Professional Documents

Culture Documents

PU GROUT Stops Water Leakage

Uploaded by

Kanda DindaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PU GROUT Stops Water Leakage

Uploaded by

Kanda DindaCopyright:

Available Formats

NCL Chemical & Equipment Sdn Bhd

Technical Data

PU GROUT

PU GROUT, is a water-reactive grout specifically designed for injection into leaking

concrete, masonry or brickwork, to stop the flow of water. Commencement of the

chemical reaction with water can be adjusted by the addition of a variable quantity of

CATALYST.

PU GROUT forms an excellent barrier against water seepage caused by

hydroscopic pressure, has good chemical resistance and is non-toxic once set. By

restraining the natural expansion created by this reaction, a strong closed-cell rigid

foam is formed, providing a permanent barrier to the ingress of water

COMPOSITION

PU GROUT is a low viscosity MDI-based isocyanate which transforms into a rigid polyurethane

foam when in contact with water. The reaction time is adjusted by the addition of CATALYST.

APPLICATION

ADVANTAGES

Basement wall

Concrete Slab

Brick Wall

Water Tank

Sewerage Structure

Wet Areas

Lift pits, sewer etc.

*

*

*

*

*

*

*

Penetrates into cracks < 200 microns

Provides a totally water resistant barrier

Excellent bond strength

Non-toxic and can be in contact with portable water

Resistant to biological attack

Unaffected by salts or contaminants in water

Solvent free

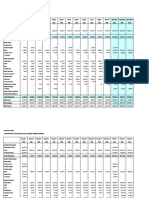

TECHNICAL DATA

PU GROUT CATALYST CATALYST

Appearance

Specific Gravity

Viscosity (25C)

Flash Point

Volatility

Compressive strength

Shelf life (unopened)

Brown

Translucent

1.13

1.02

85 cps

15 cps

>210C

>150C

Non-volatile

6.0N/mm

~ 12 months

CREAM

RISE

Dosage (%)

Time(s)

Time(s)

2

88

230

5

57

140

10

48

105

* The reaction time @ 25C varies the

amount of catalyst added and 5% of water

existence

OPERATION PROCEDURE

PU GROUT can be injected by electric-drilled operated injection pump or hand held manual pump

with the required packers. Technical experienced in handling equipment and assessment of the

site condition for suitable application should be necessary. It is recommended that pressurized

grouting at the same position for two times to ensure no water leakage.

NCL Chemical & Equipment Sdn Bhd (1108814-W)

No. 50A (Ground Floor), Jalan PJS 1/46, Taman Petaling Utama, 46000 Petaling Jaya, Selangor.

Tel: 03-7773 0929/7780 1066Fax: 03-7772 8456 Email: ncl.nce@gmail.com website: www.ncl.my

NCL Chemical & Equipment Sdn Bhd

Technical Data

STORAGE & HANDLING

Store in cool dry areas. Temperature above 50C may cause premature formation of insoluble

solids. Good housekeeping is essential in areas where chemical spillage is likely to occur.

Partly used drums/pails should be tightly sealed to prevent ingress of moisture. To increase the

Material life expectancy, partially used drum/pail should be filled with Nitrogen gas and sealed

tightly to prevent contamination. (Please refer to method statement provided)

HEALTH & SAFETY

Avoid contact with skin, eye and avoid breathing vapor. Wear gloves, goggles and full clothing

when handling with raw materials. Keep away from children. Provide adequate ventilation in

confined spaces. If contact with skin occurs PU GROUT should be removed with soap removing

cream followed by washing with soap and water. DO NOT use solvent. Should poisoning occur,

consult a physician in all cases. Should poisoning occur, call doctor immediately, DO NOT

induce vomiting, drink plenty of water or milk. MSDS shall be available upon request.

PACKING

PU GROUT: 20Kg, 25Kg and 225Kg/pail/drum

CATALYST: 1 Kg, 5Kg and 25Kg/pack/pail

Method statement

1) Drill 10mm/13mm/16mm diameter holes at 100-500mm intervals along the side of the

crack or joint, at a 45 angle in order that the path of the crack or joints intersected in the

center of the concrete slab/wall. The distance between holes will depend on the size of

the crack or joint to be injected.

2) Insert the mechanical packers into the 10mm/13mm/16mm diameter holes and tighten

securely.

3) Use a clean and dry bucket; pour in the PU GROUT to the desired amount. Add the

CATALYST gradually average recommended at 5% (5:100). Mix/stir well. Increase

the dosage if rapid curing is required.

