Professional Documents

Culture Documents

Effluent Traetment Plant Sop

Uploaded by

Fahad MaqsoodCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effluent Traetment Plant Sop

Uploaded by

Fahad MaqsoodCopyright:

Available Formats

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

Name

Author

Muhammad Ismail

Reviewed By

Rehan Siraj

Signature

Page 1

Date

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

Table of Contents

Page No.

1. Buffer storage Area

2. Neutralization Area

3. Feed tanks Area (A1-2504A/B/C)

4. Feed chiller Package (Z1-2578)

5. Deep shaft package (Z1-2538)

6. Deep shaft operation procedure

7. Air Compressor (C1-2527A/B) system

8. Degasser (A1-2510A/B) system

9. Clarifier (A1-2511A/B) system

10. Tertiary treatment Package

11. Sludge Handling Package Z1-2549

Page 2

03

09

13

15

26

28

31

35

38

42

48

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

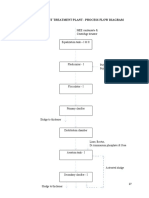

1. BUFFER STORAGE SYSTEM SCOPE

This instruction describes the effluent storage in buffer tanks A1-2500A/B/C/D.It covers the intial lining

up of the effluet in the buffer tanks,shutdown and normal operation of the buffer tanks and the effluent

feed pumps G1-2501A/B/C/D.

1. INTRODUCTION:

Plant effluent from core and non-core plants is collected for treatment in buffer tanks; A12500A/B/C/D. Contaminated water run-off from non-core areas is collected in drainage pits and

pumped over to the buffer storage tanks A1-2500 A or C. The general effluent drainage of the

effluent from core plant is collected in the core pit A1-850 and is pumped to effluent plant as waste

water via G1-851A/B .Waste water stream is cooled by E1-2526 a plate and frame type heat

exchanger with bypass. Waste water steam is mainly acidic in nature due to high percentage of the

PTA, CTA, and ACETIC ACID etc. Sometimes it becomes basic due to the excessive caustic wash at

the core plant. The buffer storage also receives direct discharge of mother liquor by diversion of its

normal flow to the neutralization by manual isolation valve now this is not applicable.

2. EFFLUENT STORAGE IN BUFFER TANKS

1.1. INITIAL CHECKS

1.

Check all PTW are completed and duly signed off.

2.

Physically check all equipment for mechanical jobs completion.

3.

Ensure all slip plates are in proper position and all drains are closed.

4.

Check all instruments are in place and on line.

5.

Check availabilities of utilities like:

a.

Instrument air

b.

Seal water for transfer pumps

c.

Potable water supply in safety shower

4.

Check that FT-5001, FT-5008, FT-5021 and Ft-5024 are normal.

5.

Check instrument air supply to LT-5012, LT-5013, LT-5014 and LT-5015 (buffer tank A12500A/B/C/D tank level transmitters) bubbler type.

6.

Checks tank is ready to take the effluent.

Page 3

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

3. NORMAL OPERATION

1. Mother liquor is not to be diverted to neutralization plant even mother liquor filter M1-1603 is inservice or not .It is due to the reason that pH probes of the both F1-2508 and F1-2519 may be

damaged due to the high temperature of the mother liquor.

2. Effluent of the plant to be lined up in the buffer storage tanks and changeover the mother liquor and

waste water accordingly.

3. Quality-wise the effluents of the plant to be lined up in the buffer storage tanks and divert the waste

water or mother liquor accordingly.

4. Physically check the level of the buffer tanks and update the DCS board man .In order to avoid the

overflowing the buffers due to malfunction of the level transmitters.

5. To increase the flow of effluent from the buffer storage tank or to take effluent from another buffer

tank FCV-5001/5008/5021/5024 should not open more than 5% at -a -time. This is due to avoid the

entrainment of the PTA powder to neutralization section and feed storage tanks A1-2504A/B/C/D.

6. Disturbance in the oxidation plant, i-e, M1-1603 by passing causes high COD effluent flow to the

buffer storage section, due to this lineup the mother liquor to the dedicated buffer. High COD

effluent will reduce the total hydraulic load of the deep shaft, so buffers management will be

required.

7. When waste water flow from the G1-851 A/B start to decrease than open the bypass valve of the

E1-2526 and check the flow, if it become normal, inform to the shift manager for chocking of inlet

strainer of E1-2526. The PTA in effluent causes chocking of E1-2625 inlet strainer.

8. Check that all pumps G1-2501A/B/C/D are available in healthy condtion and can be taken in

service.

4. EFFLUENT COLLECTION DURING PLANT SHUT DOWN

5. Select one buffer storage tank A1-2500 A/B/C/D before one week of the plant shutdown in order to

accommodate the plant flush effluent. Plant effluent may contain the metals which are toxic for the

bacteria.

6. Take maximum flow from this buffer storage tank during the week. It should not keep on filling.

Level need to be decreased up to minimum.

7. As the core plant put on flush after shutdown, then stop taking effluent from this buffer and lock

close the buffer outlet valve and stop the transfer pump G1-2501A/B/C/D.

8. Shift both waste water and mother liquor streams to this buffer storage tank, in order to collect the

effluent in one buffer.

9. Monitor the level of this buffer via DCS and also from area in order to avoid the overflowing of

effluent in other buffer storage tanks.

10. When core plant completes its flushing than take the sport sample of the both streams Mother

Liquor and waste water from IBCs sample point and check the cobalt and manganese result.

11. Line up the effluent in some other buffer storage tank if the result of the metals is normal.

Page 4

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

12. Put the buffer in which contaminated effluent is collected on settling for 24 hours then take the

sample for metals and carry out test, if metals found normal then line up this buffer for feed

preparation otherwise inform to shift manager.

5. SHUT DOWN OF THE BUFFER TANKS:

There is no shutdown in the effluent collection section, the effluent collection stop which is only for

the time being. Buffer storage pumps remain in service on kickback if required otherwise can be

stopped

only feed

to

neutralization

will

is

to

be

stopped

by

closing

the

FCV-

5001/5008/5021/5024.from DCS. For the cleaning of the buffers storage isolate the valves of this

buffer storage tank and carryout the necessary preparation for cleaning as per given procedure.

1.2. Procedure for the PTA Sludge removal From Buffer Tanks A1-2500A/B/C/D

List of the equipment to be utilized for the cleaning of the buffer tanks

S#

Equipments

Quantity

1.

Crane

01

2.

Clamp Bucket

01

3.

Dump Trucks

List of the manpower required for the buffer cleaning purpose

S

#

1

2

3

Manpower

Quantity

Supervisor

Rigger

Assistant Riggers/Helper

1.

2.

3.

1. PTW will be issued for seven days and re-validate it daily in the morning. However job will be

started daily at 08:00 hrs till sunset and will continue on Sunday and gazetted holidays.PTW

revalidation will be done at site to avoid any delay in the job.

2. Safety signs would be displayed for crane and dumpers activity.

3. No entry signs to be posted for restriction of entry of unauthorized persons/traffic to avoid any

safety incident.

4. The crane and dumpers activity area to be hard barricaded with an entry gate. A crane and only

one dumper will be parked inside barricaded area. The other waiting dumper to be parked

Page 5

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

outside the barrication. PTA will provide scaffolding team and material, while Descon will give

the exact requirement of scaffolding.

5. Tanker cleaning activity to be carried out during daylight only.

6. A scaffolding platform along with ladder on the tank to be erected by PTA scaffolding team

with plant scaffolding material.

7. Bucket movement will be controlled through a tie-rope by a rigger to avoid its hitting the tanks

walls or other surfaces.

8. The tank cleaning staff will wear proper PPEs including splash goggles, PVC gloves and

rubber boots.

9. Dump truck water arrangement will be made at working site and working staff will be changed

after every 60 minutes.

10. A resting area i.e. tank with bench/chairs will be provided near work area but outside the

barrication.

11. Immediately reported any safety incident to PTA plant area operator, who will report the matter

to Utilities shift manager.

12. All standard safety instructions and operating procedures must be followed at work site.

13. Dispensation for hot work permits for crane to be arranged by PTA (if needed).

14. Descon will explain the job method and give task instructions to their workforce before starting

the job.

