Professional Documents

Culture Documents

MW Factsheet Membrane

Uploaded by

mohamedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MW Factsheet Membrane

Uploaded by

mohamedCopyright:

Available Formats

Membrane Processes

Forward Osmosis: Desalination

Modern Water owns, installs and operates world-leading membrane

technologies and we are the world-leader in Forward Osmosis (FO)

technology. We have successfully implemented and operated our

patented desalination process internationally and produce fresh water

in some of the most demanding seawater conditions in the world.

Our FO process consistently delivers significant reductions in

operational costs, reduced lifetime costs and it reliably produces high

quality product water, even in the most challenging conditions.

We use our world-leading FO technology platform in a number of

membrane process applications other than for seawater or brackish

water desalination. These include: evaporative cooling systems,

secondary oil recovery and the development of renewable energy

using hydro osmotic power (HOP).

FO desalination benefits

A proven, reliable and robust

membrane process

Energy consumption

typically up to 30% lower

than conventional Reverse

Osmosis (RO)

Inherently low fouling

characteristics (both

particulate and biological fouling)

Significantly reduced product

boron levels without post-treatment

when compared to conventional RO

Higher availability than

a conventional RO plant due to

low fouling, simple cleaning and

ease of operation

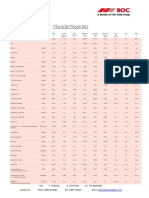

Forward Osmosis Vs Reverse Osmosis

Reverse Osmosis

(RO)

Membrane Fouling

Energy Consumption

Innovative process solution now

fully operational & commercially

available (Al Khaluf, Oman - the

worlds first commercial FO plant

began operation in 2010). 2

Competitive advantages

over RO.

Significant further process

improvements to come.

Extremely low inherent

fouling - low pressure, diffusion

driven process.

Possibility to consider

reduced pre-treatment.

* site dependent

FO Membranes are chlorine

tolerant allowing effective

treatment for bio-fouling.

Typically up to 30% less than RO.

The more difficult the feedwater

the higher the energy saving.

Mature, well established

technology (Coalinga,

California - the worlds first

commercial RO plant began

operation in1965).

Little further improvement likely.

High pressure - prone to

fouling, hydraulic forces increase

fouling - a key issue.

RO Membranes are not chlorine

tolerant.

Typically up to 30% more

than FO.

Any degree of fouling, higher

than FO.

Operational Costs

Boron Removal

Less than RO due to higher

availability, less chemical

cleaning and fewer membrane

replacements.

Extended membrane life

- FO membrane life typically

twice that of the equivalent

RO membrane.

Inherently high removal, without

the need for post treatment

(less than 1 ppm).

Very similar to RO, but with less

frequent cleaning and increased

membrane life.

More than FO due to lower

availability, higher energy costs,

more chemical cleaning and

membrane replacements.

Source

Water

(Seawater

or brackish

water)

Poor removal and may

require additional costly post

treatment system.

P1 - P2 >

Similar to FO but more

frequent cleaning and reduced

membrane life.

Process explained

Product 72 m 3/d

P2

Feed 288 m 3/d

RO

P1

A1 Khaluf FO Plant

A1 Khaluf, Oman

Reverse Osmosis (RO)

2kW

Feed 288 m 3/d

A1 Khaluf RO Plant

Brine 188 m /d

3

FO

FO Normalised Flow (m 3/h)

25kW

AI Khaluf FO Plant

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0.0

Product 72 m 3/d

Feed 288 m 3/d

Brine 216 m 3/d

Seawater or brackish

water feed

May 2010

2kW

AI Khaluf RO Plant

5.0

4.5

35% Conversion

Feed 288 m 3/d Membranes 4Installed

4.0

barg

August 2009, 4.2 m 3/h

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0.0

Jan 2010

Feb 2010

Mar 2010

Apr 2010

Jun 2010

Product 100 m 3/d

Regeneration

RO

A1 Khaluf

FO

Feb 2010

Mar

2010 Plant

Apr 2010

47% Conversion

65 barg

42% reduction in

energy consumption

vs RO at A1 Khaluf

25% Conversion

65 barg

Jan 2010

Normalised Permeate Flow (m 3/h)

