Professional Documents

Culture Documents

Welding QC 2 - Codes and Standards

Uploaded by

Exsan OthmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding QC 2 - Codes and Standards

Uploaded by

Exsan OthmanCopyright:

Available Formats

TWI

vofi,

THE WELDING D\TSTnJTE

SECTION2

TWI

700r

THE WELD ING Ij\,"ST|IUTE

- ) -

CODESAND STANDARDS

CLASSOF WORK

There are many typesof work whichrequireengineering

materiaisto be joined

by welding,for example:

pressurevessels

bridges

oil rigs

earth movingequipment

aero-engines

ventilationsystems

storagetanks

heavy vehiclechassis

car bodies

food processingplant

The quality requirementsof the joints in these fabricationsdepend on their

fitness-for-purpose and differ significantlyfrom one applicationto the next.

Pressurevesselsrequireweldswhich can withstandthe stressesand high

temperaturesexperiencedin operation.

Bridges must take into accountthe etfect of differingvehicle loads and wind

loading.

Oil rigs are designedto withstandthe effect of wave formationand wind loads.

Earth moving equipmenthas to accommodatedifferencesin terrain and earth

conditionsand is subjectto fatigueloading.

WelCsin food processingplantsmust withstandcorrosionby hot acidic liquors.

On the next page some typicalCodes of practiceand Standardswhich cover

various types of constructionsbeing fabricatedby weldingare listed.

Note: Throughoutthis text, the term Code is used to cover Code of Practice,

Standardand Specification.

WELDING TECHNOLOGY

lssue 0191

T\VI

70[t

THE WELDING INSTITLTTE

Code

Class of Work

Unfiredfusion welded pressurevessels

ASMEVIII

Americanboilerand pressurevessel code

BS 2633

Class 1 Arc weldingof ferriticsteel pipeworkfor carrying

fluids

BS 4515

Processof weldingsteel pipelineson land and offshore

t1J

Structuraluse in steelworkin building

CYCU

A W SD 1 . 1

Structuralweldingcode (American)

BS 5400

Steel concreteand compositebridges

BS 6235

Code of Practice for fixed offshore structure

A P t1 1 0 4

Standardfor weldingpipelinesand relatedfacilities

Thesedocumentscan a.lsoprovidea usefulsourceof datafor applications

whereCodesdo not exist. lt shouldbe remembered,

however,thatthe

principalcriterionin the Codeslistedis the qualityof the jointin relationto the

serviceconditions.Thereare otherapplications

wheresuccessis judgedby

differentcriteria,suchas dimensional

accuracy.

Anotherimportantconsideration

is controlling

the costof welding.Variationsin

weld timesand quantities

of consumables

can readilyresultif the methodof

makinga weld is leftto the welderto decide.

The continuousand satisfactory

performance

of weldmentsmadeto various

Codesrequiresthat specificguidelines

are laiddownto covermaterials,design

of joints,weldingprocesses,

acceptance

criteriaand

weldingconsumables,

inspectiontechniques.

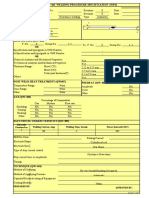

Theseguidelinesare usuallygroupedunderthe generalheadingof a Weld

Procedure.

WELDING TECHNOLOGY

t.z

lssue0191

T\MI

voflt

THFWELDING INSTITLJTE

AUESTIONS

CODESAND STANDARDS

Q1.

Ljst the typical items to be found in a Code of Practice

\-:-':,;--

':.

fl :'.- , .';r'"

-

n

1^r-;'-'-'":

Q2.

Explainthe meaningsof the terms:

Q4.

Does a Code of Practice contain all relevant information?

' 1 t '

9pg.- i;'*.'.+-,*"-'

\

C'\Q-L-;.-l

a

l\- e-A-'?

.

"-**l...,*,'*

^'

.- "J:,-|

't. Y',

'

-i'' '

Ft* r--- '-i'

o5. State the three (3) partiesgenerallymentionedin Codesor Standards

t

''

-.