4) Commence injection by using SWM1000, SWM1100 or DHP2000 electric-drilled

operated injection pump, ensuring that the crack is filled. The material must be visible

during the initial set stage (yellowish expanding foam). Always return to previously

injected packers/points and re-inject to ensure that the PU GROUT is completely

compacted.

5) In the event of filling vertical cracks or joints, commence injection from the bottom. In

case of horizontal cracks or joints, begin from either side.

6) Inexperience operating the pump may cause the injection pump clog. Increase operating

speed is required if higher dosage of catalyst is used.

7) Allow the PU GROUT to cure for 24 hours before removing the injected packers.

Exposed, solidified grout will be visible. Plug all holes with a suitable mortar.

8) It is recommended to flush the machine with non-flammable solvent before and after

used.

NCL Chemical & Equipment Sdn Bhd (1108814-W)

No. 50A (Ground Floor), Jalan PJS 1/46, Taman Petaling Utama, 46000 Petaling Jaya, Selangor.

Tel: 03-7773 0929/7780 1066Fax: 03-7772 8456 Email: ncl.nce@gmail.com website: www.ncl.my

You might also like

- Revised Malaysian Code of Timber StructuresDocument6 pagesRevised Malaysian Code of Timber Structuresmcwong_98No ratings yet

- CNC Turning Machine Programming and OperationDocument17 pagesCNC Turning Machine Programming and OperationioshhNo ratings yet

- PQC Cracks Repair 2 PDFDocument5 pagesPQC Cracks Repair 2 PDFDeven PatleNo ratings yet

- Managing Occupational Health and Safety in The Mining IndustryDocument12 pagesManaging Occupational Health and Safety in The Mining IndustryalexNo ratings yet

- CIDB BookletGreenTech PDFDocument13 pagesCIDB BookletGreenTech PDFazcompNo ratings yet

- Report BertulisDocument39 pagesReport BertulisArnie Farhana100% (1)

- Sce554 Reflective EssayDocument2 pagesSce554 Reflective EssayImran Azizi ZulkifliNo ratings yet

- 37 - Method Statement For Windsor Probe TestDocument8 pages37 - Method Statement For Windsor Probe TestNaj Nasir100% (1)

- Lifpalift Goods Lifts 2021Document12 pagesLifpalift Goods Lifts 2021Amech SalesNo ratings yet

- How To Use A Pipe Flaring ToolDocument8 pagesHow To Use A Pipe Flaring Toolmark darrelNo ratings yet

- Internship ReportDocument18 pagesInternship ReportAdib AkmalNo ratings yet

- MEM 673 Assignment Individu - 2018!04!01Document3 pagesMEM 673 Assignment Individu - 2018!04!01Azrul ZafrieNo ratings yet

- Ceramic Tile Installation MethodDocument12 pagesCeramic Tile Installation MethodGerson FernandesNo ratings yet

- Laser CuttingDocument13 pagesLaser CuttingSatish KumarNo ratings yet

- 1 List-of-IBS-Manufacturer MALAYSIA PDFDocument31 pages1 List-of-IBS-Manufacturer MALAYSIA PDFhaniskamis82No ratings yet

- Fibrous Plaster Ceiling Technical SpecificationDocument3 pagesFibrous Plaster Ceiling Technical SpecificationanhnguyenhaiNo ratings yet

- Resignation LetterDocument1 pageResignation LetterAyu Nurul Aidah BasironNo ratings yet

- EnglishDocument12 pagesEnglishNURUL HUSNA BINTI IBRAHIM -100% (1)

- Group Assignment BCT554 (Manufactoring Technology)Document15 pagesGroup Assignment BCT554 (Manufactoring Technology)MAXSWELL MANGGIE ZAMRYNo ratings yet

- ENT600 - Case Study Report Kapten Pisang PDFDocument31 pagesENT600 - Case Study Report Kapten Pisang PDFAmirul FathiNo ratings yet

- Quotation For Repair Work at Ramp G PDFDocument2 pagesQuotation For Repair Work at Ramp G PDFSURIA ROAD TRADE SDN BHDNo ratings yet

- SPYTL - Anti TermiteDocument6 pagesSPYTL - Anti TermiteMohd TameziNo ratings yet

- Mem634 Lab Work For Odl Mar-Jul 2020 Lab Session 1Document4 pagesMem634 Lab Work For Odl Mar-Jul 2020 Lab Session 1syafiq syazwanNo ratings yet