15. Bucket will be inspected at least once a week. Inspection will be arranged by PTA planning, to

avoid the wastage of contractors man-hours inspection will be done in time.

6. BUFFER TANK CLEANING PROCEDURE WITH CRANE

1. Park the crane inside the barricaded area where it will be operated.

2. The crane weight will be taken on outer riggers (jacks) with no load on wheels to ensure

balanced operation of the crane.

3. In order to ensure that crane bucket is not touching with tanker bottom. The crane bucket rope

will be marked up to 6000 mm (including basket height) and this mark should be clearly visible

and must remain outside the top surface of the PTA sludge.

4. The tank will be prepared for the entry and it will be handed over to maintenance staff before

starting cleaning operation.

5. Once dumper is parked for loading sludge. Its engine must be switched off and driver should go

to the tent. No one will enter the work site without proper PPE.

6. The rope tied up with the bucket will be held by a rigger positioned at scaffolding platform; the

rope will further be knotted with scaffolding pipes. When the bucket is at height the rigger will

loose the rope slowly in such a manner that it will not hit the tank surface or sidewalls.

7. Another rigger must be positioned at scaffolding platform who will direct the crane driver

regarding bucket movement; He will watch the depth of bucket inside the sludge tank and will

ensure the depth mark on the bucket rope that it does not touch the sludge tank top surface.

8. The site supervisor must ensure that no person is doing any activity under the crane operation.

Page 6

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

9. No sludge should fall on any person

10. Standard safety instructions for crane working must be followed.

11. The loaded dumpers will be weighed as per instructions sheet PTA Management, which would

be basis of sludge load calculation. Daily verification sheet be submitted along with the invoice.

12. Having loaded the dumper the empty bucket to be lowered down the ground and dumper would

be off loaded to desponding area.

13. Inside plant the dumper speed should not to exceed 25 km / hr.

14. The work site housekeeping must be carried out daily on closing the crane activity by Descon.

15. Crane boom will be assembled near the PTA engineering workshop area with the assistance of

PTA hydraulic crane.

7. Job method for the Leak Repair or Lining in Buffer Tank With Man riding basket

1. Crane Man riding Basket, Safety Harness, Ropes & Lifting Gear to be Inspected/Checked by

PPTA Rigging Supervisor.

2. Two trained experienced persons of Man riding Basket can do the job at-a-time.

3. Area barrication and sign posting must be done prior commencing the job.

4. Two guy ropes (Tag line) must attach with the Man riding Basket to prevent the unnecessary

swing.

5. Attached the harness with crane hook separately all the time and do not attach it with the man

riding basket.

6. The whole activity must be supervisor by the designated mechanical supervisor and job will be

audited time to time by SHE Department.

7. In case of any abnormality the activity shall be stopped immediately.

8. The maintenance staff shall secure their Tools/ equipment with a rope to prevent the equipment

falling in the pit.

9. The crane operator, with the help of a banks man shall keep the movement of the basket to the

minimum possible to avoid the basket from hitting the pit wall or lining and crane operator will

be in their cabin during the activity.

10. The whole activity to be carried out in daylight 8:00 to 18:30 hrs.

11. Instructed PPE for the job are clear L.E.P, Helmet with chin guard ,one Radio set and rubber

boots. ( If required )

8.

Page 7

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

2. Feed Neutralization System

1. INTRODUCTION:

Effluent from the buffers storage is transfer to the first neutralization tank F1-2508 via G1-2501

A/B/C/D under flow control via FCV-5001/5008/5021/5024, with an option of taking mother liquor and

CRU spent soda ash effluent into it. Caustic soda is added in to it in the form of 5% and 47% for pH

controlling purpose between5.5 to 6.0.

Effluent from F1-2508 overflows into second neutralization tank A1-2519.Caustic and HCL can be

added to this tank (depend upon pH) but due to the presence of the acid mostly pH remains in the acidic

range so HCL tank is now relocated and lines are slip plated in this neutralization tank. The pH is

maintained between 6.0 to 6.5.The effluent overflows into outlet chamber A1-2502 from where this

effluent is supplied to feed storage tanks A1-2504 A/B/C via feed cooler E1-2518 A/B.

Feed storage tanks A1-2504 A/B/C receive the neutralized effluent for final flow to biological reactor in

secondary treatment section of effluent treatment plant. Feed flow is controlled via FCV-5068

accordingly to COD load on deep shaft.

2. STARTUP OF THE NUTRALIZATION SYSTEM

INITIAL CHECKS:

1. Check that all PTWS are signed off.

2. Ensure all slip plates are in proper position and all drains are closed.

3.

4.

5.

6.

7.

8.

Check all mechanical jobs are completed and system is ready to take the effluent.

Check the effluent level in the buffer storage tanks A1-2500A/B/C/D is sufficient.

Check that G1-2501A/B/C/D are available.

Check that FCV-5008/5001/5021/5024 are working normal.

Check that G1-2508 and G1-2519 are electrically energized.

Check the availability of the following utilities

i.

ii.

iii.

iv.

v.

9.

10.

11.

12.

13.

14.

47 % caustic soda.

Seal water

Cooling water

Instrument air

Portable water for the Safety shower

Check that QT-5027/28/30/31 are available and calibrated.

Check that LT-5032 is working normal and its stroke checks completed.

Check that G1-2503A/B area available.

Check that overflow line towards buffer tank is de-isolated

Check that mother liquor line to F1-2508 is slip plated.

Check that CRU soda ash supply is offline.

Page 8

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

1.

2.

3.

4.

5.

6.

7.

8.

9.

UTY Plant Operating Procedure

ETP plant (Revision: 01)

STARTUP

For the cold startup open fire water in the F1-2508 and fill the tank up to 20 %.

Line up the buffer storage effluent via G1-2501A/B/C/D.

Fill the tank and overflow this in the A1-2519.

Check the pH of the effluent via QT-5027/28 and calibrate them if required.

Start the agitator of the G1-2508 when it level reaches up 75 %.

Fill the A1-2519 and take the G1-2519 in service.

Check the pH of the effluent via QT-5030/31 and calibrate them if required.

Complete fill the A1-2502 and lineup 47% caustic to maintain the pH.

Check any abnormal sound in the G1-2508 & G1-2519 and inform to shifty manager about

abnormality.(if any)

10. When the effluent is completely neutralized and downstream system is ready to take the

neutralized effluent then take the G1-2503A/B in service as per given startup procedure.

3. G1-2503A/B NUTRALIZATION PUMP STARTUP

1. Check all PTWS are signed off.

2. Check the system for the completion of all mechanical jobs.

3. Check that pumps G1-2503A/B are electrically energized.

4. Check that seal water line isolation valve is open and its pressure is normal on the local PG.

5. Check that sufficient liquid level is available in the A1-2502.

6. Check that E1-2518A&B are ready to take the effluent.

7. Check that E1-2518 A&B cooling water is lineup.

8. Check that feed storage tank A1-2504A/B/C is ready to take the effluent.

9. Confirm that feed tank ZCV-5040/5045/5050 is operational.

10. Check that pump kick back line is minimum 10 % open.

11. Open the suction and discharge valve of the elected G1-2503A/B.

12. Check that LCV-5032 is 50% open.

13. Pull emergency stop button and push the start button.

14. Check the pump for any abnormal sound.

15. Pressure on the discharge PG-5038/5033 must be 3.5 to 4.0 barg.

16. Confirm that suction and discharge isolation valves of the standby pump are isolated.

4. G1-2503A/B CHANGEOVER PROCEDURE

1. Ensure that seal water is lineup to the standby pump G1-2503SA/B.

2. Open suction and discharge valve of the standby pump.

3. Ensure that spill back line valve is minimum 10 % open.

4. Pull emergency stop button and push the start button.

5. Check the pump for any abnormal sound.

6. Pressure on the discharge PG-5038/5033 must be 3.5 to 4.0 barg.

7. Press emergency stop button of the running pump.

8. Isolate suction and discharge valves and put the pump on standby

5. NORMAL OPERATION:

Page 9

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

1. Physically check the level of the F1-2508 and F1-2519 should be full upto the overflow because

low level can damaged the agitator.

