0,8

1,20 1,60

0,045 max 0,045 max

CB300-V

0,050 max 0,050 max

SD390

0,29 max

0,55 max

1,80 max

0,040 max 0,040 max 0,55 max

SD 390A 25Mn2Si

and other

Q390

equal

groups

Q420

0,2 0,29

0,6 0,9

1,2 1,6

0,040 max 0,045 max

[ 0,2

[ 0,05

1 1,6

0,045

0,045

[ 0,2

[ 0,05

1 1,7

0,045

0,045

CB400-V

0,29 max

0,55 max

1,80 max

0,040 max 0,040 max 0,56 max

SD490

0,32 max

0,55 max

1,80 max

0,040 max 0,040 max 0,60 max

0,32 max

0,55 max

1,80 max

0,04 max

SD 295A

and other

equal

groups

SD 490A

and other

equal groups

CB500-V

0,050 max 0,050 max

0,040 max 0,040 max 0,50 max

0,04 max

0,61 max

5.2. Mechanical Properties of Deformed steel bar:

Yield point, tensile strength, elongation shall be determined by methods of tensile test and bend test in

cold state and conform to table 15.

TABLE 15: MECHANICAL PROPERTIES

Symbol of grade

SD 295A

and other

equal

groups

Nominal

Diameter

Yield

Point

Tensile

Strength

Elongation

d(mm)

(N/mm )

(N/mm )

(%)

295min

440 600

16 min

440 min

16 min

6 16

SD 295A

SD 295B

17 50

6 16

17 50

295390

Cold bend test

C = inside radius

d = nominal diameter

Gc un

C = 1,5d

180

C = 2,0d

180

C = 1,5d

C = 2,0d

Tccs 01:2010/TISCo

Bng 15: tnh cht c l (tip theo)

Nhm mc thp

SS 540

Nhm

SD 295A

v tng

ng

Q295

Q345

SD 345

6 16

17 50

6 16

17 50

6 16

17 41

6 16

20MnSi

17 50

SD 390

25Mn2Si

Q 390

Q 420

CB400-V

Nhm

SD 490 v

tng ng

6 40

BCT 51

CB300-V

Nhm

SD 390

v tng

ng

ng knh

danh ngha

d (mm)

SD 490

CB500-V

d [ 16

bn

ko

dn di

tng i

(N/mm )

(N/mm )

(%)

390400

540 min

13 min

180

275295

390570

23 min

180

295345

470630

21 min

180

6 16

17 50

6 16

17 50

d [ 16

16 < d [ 50

6 50

d [ 16

16 < d [ 50

C = 2,0d

C = 2,0d

C = 3,0d

C = 2,0d

C = 3,0d

345440

490 min

18 min

180

500 min

19 min

180

19 min

160 180

300min

450 min

16 < d [ 50

6 50

Th un ngui

C l dy trc un

d l ng knh danh

ngha ca sn phm

Gii hn

chy

C = 1,5d

C = 2,0d

C = 1,5d

C = 2,0d

C = 3,0d

C = 4,0d

390 510

560min

16min

180

350 390

490 650

19 min

180

380 420

520 680

18 min

180

400min

570 min

14min

160 180

490 625

620 min

12min

90

500min

650 min

14min

160 180

C = 2,5d

C = 2,0d

C = 3,0d

C = 2,0d

C = 3,0d

C = 4,0d

C = 5,0d

C = 2,5d

C = 5,0d

C = 6,0d

6. Phng php th c l, o kim hnh dng, kch thc v khi lng

6.1. Th c l:

6.1.1 Nguyn tc chung: S mu th bn v th un l mt mu ly ra t mi mt l ca cng m nu

hoc l di 50 tn v mt s kch thc khi c s khc nhau gia chng v ng knh trong khong

10mm. Vi l trn 50 tn th phi ly 2 mu.

