Professional Documents

Culture Documents

Welding QC 18 - NDT

Uploaded by

Exsan OthmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding QC 18 - NDT

Uploaded by

Exsan OthmanCopyright:

Available Formats

TWI

voot

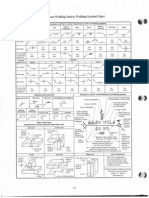

THE WELDTNG I}{STITIJTE

S EC T IO N1 8

TWI

wot

THE wp1p1p6 nrsTITuTE-

NON DESTRUCTIVE

TESTTNG

Ultrasonic inspection

Colhode - ray

IUDE

Tronsmittd pu tse

Rellected pu tse

f ine /diyonce

scole

Sen siliYily

control

pulse

Type of operatlon:

Manualor mechanised

Rellec(edputse

Probe Gre ose

Work

oelecl

Equlpment:

Main unit containingpulsegenerator,

displayoscilloscope,

probe(chosento

suitwork).

Modeof operation:

A pulseof electricar

energy.isfed to the probein whicha piezo-erectric

crystal

convertsit to mechanicalvibrationsat an ultrasonicfrequency. ne vinratiim.

are transmitted(via a rayerof greaseto excrudethe air) throughthe work: if

they encountera defectsomeare reflectedbackto the probe,wherethey

regeneratean electricalsignal. A cathoderay tubetraceis startedwhenthe

originalsignalis sent,dispraysthe reflecteddlfect signar,and from it time,

indicatingdistancefrom probe,and ampritude,

indicating

defectsize,can be

calculated.

Materials:

Most metal,exceptthosewithcoarseor varyinggrainstructure

WELDING TECHNOLOGY

lssue 0191

1.1

T\)t/I

wor

THE \4I-DING NSTm_rfE

Overall advantages:

lmmediatepresentationof results

n:ed to move personnelout

lo

uan De Dafterypowered

Depth locationsof defects.

Overall limitations:

Trained and skiiledoperatorrequired

No pictorialrecord

Safety

Moderatecare neededas for other electronic

equipment.

to.z

WELDINGTECHN'LOGY

Issueolgl

i

T\4/I

wot

TE

WELDING U{STI|IJ-TE

Magneticparticleinspection

Currenl

t'lognelic t ietd

Type of operation:

Manuajor mechanised.

Equipment:

Powersupply

Contactsor coil

Ultra-violetla.rnp(optional)

Portableor fixedinstallation.

Mode of operation:

The work is magnetised

eitherby passinga currentthroughit, or through

a coil

surroundingit' Defectson or nearthe

surface

disrupt

the

magnetic

fierd

(unlessthey are para'el to

4 T;Sn;ti; p".ti"f" nriO suspensionis apptied

whichconcentrates

aroundit]

tre oetecis.-rn! ""riii! vrewecr

eitherdirecty or

by.-ultra-violet

lightsusinga dye whichfluoresces;

tfrat

is,

emitsvisibleliqht

(.nrsmustbe donewhere

normal

tishtins

is il;ili.'

be demagnetisedif required.

;iJ;'i;,i";, ;"H,;",

Materials:

Magnetic materialsonlv

Ferriticsteels

Some nickel ajlovs

WELDING TECHNOLOGY

Issue Ol gl

't9.3

II

T\^/I

wot

I,ELDING NSTrnJTE

Overalladvantages:

Directindicationof defectlocation

Initialinspection

by unskilled

labour(goor no_qo)

Someindicationof sub_surface

defecisOrt of il-ui,sensitivity

Not criticallydependenton surfacecondition.

Overalllimitations:

Io.use for non-magneticmaterials

uerectdetectioncriticarvdependenton arignment

Sub-surfaceflawsrequirespecialprocedures. acrossmagneticfield

Safety:

Moderatecare neededin handringerectric

equipment

and flammabre

fluids.