2. Physical check any abnormal sound from the agitator of the all neutralization tanks, i-e, G1-2508

and G1-2519.

3. Switch off /stop the agitator if any abnormality is observed from them and inform to shift manager.

4. To increase the flow or start taking effluent from buffer storage FCV-5001/5008/5021/5024 to be

opened slowly not more than 5% at a time.

5. Check any abnormality in the pH at DCS (in the Process value and set point).

6. Mother liquor not to be lined up in the F1-2508 neutralization tank even M1-1603 is (mother liquor

filter) in service or not. It must remain line up in buffer storage tanks.

7. When there is low pH problem then check the acetic acid concentration in the buffers and also

check the buffers tank level physically.

8. When pH value in the A1-2519 is lower than 6 then do not forward this batch to the feed tanks F12504A/B.

9. When pH become low then reduce the flow from buffers and increase QT-5027 /5030 pH set

point.

6. EMERGENCIES:

In normal operation of the neutralization systems following emergencies can occur.

1. High or low pH disturbance due to the powder in the feed from the buffer tanks.

2. High or low pH issue due the malfunction of the QT-5027/5030.

3. Gear box problem of the G1-2508 & G1-2519.

4. Actuator failure of the LCV-5032.

5. Power failure

6. MCC# 22 power failure or any other issue on the MCC#22.

7. 47% caustic header leakage or G1-2621A/B failure.

8. G1-2503A/B duty pump failure while standby is under maintenance.

Page 10

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

3. Neutralized Feed Storage System

1. Introduction:

Neutralized and cold deep shaft feed is stored in the batch tanks A1-2504A/B/C. In A1-2504A/B/C

this feed is further circulated for cooling and mixing purpose. There are three tanks in this area; each

has working volume of 1350 M3. Neutralized feed is transfer in the batch tank where its sampling of

the COD and pH is carried out. If COD and pH are matching the required value ( i-e, <8000 and 6-9

respectively) then this batch is ready to transfer to the deep shaft otherwise this is diverted to buffer

storage area via divergent line located at outlet of the G1-2505A/B/C. in normal operation one feed

tank remains on filling second on the mixing and third on feed forward. Scope of this document is to

introduce the area operator about safe startup, shutdown and normal operation of feed batch tank area.

2. Start up of Feed/Batch Tanks A1-2504A/B/C

Initial checks

1.

2.

3.

4.

5.

6.

7.

8.

Check that all PTWs are signed off.

Physically check of all equipments for mechanical jobs are completed.

All slip plates are removed.

Check feed tanks are ready to receive the neutralized feed.

Check that neutralized feed is available in A1-2502.

Check that G1-2503A/B is available and are electrically energized.

Check that E1-2518A&B are available.

Check the availability of the following utilities:

i.

Cooling water

ii.

Raw water for sealing

iii.

Instrument air

9. Check the availability of the following instrument:

i.

Feed tanks inlet ZCV-5040, 5045and 5050 are in place and working normal.

ii.

Feed tanks LT-5041, 5046 and 5051 are in place and level indication is normal.

iii.

Feed tanks pH QT-5056, 5059 and 5062 are in place and working normal.

iv.

G1-2505A/B/C kick back ZCV-5044, 5049 and 5053 are in place and working normal.

v.

G1-2505A/B/C outlet ZCV-5044, 5049 and 5053 are in place and working normal.

vi.

Feed out let FCV-5068 is normal.

10. Check that G1-2505A, B& C are available.

Start up of the batch tanks A12504 A/B/C:

1. Open the inlet ZCV-5040/5045/5050 of the respective feed tank.

2. Open the isolation valves of the cooling water and process side of E1-2518A & B.

3. Check the system for any leakage of process and cooling water across the E1-2518A/B and

process inlet line of the A1-2504A/B/C .For this open suction and discharge isolation valves of

the G1-2503A/B and open the LCV-5032 100%.if observe any leakage then first rectify this

then start the G1-2503A/B.

4. Take G1-2503A/B in service as per SOP.

5. Open LCV-5032 with the set point of 50% on auto.

Page 11

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

6. Check E1-2518A&B discharge temperature on TIA-5067. It should be <45 0C.At-a- time both

E1-2518 A & B can be taken in service but one E1-2518A/B is enough for the maximum flow

of effluent.

7. Confirm LT-5041/5046/5051of the select feed tank working normal and cross check it from the

area.

3. Start up of the feed pump G1-2505 A/B/C:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

Check all PTWS are signed off.

Check the system for the completion of all mechanical jobs.

Check that pumps G1-2505A/B/C are electrically energized.

Check that feed storage tank A1-2504A, B & C any two are filled with neutralized effluent.

Check that seal water line isolation valve is open and its pressure is normal on the local PG.

Check that sufficient liquid level is available in the A1-2504A/B/C.

Check that E1-2582 is ready to take the effluent.

Check that E1-2582 chilled water is lineup.

Check that G1-2583 chilled water pump is in service.

Check that deep shaft package is ready to take the effluent.

Check that chiller package is ready to be taken in service.

Check that pump kick back line is 100% open.

Check that each pump feed diverge line to buffer storage area is fully isolated.

Open the suction and discharge valve of the elected G1-2504 A/B/C.

Check that FCV-5068 is fully close.

Pull emergency stop button and push the start button.

Check the pump for any abnormal sound.

Pressure on the discharge PG-5055/5058/5061 is normal.

4. NORMAL OPERATION:

1.

2.

3.

4.

Take the reading as per log sheet.

Check if any abnormality is in the parameters.

Check any abnormal sound from the pumps and inform to shift manager.

Before line up of any feed tank on forward ask board man about the COD and pH result. Its

COD must be < 8000 PPM and pH =6-9.

5. Purge the QT-5056, 5059 and 5062 once the in the shift.

6. Divert the feed back to buffer storage tan if the pH and COD are out of order.

7. The feed flow to the deep shaft should not be less than 50 m 3/hr because absorption chiller will

tripped on 50m3/hr as per logic.

5. EMERGENCIES:

Following emergencies can be occurred on this plant

1. Power failure.

2. FCV-5068 mal function.

3. Feed Quality (if it is out of order then transfer this to the buffer storage are via divergent line).

Page 12

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

ETP CHILLERS PACKAGE Z1-2578 OPERATING PROCEDURE

1. Startup of G1-2583 Chilled water pump:

1.

2.

3.

4.

5.

6.

7.

Check all PTWs are signed off.

Check that lube oil in the sight glass is 100 % full.

Open chilled water inlet & outlet valves of the G1-2583.

Check any leakage from E1-2582.

Take G1-2583 is in service.

Open the vent valve of the chilled water circuit located at the outlet line of G1-2583.

The expansion tank F1-2584 level should be 100 % full during the purging of the chilled water

circuit

8. On completion of purging close vent valve of the chilled water circuit

9. The sound of the G1-2583 should be normal.

10. Check the pump outlet pressure at the PG-5068; it should be around 2.5 brag

2. INTIAL PREPARATION OF Z1-2576 ABSORPTION CHILLER:

1.

2.

3.

4.

5.

6.

Check all work permits are signed off and returned.

Check all equipment for mechanical job completion.

Check G1-2583 is normal in service.

Check steam is available in the steam circuit.

Check steam inlet isolation valve is open and steam trap works normally.

Check condensate of the steam supply line is completely drained out from the steam circuit to

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

avoid the hammering in steam circuit and in the tubes of the absorption chiller.

Check chilled water inlet & outlet valves are opened.

Check cooling water inlet and out valves are opened.

Check if there is leakage from the chiller all supply circuits.

Check the lube oil level in the vacuum pump G1-2596.

Checks purge tank pressure it should be less than 2.0 kPa.

Check cooling water inlet pressure on the PG-5106 it should be higher than 3.5 barg.

Check chilled water supply pressure on PG-5105 it should be 2.5 barg.

Check absorption chiller power supply is resumed.

Check that the millennium panel works normally.

Check all parameter and set point of the absorption chiller.