6.1.2. Phng php th bn v th un: Phng php th bn theo JIS Z 2241 - 98 v th un theo JIS Z

2248-96. Tuy nhin, v phn din tch tit din t c gii hn chy hay ng sut ph hu 0,2%

v gii hn bn, din tch tit din thc t cho trong bng 9 s c s dng.

6.2. o kim tra hnh dng, kch thc v khi lng:

Phng php ly mu th v phng php o kim hnh dng, kch thc v khi lng thp thanh

vn:

a. Mt mu th c chiu di / 0,5m c ly ra t mi l sn phm c cng hnh dng kch thc

trong mt t cn.

Tccs 01:2010/TISCo

TABLE 15: MECHANICAL PROPERTIES (Next)

Symbol of grade

SS 540

Nhm

SD 295A

v tng

ng

Q295

Q345

SD 345

Tensile

Strength

Elongation

d(mm)

(N/mm )

(N/mm )

(%)

6 40

390400

540 min

13 min

180

275295

390570

23 min

180

295345

470630

21 min

180

6 16

17 50

6 16

17 50

6 16

17 41

6 16

20MnSi

17 50

SD 390

25Mn2Si

Q 390

Q 420

CB400-V

Nhm

SD 490 v

tng ng

Yield

Point

BCT 51

CB300-V

Nhm

SD 390

v tng

ng

Nominal

Diameter

SD 490

CB500-V

d [ 16

6 16

17 50

6 16

17 50

d [ 16

16 < d [ 50

6 50

d [ 16

16 < d [ 50

C = 2,0d

C = 2,0d

C = 3,0d

C = 2,0d

C = 3,0d

345440

490 min

18 min

180

500 min

19 min

180

19 min

160 180

300min

450 min

16 < d [ 50

6 50

Cold bend test

C = inside radius

d = nominal diameter

C = 1,5d

C = 2,0d

C = 1,5d

C = 2,0d

C = 3,0d

C = 4,0d

390 510

560min

16min

180

350 390

490 650

19 min

180

380 420

520 680

18 min

180

400min

570 min

14min

160 180

490 625

620 min

12min

90

500min

650 min

14min

160 180

C = 2,5d

C = 2,0d

C = 3,0d

C = 2,0d

C = 3,0d

C = 4,0d

C = 5,0d

C = 2,5d

C = 5,0d

C = 6,0d

6. Methods for testing mechanical properties, measurement of shape, dimension and mass.

6.1. Mechanical test:

6.1.1. Test in general: The number of tensile test piece and bend test piece shall be each one sample

taken from each lot of the same heat or lot below 50MT in mass and several size where the difference

of diameter or nominal diameter omong them falls within 10mm. However, respective two samples

shall be taken from a lot exceeding 50MT.

6.1.2. Method for tensile test and bend test:

The method of tensile test shall be in accordance with JIS Z 2241-98 and bend test shall be according

to JIS Z 2248-96. However, as to the sectional area for abtaining the yield point or 0.2% proof stress

and tensile strength, the nominal sectional area given in Table 9 shall be applied.

6.2. Measurements of shape, dimension and mass: Sampling method for measurement of shape,

dimension and mass of deformed steel bars:

a. One specimen 0.5m or over in length shall be taken from every lot of products rolled to the same

shape and dimension within an identical roll chance.

Tccs 01:2010/TISCo

b. Gc to bi gai v ng trc dc (a) ca thp vn c o bng gi tr khai trin b mt thp

ct b tng cn nng (xem hnh 3).

c. Bc gai trung bnh l gi tr c xc nh bng cch chia thnh 10 phn bng nhau ca tng

10 bc gai lin tip o theo hng dc trc.

d. Chiu cao ca 1 gai s l trung bnh ca 3 gi tr cao (o ti 3 im chia gai thnh 4 phn

bng nhau).

e. Kim tra khi lng theo ng knh danh ngha bng 9, dung sai bng 12 & 13.

g. Phc tra: L thp cn phc tra, c ly mu theo quy nh sau:

- Ln 1: S mu phi ly gp 2 ln so vi mc 6.1.1. trong Quy nh ny.