18.4

WELDING TECHNOLOGY

lssue O191

. :

TWI

Wg

T}|E !!T LDI Nc lr.'sTn-Lrf:

G a m m ar a d i o g r a p h y

Handle

Shulter

Shierding

P h al o gr a p h i c

I t g h l c o s s el l e

'-*!ource

So u r c en o l l e n V.in

0ock shteldtng

Xr

rQltoh

Type of operation:

Static

Development

maybe mechanrsed

Equipment:

Radioactiveisotopein storagecontalner

Hemotehandlinggear

Lightproof cassette

Photographic

development

facilities

uarKroomand illuminatorfor asses.sment

Mode of operation:

Gamma-rays, similarto X-rays, but

of shorterwaveleng,th

are emitted

continuouslyfrom the isotope:it cannot

o",rn i;n"J ofr, so that when not in

use it is kept in a heavy storage container

whiin J-"oro" radiation. They pass

nrough the work to be inspected. parts

of the work presentingless

gamma-rays, such as cavitiesof

inclusions,

-"

:.?:l'"]i"" i9

ajlow increased

exposure

of the firm' The firm is oevetopedl0

ro'i'ini.*n.ss

,uoiograph

with cavities

or inclusionsindicatedbv darker images.

s".tion

increases

(such as

weld) appear as les_sdense rmaqes.

Materials:

Most weldablemetalsmay be inspected_

WELDING TECHNOLOGY

Issue 0191

T\vI

70cr

THE W.ELDING NSTrn,TTE

X-radiographs

rleot ed colhode

Anade

tfork

Phologrophic

t rocualed

X-my

lube

X - rn".

Lighr- tighl

cosJe//e

rposure

View

Type of operation:

Staticor transportable.

Equipment:

X-ray tube

Standand controlqear

Ught-proof casset6

Photographic

development

facilities

uarK roomand illumination

for assessment.

Modeof operation:

X-rays are emittedfrom the

yf-" Td. eay throrlOhthe work to be inspected.

presentingtessobstruction

to Xlrays, sucn as cavitiesor

l^:P,:i!. alrow

,york

Incrusrons,

increasedexposureof the firm. 'r" dr r.

oevetofeJto rurm

a radiographwith cavities incrusions

i"oi*i"o

oy

ourr"'

images.

section

-orwetd

thicknessincreases(suchas

under-beaJi.oJ"o as ressdenseimaoes.

Materials:

Mostweldablemetalsmay be inspected.

19.6

WELDINGTECHNOLOGY

lssueOlgI

rI

T\VI

WZT$

THE \IELDINC INSTit-L-ta

Overall advantages:

AccuTatepictorialpresentation

of results

Radiographsmay be kept as a pernnanent

record

Not confined to welds

O v e r a l lI i m i t a t i o n s :

Personnelmust be clearof area duringexposure

Cracksparallelro film amy not show up

F m expenstve.

gog

INTERNATIONAL

RADIATIONWARNINGSYMBOL

Safety:

Cumulativeradiationrisk to personnelrequires

stringenrprecaLjtions.

WELDING TECHNOLOGY

Issue O19l

IE'.1

.I

T\)t/I

THE WELDING L\STMJTE

EXAMPLE OF IMAGE OUAUW INDTCATORS

Step-hole type

B S3 9 7 1

9FEI5

Wire t ype

18.8

Duplex t vDe

WELDING TECHNOLOGY

Is.sueO19l

:

T\MI

wot

rTHE ILDING

TNSTmI|E

Dye penetrantdetection

t:.t-2:?r,y,!r rbiii,,,u,o,,

pouderdevetoper

and exomine

utio-'ii'orct

Type of operation;

Manuajor mechanised

Equipment:

Min:

Max:

Aerosolscontaining

dye, developeretc.

Tanks_ worxhanJlini gear (in ir"

"ou" uttra_violet

tamp).

Modeof operation:

A specialdye is appriedto the surfaceof the

articreto be tested. An intervalof

1-10 min arrowsit to soak.into.any

"urru"" o"r".i"i The surfaceis then freed

from surplusdye and the dye in the crack

r*""Ll'Oy "rtn"r,

(a)

applyinga whitepowderdeveloperintowhicn

the dye is absorbed

producinga colourcontrastindication.

or

(b)

i'uminatingwith ultra-vioret

rightunderwhichthe dye fluoresces;

that

is, emitsvisibtelight. Thismust be donerrnur"

noi,nilidt,.;;"-.

subdued.

WELDINGTECHNOLOGY

lssueO19l

.to o

rI

TWI

wos

TiG WELDINC INSTm_rt:

M at e r i al s :

O v e r a l la d v a n t a g e s :

Low cost

Directindicationof defectlocation

Initialexaminationby unskilledlabour(go

or no go)

Overall limitations:

Surfacedefectsonly detected

Uetectscannotreadilybe^rewelded

due to entrappeddye. Roughwelds

producespuriousindications.