Check that chiller ready to start is indication is appearing and on pressing the status key NO

MALFUNCTION appear.

18. Check that local mode is selected before taking the chiller in service.

3. Z1-2576 ABSORPTION CHILER STARTUP

1.

2.

3.

4.

5.

Complete the startup checklist.

Check ready to start indication is appearing on the millennium panel.

Before chiller startup inform to DCS board man.

Press the startup key of the absorption chiller.

Sequence of the absorption chiller startup is given as.

i.

First condensate drain will be open.

ii.

L.P Steam control valve FRC-5100 opening on panel in will start to increase.

iii.

When 1st stage generator pressure will reach to 6kpa then refrigerant pump will take

iv.

start.

When 1st stage generator pressure will reach to 15kpa then Solution pump will take

start.

Page 13

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

v.

vi.

UTY Plant Operating Procedure

ETP plant (Revision: 01)

Confirm that condensate coming out from condensate line properly.

Lithium bromide solution concentration will appear on the panel when 1 st generator

temperature will reach to 1210C.

vii.

Confirm that solution concentration should not exceed 63%.

6. Ensure that chiller is normal in service.

4. Z1-2576 NORMAL OPERATION

1. Take the reading as per log sheet

2. Manually increase the steam flow by opening drain isolation valve and communicate to DCS

3.

4.

5.

6.

board man.

Now check the chiller parameters and confirm that it is normal in service.

Check if any abnormality is in the parameters.

Check any abnormal sound and leakage from any header and inform to shift manager.

Keep the feed flow rate should be >50 m 3/hr in order to avoid the tripping of the absorption

chiller.

5. ABSORPTION CHILLER SHUT DOWN

1. Press stop button to stop the absorption chiller.

2. Check dilution cycle is started and it will remain for 20 minutes.

3. For the longer period physically isolate the L.P steam valve and ensure that no steam is passing.

6. Method for fault resetting of the Absorption chiller

Following are the steps to reset the fault.

1. Press Status key on the Panel of absorption chiller to check the

fault.

2. Press the Access Code on the panel.

3. Enter the password YORK. 9675

4. Press Enter on the panel and access accepted will appear on the

screen.

5. Press the MODE on panel and select the service mode.

6. Again press Enter on panel for the selection of service mode.

7. First press the Reset button second to start button (new changed

one) than press the warning reset on panel.(hold this for 30 seconds

to one min)

8. Press Status again on panel than warning should not be appearing.

9. Again repeat the steps #2, 3, 4, 5 to change the mode from service to

local only if the timer has expired, otherwise just repeat the step # 5,6

to change the mode (service

local).

10.

Take the chiller normal in service.

7. Method of Manual purging of purge tank:

NOTE: Dont open purge valve of condenser in any case while the absorption chiller is in service.

Page 14

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

1. The purge tank to be purge when the pressure exceeds 60 mmHg. The purge tank will be

evacuated until tank pressure is reduced to 30 mmHg.

2. The Micropanel should be set to operate in the manual purge mode.

3. Operate purge pump G1-2596 for 10 minutes to warm up oil with gas ballast open, leak rate

valve open and all purge system valves closed.

4. Check that the purge pump G1-2596 is capable of pulling down to at least 3 mm Hg by opening

manual valves slowly and reading the purge pump pressure on the vacuum indicator gauge.

5. Slowly open purge tank valve to read the purge tank pressure on the vacuum indicator gauge. If

the pressure exceeds 30 mm Hg absolute, the purge tank may be purged although it is not

necessary unless the tank pressure is equal to or exceeds 60 mm Hg absolute.

6. Slowly open purge tank valve. Watch the purge tank pressure. When it is lowered to 30 mm Hg

absolute, close the valves.

7. Run purge pump for 10 minutes more to clean up oil.

8. Method of Manual purging of the absorber:

NOTE: Do not purge the absorber if the absorber solution level is in the top sight glass of the

absorber shell, or solution may be drawn into the vacuum pump.

Dont open purge valve of condenser in any case while the absorption chiller is in service.

1. The Micropanel should be set to operate in the manual purge mode.

2. Operate purge pump G1-2596 for 10 minutes to warm up oil with gas ballast open, leak rate

valve open and all purge system valves closed.

3. Check that the purge pump G1-2596 is capable of pulling down to at least 3 mm Hg by

opening manual valves slowly and reading the purge pump pressure on the vacuum indicator

gauge.

4. Open the absorber purge valve to G1-2596.

5. After purging is complete, close purge valve to G1-2596.

6. Run purge pump for 10 minutes more to clean up oil.

9. EMERGENCIES:

Following are the possible emergencies in the absorption chiller.

1. Power failure.

2. L.P Steam failure

3. L.P Steam MOV failure

4. Cooling failure

5. Chilled water failure

6. Feed pump failure or lower flow rate <50 m3/hr.

Page 15

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

CENTRIFUGAL CHILLER C1-2580 A/B/C STARTUP

1. Initial checks:

1.

2.

3.

4.

5.

6.

7.

8.

All jobs are completed and PTW are signed off.

Check that chiller Z1-2580A/B/C main motor and auxiliaries power is on.

Check G1-2583 is in service.

Check that oil level in the sight glass is normal.

Check that oil reservoir temperature is > 60 0C or it must be refrigerant temperature plus 50 oC.

Check chilled water inlet and outlet isolation valves are fully opened

Check cooling water inlet and outlet valves are fully opened.

Check parameters and set points of chiller from the local panel (comfort screen) as

pressMENU from (CCN, LOCAL RESET, MENU) keys.

9. Then Press STAUS KEY

10. Bring the cursor to STATUS O1 by pressing PREVIOUS or NEXT key then press

SELECTKEY. The screen will start showing the status of all parameters on that condition and

respective keys will change to NEXT,SELECT,EXIT,

11. After checking all the parameter press EXIT KEY twice to come at first screen.

12. To check the set points press the MENU KEY and then press SET POINTkey. The screen

will show the set points as

i.

Base demand limit

100 %

ii.

LCW set point

9.0 oC

iii.

ECW set point

18 oC

iv.

Ice build set point

4.4 oC

13. Bring the first screen by pressing the ENTER and then EXIT key.

2. STARUP OF THE C1-2580A/B/C

1. LOCAL STARTUP (MANUAL STRATUP):

i.

Local startup is initiated by pressing LOCAL menu soft key on comfort screen. Local

start-up can proceed when the chiller schedule indicates that the current time and date

have been established as a run time and date, and after the internal 15-minute start-tostart and the 1-minute stop-to-start inhibit timers have expired. The timer must expire

ii.

before the chiller will start.

Once local start-up begins, chiller; control system performs a series of pre-start tests to

verify that all pre-start alerts and safeties (i.e. number of starts , bearing temperature,

motor

temperature,

compressor

discharge

temperature,

evaporator

refrigerant

temperature, oil sump temperature, condenser pressure and line voltage) are within the

iii.

limits then control reads PRESTART otherwise the startup will be delayed or aboard.

If chiller reads PRESTART then the following sequence will start.

a. The chilled water relay energizes, and the MAINSTAT screen line now reads

STARTUP.

b. After Five seconds, the cooling water relay energizes.

c. After point b (minimum 30 seconds to maximum 5 minutes) the control system

monitors the flow of chilled water and cooling water by the PDS-5230/32/5234 &

PDS-5229/31/5233 respectively.

Page 16

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

d. Now control system will check the chilled water temperatures against set point. If

temperature will be below or equal to the set point plus chilled water dead

band then sequence will not proceed and if the chilled water temperature is high

enough, then start-up sequence continues.

e. Now control will check the guide vane position. If the guide vanes are more than

f.

4% open, the start-up waits until the control system closes the vanes.

If the vanes are closed and the oil pump pressure is less than 4 psi (28 kPa), the oil

pump relay energizes. The control system then waits until the oil pressure reaches

a maximum of 18 psi (124 kPa). Oil pressure verified (15 seconds minimum, 300

seconds maximum after point e.)

g. After oil pressure is verified, the control system waits for 40 seconds, and the

compressor start relay (1CR) energizes to start the compressor.