- Ecothene DPM: DescriptionDocument3 pagesEcothene DPM: DescriptionAbdul Wafiy NaqiuddinNo ratings yet

- Universiti Teknologi Mara: Civil Engineering Problems. (P6)Document9 pagesUniversiti Teknologi Mara: Civil Engineering Problems. (P6)Nasiruddin HakimiNo ratings yet

- ENT600 G3 NPD Project - TGGL SummaryDocument23 pagesENT600 G3 NPD Project - TGGL SummaryFahmi YahyaNo ratings yet

- 29.sec.2900 (Pipe Culverts)Document4 pages29.sec.2900 (Pipe Culverts)Rakesh ParaliyaNo ratings yet

- Door & Window ScheduleDocument4 pagesDoor & Window ScheduleMeeyi SiowNo ratings yet

- Most Projects Are Awarded On Competitive Bidding BasisDocument3 pagesMost Projects Are Awarded On Competitive Bidding BasisArefiq ShafikNo ratings yet

- Lab Exercise Iii - FinishesDocument31 pagesLab Exercise Iii - FinishesNur MasturinaNo ratings yet

- Quotation: QTY Unit Item / Specification Unit Price TotalDocument2 pagesQuotation: QTY Unit Item / Specification Unit Price TotalmynameteacherijaNo ratings yet

- Compressive Strength Properties of Malaysian Tropical Timber in Structural Size: Timber Strength GradingDocument9 pagesCompressive Strength Properties of Malaysian Tropical Timber in Structural Size: Timber Strength GradingWai Soon HanNo ratings yet

- STP Wall Working MethodsDocument7 pagesSTP Wall Working MethodsReza AndrianaNo ratings yet

- FOUNDATION DESIGN IN LIMESTONE AREASDocument23 pagesFOUNDATION DESIGN IN LIMESTONE AREASAnonymous DNb6yWERfBNo ratings yet

- Destructive TestDocument17 pagesDestructive TestRamzi BEN AHMEDNo ratings yet

- Assignment 2 - VIDEO PM2 ASSESSMENTDocument3 pagesAssignment 2 - VIDEO PM2 ASSESSMENTnur shafiqahNo ratings yet

- Group Project AsignmentDocument22 pagesGroup Project AsignmentAzizi MustafaNo ratings yet

- Ete101 Industrial SafetyDocument11 pagesEte101 Industrial SafetyZunnur ZamzamNo ratings yet

- MS For Crack RectificationDocument5 pagesMS For Crack RectificationThushara WickramasuriyaNo ratings yet

- Pumpable cementitious grout for filling voidsDocument4 pagesPumpable cementitious grout for filling voidsIqbal Muhammad100% (1)

- MEC600 Individual AssignmentDocument11 pagesMEC600 Individual AssignmentAdib AkmalNo ratings yet

- Datuk Seri NelsonDocument21 pagesDatuk Seri NelsonafiqahNo ratings yet

- A910 Line Dulux Weathershield Acrylic Exterior Wall FinishDocument2 pagesA910 Line Dulux Weathershield Acrylic Exterior Wall FinishAbd Aziz MohamedNo ratings yet

- Work Program For Building RehabilitationDocument1 pageWork Program For Building RehabilitationthomasNo ratings yet

- SAB 2032 Fire Fighting Systems OverviewDocument34 pagesSAB 2032 Fire Fighting Systems OverviewTuan JalaiNo ratings yet

- Lab Assignment 4Document6 pagesLab Assignment 4Mohd SuhaimiNo ratings yet

- DwerweDocument2 pagesDwerwefaizal aziz100% (1)

- Calibration of Vernier Calliper 10003020Document7 pagesCalibration of Vernier Calliper 10003020Ritu GavasaneNo ratings yet

- RMK 232 - Pricing and EstimatingDocument13 pagesRMK 232 - Pricing and EstimatingerickyfmNo ratings yet

- Total Quality in WeldingDocument21 pagesTotal Quality in WeldingshruthiNo ratings yet

- Expanded Metal Price ListDocument2 pagesExpanded Metal Price ListaashuranjanNo ratings yet

- CASH FLOW STATEMENTDocument5 pagesCASH FLOW STATEMENTFaFa TeanaNo ratings yet

- Industrial Training Report Cover (Wani)Document3 pagesIndustrial Training Report Cover (Wani)AmiruddinMohktarNo ratings yet

