Professional Documents

Culture Documents

Welding QC 13 - SA

Uploaded by

Exsan OthmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding QC 13 - SA

Uploaded by

Exsan OthmanCopyright:

Available Formats

TWI

voot

THE-WELDTNG NSTmUTE

SECTION13

T\vI

700t

TIIE \VEIDING

Ir\ STN-LII-E

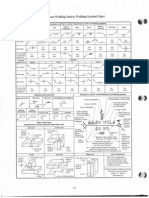

A ',FL AT 'A RC P RO CE SS(C ON ST A N TVOL

)

TAGE

SUBMEBGED-ARC

(SA)

Typicaldefectsassociated

with this

process:

Porosity.

Cracking.

o S l a gi n c l u s i o n s .

Type of Operation

Mechanised,

automaticor semi-automatic. . Incompletepenetration.

Modeof Operation

Excessivepenetration.

An arc is maintainedbetweenthe end of a

barewire electrodeand the work-As the

Weld profiledefects.

electrodeis melted,it is fed intothe arc bv

a set of rolls,drivenby a governedmotor.

. undercut

Wire feed speedis automatically

controlled

to equalthe rateat which the electrodeis

Lackof fusion.

melted,thus arc lengthis constant.

The arc

operatesundera layerof granularflux

(hence'submerged,arc).Someof the flux

meltsto providea protectiveblanketover

the weld pool; the remainderol the flux is

unaffectedand can be recovered

and

re-usedprovidedit is dry and not

contaminated.

A semi-automatic

versionis available

in

which the operatorhas controlof a

weldinggun which carriesa smallquantitv

of flux in a hopper.

WELDING TECHNOLOGY

lssue O191

13.1

TWI

,t/i8

S U B M E R G E DA R C W E L D I N G :

PROCESSAND EOUIPMENT

FUNDAMENTALS

The principreof tne submerged-arcprocessis shownschemaircary

beiow. A

power sourceP, is connectedacros-s

the contectnozzteon tne werdinci.p".

and the workpiece.The powersourcecan be a transformer

fof AC *J,oi.g'",.

a rectifier(or motor generator)for DC werding. The firer materiars

are an

uncoatedcontinuouserectrode

and a granurarwerdingflux fed down to rne

joint by way of a hose from the flux hopper. To prevJnt

tne electroOe

overheatingat high currentsthe weldingcurrent is transfened to

the electrode

ar a porntvery croseto the erectricarc. The arc is burning in a cavity

filJed

with gas (cor, co, etc) and metal fumes. In front the cav-ityis warteo

in oy

unfused parent materiar,and behindthe arc by soridifyingwerd

metar. The

covering over the cavity consistsof mortensrag. The diagram

berowaiso

shows the solidifiedwerd and the thin coveringof soridsrJg which

has ro oe

detached aftef the completionof each run.

C.orlti,iEqr

3;Jir.d

Er.

.h<.rd.

W.ld c@l

since the arc rs compretely

submergedby the fruxthere is none of the initating

arc radiatjonwhich is so characteristic

of the open arc processes;werding

screensare thereforeunnecessary.

The weldingflux is nevercompletelyconsumedand the surplusquantity

left

ca,'l be collectedeither by hand or automatjcallyand returned

io the flux

h o p p e rt o b e u s e da a a i n .

ll.z

WELDING TECHNOLOGY

lssue 0191

cI

T\vI

THE WETTING [\iSf|T]]-IT

Althoughsemi-automatic

submerged-arcweldingequipmentexists

and is

convenientfor certainapplicationsl

most,of ttresJomerieo-arJrietoing

carriec

out today makes use of fullymechanised

tne majn virtuesof the submerged-arc weldingequipment.lndeed,one of

processis the ease withwhjch it

can

be incorporated

into fu,y r""nlnlJ

*erding.systemsto give high deposrtion

rates and -::l:l"i,t

weld quaiity. Welo metatrecovery

approachest0O%

since losses throughspatte'rare

exremety smat. Heat rossesfrom rne

arc are

aiso quite low..gwingto the insulating-effect

of the flux bed, and for this reason

the therma, efficiencyof the submeri"o_"r"

pro""." can be as hign as 60%

compared with about 2s/" for manuij

metatja;a"MA) ;;;s.,,,

FIux consumptionis approximately

equal to the wire consumption,the

actual

ratio_ weishtof wireconsumeo:

weiqhiorftil;;;;;;:'

on the flux type and the weldingpara"merers

useo.