35% Conversion

4 barg

Jul 2010

19kW

Aug 2010

Sep 2010

Oct 2010

Nov 2010

Reject from FO System

Dec 2010

Typical Year

47% Conversion

65 barg

Product in OA 100 m 3/d

Product 100 m 3/d

FO System

New Membranes Installed

Regeneration

FO

30% Decline in Output Over Just Five Months

May 2010

Jun 2010

Jul 2010

Typical Year

Aug 2010

Sep 2010

Concentrated

Osmotic Agent

Diluted

Osmotic Agent

3

/d on New Membranes

Brine

188 m

Cleaning

Activity

Oct 2010

Nov 2010

Dec 2010

Regeneration System

At the heart of the Modern Water

process is a recirculating osmotic agent

system that transfers pure water from

the feedwater (eg seawater) to the

regeneration (permeate extraction) system.

By linking two highly optimised systems,

the FO system and the regeneration

system, significant benefits are achieved.

19kW

Product in OA 100 m 3/d

42% reduction in

energy consumption

vs RO at A1 Khaluf

25% Conversion

65 barg

Brine 216 m 3/d

Forward Osmosis (FO)

Similar capital cost on a

like-for-like basis

Reverse Osmosis (RO)

25kW

Osmotic

Agent

(High

Osmotic

Pressure)

Similar capital cost on a

like-for-like basis.

P1

A1 Khaluf RO Plant

Source

Water

(Seawater

or brackish

water)

Capital Cost

P2

Osmotic

Agent

(High

Osmotic

Pressure)

Forward Osmosis (FO)

Ease of Operation

P1 - P2 >

Forward Osmosis

(FO)

Technology Status

Product Water

In the first stage, feedwater is fed under

low pressure to the forward osmosis

membranes, which are highly resistant to

fouling and are resistant to oxidising agents.

The osmotic agent, on the other side of

the membrane, draws fresh water from the

seawater due to a difference in osmotic

pressure. This fresh water dilutes the

osmotic agent.

In the second stage, permeate is extracted

from the system. The pure water is

removed from the dilute osmotic agent

which is regenerated (or concentrated)

for reuse in the first stage. This can be

achieved in a number of ways depending

on the proprietary osmotic agent selected.

To find out how we can help you please contact us on:

+ 44 (0)1483 696 000

Modern Water plc

Bramley House, The Guildway

Old Portsmouth Road

Guildford

Surrey GU3 1LR

United Kingdom

Other offices:

Modern Water

Villa 10593

Way No 4494

Azaibah

Muscat

Sultanate of Oman

Modern Water

903, Al Thuraya

Tower 1

Dubai Media City

Dubai

UAE

Modern Water

Unit 1701-2

Westgate Tower

1038 Nanjing Road W

Shanghai200041

China

+ 968 244 918 33

+ 971 4 4515 988

+ 86 21 6218 5183 Ext.140

www.modernwater.com

DesalJun12

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- NATURAL GAS SPECIFIC COURSEDocument17 pagesNATURAL GAS SPECIFIC COURSEmohamedNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 14.1 Matter & Thermal Energy (Press Read Only To Open)Document104 pages14.1 Matter & Thermal Energy (Press Read Only To Open)Abdullah Alqahtani100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Pressure Relief Valve Engineering HandbookDocument93 pagesPressure Relief Valve Engineering Handbookakrouti92% (12)

- Measurement of Density, Specific Gravity and Viscosity of LiquidsDocument10 pagesMeasurement of Density, Specific Gravity and Viscosity of LiquidsSaid Ahmed Ali100% (2)

- NATURAL GAS PROCESSING TROUBLESHOOTINGDocument17 pagesNATURAL GAS PROCESSING TROUBLESHOOTINGmohamedNo ratings yet