Further reading:

Non-destructive

testjnq

GenerajDynamics

ConvairDiv

ban urego

usA (1s67)

Safety:

Low flash pointdye and properrant

gases.

1S.10

WELDING TECHNOLOGY

Issue 0191

TWI

Wg

T}G WELDING [\STMT-E

OUESTIONS

NON-DESTRUCTIVE

TESTING

01

Q2

Q3

04

Q5

Name four (4) NDT methods

State the two typesof rays used

in radiograpnyand a limitationof

What processuses mechanical

vibrationsto detect defects?

Name a limitationof Mpl.

what is the mainrimitation

of usingthe 'dye'methodof inspection?

QSlE

You might also like

- PETRONAS Employee Medical Top-Up PlanDocument2 pagesPETRONAS Employee Medical Top-Up PlanExsan OthmanNo ratings yet

- A-Health Advance - Application Form With InstructionsDocument14 pagesA-Health Advance - Application Form With InstructionsExsan OthmanNo ratings yet

- TUBE INSPECTION SOLUTIONS: SELECTION GUIDEDocument28 pagesTUBE INSPECTION SOLUTIONS: SELECTION GUIDEAkhileshNo ratings yet

- Engineering Your Future PDFDocument605 pagesEngineering Your Future PDFExsan OthmanNo ratings yet

- RFET Technique Detects Local and Gradual DefectsDocument4 pagesRFET Technique Detects Local and Gradual DefectsExsan OthmanNo ratings yet

- Astm C 871Document5 pagesAstm C 871Exsan Othman100% (2)

- Farris Valve ManualDocument11 pagesFarris Valve ManualsumsolcaggNo ratings yet

- April 2015. Any New Application Form Must Reach Us Before The Stipulated DateDocument1 pageApril 2015. Any New Application Form Must Reach Us Before The Stipulated DateExsan OthmanNo ratings yet

- Farris Series 2600Document96 pagesFarris Series 2600johngoff100% (1)

- Senarai Nama Arkitek BerdaftarDocument150 pagesSenarai Nama Arkitek BerdaftarCgu Bola Tampar83% (6)

- P91 T91 Engl PDFDocument3 pagesP91 T91 Engl PDFparmodrtkNo ratings yet

- SSI Guideline V3 PDFDocument34 pagesSSI Guideline V3 PDFSyed Mohd FirdausNo ratings yet

- Astm C 692 PDFDocument7 pagesAstm C 692 PDFExsan Othman100% (1)

- MetrodeHandbook - ZavarivanjeDocument416 pagesMetrodeHandbook - ZavarivanjetonicmiraNo ratings yet

- AWS Specifications For Filler MaterialDocument9 pagesAWS Specifications For Filler MaterialExsan OthmanNo ratings yet

- AWS Weld Symbol ChartDocument1 pageAWS Weld Symbol ChartExsan OthmanNo ratings yet

- EPA RMP OSHA PSM State Law SummaryDocument1 pageEPA RMP OSHA PSM State Law SummaryExsan OthmanNo ratings yet

- Asmt C 795Document4 pagesAsmt C 795Exsan OthmanNo ratings yet

- MaterialsDocument181 pagesMaterialsExsan OthmanNo ratings yet

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Document6 pagesCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanNo ratings yet

- Nozzle Design Tool AnalysisDocument2 pagesNozzle Design Tool AnalysisArt G. EnziNo ratings yet

- Calculation Minimum Required Thickness For Bending Pipe r2Document11 pagesCalculation Minimum Required Thickness For Bending Pipe r2Exsan OthmanNo ratings yet

- Pipeline DataDocument4 pagesPipeline DataExsan OthmanNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariNo ratings yet

- Material CharacteristicsDocument4 pagesMaterial CharacteristicsExsan OthmanNo ratings yet

- Piping CalDocument13 pagesPiping CalglazetmNo ratings yet

- Mechanical Design SpreadsheetDocument1 pageMechanical Design SpreadsheetHoney TiwariNo ratings yet

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- FM End-Sem Question Paper - 2021Document1 pageFM End-Sem Question Paper - 2021Anshu MeenaNo ratings yet