- Ln 2: S mu phi ly gp 4 ln so vi mc 6.1.1. trong Quy nh ny.

Nu l thp phc tra c 3/4 s mu t th l hng t cht lng.

7. nh du:

nh du trn mi thanh thp: nhn dng mc thp, cc thanh thp phi c nh du theo

quy nh bng 16.

Bng 16: Phng php nh du:

K hiu phn loi

SD295A, BCT 51, 20MnSi,

CB300-V.

Phng php nh du cho nhn dng v phn loi

bng nh du mu.

Sn ti (trn hai mt tit din)

SD390, 25Mn2Si, CB400-V

Xanh l cy (trn hai mt tit din) v nh s 3

trn cy thp vo khong gia 2 ch TISCO.

SD490, CB500-V

Xanh da tri (trn hai mt tit din. )

8. phng php bao gi v ghi nhn mc sn phm.

8.1: Bao gi: Nhng thanh thp phi c cung cp bng b vi khi lng khong 3 tn, c

b t nht 5 mi bng dy thp trn hoc ai thp dt.

8.2: Ghi nhn mc: Mi mt b thp thnh phm khi lng khng nh hn 500 kg phi c

mt t kt. Khi treo et kt (nhn mc) vo b thp thnh phm, phi ghi r n v sn xut,

mc thp, quy cch, khi lng, ngy sn xut, s l sn phm, s b, s thanh, m s ngi

kim tra v tn Tiu chun p dng.

8.3 Vn chuyn: bng phng tin vn chuyn thng thng.

Tccs 01:2010/TISCo

b. The angle formed by the knot and the axial line of the deformed steel bar (a) shall be measured with

the development figure of surface of deformed steel bar (see fig.3).

c. The mean interval between knots shall be obtained by dividing in to 10 equal parts the sum of ten

consecutive knot intervals measured on the centerline of knots.

d. The height of knot shall be obtained by averaging the values of three heights measured at points

dividing the knot in to four equal parts.

e. The test of mass on nominal diameter shall conform to Table 9, and tolerances to

Table 12 and 13.

g. Inspection: The specimen for lot to be inspected shall be taken as follows:

- First time: Double the numbers of specimen given in 6.1.1. of this standard.

- Second time: Multiply 4 times the numbers of specimen given in 6.1.1. of this standard.

In case of the inspected lot has 3/4 of total specimens complied with requirement, the lot shall

be considered as qualified lot.

7. Marking:

Marking on each piece: The deformed steel bar shall indicate the markings indentifying the

grade in accordance with Table 16.

table 16: marking method

Symbol of grade

SD295A, BCT51, 20MnSi,

CB300-V.

Marking methods for identification and classification

using colored

Red paint on both sides of section

Green paint on both sides of section and carved

SD390, 25Mn2Si, CB400-V number

3 onsteel bar in the middle of two TISCO words.

SD490, CB500-V

Ice blue paint on both sides of section

8. Method for packing and labeling products

8.1. Packing: The supply steel bars shall be implemented by bundle. One bundle is about three

(3) tons in weight and bunched by roll or flat steel string with at least 5 places.

8.2. Labeling: Each bundle with 500kg or over in weight shall be attached an Eteket. Eteket

(label) hung on the bundle shall clearly indicate producer name, symbol of grade, designation,

weight, date of manufacture, lot number, bundle quantity, bar quantity, supervisor code and

stated standard name.