#i;

aepenoent

werdingparameters

are maintained

at theirset varuesby the arc conrrorunit.

A feed-backsystemis usuatyusedto

maintain" "tJr"'"r"l.iiri

.o ,nu, "

changein the ar^clength,_corresponJing

ro

u

change

_ will

in

arc

voltage

producean increaseor decrease

in the wirefeedspeeduntirthe originalarc

tengthis regained.

Joint preparation

Joint preparation

dependson plate

'and thickness,

andtypeof joint,e.g.

circumferentiar

or rongitudinar, to somee:tent,on

the standardsto which

the structure

is beingmade.

Pratesof up to.14mmthickcan be butt

werdedwithoutpreparation

wrtha gap

not exceeding

or 10% of tne prail inicr<ness,

whichever

is the ore:rer

Thicker

pr",". ]m1

iirrriip-enetration

is

to

be

obtained.

v:r1"rl"

fitupcannotbe1^:lllparation

tolerated.

A wetder,.'"n.:l:l:::tr:d_..

to copewith varyins

:an adjusthis technique

'a'j:::",?"#.1tf::l ru"". or varvins

dimensions.Not so an automaticweldins

"JffJL[::1'

";j*

;

o

r

3

m

m,

r,

'"*ii"d'il

:on,

:,::,'ilT"H;

li

ru.

*"

such circumstances

a hand-wetoeo

rooirun usingMrGor MMAerectrodes

is

advisable. All plate edges must O"

"U"of rt"fy

clean and free from

mi|scare,paint

rflmpuritiesare prl-s"nt*o are meltedinto rust, oil,

the werd,

.etc-_can easily

porosityand cracking

occur.

Time spent'n

suchdefectsby caretutjointpreparation

and

T,1,1:l.nn

thoroughinspection

priorto werdingis tirirewe, spentsince

cuttingout werd

defectsand then reweldingi, u".yirl"n"ive

andttme_consumino

WELDINGTECHNOLOGY

I s s u e0 1 9 1

13 . 3

TWI

TllE WELDINGL\sTriuTE '

Weldingprocedure

tn generarthe moreseverethe requirements

regardingrowtemperature

notch

toughnessthe lowerthe maximumweldingcurrentthat can be used

to

minimiseheatinput,whichmeansthat a multipasstechnrqueis ca.Ied

for.

when werdingstainress

steersthe heatinputshourdbe keptrowfor other

reasons:stainress

steelhas poorthermajconductivity

and a highcoefficient

of

expansioncomparedwith mirdsteer. Thesetwo effectsreadto overheatino

and excessivedistortionif largediameterwiresand highcunenti

;";";;:

Multirunweldsusingsmalrdiameterwiresare thereforerecommended

for

stainlesssteelsand highnickelalloyssuch as Inconel.

Selectionof weldingconditions

selectionof the correctwerdingconditions

for the pratethicknessand joint

preparationto be weldedis very importantif satisfactoryjoints free

from

defectssuch as cracking,porosity,and undercutare to be obtained.The

processvariableswhichhaveto be considered

are:

electrodepolarity

weldingcurrent

c . electrodediameter

arc voltage

weldingspeed

f. electrodeenension

s. electrodeangle

h . flux depth

h

These are the variableswhich determinebead size, bead shape,

depth of

penetration,and, in some circumstances,metallurgical

effectssuch as

incidenceof cracking,porosityand weld metal coriposition.

a.

electrodepolarity

The deepest penetrationis usuafiyobtainedwith Dc reverseporarity(erectrode

+ve) which a.lsogives the best surfaceappearance,beao shape, and

reststanceto porosity.