- Doppler EffectDocument8 pagesDoppler EffectJemimah MpofuNo ratings yet

- rinhs science 9 4th activity 2 projectile motion word puzzleDocument2 pagesrinhs science 9 4th activity 2 projectile motion word puzzleRyan BersaminNo ratings yet

- Chemical Equilibrium and Industrial Applications PDFDocument5 pagesChemical Equilibrium and Industrial Applications PDFRida MariamNo ratings yet

- 5.60 Thermodynamics & Kinetics: Mit OpencoursewareDocument7 pages5.60 Thermodynamics & Kinetics: Mit OpencoursewarecaptainhassNo ratings yet

- Ad 0299980Document68 pagesAd 0299980alexNo ratings yet

- Physics Module Form 5 GCKL 2010Document29 pagesPhysics Module Form 5 GCKL 2010Jo Ey Goh75% (4)

- Significant Figures, Scientific Notation and Metric PrefixesDocument3 pagesSignificant Figures, Scientific Notation and Metric PrefixesmphoNo ratings yet

- Bet Article PDFDocument23 pagesBet Article PDFGabriel de SáNo ratings yet

- Appendix For GlassDocument2 pagesAppendix For GlassGian ClimacoNo ratings yet

- Radio Propagation and Network PlanningDocument46 pagesRadio Propagation and Network Planningمحمد فاضلNo ratings yet

- Enrtl-Rk Rate Based Dipa ModelDocument34 pagesEnrtl-Rk Rate Based Dipa ModelsamandondonNo ratings yet

- Liserre Lecture 8Document23 pagesLiserre Lecture 8jack_cliftNo ratings yet

- In Each of Problems 1 Through 8 Solve The Given Differential EquationDocument21 pagesIn Each of Problems 1 Through 8 Solve The Given Differential EquationJonathan HuNo ratings yet

- Radiation Protection and Dosimetry Assessment 2Document2 pagesRadiation Protection and Dosimetry Assessment 2George ChahniNo ratings yet

- 2 - Ec3 1 8Document5 pages2 - Ec3 1 8dmardetkNo ratings yet

- 18mat11 PDFDocument3 pages18mat11 PDFRavi TilaganjiNo ratings yet

- Final Project ReportDocument20 pagesFinal Project ReportNimisha Srivastava0% (1)

- Experiment No: Objective: ApparatusDocument3 pagesExperiment No: Objective: ApparatusAfzaal FiazNo ratings yet

- MATLAB Solution To Microwave Engineering Pozar 4th Ed. Example 1.5Document5 pagesMATLAB Solution To Microwave Engineering Pozar 4th Ed. Example 1.5John Bofarull GuixNo ratings yet

- General Relativity: Proff. Valeria Ferrari, Leonardo GualtieriDocument327 pagesGeneral Relativity: Proff. Valeria Ferrari, Leonardo GualtieriRimple MaheyNo ratings yet

- Lab01 - Metallic Crystal StructuresDocument8 pagesLab01 - Metallic Crystal StructuresPok ThungNo ratings yet

- Mechanics 3 Revision NotesDocument45 pagesMechanics 3 Revision NotesDexter FungNo ratings yet

- Magnetic InteractionsDocument13 pagesMagnetic InteractionsZsuzsa BorsayNo ratings yet

- Antennas PropagationDocument1 pageAntennas Propagationzoe gypsyNo ratings yet

- 05-Dinamika Fluida Lanjut - Turbulent FlowDocument17 pages05-Dinamika Fluida Lanjut - Turbulent FlowSri Peni WijayantiNo ratings yet

- Energy: X. Chen, R.Z. Wang, S. DuDocument9 pagesEnergy: X. Chen, R.Z. Wang, S. DualmadhagiNo ratings yet

- Optical Gyroscope With Whispering Gallery Mode Optical CavitiesDocument6 pagesOptical Gyroscope With Whispering Gallery Mode Optical Cavitiesjalamia8796No ratings yet

- Franck-Hertz Experiment With A Hg-Tube: Physics Modern Physics Quantum PhysicsDocument11 pagesFranck-Hertz Experiment With A Hg-Tube: Physics Modern Physics Quantum PhysicsSebastian M.No ratings yet

- Phototubes: A Concise History of Early Light Detection DevicesDocument5 pagesPhototubes: A Concise History of Early Light Detection Devicesdhananjaymohapatra2009No ratings yet