^.1

' / I

osz

_<_r,

, - .a

'

.ar.Fr

\

)

You might also like

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerFrom Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerNo ratings yet

- WP May09 Final HighResDocument4 pagesWP May09 Final HighResJohn VarelaNo ratings yet

- Some Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentFrom EverandSome Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentRating: 3.5 out of 5 stars3.5/5 (2)

- Design of Pressure Vessel Using Asme Code, Section Viii, Division 1Document7 pagesDesign of Pressure Vessel Using Asme Code, Section Viii, Division 1bbmoksh100% (2)

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- 15A10 - Superstructures I (Topside)Document23 pages15A10 - Superstructures I (Topside)Viktor DươngNo ratings yet

- Offshore StructuresDocument24 pagesOffshore StructuresSaaiyogeshNo ratings yet

- Wind Turbines Designed For Easy InstallationDocument9 pagesWind Turbines Designed For Easy InstallationTay BoNo ratings yet

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Offshore General Introduction AnalysisDocument28 pagesOffshore General Introduction AnalysisOkolo Obinna100% (3)

- Mil S 901DDocument83 pagesMil S 901Dadithegrea83No ratings yet

- WG 15a Structural Systems - OffshoreDocument273 pagesWG 15a Structural Systems - OffshoreIlkin hasanovNo ratings yet

- Book Offshore... OffshoreDocument210 pagesBook Offshore... Offshoren73686861100% (2)

- Accidents in Pressure Vessels Hazard AwarenessDocument4 pagesAccidents in Pressure Vessels Hazard AwarenessvictorvikramNo ratings yet

- Vibration ProblemsDocument18 pagesVibration ProblemsKarthick RamNo ratings yet

- Ship Construction Syllabus - Chief Mate P1Document1 pageShip Construction Syllabus - Chief Mate P1pramodNo ratings yet

- Design of Pressure Vessel For Improvement of A System in A Process UnitDocument8 pagesDesign of Pressure Vessel For Improvement of A System in A Process UnitTJPRC PublicationsNo ratings yet

- Technical Specification FOR Pressure VesselDocument19 pagesTechnical Specification FOR Pressure Vesselwaghmarepranav890No ratings yet

- Technical Specification FOR Pressure VesselDocument65 pagesTechnical Specification FOR Pressure VesselAjay TulpuleNo ratings yet

- Technical Specification For Pressure VesselsDocument16 pagesTechnical Specification For Pressure VesselsANIMESH JAIN100% (1)

- Technical Specification - Pressure VesselDocument30 pagesTechnical Specification - Pressure VesselMurli RamchandranNo ratings yet

- Engineering Insurance 211012 PDFDocument160 pagesEngineering Insurance 211012 PDFAnonymous brpVlaVB89% (9)

- Seismic Design of Water TanksDocument17 pagesSeismic Design of Water TanksJeevan ReddyNo ratings yet

- Bere DesignDocument61 pagesBere DesigndaniNo ratings yet

- Mil S 901DDocument83 pagesMil S 901DParamaet TamNo ratings yet

- Structural Systems OffshoreDocument281 pagesStructural Systems Offshoretambok100% (3)

- Esdep Offshore Structures General IntroductionDocument187 pagesEsdep Offshore Structures General Introductiondfal13No ratings yet

- Offshore Platform InstallationDocument189 pagesOffshore Platform InstallationAdaghara100% (2)

- Cargo Containers, Rail Cars, Trailers, and TrucksDocument11 pagesCargo Containers, Rail Cars, Trailers, and TrucksBryan VertuodasoNo ratings yet

- The Design of Vertical Pressure Vessels Subjected To Applied Forces and Vibrational ConditionsDocument8 pagesThe Design of Vertical Pressure Vessels Subjected To Applied Forces and Vibrational ConditionsIAEME PublicationNo ratings yet

- Mathcad Marine TechnologyDocument22 pagesMathcad Marine TechnologyOkolo ObinnaNo ratings yet

- Technical Session Transmission Line - IIIDocument80 pagesTechnical Session Transmission Line - IIIKaushal Ghimire100% (2)

- ISO 12944 2022 MasterDocument22 pagesISO 12944 2022 MasterJosé Román MenaNo ratings yet