8.2. Delivery: by normal transportation means.

You might also like

- CHEN Zhuo Et YANG Li-Juan:, QIN Lu-FangDocument4 pagesCHEN Zhuo Et YANG Li-Juan:, QIN Lu-Fangchaib boudabNo ratings yet

- Cond SecoDocument5 pagesCond SecoalmshNo ratings yet

- Cours de ChimiométrieDocument93 pagesCours de ChimiométrieKeith Kelewou67% (3)

- Manchons MBTplakaDocument6 pagesManchons MBTplakabujonstNo ratings yet

- Examen de RDM Tronc Commun - Novembre 2012Document6 pagesExamen de RDM Tronc Commun - Novembre 2012Youness ZahiNo ratings yet

- Le TaraudageDocument8 pagesLe Taraudagesaded05No ratings yet

- Assemblages Par Boulons NormauxDocument141 pagesAssemblages Par Boulons NormauxKarim BakrimNo ratings yet

- TD 1 Dim Outil PresseDocument6 pagesTD 1 Dim Outil Pressetout_tout100% (1)

- Dimensions Des Chambrages Lamages Fraisures Pour Vis PDFDocument2 pagesDimensions Des Chambrages Lamages Fraisures Pour Vis PDFNicolas Hakime100% (1)

- TP ForageDocument10 pagesTP Forageعبد العزيز مروىNo ratings yet

- Iso 13920Document13 pagesIso 13920Мунир левNo ratings yet

- Dossier Technique CLT FRDocument332 pagesDossier Technique CLT FRJulie BaronNo ratings yet

- Direction Recherche Et Ingenierie de LaDocument4 pagesDirection Recherche Et Ingenierie de LaHamza FettahNo ratings yet

- CODAPDocument19 pagesCODAPOur SalahEddine100% (1)

- 1 TP1 IncertitudeDocument3 pages1 TP1 IncertitudeRamzi OunisNo ratings yet

- Steinel Normalien Catalog 05a enDocument82 pagesSteinel Normalien Catalog 05a enPatoCOBRANo ratings yet

- Ebauche LEYMENTDocument15 pagesEbauche LEYMENTFootball on fireNo ratings yet

- Critères NDTDocument33 pagesCritères NDTrbibouhNo ratings yet

- ExerciceDocument2 pagesExercicethouraya hadj hassenNo ratings yet

- Données de Panel StataDocument32 pagesDonnées de Panel StataayoubhaouasNo ratings yet

- Taper Lock BushesDocument3 pagesTaper Lock BushesLester FonsecaNo ratings yet

- Recrut Test ACTED Chargé de ProjetDocument6 pagesRecrut Test ACTED Chargé de ProjetGuillaume Djerabe100% (1)

- nf384 Document Technique N 384 01 Rev01 290420Document17 pagesnf384 Document Technique N 384 01 Rev01 290420Amakhand EloyeNo ratings yet

- EXAMEN - TD - 2016 - 2017 - Corrige 2Document15 pagesEXAMEN - TD - 2016 - 2017 - Corrige 2Abdoulaye DiopNo ratings yet

- Le TaraudageDocument8 pagesLe TaraudageMartinezNo ratings yet

- Assemblagesvisss 130202064532 Phpapp01Document42 pagesAssemblagesvisss 130202064532 Phpapp01saded05No ratings yet

- EPREUVE EPS BAT 2018 Sujet 1Document7 pagesEPREUVE EPS BAT 2018 Sujet 1Hyacinthe SikadiNo ratings yet

- Installation & Operation: SVC - S V C WDocument4 pagesInstallation & Operation: SVC - S V C WImanuel SinarNo ratings yet

- TP 44Document13 pagesTP 44Ricardo Mi GustaNo ratings yet

- Ex TH TSMFM FF 09Document11 pagesEx TH TSMFM FF 09ŶŐÚŚŚĔŦ ßĔĹМÁĤĨNo ratings yet

- Synthese Calc Etude Moule BOITIERDocument1 pageSynthese Calc Etude Moule BOITIERMahdi DalyNo ratings yet

- Couple Serrage BV Ldoc18Document3 pagesCouple Serrage BV Ldoc18David HoffmanNo ratings yet

- RDMTPDocument12 pagesRDMTPziatNo ratings yet

- Exercice Outillge Et Presses A SuivreDocument4 pagesExercice Outillge Et Presses A SuivreOussama NiverNo ratings yet