Direct current straightporarity(erectrode-ve)gives faster burnoff (about

35%)

and decreasedpenetrationsince the maximumheat is deveroped

at the tip of

the electrodeinsteadof at the surfaceof the prate. For this reason

DC-ve

polarityis often used when weldingsteels of ljmitedweldability

and when

surfacingsince, in both instances,penetrationinto the parent material

must be

kept as low as possible. The fluvwire consumptionratio is less with electrode

-ve polaritythan with electrode

+ve so that alloyingfrom the flux is reduced.

13.4

WELDING TECHNOLOGY

Issue 0191

,

rI

T\vI

WE

l-HE \i ELDINC i\.STflf_t

In changingfrom erectrode+ve to -ve porarity

some Increasejn arc voitace

b: necessaryto obtajn" "ornp.ruti" Ouuo

"nup". ,eltematrng

T"l a

";;;, ',.

grves

resultabouthalf way betweenDC electrode

*u",n.r _"" ,i.';;,":

particutarty

usetul

whenarc'blow

is a prolrem-J:".J-""il;r;;:ff::_

sysrems,where a DC +ve electrodeis used

as tne leadjnge]ectrode;; ;

AC electrodeas the trail

b.

5,:

welding current

Increasingthe wire feed speed increases

the werdrngcurrentso that the

depositionrate incfeaseses the werding

"rrr.liin"r.u"es.

The current

densitydeterminesthe O.jrl^"t_,?:l.j*ion:

tne nign.r' ,n. currentdensity the

greater the penetration. For a given

flux, arc stalitity w* be rost below a

mrnimumthreshordcurrent deniity so that

if tne cuirent for a grvenerectrode

.rameter is too row arc stabirityis rost

and a russed rnegurarbead is obtained.

Too high a current densityalso reao" to

in"troiiiT-i"."r." rne erectrode

overheals. Undercuttingmay also occur.

c.

electrodediameter

current, changingthe electrodediameterwiil

changethe current

l::_9::""

density,which means in oracticethat a

larger diameterwill reduce penetiation

and the liketihoodof burnthrough,but at th;-;;

ile arc stnkingis more

difficultand arc stabilityis reduced.

o.

arc voltage

"{:O of arc voltage is often misunderstood

becauseif affectsdilution

1:

rather than penetration. Bead_on_plate

wetOsanJ square edge close butt

welds (no gap) have increasedwidtn and

dirutionas arc vo[age increases,but

depth of penetrationremainsthe same.

E tfrt

ol.-c

ta/q.

c.1b.d r\.-.

WELDING TECHNOLOGY

Issue 0191

t5 c

T\^/I

voTN

rlJlJy

'n1E

wa1p1\.'c i\-STi]l_tT

lf the joint is ,open,,* f':r^ilrnil:

in a butt jojnt with raiher smalt anqted

preoaration,increasrngthe

V

arc voltage c_andecrease the penetratjon.

lncreasingthe arc voltaqe lengthens

the arc so thal weld bead wjdih js

increased, reinforcemenlis

de-creased,

ir* """*"

probabir*v

orarcbrow-is

arso

increased.

*n"" ",,ifil"J,iJrli?T?,Li'rj."'r"

length and hence

arc voitag:,is u",y importani',;;;"

" hrgharc voltagesmore

flux is meitedso that more ajloying

elements.nGi rn" weld rnetal.

Tnus arc

vottageca,l affect weld merar

composition

e.

welding speed

Beadsize is inverselypril"T]?11

ro weili1o speed.

penetration

and beadwidth,increasetne titJtinooo Fasterspeedsfeduce

of porosityand,if takento

the eltreme,produceundercuning

*d irr{;l;;;l"or.

ot highwetding

the arc volraseshoutdbe keptfr;;l;;

Ji.,i*,.u

arc btowis riketvto

;:ff:.

lf the weldingspeedis too slowburn-through

c3n occur. A combination

of

high arc volLage

and stowwelding"p";;;

p;,-ile

a

mu.nroom_shaped

weld beadwith solidification

cracis at the beaOside!.