3. NORMAL OPERATION OF C1-2580 A/B/C

1. Take the reading as per log sheet.

2. Check the Running System After the compressor starts, the operator should monitor the

control screen display and observe the parameters for normal operating conditions.

3. The oil reservoir temperature should be above 120 F (49 C) during shutdown.

4. The bearing oil temperature accessed on the COMPRESS table should be 120 to 165 F (49 to

74 C). If the bearing temperature reads more than 180 F (83 C) with the oil pump running, stop

the chiller and determine the cause of the high temperature. Do not restart the chiller until

corrected.

5. The oil level should be visible anywhere in one of the two sight glasses. Foaming oil is

acceptable as long as the oil pressure and temperature are within limits.

6. The oil pressure should be between 18 and 30 psid (124 to 207 kPad) differential, as seen on the

control panel default screen. Typically the reading will be 18 to 25 psid (124 to 172 kPad) at

initial start-up.

7. The moisture indicator sight glass on the refrigerant motor cooling line should indicate

refrigerant flow and a dry condition.

8. The condenser pressure and temperature varies with the chiller design conditions. Typically the

pressure will range between 60 and 135 psig (390 to 950 kPa) with a corresponding

temperature range of 60 to 105 F (15 to 41 C). The condenser entering water temperature

should be controlled below the specified design entering water temperature to save on

compressor kilowatt requirements.

9. Cooler pressure and temperature also will vary with the design conditions. Typical pressure

range will be between 60 and 80 psig (410 and 550 kPa), with temperature ranging between 34

and 45 F (1 and 8 C).

10. Check the chiller for any abnormal sound and inform to shift manger about the abnormality.

11. Check G1-2583 for any abnormal sound and the cavitation of the pump.

Page 17

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

12. Check any external leakage in E1-2582 (large quantity of the makeup water indicates that there

is some leakage of the chilled water inside the circuit this continuous makeup water will not

give the required cooling).

13. If two chillers are parallel in service and chilled water entering temperature reaches to the 16 0C

then stop one of the chillers in order to run one chiller on maximum load.

14. Start the second chiller when the chilled water entering temperature is 22 to 23 0C.

4. SHUTDOWN OF THE C1-2580A/B/C:

In normal operation there is no shutdown of the chillers, it is only stopped when there is low heating

load at the chiller, the feed flow to deep shaft is below than 5o m 3/hr or any maintenance is required.

Chiller shutdown begins if any of the following condition occurs:

1. The STOP button is pressed for at least one second (the alarm light blinks once to confirm the

stop command)

2. A recycle condition is activated

3. The time schedule has gone into unoccupied mode

4. The chiller protective limit has been reached and chiller is in alarm

5. The start/stop status is overridden to stop from the control network.

The chiller shutdown sequence is given as below:

a. When a stop signal occurs, the shutdown sequence first stops the compressor by deactivating

the start relay (1CR). Status message of SHUTDOWN IN PROGRESS, COMPRESSOR

DEENERGIZED is displayed, and the compressor on time and service on time stop.

b. The guide vanes are then brought to the closed position.

c. The oil pump relay and the chilled water pump relay shut down 60 seconds after the

compressor stops.

d. The condenser water pump shuts down at the same time if the ENTERING CONDENSER

WATER temperature is greater than or equal to 115 F (46.1 C) and the CONDENSER

REFRIGRANT TEMP is greater than the CONDENSER FREEZE POINT plus 5 F (150C).

e. The stop-to-start timer now begins to count down. If the start-to-start timer value is still

greater than the value of the start-to-stop timer then this time displays on the control logic

display screen.

*Certain conditions that occur during shutdown can change this sequence.

f.

If the AVERAGE LINE CURRENT is greater than 5% after shutdown, or the starter contacts

remain energized, the oil pump and chilled water pump remain energized and the alarm is

displayed.

g. The condenser pump shuts down when the CONDENSER PRESSURE is less than the COND

PRESS OVERRIDE threshold minus 3.5 psi (24.1 kPa) and the CONDENSER REFRIG

Page 18

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

TEMP is less than or equal to the ENTERING CONDENSER WATER temperature plus 3 F

(1.6 C).

h. If the chiller shuts down due to low refrigerant temperature, the chilled water pump continues

to run until the LEAVING CHILLED WATER temperature is greater than the CONTROL

POINT temperature, plus 5 F (3 C).

5. OPERATION OF CARRIER COMFORT SCREEN

1.

When chiller is in normal operation a massage on the LED screen appears RUNNING

TEMPERATURE CONTROL LEAVING CHILLED WATER. it changes to indicate the abnormality

(alarm/trip).

2. For checking the history and trouble guide from the screen carry out the following actions.

i.

Press

MENU

KEY

(This

key

changes

to

STATUS

ii.

SCHEDULE,SETPOINT,SERVICE

Press 1key four time to enter the password and you will observe the **** on the main

iii.

screen.

Note the alarm history / massage and press EXIT key.

6. SETPOINT CHANGING METHOD

NOTE: set point changing can only be done by the shift instrument tech ,shift manager or

3.

4.

5.

6.

plant manager.

Press MENU key

Press SETPOINT key.

Bring the cursor to the desire setpoint by pressing NEXTOR PREVIOUS KEYS.

Press select key

The cursor on that set point and the keys will change to

INCREASE,DECREASE,QUIT,ENTER.

7. Press key INCREASEOR DECREASE to change the value of the required set point

8. Press key ENTER

9. Again press keyEXIT;

7. Refrigerant charging (HFCKLEA134a)

When chiller is in operation and refrigerant makeup is to be done.

1.

2.

3.

4.

5.

Confirm evaporator bottom valve which is used for the refrigerant charging is close.

Remove the plug of the refrigerant charging line slowly.

Fit the Gas charging adaptor at the place of plug .

Fit charging manifold at adopter.

Slightly open the gas charging valve then manifold valve to remove the air from the manifold

pipes.(air purging is carried out to avoid air mixing with the refrigerant)

6. Fit manifold middle pipe at the cylinder valve and keep this valve with minimum opening,

slightly open the manifold valve, as some refrigerant starts coming from this then tight manifold

pipe.

7. Keep cylinder valve open in downward direction and open the cylinder valve then manifold

valve and start the refrigerant charging in the chiller.

8. Manual Guide Vane Operation:

Page 19

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

It is possible to manually operate the guide vanes in order to check control operation or to

control the guide vanes in an emergency. Manual operation is possible by overriding the target

guide vane position.

1. Access the COMPRESS screen on the control screen and scroll down to highlight TARGET

GUIDE VANE POS.

2. To control the position, use the INCREASE or DECRESE soft key to adjust to the percentage of

guide vane opening that is desired.

3. 0% is fully closed and 100% is fully open. To release the guide vanes to automatic control, press

the RELEASE soft key.

NOTE: Manual control overrides the configured pull down rate during start-up and permits the guide

vanes to open at a faster rate. Motor current above the electrical demand setting, capacity overrides,

and chilled water temperature below the control point override the manual target and close the guide

vanes.

9. EMERGENCIES:

Following emergencies are possible

a) Feed is not available for deep shaft due to high pH and high COD in A1-2504A/B/C and the level of

the feed tanks is full.

1. Stop all chillers and divert 50 % feed tank in buffer A/C.

2. Add high pH effluent in this feed tank and check the pH from the lab and also calibrate the pH

analyzer of this feed tank.

3. When pH is in the normal range, then open feed to deep shaft at the minimum flow rate of 55 m 3/ hr

via FCV- 5068 and start the chiller.

4. If the FCV-5068 close stuck then all chillers need to stopped, as there is no bypass available for

5.

6.

7.

8.

9.

10.

11.

FCV-5068.

Heavy leakage in the cooling water circuit.

Heavy leakage in the chilled water circuit..

Failure of the G1-2583.

Heavy leakage in the E1-2582.

Fault in the MCC#21 & 22 the chiller trips.

Power failure

Chiller control mal operation.

Page 20

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

DEEP SHAFT PACKAGE (Z1-2538) OPERATION

1. INTRODUCTION:

The Deep shaft effluent treatment package (Z1-2538) treats effluent from PTA plant. The objective of the

deep shaft is to reduce the chemical oxygen demand and concentrates the suspended solids in order to

achieve the discharge effluent quality.