- Bilfinger Water Technologies - Global Unit Water Treatment - EDocument40 pagesBilfinger Water Technologies - Global Unit Water Treatment - EmohamedNo ratings yet

- Turbo Expander FinalDocument25 pagesTurbo Expander Finalmohamed100% (2)

- Bilfinger Water Technologies - Solutions For Fine and Micro-SievingDocument8 pagesBilfinger Water Technologies - Solutions For Fine and Micro-SievingmohamedNo ratings yet

- Natural Gas TreatmentDocument33 pagesNatural Gas Treatmentmohamed100% (1)

- Separator SpeadsheetDocument8 pagesSeparator SpeadsheetShabrina GhassaniNo ratings yet

- Bilfinger Water Technologies - Solutions For Sludge TreatmentDocument8 pagesBilfinger Water Technologies - Solutions For Sludge TreatmentmohamedNo ratings yet

- PSV Sizing - API-520 PDFDocument8 pagesPSV Sizing - API-520 PDFAnonymous da6X60VpII100% (1)

- Hazen William FormulaDocument4 pagesHazen William FormulaShahbaz Manzoor100% (1)

- Understanding Production LoggingDocument172 pagesUnderstanding Production LoggingJavier Johnson Lesciur0% (1)

- NATURAL GAS SPECIFIC COURSEDocument28 pagesNATURAL GAS SPECIFIC COURSEmohamed100% (1)

- Project-Closeout-Checklist - Structural SlabDocument2 pagesProject-Closeout-Checklist - Structural SlabmohamedNo ratings yet

- 01 - X - Appendix 1-C - Project Closeout ChecklistDocument6 pages01 - X - Appendix 1-C - Project Closeout ChecklistmohamedNo ratings yet

- PF - Passavant Shut-Off DevicesDocument4 pagesPF - Passavant Shut-Off DevicesmohamedNo ratings yet

- PF - PASSAVANT Bar Screen With Grab Cleaner SGRDocument2 pagesPF - PASSAVANT Bar Screen With Grab Cleaner SGRmohamedNo ratings yet

- PF - Johnson Screens Multi Rake Bar Screen Defender DuoDocument2 pagesPF - Johnson Screens Multi Rake Bar Screen Defender DuomohamedNo ratings yet

- Contractor Project Closeout Procedure and ChecklistDocument1 pageContractor Project Closeout Procedure and ChecklistmohamedNo ratings yet

- CourseBook Semester1 AlTarbyiahDocument94 pagesCourseBook Semester1 AlTarbyiahmohamedNo ratings yet

- PF - Geiger Climber Screen KRCDocument2 pagesPF - Geiger Climber Screen KRCmohamedNo ratings yet

- PF - PASSAVANT Cable Operated Bar Screen RMGWDocument2 pagesPF - PASSAVANT Cable Operated Bar Screen RMGWmohamedNo ratings yet

- PF - Passavant Revolving Chain Screen Kur-CDocument2 pagesPF - Passavant Revolving Chain Screen Kur-Cmohamed100% (1)

- PF - Geiger Climber Screen KRCDocument2 pagesPF - Geiger Climber Screen KRCmohamedNo ratings yet

- Bilfinger Water Technologies - Solutions For Inlet Works - HeadworksDocument20 pagesBilfinger Water Technologies - Solutions For Inlet Works - HeadworksmohamedNo ratings yet

- Natural Gas Production: FormationDocument11 pagesNatural Gas Production: FormationmohamedNo ratings yet

- Bilfinger Water Technologies - Solutions For Biological TreatmentDocument12 pagesBilfinger Water Technologies - Solutions For Biological TreatmentmohamedNo ratings yet

- Oil and Gas FormationDocument5 pagesOil and Gas FormationmohamedNo ratings yet

- What Is Natural GasDocument7 pagesWhat Is Natural GasmohamedNo ratings yet

- Properties of Natural GasDocument9 pagesProperties of Natural GasmohamedNo ratings yet