f.

electrodeextension (stickout)

Electrodeextensionis an important

variablesince

- it governsthe arnountof

resistanceheatingwhich occurs

in the erectrod". ii tn" eltension is

short the

neatingeffectts smallanc

jjtJ;,[.J,.::::,T:;$T:j?:,

increaies,n"t",p",.",i.".,.Ti;t:":i1,..?,

Deposition

rateis increased.IncreaseJ;;";;i;;

therefore

usefutin

and surfacingapplications

Ort .i"p. r,"""'io oe takento guidethe

:i::jig

etectrode

otherwise

it wanders

ror normarwerding

the erectrode

enensionshourdbe 25-3ommfor mildsteer

and ratherress'say 2o-25mm'for

stainless.rni. i, o".uure the erectrical

sensitivityof starnless

wireis appreci"'v gi".i"i ih"n thatof

mildsteelwire.

1? A

WELDINGTECHNOLOGY

lssueOl9l

T\vI

w[f

TT WEI.DINGU\STTTUTE

S.

electrodeangle

since the angiebetweenthe eiectrode

and the piateoetermines

the pointof

appiicationand directionofrhe arc

i"."-it

n*

J'p'rJtorno

effect

on both

penetrationand undercut. The-trgures

.noru

,.r"Jt;"t

on

horizontalfuerticaJ

,

fiiretwerds,and comparethe efreit obtai;;J

"i,r "'iu.t,".r arc withthose

andtraiting

arcs.rhe-"#"rt-""undercuttins

canbe

;:liffX,;Hjgadins

EqJd Lf t r!d!

Oa.9-t

F,ll

lddr

Hin.

'f.nd.icy

tur

ts qx,..dn:

s-rn

El{<1 ol .tadd.

Mod...r.

trlt.:

Irl H V nkt

..id..lb,

Urc F,ld-

WELDINGTECHNOLOGY

IssueOfgl

. 1i.2

T\4/I

I}{E-i4Ii)tNc

h.

n\slm,t:

ftux depth

The fiux burden or the

simp,vheaped; u;;,["'.[:jJEH:ff [":j il::::,fl:_f"j: yi;ffi

"_

resurtsare to be obtainedthe flux

oeptnsrrou-ri-oe

just sufficientto coverthe

arc' arthoughat the pointwherethe

erectrode

"nte..stn" fruxbedrightrefrected

rromthe arc shouldjust.bevisibre.

roo "r'urL* "

b:d givesflash-through

and can causeporosity

ryl

ot

inaOequate'mlbllurgical

protection

-b:?r"g

moten metal. Too deeo

a flux.bedgiu"a;*or." oeaoappearance of the

and can

leadto spitageon circumferentiaL;;rd;.il;;

preparations

in

thick

prateit

important

t::".,! """"."iu.-nr"-i!itn otr.,"nn

:"|:l':!lyty

i"e

the

weld

snape and slag removalcan be

beao

unsatisfactorv.

Strip ctadding

Althoughmost appticatioT-:1.!_"

"yOrerged arc processmakeuse of

sinole_

or murtiwiresystemsusinground

wires,eiectrodeJintn" form a strip ar"

usedfor ctaddingpurpose-s.

o-ften

strpsare'usJ;iift;r,

thick,the commonest

skip widthbeins60mm.b_t1l^li!:r

"qp"1;.; ioom can be usedwithout

lossof quality. The biq a

anv

jrrvuiinil"t",fl

,*1",j;nij;,il'

particu

::"5:o:r,.",1u:lff

fl

:;J:,ffi

hish. Modem ftuxesdesisnel f.::!l"t

srearercurrenttolerance

than earliertypes and use of currents if:iddi;;;;;

or

up

to

izboA

with

austeniticstainress

steelstripsgivesdepositio:

o{.uq

to

Z2mglhr

with

DC

etectrode+ve

polarity.lnconelcan also -.i""

jffi

jt;,:""l,sJ,t

;#ii{l!"fl

,1u:511

1_dl1"r:i;;H;ffi

,iH

can be obtained.Monet,atuminium

b.;",;;k;i

ano .,rzci. stripshave

arso

Deensuccessfuily

,.._g stripcraalinger;;i;"".

contactbetweenthe strip and- feed'nozzle

i"-"."-.]i'tl,.