The PTA plant deep shaft package (Z1-2538) consists of the mixing box (A1-2562), deep shaft head tank

(A1-2547), deep shaft (A1-2507), Degasser (A1-2510A/B), degasser blower package consists of the two

degasser blowers (C1-2509A/B) with two degasser ventilation fans (C1-2514 A/B),clarifier basins (A12511A/B) with clarifier scrapers (G1-2511 A/B), RAS pumps (G1-2512A/B/C) and air compressor

package consisting of two Air compressor (C1-2527A/B) with auxiliaries equipment.

The mixing box (A1-2562) receives the effluent from the three areas of the effluent treatment plant. The

main flow is aqueous effluent from PTA plant which has been neutralized and then cooled by the chiller

package Z1-2578.The remaining flow consists centrifuge concentrate return via G1-3107A/B and

tertiary clarifier A1-3102 sludge transfer pumps G1-3104 A/B.These effluents are mixed with the return

activated sludge from the clarifier basin A1-2511A/B coming through the RAS pumps (G1-2512 A/B/C).

These influents are fed continuously via an underground side pipe to the down comer side of the deep

shaft (A1-2507) which dilutes the large volume of the liquor recirculating with in the deep shaft. In deep

shat the effluent is contacted with the biomass and oxygen to biochemically oxidize the organic

pollutants. The oxygen for the biochemical reaction is provided by air compressor package (C12527A/B).Air is injected in the deep shaft via six down comers and six risers sparge pipes. The treated

effluent liquor overflows form deep shaft head tank to the integral off-take channel to A1-2510A/B

degasser. Degassing is achieved from the bubbling air through the liquor via a system of sparge pipe

situated on the floor of the degasser. Air for degassing is supplied by C1-2509 A/B. This degassed liquid

is transferred to the clarifier A1-2511A/B via underground pipes under the gravity flow. The settled

sludge is transferred to the deep shaft via G1-2512A/B/C (Return Activated sludge pumps) and

remaining fluid is bleed off to sludge centrifuge M1-2548 A/B as WAS (waste activated sludge).The

overflow of the clarifier is mixed with coagulant and then flocculent then it moves to the A1-3102

tertiary clarifier. The sludge of A1-3102 is transfer to deep shaft via G1-3104A/B and the treated effluent

is drained to outfall.

Page 21

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

1. DEEP SHAFT OPERATION:

Deep shaft operation is maintained on the basis of plant load and effluent condition, there are three

defined ways to operate the deep shaft process and details of each method are given below:

NORMAL OPERATION

This condition refers to plant operating at process feed flow sheet of combined influent of 213.6

m3/hr and a COD load of up to 18.4 te /day. Under this regime normally both degasser and both

clarifier basins are operational. However it is possible to run the plant with one degasser lane and

one clarifier. During the normal plant operation one degasser and one clarifier can be handed over

for maintenance.

MAXIMUM OPERATION

This condition refers to the plant operating at process feed flow rates of combined influent between

213.6 m3/hr to 322.6 m3/hr with COD load between 18.4 te /day to 26.5 te/day. Under this regime

both degasser lanes (A1-2510A/B) and clarifiers (A1-2511A/B) must be operational.

TICKOVER OPEARTION

Deep shaft is designed to operate continuously. During the period of plant shutdown the deep shaft is

operated at low flow which is called tickover (to run the plant at low COD load without any major

change) operation.

Under above described conditions the plant must be left on tickover to prevent anaerobic condition

occurring in the process. This requires one compressor, one degasser blower, both clarifiers scarpers

and at least two RAS pumps in service. In this condition one clarifier can be taken offline. It is

necessary to reduce the MLSS concentration in the deep shaft during tickover to prevent excessively

low F/M (How much food a single pound of organisms will eat every day) ratio which loads to

the long sludge age. Long sludge age may lead to nitrification in the clarifier basins. This in turn can

lead to sludge floatation as the nitrogen attaches itself to the flocs.

Page 22

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

DEEP SHAFT OPERATING PROCEDURE

2. FILLING OF THE DEEP SHAFT PACKAGE

NOTE: only applicable for initial start up of deep shaft or when deep shaft is completely drained out

1. Check all work permits are signed off and retuned.

2. Check all isolation gates are removed for plant normal operation.

3. Check that isolation gate is located on its position for positive isolation if one of the degassers

4.

5.

6.

7.

8.

or clarifiers is under maintenance work.

Put a fire water hose into the mixing box (A1-2562) and open the water.

Check that deep shaft is completely filled with fire water.

Confirm that deep shaft, degasser and clarifier basins are completely filled with water.

Stop the fire water filling in the deep shaft package.

Deep shaft system has been filled with water and is ready for biomass seeding.

3. SEEDING THE DEEP SHAFT WITH BIOMASS

NOTE: It is applicable only for

Initial startup

After any ETP shutdown

After loss of MLSS during the normal operation of ETP

1. Check that whole system is filled with water/ liquor.

2. Check that sufficient activated sludge seed is available near the deep shaft mixing box. Seed

may be provided by the vendor or by local resources.

3. Check that maximum biomass seed is available on the site because it should take minimum

4.

5.

6.

7.

8.

9.

time to seed the maximum biomass in the deep shaft.

Confirm that WAS outlet valve is lock closed, to avoid the loss of the biomass.

Start the degasser blower C1-2509A/B

Start the clarifier scraper G1-2511A&B

Start the RAS transfer pump G1-2512A/B/C any two selected pumps.

Start the deep shaft air compressor C1-2527 A/B.

Confirm the concentration of the dissolve oxygen on DCS at QT-5142 and also locally check it

with the help of portable DO meter. It must be greater than 2 ppm.

10. Start the dosing of the Nutrient by taking the G1-2525A/B in service and maintain the reserves

11.

12.

13.

14.

15.

16.

17.

18.

of phosphate, ammonical nitrogen and ammonia in the deep shaft.

Add the activated sludge in the deep shaft gradually in the mixing box.

Check the MLSS on daily basis.

Line up fresh neutralized feed to deep shaft by opening the FCV-5068 gradually.

Check the deep shaft feed temperature it should be less than 18 oC on TT-5083.

Start the chiller package (Z1-2578) to cool the deep shaft feed up to desired temperature.

Increase the flow to deep shaft as MLSS concentration increases in the deep shaft.

Stop the seeding of biomass as MLSS concentration reaches to 5000.0 mg/l in the deep shaft.

Adjust all the parameter of deep shaft as per design operating conditions.

4. DEEP SHAFT START UP FROM TICKOVER/SHUTDOWN

1. Confirm that sufficient biomass is present in the deep shaft.

Page 23

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

2.

3.

4.

5.

6.

7.

8.

9.

10.

UTY Plant Operating Procedure

ETP plant (Revision: 01)

Confirm that deep shaft is filled with liquid.

Start the degasser blower C1-2509 A/B after filling its startup check sheet.

Start the Clarifier scraper of G1-2511A&B after filling its startup check sheet.

Start the air compressor (C1-2527 A/B) and lineup the air to deep shaft.

Confirm the rotation of the deep shaft; it must be anticlockwise from the head tank.

Confirm the degasser (A1-2510 A/B) is giving the even distribution of the air bubbles.

Start the chiller package (Z1-2578) as per SOP.

Start the RAS pump G1-2512 A/B/C any two of three pumps.

Adjust the RAS and WAS flow as per deep shaft condition by adjusting the air flow at

pneumatic PCV-5213 also check the pressure on the PG-5376.

11. Gradually increase the load on the deep shaft.

12. Monitor all the parameters of the seep shaft.

5. INCREASE THE LOAD FROM NORMAL TO MAXIMUM OPERATING

CONDITION

1. Check that both degasser lanes (A1-2510 A/B) are in service and normal.

2. Check that both clarifiers (A1-2511 A/B) are in operating condition, if one of these is not in

operation then increase in flow is not permitted.