- V001t02a007 Ipc2000 117Document10 pagesV001t02a007 Ipc2000 117zafarbadalNo ratings yet

- MC-DUR 2500: The Hybrid Screed System For Heavy-Duty Industrial FlooringDocument4 pagesMC-DUR 2500: The Hybrid Screed System For Heavy-Duty Industrial Flooringpetronela.12No ratings yet

- SHELL Product Data Guide Industry 2013Document78 pagesSHELL Product Data Guide Industry 2013Edgar Real ViúlaNo ratings yet

- 5 - 6271415119956151874 - 240229 - 224949 - Dipak PandaDocument8 pages5 - 6271415119956151874 - 240229 - 224949 - Dipak Pandasatyabrata.podder.eceNo ratings yet

- Vallourec Oil & Gas Magazine - Premium Connection TestingDocument5 pagesVallourec Oil & Gas Magazine - Premium Connection Testingkaveh-bahiraeeNo ratings yet

- 1.10 Change of Occupancy (IEBC) : Chap. 11Document1 page1.10 Change of Occupancy (IEBC) : Chap. 11jcvalenciaNo ratings yet

- Notes On Marine EngineeringDocument19 pagesNotes On Marine Engineeringavm4343100% (2)

- From Evolution To Revolution Electric Motors in Oil and Gas Exploration - Whitepaperpdf.renderDocument5 pagesFrom Evolution To Revolution Electric Motors in Oil and Gas Exploration - Whitepaperpdf.renderveeraNo ratings yet

- Offshore StructureDocument124 pagesOffshore Structureirawantani100% (2)

- BGAS Grade 1 CourseDocument71 pagesBGAS Grade 1 Course9440864459No ratings yet

- Liquid WaterproofingDocument9 pagesLiquid Waterproofingjuli_radNo ratings yet

- K.muhlberg Corrosion Protection For WindmillsDocument12 pagesK.muhlberg Corrosion Protection For WindmillsTiago Lopes100% (1)

- Ship and Boat Building and Repair-1Document5 pagesShip and Boat Building and Repair-1navalmamunNo ratings yet

- Chapter 92 - Ship and Boat Building and Repair PDFDocument25 pagesChapter 92 - Ship and Boat Building and Repair PDFnavalmamunNo ratings yet

- Offshore Platform Basic Type: Jacket Based Platform For Shallow Water Jacket and Gravity Based Platform For Deep WaterDocument22 pagesOffshore Platform Basic Type: Jacket Based Platform For Shallow Water Jacket and Gravity Based Platform For Deep WaterNabigh NabiylNo ratings yet

- Water House J DavidDocument28 pagesWater House J DavidvelmuruganNo ratings yet

- Offshore Platform InstallationDocument189 pagesOffshore Platform Installation1001018100% (8)

- Auma Control Valve ManualDocument20 pagesAuma Control Valve ManualAnto ThoppilNo ratings yet

- Aramv22 N1 P1 12Document12 pagesAramv22 N1 P1 12hamedpdmsNo ratings yet

- Diaphragm AFGlobal High-PressureDocument8 pagesDiaphragm AFGlobal High-PressureAnonymous nw5AXJqjdNo ratings yet

- CVLE548-Loads On Tall BuildingsDocument40 pagesCVLE548-Loads On Tall BuildingsReza KarimiNo ratings yet

- Tankfarm - Types, Design Considerations, Plot Plan Arrangement, Dyke EnclosureDocument8 pagesTankfarm - Types, Design Considerations, Plot Plan Arrangement, Dyke EnclosureteaNo ratings yet

- Advanced Steel Structures Training ProgramDocument6 pagesAdvanced Steel Structures Training ProgramVinoth RajNo ratings yet

- Mitted To Building LifeDocument6 pagesMitted To Building LifeDylan RamasamyNo ratings yet

- Isgec Project Report 2Document24 pagesIsgec Project Report 2Manu BhaRdWaJNo ratings yet

- A-Health Advance - Application Form With InstructionsDocument14 pagesA-Health Advance - Application Form With InstructionsExsan OthmanNo ratings yet