- AA14213Document54 pagesAA14213Muhamad HafiziNo ratings yet

- RP Kelapa SawitDocument6 pagesRP Kelapa SawitTimothy Glare JoniunNo ratings yet

- Case Study 1 (OSHA)Document14 pagesCase Study 1 (OSHA)Geetha SivakumarNo ratings yet

- PU-300 Polyurethane Grouting Stops Water Leakage PermanentlyDocument2 pagesPU-300 Polyurethane Grouting Stops Water Leakage Permanentlymarklester100% (1)

- Conbextra CapsulesDocument2 pagesConbextra CapsulesBinoy Sankar SarkerNo ratings yet

- 270 - MegaFlow SP103Document2 pages270 - MegaFlow SP103Naeem Saleem100% (1)

- TE LPkids RD SuperherohighDocument3 pagesTE LPkids RD Superherohighpepac414No ratings yet

- Versel QuotationDocument2 pagesVersel QuotationKanda DindaNo ratings yet

- ESL Worksheet Articles and Plurals KidsDocument1 pageESL Worksheet Articles and Plurals Kidsiyireland8808No ratings yet

- Stories Eric The Engine Worksheet Final 2012 11 01 PDFDocument2 pagesStories Eric The Engine Worksheet Final 2012 11 01 PDFKanda DindaNo ratings yet

- Statements and Questions: A Statement Ends With A Period. A Question Ends With A Question MarkDocument1 pageStatements and Questions: A Statement Ends With A Period. A Question Ends With A Question MarkKanda DindaNo ratings yet

- 040 Activities Book 1 4Document7 pages040 Activities Book 1 4Kanda DindaNo ratings yet

- 040 Activities Book 1 4Document7 pages040 Activities Book 1 4Kanda DindaNo ratings yet

- 041 Alphabetti Book 1 5 PDFDocument8 pages041 Alphabetti Book 1 5 PDFKanda Dinda100% (1)

- Wfun15 Butterfly Lowercase Letter Tracing 1Document1 pageWfun15 Butterfly Lowercase Letter Tracing 1SureshNo ratings yet

- TE LPkids RD SuperherohighDocument3 pagesTE LPkids RD Superherohighpepac414No ratings yet

- Rearrange SentencesDocument1 pageRearrange SentencesKanda DindaNo ratings yet

- 2010percubaanjohormtk2 120430161731 Phpapp01Document8 pages2010percubaanjohormtk2 120430161731 Phpapp01Aisyah HamdanNo ratings yet

- Miz Miz Katz Katz Ratz Ratz N. N.: Alphabetti Book 1-1Document11 pagesMiz Miz Katz Katz Ratz Ratz N. N.: Alphabetti Book 1-1Kanda DindaNo ratings yet

- Body Parts Flash CardsDocument12 pagesBody Parts Flash CardsNana DianaNo ratings yet

- Latihan Numerasi - What Comes NextDocument2 pagesLatihan Numerasi - What Comes NextKanda DindaNo ratings yet

- ESL Worksheet Articles and Plurals KidsDocument1 pageESL Worksheet Articles and Plurals Kidsiyireland8808No ratings yet

- 134 Alphabetti Book 3 11 Printer VersionDocument12 pages134 Alphabetti Book 3 11 Printer VersionKanda DindaNo ratings yet

- Rajah Sistem Pendidikan USDocument1 pageRajah Sistem Pendidikan USKanda DindaNo ratings yet

- 129 Activities Book 3 7Document6 pages129 Activities Book 3 7Kanda DindaNo ratings yet

- 134 Alphabetti Book 3 11 Printer VersionDocument12 pages134 Alphabetti Book 3 11 Printer VersionKanda DindaNo ratings yet

- 046 Alphabetti Book 1 10Document11 pages046 Alphabetti Book 1 10Kanda DindaNo ratings yet

- 134 Alphabetti Book 3 11 Printer VersionDocument12 pages134 Alphabetti Book 3 11 Printer VersionKanda DindaNo ratings yet

- 045 Activities Book 1 9Document9 pages045 Activities Book 1 9Kanda DindaNo ratings yet

- 045 Alphabetti Book 1 9Document13 pages045 Alphabetti Book 1 9Kanda DindaNo ratings yet

- Department of Education Leadership and OfficesDocument8 pagesDepartment of Education Leadership and OfficesKanda DindaNo ratings yet

- Eric the Engine Saves the DayDocument1 pageEric the Engine Saves the DayKanda DindaNo ratings yet