- TP Traction-1Document8 pagesTP Traction-1Paul RebourNo ratings yet

- Epreuve de Physique: Concours Avenir - 8 Mai 2014Document16 pagesEpreuve de Physique: Concours Avenir - 8 Mai 2014Khalid ZegNo ratings yet

- TDs Elements Filetes ProfDocument1 pageTDs Elements Filetes Profsaded05No ratings yet

- 7722 E4 Bts Ip Europlastic 2016 Partie 1 SujetDocument13 pages7722 E4 Bts Ip Europlastic 2016 Partie 1 SujethssanhemdaniNo ratings yet

- TP RDM TorsionDocument10 pagesTP RDM Torsionmerwa sefirNo ratings yet

- Sujet TP UsureDocument10 pagesSujet TP UsureAmina RemadiNo ratings yet

- Iso 527-3 2018 (F)Document7 pagesIso 527-3 2018 (F)chouaibNo ratings yet

- Projet ModuleDocument16 pagesProjet Moduletahermehdi213No ratings yet

- Bardad Salah Eddine - TP RDM 2Document12 pagesBardad Salah Eddine - TP RDM 2bourorga chaimaàNo ratings yet

- Correction EMD Moulage Injection Plastique 2021 BOUTAANI MSDocument5 pagesCorrection EMD Moulage Injection Plastique 2021 BOUTAANI MSHocine BoukhiarNo ratings yet

- Chapitre 3Document14 pagesChapitre 3Khen LokmanNo ratings yet

- Roue AvantDocument3 pagesRoue AvantANo ratings yet

- Analyse DefaillanceDocument50 pagesAnalyse DefaillanceSakhara Saadi100% (1)

- Diffraction ProblemeDocument2 pagesDiffraction ProblemeYassine Bibot100% (1)

- Echographe: Mise À Jour Du Jeu de ManuelsDocument9 pagesEchographe: Mise À Jour Du Jeu de ManuelsFoued MbarkiNo ratings yet

- DC TreillisDocument15 pagesDC TreillisbettyNo ratings yet

- Caplp Ext 2022 GM Option Prod Epreuve 1 CorrectionDocument19 pagesCaplp Ext 2022 GM Option Prod Epreuve 1 CorrectionSilver679No ratings yet

- Caractérisation Sandwich en FlexionDocument8 pagesCaractérisation Sandwich en FlexionNico PonsNo ratings yet

- EmelineDocument10 pagesEmelineaahmadouroufaouNo ratings yet

- Dépannage de l'impression 3D: Le manuel complet pour un dépannage rapide et facile de l'impression FDM 3DFrom EverandDépannage de l'impression 3D: Le manuel complet pour un dépannage rapide et facile de l'impression FDM 3DNo ratings yet

- Graphique raster numérique: Dévoilement de la puissance des graphiques raster numériques dans la vision par ordinateurFrom EverandGraphique raster numérique: Dévoilement de la puissance des graphiques raster numériques dans la vision par ordinateurNo ratings yet

- Tremblement: Dither : bruit visuel dans la vision par ordinateurFrom EverandTremblement: Dither : bruit visuel dans la vision par ordinateurNo ratings yet

- L'impression 3D - un guide étape par étape: Le guide pratique pour les débutants et les utilisateursFrom EverandL'impression 3D - un guide étape par étape: Le guide pratique pour les débutants et les utilisateursRating: 1 out of 5 stars1/5 (1)

- Dépannage de l'impression 3D: Le manuel complet pour un dépannage rapide et facile de l'impression FDM 3D pour les débutants et les utilisateurs avancésFrom EverandDépannage de l'impression 3D: Le manuel complet pour un dépannage rapide et facile de l'impression FDM 3D pour les débutants et les utilisateurs avancésNo ratings yet

- Assurance AutomobileDocument8 pagesAssurance AutomobileMagie Douda HindNo ratings yet

- Facteur Damplification DynamiqueDocument3 pagesFacteur Damplification DynamiqueMoulay ZoubirNo ratings yet