3. Check the flow rate according to COD load.

4. Increase the air flow rate to deep shaft up to the required amount at the defined rate, by

opening the guide vanes of the on duty air compressor C1-2527A/B.

5. Check that chiller package is ready to take the high heat load.

6. Increase the flow to deep shaft via FCV-5068.

7. Increase the RAS flow rate adjusting the requirement by the PVC-5213, FCV-5130 (vortex

type) in order to maintain the deep shaft MLSS concentration in the region of 5000 mg/l.

6. DECREASE THE LOAD FROM MAXIMUM TO NORMAL OPERATING

CONDITION

Such condition occurs when either one degasser / clarifier needs to be handed over for

maintenance job or effluent COD condition dictate to reduce the load.

1. Reduce the load on deep shaft.

2. Check the COD of the feed samples (ET-06/07/08).

3. Decrease the air flow to deep shaft by decreasing the guide vanes of the duty compressor.

4. Decrease the RAS flow by maintaining the set point of the PCV-5213.inorder to maintain

the MLSS concentration in the region of 5000 mg/l.

After these changes one degasser and clarifier can be handed over for maintenance job

.

Page 24

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

DEEP SHAFT NORMAL OPERATING INSTRUCTION

1. Startup of the deep shaft (Air introduction)

1.

2.

3.

Ensure that biomass is present in the deep shaft.

Ensure that deep shaft is filled with liquid.

Start the air compressor (C1-2527A/B), ask DCS board man to open the FCV-5120 up to

4.

100%on manual.

Check that all the air is flowing to the riser pipes and the shaft liquor is circulating. Once all

5.

6.

7.

8.

the air flow is established to the risers and carryout the following steps

Wait for 10 minutes

Manually adjust the flow at FCV-5120 up to 1600 m3/hr.

Wait for further 15 minutes

Once the dissolved oxygen value reaches to >2 mg/l, adjust the air flow using the air

9.

compressor inlet guide vanes to its correct operating value of 4581 Nm 3/hr.

Confirm the deep shaft is now circulating at its normal operating point.

2. Normal operation of the deep shaft

1. Check the color of the effluent in the deep shaft head tank A1-2547, if the color is blackish

increase the WAS flow rate.

2. Check air flow and adjust by maintaining the dissolves oxygen in the head tank A1-2547, if

it is less than 2 PPM then increase air flow to deep shaft.

3. Check the foam on head tank A1-2547, if excessive foam is observed then add anti- foam

after asking from shift manager.

4. Check the temperature of the deep shaft tank A1-2547 if it is increasing above 38 0C open

fire water at deep shaft.

5. When feed to deep remains off line for a longer time then increase the air to risers by100

m3/hr.

6. Check the level of A1-3100, if it is higher, and then increase the RAS flow to deep shaft.

7. Check the air distribution is homogeneous in the degasser A1-2510 A/B. (Air is coming

from all sides) if air is not coming from effluent surface then check C1-2509 A/B discharge

pressure which should be higher than 0.5 brag. Otherwise start the standby blower.

8. Fortnightly change over the compressor as per plant routine document and follow the routine

change over procedure.

Page 25

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

3. Shutdown of the deep shaft

1. Stop the flow of the return activated sludge to the deep shaft feed mixing box by closing the

2.

3.

4.

5.

6.

pump outlet on the RAS line.

Reduce the RAS flow to the deep shaft and maintain the flow towards WAS.

Open the drain valve of the RAS line into the drainage pit.

Stop the influent flow to deep shaft; stop the feed pump G1-2505A/B/C.

Insert the isolating stop logs in the splitter box located at the outlet of the A1-2510A/B.

Increase the air flow rate from the compressor package to its maximum value by opening the

inlet guide vanes.

7. Open the riser air flow control valves FCV-5120 fully.

8. Stop the flow of WAS by stopping the RAS pump (G1-2512A/B/C).

9. Stop the clarifier scraper (G1-2511A/B/C) according to the SOP.

9.

Page 26

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

4. AIR COMPRESSORS (C1-2527A/B) STARTUP

Initial checks

1.

2.

3.

4.

5.

6.

All work permits are signed off on compressor and returned.

Check the power is available on compressor CMC control panel

Check the availability of the instrument air.

Check that cooling water valves (inlet and outlet) are fully opened.

Check that air outlet manual valve of the compressor is fully opened.

Open air bleeding valves of the stage cooler for a short time for removing the trapped air in cooling

water circuit then close.

7. Check that seal air valve is fully open. Logically compressor pre-lube oil will not take start without

seal air availability, in order to avoid the ingression of oil in the inter stage coolers.

8. Check that air knob is at zero, to start the compressor with no flow to deep shaft.

9. Check that the compressor is on un-load condition.

10. Check that down comer individual valves at the inlet of the each down comer are completely deisolated.

11. Check that the main isolation valve on the risers side is fully open. Ask Utilities DCS board man to

open FCV-5120 fully.

Air Compressor (C1-2527A/B) startup

1.

2.

3.

4.

5.

Fill the startup check list of the compressor.

Release emergency switches of the selected compressor.

Switch on the controlling power and check that the pre-lube oil pump is started.

Check the lube oil pressure it must be higher than 168 kPa.

Check that all parameters in the C1-2527 A/B MP-3 panel are normal and compressor ready

indication is appearing.

6. If compressor ready indication does not appear on the MP-3 panel then check all the parameters of

the compressor and identify the wrong parameter.

7. Inform to shift manager and see the trouble shooting guide.

8. Push the start button.

9. Keep the compressor in operation on unload condition for small time then press the load soft key on

10.

11.

12.

13.

CMC panel.

Confirm the opening of inlet valve and closing of the bypass valve.

Ask DCS Boardman to put the FCV-5120 on manual and open up to 100 %.

Turn the flow knob of the compressor from 0% to 100% gradually.

Increase air flow to deep shaft by rotating knob of air flow and set at 3000 m 3/hr (read at FIA-5360

A/B).

14. Check the flow direction of deep shafts, if it is normal, increase the flow to 3500 and then to 4000

m3/hr, otherwise decrease the flow to zero and find the reason.

15. Open the six valves of the deep shaft and check the direction of the deep shaft.

16. Ask DCS Boardman to put the FCV-5120 on auto with set point 1550 to 1600 m3/hr.

Page 27

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

17. Adjust the total air flow from air compressor to 4250 to 4300 m 3/hr at the FIA-5360, as per

requirement.

18. Check passing of stand by compressor discharge valve.

5. NORMAL OPERATION OF THE COMPRESSOR (C1-2527A/B)

1. Take the reading periodically of the air compressor as per log sheet.

2. Check any abnormal sound from air compressor if there is any abnormality then stop/changeover

the compressor and inform the shift manager about the abnormality.

3. Check that air traps are working properly; check the direction of deep shaft flow.

6. SHUT DOWN /CHANGEOVER OF THE ON DUTY COMPRESSOR

(C1-2527A/B)

1. On duty compressor can be changed over to the standby compressor

2. Compressor package is stopped completely due the some maintenance work on the compressor

discharge line.

3. For the compressor change over just apply the change over procedure of standby compressor

4. For the compressor shutdown carry out the following steps

5. Inform to DCS Boardman about compressor shutdown decrease air flow to zero by rotating the

knob to zero position and then unload the compressor.

6. Keep it un-load during for a few minutes and then push the stop button.

7. Keep the pre-lube oil pump in service for about fifteen minutes and then switch off the control

power.

8. Hand over the line for the maintenance

9. Stop G1-2505 A/B/C and fresh feed to deep shaft is standby compressor is not available.

Page 28

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

7. Start up of the degasser (A1-2510A/B) system

Initial Startup

1.

Check that splitter box, degasser and degasser outlet tank are full of liquid to the normal operating

2.

3.

4.

5.

6.

level.

Confirm that isolation stop-log in the splitter box and degasser outlet line is free to take in service.

Check the clarifier is ready to take the effluent.

Check that C1-2509A/B are ready to be taken in service.

Check that G1-2514 A/B ventilation fan is in healthy condition.

Select the degasser blower to be taken in service, start the ventilation fan of that blower and

7.

confirm that it is working normal.