- 032 Int Book 15 Print VersionDocument17 pages032 Int Book 15 Print VersionKanda DindaNo ratings yet

- 032 Int Book 15 Screen VersionDocument34 pages032 Int Book 15 Screen VersionKanda DindaNo ratings yet

- The Plural of The NounsDocument1 pageThe Plural of The NounsMaria-Magdalena CirlanNo ratings yet

- 72 Names of God in HasidimDocument16 pages72 Names of God in HasidimFrancesco VinciguerraNo ratings yet

- Exercise 56 - Narration and SequenceDocument14 pagesExercise 56 - Narration and SequenceLéoKostasNo ratings yet

- Sports AcousticsDocument43 pagesSports Acousticssiddhant raoNo ratings yet

- Solving Problems Involving Kinds of Propotion StudentDocument18 pagesSolving Problems Involving Kinds of Propotion StudentJohn Daniel BerdosNo ratings yet

- Introduction: Use Chapter 2 Section 2 in Your Flexbook To Define The FollowingDocument5 pagesIntroduction: Use Chapter 2 Section 2 in Your Flexbook To Define The FollowingNathalieNo ratings yet

- Energy Monitoring With Ultrasonic Flow MetersDocument35 pagesEnergy Monitoring With Ultrasonic Flow MetersViswa NathanNo ratings yet

- SmogDocument5 pagesSmogAlain MoratallaNo ratings yet

- 2G Call FlowDocument71 pages2G Call Flowm191084No ratings yet

- Plant Seedling Classification Using CNNDocument12 pagesPlant Seedling Classification Using CNNYugal Joshi0% (1)

- Understanding the Four Aspects of EmotionsDocument13 pagesUnderstanding the Four Aspects of EmotionsRaymond FaeldoñaNo ratings yet

- Assignment 1 Systems Analysis - EME5601Document7 pagesAssignment 1 Systems Analysis - EME5601Travis GrantNo ratings yet

- John 16 33 Sweet Peace For Tried Believers - Charles SpurgeonDocument15 pagesJohn 16 33 Sweet Peace For Tried Believers - Charles Spurgeonstevel75No ratings yet

- The UFO MonthlyDocument21 pagesThe UFO MonthlySAB78No ratings yet

- Steam TurbineDocument25 pagesSteam TurbineIshan JunejaNo ratings yet

- PV Elite ResultDocument18 pagesPV Elite ResultVeny MartianiNo ratings yet

- Hoa ReviewerDocument3 pagesHoa ReviewerRachel Mae BahoyNo ratings yet

- SWZ Upgrade Points 062022Document19 pagesSWZ Upgrade Points 062022IcyAviatorNo ratings yet

- Me 6401 Kom - Uti Ans KeyDocument11 pagesMe 6401 Kom - Uti Ans Keylogeshboy007100% (1)

- 1625-De Dwks Parts ListDocument69 pages1625-De Dwks Parts ListSasan AbbasiNo ratings yet

- 1 5109354204116287644 PDFDocument336 pages1 5109354204116287644 PDFGerardoNo ratings yet

- Got 1000 Connect To Alpha 2Document42 pagesGot 1000 Connect To Alpha 2supriyo110No ratings yet

- GPS Navigator: ModelDocument99 pagesGPS Navigator: ModelMain UddinNo ratings yet

- Culinary History and Nouvelle CuisineDocument4 pagesCulinary History and Nouvelle CuisineARPITA BHUNIANo ratings yet

- SRWM M.PDocument34 pagesSRWM M.PAmare BayeNo ratings yet

- Raise The Limits: Eppendorf Research PlusDocument12 pagesRaise The Limits: Eppendorf Research PlusZahia Slama Ep AchourNo ratings yet

- TDS - RheoFIT 762Document2 pagesTDS - RheoFIT 762Alexi ALfred H. TagoNo ratings yet

- MSE Admission and Degree RequirementsDocument6 pagesMSE Admission and Degree Requirementsdeathbuddy_87No ratings yet

- Sri Lanka's Mineral Resources Can Enrich Country's CoffersDocument139 pagesSri Lanka's Mineral Resources Can Enrich Country's CoffersPrashan Francis100% (3)

- Countable UncountableDocument4 pagesCountable UncountablePaoLo Mena la TorreNo ratings yet

- 13.phase Feeding and Feeding SystemsDocument21 pages13.phase Feeding and Feeding SystemsAsfand Ali SheikhNo ratings yet