- Farris Series 2600Document96 pagesFarris Series 2600johngoff100% (1)

- Senarai Nama Arkitek BerdaftarDocument150 pagesSenarai Nama Arkitek BerdaftarCgu Bola Tampar83% (6)

- Remote Field Eddy CurrentDocument4 pagesRemote Field Eddy CurrentExsan OthmanNo ratings yet

- Farris Valve ManualDocument11 pagesFarris Valve ManualsumsolcaggNo ratings yet

- April 2015. Any New Application Form Must Reach Us Before The Stipulated DateDocument1 pageApril 2015. Any New Application Form Must Reach Us Before The Stipulated DateExsan OthmanNo ratings yet

- A-Health Advance-I Premium RatesDocument2 pagesA-Health Advance-I Premium RatesExsan OthmanNo ratings yet

- Tube Inspection GuidebookDocument28 pagesTube Inspection GuidebookAkhileshNo ratings yet

- Engineering Your Future PDFDocument605 pagesEngineering Your Future PDFExsan OthmanNo ratings yet

- Astm C 871Document5 pagesAstm C 871Exsan Othman100% (2)

- SSI Guideline V3 PDFDocument34 pagesSSI Guideline V3 PDFSyed Mohd FirdausNo ratings yet

- MetrodeHandbook - ZavarivanjeDocument416 pagesMetrodeHandbook - ZavarivanjetonicmiraNo ratings yet

- P91 T91 Engl PDFDocument3 pagesP91 T91 Engl PDFparmodrtkNo ratings yet

- Asmt C 795Document4 pagesAsmt C 795Exsan OthmanNo ratings yet

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Document6 pagesCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanNo ratings yet

- Astm C 692 PDFDocument7 pagesAstm C 692 PDFExsan Othman100% (1)

- AWS Specifications For Filler MaterialDocument9 pagesAWS Specifications For Filler MaterialExsan OthmanNo ratings yet

- Chat For Organization of CodeDocument1 pageChat For Organization of CodeExsan OthmanNo ratings yet

- MaterialsDocument181 pagesMaterialsExsan OthmanNo ratings yet

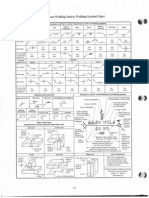

- AWS Weld Symbol ChartDocument1 pageAWS Weld Symbol ChartExsan OthmanNo ratings yet

- Calculation Minimum Required Thickness For Bending Pipe r2Document11 pagesCalculation Minimum Required Thickness For Bending Pipe r2Exsan OthmanNo ratings yet

- Material CharacteristicsDocument4 pagesMaterial CharacteristicsExsan OthmanNo ratings yet

- Nozzle Repad Design SpreadsheetsDocument2 pagesNozzle Repad Design SpreadsheetsArt G. EnziNo ratings yet

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNo ratings yet

- Piping CalDocument13 pagesPiping CalglazetmNo ratings yet

- Pipeline DataDocument4 pagesPipeline DataExsan OthmanNo ratings yet

- Mechanical Design SpreadsheetDocument1 pageMechanical Design SpreadsheetHoney TiwariNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariNo ratings yet

- 3L Filters CompleteDocument66 pages3L Filters CompleteHugo Ruiz100% (1)

- AWS D1 1 D1 1M 2015 Structural Welding Code Steel Errata PDFDocument2 pagesAWS D1 1 D1 1M 2015 Structural Welding Code Steel Errata PDFbilling cbi housingNo ratings yet

- BS en Iso 9606-1-2017Document46 pagesBS en Iso 9606-1-2017LUZ MERY100% (3)

- List PWPS StructureDocument1 pageList PWPS StructureYUDI IRMAWANTONo ratings yet

- QW 381Document1 pageQW 381Waqas WaqasNo ratings yet

- Welded ConnectionsDocument144 pagesWelded ConnectionsshivaniNo ratings yet

- Price List: Inspection (Cwi, Cawi, Scwi)Document1 pagePrice List: Inspection (Cwi, Cawi, Scwi)hamedNo ratings yet

- Note 6 - Welder Test RequirementDocument29 pagesNote 6 - Welder Test RequirementMohamad Yusuf Helmi100% (1)