- FocométrieDocument7 pagesFocométrieSaidi AdemNo ratings yet

- Action Thermique 2015 - PontDocument20 pagesAction Thermique 2015 - PontDaha ZoraNo ratings yet

- Colloïde - WikipédiaDocument9 pagesColloïde - WikipédiaTahafanMaggedonNo ratings yet

- TD1GL4Document3 pagesTD1GL4Marwen GuesmiNo ratings yet

- Prévention Et Lutte Contre L'incendie: Combustible ComburantDocument7 pagesPrévention Et Lutte Contre L'incendie: Combustible Comburantطارق بوشنينNo ratings yet

- Presentation SYSOCO PDFDocument15 pagesPresentation SYSOCO PDFsalim sadekNo ratings yet

- AérodromesDocument40 pagesAérodromesDong LINo ratings yet

- Les Ancres de CarrièreDocument12 pagesLes Ancres de CarrièreKerstin Dupont100% (1)

- Ilnas-En 13779:2007Document9 pagesIlnas-En 13779:2007hamz joNo ratings yet

- Expérience de Milikan: Détermination de La Charge ÉlémentaireDocument2 pagesExpérience de Milikan: Détermination de La Charge ÉlémentaireboustakatbNo ratings yet

- Pratique Matrice (AD)Document2 pagesPratique Matrice (AD)hanae elharounNo ratings yet

- Alzheimer PDFDocument50 pagesAlzheimer PDFBIENESTAR ORIENTALNo ratings yet

- Exemple de Manuel HSEDocument12 pagesExemple de Manuel HSEAmira Smine100% (1)

- Nadia MOHYA - La Fête Des KabytchousDocument110 pagesNadia MOHYA - La Fête Des Kabytchousbdjioua1916No ratings yet

- Cartographie Des Outils Et Des Acteurs Mobilisables Pour Le MaintienDocument1 pageCartographie Des Outils Et Des Acteurs Mobilisables Pour Le MaintienTor La sagesse0% (1)

- Activites Pour Le Cecr - B2 by Eliane Grandet, Martine Corsain, Elettra Mineni, Mariella RainoldiDocument193 pagesActivites Pour Le Cecr - B2 by Eliane Grandet, Martine Corsain, Elettra Mineni, Mariella RainoldiFouad HechaichiNo ratings yet

- Cours Microsoft Excel Efp-TpDocument17 pagesCours Microsoft Excel Efp-TpAbû bakr sondéNo ratings yet

- BarakiDocument90 pagesBarakizakaria lokmane100% (4)

- Etude D'un Groupe Electrogene - BOUCHRI Yousra - 2669 PDFDocument35 pagesEtude D'un Groupe Electrogene - BOUCHRI Yousra - 2669 PDFAZIZ50% (2)

- Fiche Technique CrossDocument2 pagesFiche Technique CrossAleksandre MarkovicNo ratings yet

- Fiche HaricotDocument2 pagesFiche Haricotnuit100% (1)

- Techno Topo 2020Document2 pagesTechno Topo 2020abeyapapsNo ratings yet

- Développer en Back-End - 10 MigrationDocument17 pagesDévelopper en Back-End - 10 Migrationkhadija kharifNo ratings yet

- TD Algorithmes Recherche Nombre Occurrence ListeDocument7 pagesTD Algorithmes Recherche Nombre Occurrence Listemulk omarNo ratings yet

- Exo Nombre RationDocument8 pagesExo Nombre RationmemtolombernaNo ratings yet

- Stratégies Pour Améliorer La Communication de L'équipeDocument14 pagesStratégies Pour Améliorer La Communication de L'équipeMustaphaNo ratings yet

- Projet Soutenance - Ferra PoutreDocument5 pagesProjet Soutenance - Ferra Poutrejacques martial ndindjockNo ratings yet

- PDF Renover - Rehabiliter - Agrandir Sa Maison PDFDocument72 pagesPDF Renover - Rehabiliter - Agrandir Sa Maison PDFlaunayrNo ratings yet