13.8

Goodetectrical

WELDINGTECHNOLOGY

Issueolgl

i

TWI

ZZry

T}IE \4'EI.DING OVSTJ-n,"IE

QUESTIONS:

SUBMERGEDARC WELDING

(SAW)

Ql

. What are the weldingparameters

in SAW?

Q2

03

State three (3) itemswhichcontrol

weld metajcompositionin SAW.

Statethree(3) itemsof a flux

whichrequireinspection.

Q4

,.""ffffiJ:,

Q5

il:.*

a)

b)

c)

tvpesof a fluxusedin sAWandgive

briefdetairs

of

advantageand applicationfor

each of the

DCVe+

DCVeAc

QSle

foltowingpower

You might also like

- PETRONAS Employee Medical Top-Up PlanDocument2 pagesPETRONAS Employee Medical Top-Up PlanExsan OthmanNo ratings yet

- A-Health Advance - Application Form With InstructionsDocument14 pagesA-Health Advance - Application Form With InstructionsExsan OthmanNo ratings yet

- TUBE INSPECTION SOLUTIONS: SELECTION GUIDEDocument28 pagesTUBE INSPECTION SOLUTIONS: SELECTION GUIDEAkhileshNo ratings yet

- Engineering Your Future PDFDocument605 pagesEngineering Your Future PDFExsan OthmanNo ratings yet

- RFET Technique Detects Local and Gradual DefectsDocument4 pagesRFET Technique Detects Local and Gradual DefectsExsan OthmanNo ratings yet

- Astm C 871Document5 pagesAstm C 871Exsan Othman100% (2)

- Farris Valve ManualDocument11 pagesFarris Valve ManualsumsolcaggNo ratings yet

- April 2015. Any New Application Form Must Reach Us Before The Stipulated DateDocument1 pageApril 2015. Any New Application Form Must Reach Us Before The Stipulated DateExsan OthmanNo ratings yet

- Farris Series 2600Document96 pagesFarris Series 2600johngoff100% (1)

- Senarai Nama Arkitek BerdaftarDocument150 pagesSenarai Nama Arkitek BerdaftarCgu Bola Tampar83% (6)

- P91 T91 Engl PDFDocument3 pagesP91 T91 Engl PDFparmodrtkNo ratings yet

- SSI Guideline V3 PDFDocument34 pagesSSI Guideline V3 PDFSyed Mohd FirdausNo ratings yet

- Astm C 692 PDFDocument7 pagesAstm C 692 PDFExsan Othman100% (1)

- MetrodeHandbook - ZavarivanjeDocument416 pagesMetrodeHandbook - ZavarivanjetonicmiraNo ratings yet

- AWS Specifications For Filler MaterialDocument9 pagesAWS Specifications For Filler MaterialExsan OthmanNo ratings yet

- AWS Weld Symbol ChartDocument1 pageAWS Weld Symbol ChartExsan OthmanNo ratings yet

- EPA RMP OSHA PSM State Law SummaryDocument1 pageEPA RMP OSHA PSM State Law SummaryExsan OthmanNo ratings yet

- Asmt C 795Document4 pagesAsmt C 795Exsan OthmanNo ratings yet

- MaterialsDocument181 pagesMaterialsExsan OthmanNo ratings yet

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Document6 pagesCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanNo ratings yet

- Nozzle Design Tool AnalysisDocument2 pagesNozzle Design Tool AnalysisArt G. EnziNo ratings yet

- Calculation Minimum Required Thickness For Bending Pipe r2Document11 pagesCalculation Minimum Required Thickness For Bending Pipe r2Exsan OthmanNo ratings yet

- Pipeline DataDocument4 pagesPipeline DataExsan OthmanNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariNo ratings yet