- Mitshubishi PACDocument165 pagesMitshubishi PACRizal Abdul Hamid0% (1)

- Price Quotation Form: Technical Education & Skills Development AuthorityDocument2 pagesPrice Quotation Form: Technical Education & Skills Development AuthorityKhael Angelo Zheus JaclaNo ratings yet

- Chapter 5 - Welded Connections: A Beginner's Guide To The Steel Construction Manual, 13 Ed. (Old)Document5 pagesChapter 5 - Welded Connections: A Beginner's Guide To The Steel Construction Manual, 13 Ed. (Old)AngelTinocoNo ratings yet

- Jeffus ChaptersDocument16 pagesJeffus ChaptersAnonymous dh6DITNo ratings yet

- Welding FundamentalsDocument44 pagesWelding FundamentalsDhinasuga DhinakaranNo ratings yet

- Figure 1. Friction Stir Welding ProcessDocument4 pagesFigure 1. Friction Stir Welding ProcessINfo WTCSNo ratings yet

- Manual Tecnico SRK-ZMPDocument64 pagesManual Tecnico SRK-ZMPJoaoNo ratings yet

- Tos 2nd Quarter SmawDocument6 pagesTos 2nd Quarter SmawArnelson Derecho100% (10)

- An Experimental Study On The Effect of MIG Welding Parameters On The Weld-Bead Shape CharacteristicsDocument5 pagesAn Experimental Study On The Effect of MIG Welding Parameters On The Weld-Bead Shape Characteristicstejap314No ratings yet

- GMAW PreTest1Document3 pagesGMAW PreTest1Winalyn PersiaNo ratings yet

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- Welding Procedure Specifications (WPS) - Qw482Document23 pagesWelding Procedure Specifications (WPS) - Qw482vichu_villamarNo ratings yet

- Electrode Pressure Bar Welding Current, Amp Welding Time, Second Power Source (AC/DC)Document1 pageElectrode Pressure Bar Welding Current, Amp Welding Time, Second Power Source (AC/DC)Mohit TiwariNo ratings yet

- ESAB - Stainless Handbook PDFDocument92 pagesESAB - Stainless Handbook PDFfarshid KarpasandNo ratings yet

- Beginner's Guide To Welding 101 - All You Need To Know PDFDocument60 pagesBeginner's Guide To Welding 101 - All You Need To Know PDFisaias.prestesNo ratings yet

- Aws WPQDocument3 pagesAws WPQKaliman MendozaNo ratings yet

- Metal Inert Gas WeldingDocument8 pagesMetal Inert Gas WeldingShubhamNo ratings yet

- A6V10256195 - Room Thermostats With LCD For Wall Mounting RDG100 - en PDFDocument80 pagesA6V10256195 - Room Thermostats With LCD For Wall Mounting RDG100 - en PDFFlorin GeamanuNo ratings yet

- Parker Substrate 4250-InTRAFLOW Dec 2003Document12 pagesParker Substrate 4250-InTRAFLOW Dec 2003Laurence MalanumNo ratings yet

- ACTIVITY REQUEST For - GarbageDocument1 pageACTIVITY REQUEST For - Garbagejoan dalilisNo ratings yet

- CSWIP 3.0 Welding InspectionDocument43 pagesCSWIP 3.0 Welding InspectionScott K.L LeeNo ratings yet

- Answers Drawing BDocument9 pagesAnswers Drawing Bharoub_nasNo ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (52)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesFrom EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesRating: 4 out of 5 stars4/5 (2)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Casing and Liners for Drilling and Completion: Design and ApplicationFrom EverandCasing and Liners for Drilling and Completion: Design and ApplicationRating: 5 out of 5 stars5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Heavy and Extra-heavy Oil Upgrading TechnologiesFrom EverandHeavy and Extra-heavy Oil Upgrading TechnologiesRating: 4 out of 5 stars4/5 (2)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- The Petroleum Engineering Handbook: Sustainable OperationsFrom EverandThe Petroleum Engineering Handbook: Sustainable OperationsRating: 3.5 out of 5 stars3.5/5 (5)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)