- What Is An Oil and Natural Gas ReservoirDocument104 pagesWhat Is An Oil and Natural Gas ReservoirmohamedNo ratings yet

- Natural Gasprocessing TopicstDocument2 pagesNatural Gasprocessing TopicstmohamedNo ratings yet

- Thermal Design of Shell and Tube Heat ExchangersDocument5 pagesThermal Design of Shell and Tube Heat ExchangersmohamedNo ratings yet

- Natural Gasprocessing TopicstDocument2 pagesNatural Gasprocessing TopicstmohamedNo ratings yet

- Calculation ReportDocument1 pageCalculation ReportMohammedNo ratings yet

- Assignment-1 Noc18 Me46 86Document2 pagesAssignment-1 Noc18 Me46 86Namita GondNo ratings yet

- Simple and Fractional DistillationDocument5 pagesSimple and Fractional DistillationAlliah VegaNo ratings yet

- Wash Water Injection in Hydroprocessing UnitsDocument13 pagesWash Water Injection in Hydroprocessing Unitscüneyt şanNo ratings yet

- Zeotropic Blend (20 % R-32, 40 % R-125, 40 % R-134a) : Main Applications OilsDocument5 pagesZeotropic Blend (20 % R-32, 40 % R-125, 40 % R-134a) : Main Applications OilsTomas ZapataNo ratings yet

- 17 Jan Test 1 g112016Document6 pages17 Jan Test 1 g112016Chi NgọcNo ratings yet

- Hydraulic ConductivityDocument7 pagesHydraulic ConductivityDragomir Gabriela MarianaNo ratings yet

- Salt Concentration: Fresh WaterDocument31 pagesSalt Concentration: Fresh WaterAli Raza (Alee)No ratings yet

- Solutions For Heat Transfer Quiz-II: D. Height of The CylinderDocument2 pagesSolutions For Heat Transfer Quiz-II: D. Height of The CylindermkvemulaNo ratings yet

- Gas Laws: Sagana National High SchoolDocument17 pagesGas Laws: Sagana National High SchoolHelma Jabello AriolaNo ratings yet

- GE E Cell MK 3 LDocument1 pageGE E Cell MK 3 LNicolas FriasNo ratings yet

- Lab 1St FloorDocument5 pagesLab 1St FloorAditya PranotoNo ratings yet

- Substation Stormwater ManagementDocument106 pagesSubstation Stormwater ManagementOm DasNo ratings yet

- Gases: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDocument28 pagesGases: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenAmalia AnggreiniNo ratings yet

- Physical Properties of Common GasesDocument4 pagesPhysical Properties of Common GasesChrina MalolotNo ratings yet

- Shambhu AzadDocument6 pagesShambhu AzadMohit AgarwalNo ratings yet

- Hamworthy Topping Up Generator PDFDocument2 pagesHamworthy Topping Up Generator PDFHARISHNo ratings yet

- Fluid MechanicsDocument2 pagesFluid MechanicsLokendra Singh JhalaNo ratings yet

- VG64 ManualDocument8 pagesVG64 ManualJonathan StewartNo ratings yet

- NPSH Calculation - A Step-by-Step GuideDocument7 pagesNPSH Calculation - A Step-by-Step GuideSrihariGopalakrishnanNo ratings yet

- Centrifugal Pump Classification by FlowDocument2 pagesCentrifugal Pump Classification by FlowrajashruthyNo ratings yet

- National Technical Regulation On Industrial WastewaterDocument5 pagesNational Technical Regulation On Industrial WastewaterpaultonkesNo ratings yet

- ME401 Assignment 4 compressor calculationsDocument3 pagesME401 Assignment 4 compressor calculationsPrakhar GuptaNo ratings yet

- Solucionario Química Capitulo 12 - Whitten - 10 EdiciónDocument21 pagesSolucionario Química Capitulo 12 - Whitten - 10 EdiciónDanielNo ratings yet