- Material CharacteristicsDocument4 pagesMaterial CharacteristicsExsan OthmanNo ratings yet

- Piping CalDocument13 pagesPiping CalglazetmNo ratings yet

- Mechanical Design SpreadsheetDocument1 pageMechanical Design SpreadsheetHoney TiwariNo ratings yet

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Excel Control de TaxiDocument72 pagesExcel Control de TaxiOrlando MendezNo ratings yet

- DPR 3Document68 pagesDPR 3MITHUNNo ratings yet

- The ElonDocument12 pagesThe ElonanishNo ratings yet

- PQR WPSDocument2 pagesPQR WPSMiguel Alejandro SierraNo ratings yet

- Chloroform NotesDocument10 pagesChloroform NotesMukil MNo ratings yet

- Copy of Copy of Copy of Copy of WEEK 29 COMPLETEDDocument58 pagesCopy of Copy of Copy of Copy of WEEK 29 COMPLETEDAnilkumarGopinathanNairNo ratings yet

- Welding Handbook Vol 3 Materials and Applications Part 1Document533 pagesWelding Handbook Vol 3 Materials and Applications Part 1Ari SupramonoNo ratings yet

- MSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryDocument1 pageMSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryMohd SaffririzalNo ratings yet

- Manual Despiece M250MDocument115 pagesManual Despiece M250MFelipe VegaNo ratings yet

- Tarifa General Leucos 2012 P.V.P. + Ecoraee LeucosDocument46 pagesTarifa General Leucos 2012 P.V.P. + Ecoraee LeucosVEMATELNo ratings yet

- Reporte Prodom Vendor 20-6-2015Document1,452 pagesReporte Prodom Vendor 20-6-2015ljv004No ratings yet

- Manual arc welding guideDocument35 pagesManual arc welding guideLinh TranNo ratings yet

- As Built Template Tie InsDocument1 pageAs Built Template Tie InsRicardo MachadoNo ratings yet

- Group 2BDocument7 pagesGroup 2BYojana SonawaneNo ratings yet

- Radiographic Interpretation: Radiographs of WeldsDocument22 pagesRadiographic Interpretation: Radiographs of WeldsManoj BallaNo ratings yet

- Weld HistoryDocument64 pagesWeld HistoryMITHUN100% (1)

- Welding Summary by Test PackageDocument11 pagesWelding Summary by Test PackageSANUNo ratings yet

- Welder IdentificationDocument9 pagesWelder Identificationdandiar1No ratings yet

- Welding Inspection ReportDocument14 pagesWelding Inspection ReportManoj KumarNo ratings yet

- Alcance Proyecto CartagenaDocument3 pagesAlcance Proyecto CartagenamarraezNo ratings yet

- Welding and Welder Performance 10 July 2015Document26 pagesWelding and Welder Performance 10 July 2015Achmad AffandyNo ratings yet

- Gasoline Blending Components AnalysisDocument2 pagesGasoline Blending Components AnalysisGunjan SolankiNo ratings yet

- WPQT List Pt. AbgDocument5 pagesWPQT List Pt. AbgabdiNo ratings yet

- Piping Works Daily ReportDocument17 pagesPiping Works Daily ReportGomathyselviNo ratings yet

- Welding procedure specification guideDocument3 pagesWelding procedure specification guideAnilNo ratings yet

- WEEK 22 LS Repair TrendDocument2 pagesWEEK 22 LS Repair TrendAnilkumarGopinathanNairNo ratings yet

- Plantilla Excel Control de TaxiDocument65 pagesPlantilla Excel Control de TaxiNacho RojasNo ratings yet

- Welders Qualification Test Record For Approval: Marjan Development ProgramDocument8 pagesWelders Qualification Test Record For Approval: Marjan Development ProgramJoni Carino SuniNo ratings yet

- Sucker Rod SpecificationsDocument2 pagesSucker Rod SpecificationsAngelosNo ratings yet

- Satr W 2013 Tanmia WRRDocument12 pagesSatr W 2013 Tanmia WRRasiq0% (1)