Start the selected duty blower (C1-2509 A/B) as per startup procedure, and confirm that it is

normal in service.

8. Check that air bubble can be seen breaking the surface of the liquor in the degasser.

9. Check the discharge temperature of the blower at the TG-5244 it should be less than 100 0C

10. Check the discharge pressure of the blower at the PG-5242 and it must be less than .5 barg.

Degasser (A1-2510A/B) system is now operating normally.

8. Start up of the degasser standby blower C1-2509A/B

Before the startup of the blower ensure that both the standby blower and its ventilation fans are in

healthy condition.

1.

2.

3.

4.

Check all permit to work are signed off and returned.

Check that power of the blower is on.

Check that system is ready to be taken in service.

Check that plant air is available on nearby utility point with air hose, and air fitting is installed on

5.

6.

7.

8.

9.

10.

11.

the inlet line of the degasser.

Open the discharge valves of the selected blower (C1-2509A/B).

Start the ventilation fan of the standby blower and ensure that it is working normal.

Start the C1-2509A/B standby blower as per procedure.

Check that it is working normal.

Stop the running blower; stop the ventilation fan of this blower.

Close the discharge valve of the stopped blower.

Check that air bubble can be seen breaking the surface of the liquor in the degasser and that these

bubbles are evenly distributed across the surface.

The standby blower degasser blower has now been successfully started and lined up

9. Shutdown of the Degasser (A1-2510A/B) both/one lane

The degasser system will have shut down due to the following conditions

I.

Maintenance of the blower

II.

Air supply pipe maintenance

III.

Sparger pipe work maintenance

Page 29

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

10. Shutdown due to maintenance of C1-2509A/B

For the maintenance of the degasser blower the standby unit needs to be taken in operation to

continue the treatment.

1. Shut down due to Air supply pipe maintenance

For the maintenance of the air supply pipe work the degasser system must be completely shutdown.

If the maintenance period is likely to increase beyond 24 hrs and temporary plant air hose cannot

meet the requirement of the degasser then it is recommended to pump out the degasser and the

clarifier and put the deep shaft on just aeration. For shorter maintenance period it is not necessary to

pump out and flush the system.

2. Shut down due to Sparger pipe work maintenance

Degasser sparger piping maintenance requires the complete shutdown of the respective degasser

A1-2510A/B. For this following procedure applies.

1.

2.

3.

4.

5.

6.

7.

Ensure that deep shaft load has been deceased.

Stop the degasser blower C1-2509A/B and C1-2514A/B as per procedure.

Isolated the discharge valve of the degasser blower C1-2509A/B.

Insert the isolation stop logs in the splitter box and degasser outlet.

Drain the degasser completely for maintenance purpose.

Put the pneumatic pump in the degasser for completely draining it out.

After the complete draining erect the scaffolding, remove the pipe, carry out the maintenance and

installed back the sparger pipe.

8. Remove the scaffolding and revert the system on normal condition.

11. Normal operation of the Degasser A1-2510A/B

1. During normal operation air from the duty degasser blower is continuously sparged into the two

lanes of degasser.

2. It is possible to run with only one operational degassing lane at normal load flow although this

3.

4.

5.

6.

would only occur if one of the lanes had been shut down for maintenance.

Ensure that regular sampling of the degasser liquor is sampled to confirm the MLSS concentration.

Monitor the blower discharge pressure at PG-5242 and discharge temperature on TG-5244.

Check that the duty degasser blower is in healthy condition.

Check that a regular distribution of bubbles can be seen breaking the surface of the liquor in the

degasser.

7. Ensure that all the alarms are regularly monitored.(i-e,FSL-5314,etc)

8. Respond to alarm condition and rectify as necessary.

9. Ensure that degasser blower is running normal.

Page 30

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

12. ETP Clarifier A1-2511A/B system

This section describes the startup, shutdown, normal operation and maximum operation of the

clarifier system.

Startup of the clarifier Scrapers (G1-2511A/B)

1. Ensure that clarifier liquid level is at its normal operating level.

2. Ensure that all clarifier conditions are normal.

3. Start the clarifier scraper

The clarifier scarper is now operational.

Startup of the clarifier basin

1. Ensure that both stop-logs in the degasser outlet are removed.(if one clarifier is under

maintenance then the stop-log of that clarifier must be left in place)

2. Ensure that effluent starts to flow into the clarifier basin. This can be checked from the top of the

clarifier scraper bridge.

3. Check that effluent from the clarifier basins overflow the weir into the launder.

The clarifier basins are now operational normally.

13. Startup of the RAS pump G1-2512A/B/C

Initial Checks and Startup

1.

2.

3.

4.

5.

6.

7.

Check all work permits are signed off and returned.

Check pumps are electrically energized.

Check the lube oil level in the sight glass.

Check that suction isolation valves are open.

Check that discharge valve is close.

Check that WAS discharge valve is close.

Ensure that deep shaft is operational and is ready to accept the RAS and that the clarifiers are

full of liquid.

8. Ensure that before the start-up all conditions relating to RAS pumps to be started are healthy.

9. Start the selected RAS pumps (G1-2512A/B/C) after filling the startup chick list.

10. The RAS pump to be run with the isolation of the WAS valve unless the MLSS concentration in

the deep shaft reaches the operating level of the 5000 mg/l or sludge blanket level in the

clarifiers reach up to 3 feet.

11. Check that sludge centrifuge M1-2548A/B are ready to accept the WAS.

12. Open the WAS valve when MLSS concentration in the deep shaft ET-10 sample reaches to

operating level of 5000 mg/l.

13. Open the WAS take-off valve slowly to 100%.

Page 31

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

14. Increase the RAS pump discharge flow on FI-5130

by adjusting the opening of the pneumatic

air to the PCV-5213 located on the RAS line to its normal operating rate before opening the

WAS valve.

15. Daily monitor the concentration of the MLSS in the deep shaft and adjust the RAS flow to

maintain it accordingly.

The RAS pumps are operating normally 2 out of 3

14. Shut Down of one clarifier:

Under normal operating condition both clarifier basin are in use. However each clarifier is sized to

take all of the normal flow so that one clarifier basin can be shut down for maintenance without

effecting the operation of the plant. If the plant is operating on maximum load conditions then flow

must be reduced as per normal load conditions. One clarifier is mostly off lined due to the following

conditions.

1. For the cleaning of the clarifier basin

2. The inspection of the clarifier

15. Shutdown of one clarifier for cleaning

1.

2.

Insert the stop -log to the clarifier basin to be shut down

Drain the clarifier until all of the sludge has been pumped out by the RAS pumps. The decrease

3.

4.

5.

6.

7.

in the sludge blanket level can be monitored visually

Close the under flow valves from the drained clarifier.

Insert the blinds to prevent the back-filling from the A1-3100 coagulant mixing tank.

Stop the clarifier scarper of the shutdown clarifier basin.

Stop one of the duty RAS pump according to the requirement of the RAS flow.

Drain the remaining water from the shutdown clarifier basin using a submersible pump. The

8.

water should either be pumped to the working clarifier basin or the degasser outlet.

Put one fire water hose down to the bottom of the clarifier basin with water open for leaning

9.

purpose and pump out with the help of submersible pump.

Continuously monitor the sludge blanket level in the working clarifier and adjust the RAS / WAS

flow accordingly.

10. Check that clarifier is ready for the required job.

11. Carry out the necessary checks before entering the vessel.

12. Clarifier basin is now ready for the maintenance job.

16. Normal operation of the Clarifiers

During normal operation:

1. Ensure that samples of the deep shaft head tank liquor and the clarifier basin under flow are taken

to confirm the MLSS concentration in ET-10 sample.

2. RAS flow is adjusted according to the requirement of the plant.

3. Ensure that all alarms are regularly monitored.

4. Respond to all alarms conditions and rectify as necessary.

Page 32

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

5. Ensure that water is available for flushing when RAS pumps are stopped.

Ensure RAS pumps run in accordance with the required operating instruction.

Page 33

LOTTE PAKISTAN PTA

T-11 UTILITIES PALNT

UTY Plant Operating Procedure

ETP plant (Revision: 01)

17. EMERGENCIES: