Professional Documents

Culture Documents

22 Plumbing PDF

Uploaded by

Ritesh JainOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

22 Plumbing PDF

Uploaded by

Ritesh JainCopyright:

Available Formats

BGSU Construction Standards

Office of Design & Construction

Bowling Green State University

DIVISION 22 PLUMBING

FORMAT

1. Technical specifications content and numbering system shall be based on 2004

version of CSI MasterFormat.

BASIS OF DESIGN

1. BGSU Design standards shall not replace fully developed, project and market

specific technical specification. Associate shall utilize the Standards as a minimum

standard to guide the design and execution in the field. Exceptions to these

standards are allowed provided they are approved by Design & Construction.

2. In instances where fewer than 3 manufacturers are indicated in the Mechanical

Preferred Manufacturers List, the Associate shall insert or approved equal in the

Products section of the technical specifications.

3. All submitted substitute products shall be brought to the attention of Design &

Construction, prior to approval. Provide fully functional samples upon request.

4. New technology will be considered by BGSU for plumbing installations.

RELATED SECTION

23MECHANICAL

26ELECTRICAL

Appendix B - ENERGY CONSERVATION

Appendix D - INFRASTRUCTURE

GENERAL PROVISIONS

1. Access Panels

a. Provide access panels for valves, clean outs, equipment, etc., installed above an

inaccessible ceiling such as plaster or concealed spline.

2. Plumbing Identification

a. Provide labels to identify all control panels, disconnects, motor control centers as

well as equipment served.

b. All piping shall be identified by stencil or label indicating service and direction of

flow. As referenced by OSHA, labeling shall comply with ANSI A13.1 standard.

3. Housekeeping Pads

a. All floor mounted equipment shall be set on 4 housekeeping concrete pads.

5. Support & Anchors

a. Piping

i.

Attached to structural members by beam clamps bearing on both sides.

Do not weld.

ii.

When attaching to bar joists, attach at the panel points only.

iii.

Attach to concrete decking using expansion bolts or concrete anchors.

iv.

Wrought iron clevis type, Grinnell No. 260.

v.

Copper-plated plastic-coated hangers, Grinnell Fig. CT-99C.

vi.

Insulated pipe provide oversized hangers to fit on the outside of the pipe

saddles and shields.

September 27, 2013

DIVISION 22PLUMBING

Page 1 of 13

BGSU Construction Standards

Office of Design & Construction

Bowling Green State University

220719 PLUMBING PIPING INSULATION

1. Composite assembly shall have a flame spread rating not over 25 and a smoke

developed rating not higher than 50.

2. Piping Insulation Above Ground, Mineral Fiber or Cellular Glass. All service jacket

with self-sealing lap adhesive. Thermal conductivity (k) shall not exceed 0.24 BTUH

square foot F/inch.

3. Pipe fittings shall be covered with insulating cement or preformed insulating fitting

cover. All exposed piping insulation shall be covered with a PVC jacket.

4. Handicap lavatories with exposed P-trap, hot and cold water angle stops and

supplies shall be insulated.

5. Buried or under floor services shall be avoided wherever possible. When not

avoidable, these services shall be coordinated with other trades and dimensionally

located and noted so other service shall be installed over such services.

6. Insulate the piping to minimum requirements of current ASHRAE 90.1 standard.

September 27, 2013

DIVISION 22PLUMBING

Page 2 of 13

BGSU Construction Standards

Office of Design & Construction

Bowling Green State University

221005 PLUMBING PIPING

1. Schedule of Piping

SERVICE

PIPE

SIZE

MINIMUM

WORKING

PRESSURE &

TEMPERATURE

MATERIALS

Copper ASTM

AB88 Type L

Indoor,

Aboveground

Domestic

Cold & Hot

Water

2 1/2

inch

and

smaller

150 psig

200F

3 inch

and

larger

150 psig

200 F

Schedule 40

ASTM

A 312/A 312

M

150 psig

200F

Schedule 40,

Carbon Steel,

ASTM A 53,

Type E or S,

Grade B

2 inch

and

smaller

PEX piping

will be

considered for

use upon

approval by

BGSU

JOINT

FITTINGS

UNIONS / FLANGES

/ COUPLINGS

Solder

ASTM B 32,

lead-free

alloys. with

waterflushable

flux per

ASTM B 81

3 or Pressfit

type system

pressure

seal with

EPDMrubber Oring seal in

each end

WroughtCopper Fittings:

ASME B16.22.

Or

Pressfit type

system

Wrought-Copper

Unions:

ASME B16.22.

Or

Pressfit type system

-----

Mechanical

SS ASTM

A 815/A815 M

Mechanical Couplings

for grooved end

EPDM-rubber

gaskets suitable for

hot and cold water

Screwed

Malleable-Iron,

ASME B16.3,

Class 150,

standard

pattern.

ASME B16.39,

Class 150, malleable

iron with brass-to-iron

seat, ground joint

----

ASTM A234,

forged steel

Class 150

Class 300 steam

forged steel slip-on

flanges or weld

neck flanges for

carbon steel

Spiral wind style,

316L metal winding

strip, with flexible

graphite filler and

Stainless Steel

316L centering ring

gaskets.

Indoor,

Aboveground

Natural Gas

2 1/2

inch

and

larger

150 psig

200F

Schedule 40

Carbon Steel

ASTM A53

Grade B ERW

Butt

Welded

ANSI/AWS

D1.1

September 27, 2013

GASKETS

MANUAL ISOLATION

VALVES

2 inch and smaller - Ball,

Full port, two piece, bronze

body, stainless steel stem,

PTFE or TFE seats,

stainless steel vented ball.

MSS SP-110. Screwed joint

ends.

2 1/2 inch and larger Ball

as noted above or Butterfly

type flanged with cast iron

body, and EDPM liner

Ball, Full port, two piece,

175 CWP, bronze body ,

bronze blowout proof stem,

reinforced PTFE blowout

proof seats, chrome plated

ball. MSS SP-110, ASTM

B584, Threaded ends.

Cast Iron nonlubricated plug

valve, 200 psig WOG, cast

iorn body, bronze or nickle

plated cast iorn plug,

thermoplastic coated seat,

square head or lug type

operator with tamperproof

feature where indicated,

flanged ends.

EXPANSION

Bronze hoses and

single-braid

bronze sheaths

with 450 psig at

70 deg F and 340

psig at 450 deg F

ratings. Copperalloy fittings with

solder-joint end

connections.

-----

-----

DIVISION 22PLUMBING

Page 3 of 13

BGSU Construction Standards

Office of Design & Construction

Bowling Green State University

Schedule of Piping (continued)

SERVICE

PIPE

SIZE

2 inch

and

smaller

Indoor,

Aboveground

Compressed

Air (150 psig)

2 1/2

inch

and

larger

2 inch

and

smaller

Indoor

Aboveground

Vacuum

Piping

2 1/2

inch

and

larger

MINIMUM

WORKING

PRESSURE &

TEMPERATURE

MATERIALS

150 psig

200F

Schedule 80

Carbon Steel

ASTM A53

Grade B

ERW

150 psig

200F

Schedule 40

Carbon Steel

ASTM A53

Grade B

ERW

150 psig

200F

Schedule 80

Carbon Steel

ASTM A53

Grade B

ERW

150 psig

200F

Schedule 80

Carbon Steel

ASTM A53

Grade B

ERW

JOINT

FITTINGS

UNIONS / FLANGES /

COUPLINGS

GASKETS

ANSI/ASTM

B16.3,

malleable iron

Class 150

ANSI/ASTM B16.3,

malleable iron Class 150

----

Butt Welded

ANSI/AWS

D1.1

ASTM A234,

forged steel

Class 150

Class 300 steam forged

steel slip-on flanges or

weld neck flanges for

carbon steel

Spiral wind style,

316L metal winding

strip, with flexible

graphite filler and

Stainless Steel

316L centering ring

gaskets.

Screwed

ANSI/ASTM

B16.3,

malleable iron

Class 150

ANSI/ASTM B16.3,

malleable iron Class 150

----

ASTM A234,

forged steel

Class 150

Class 300 steam forged

steel slip-on flanges or

weld neck flanges for

carbon steel

Spiral wind style,

316L metal winding

strip, with flexible

graphite filler and

Stainless Steel

316L centering ring

gaskets.

Screwed

Butt Welded

ANSI/AWS

D1.1

September 27, 2013

MANUAL ISOLATION

VALVES

Ball, Full port, two piece,

600 CWP, bronze body ,

stainless steel stem,

PTFE or TFE seats,

stainless steel vented

ball. MSS SP-110.

Threaded ends.

Ball, Full port, two piece,

600 CWP, bronze body,

stainless steel stem,

PTFE or TFE seats,

stainless steel vented

ball. MSS SP-110.

Threaded ends.

Ball, Full port, two piece,

600 CWP, bronze body ,

stainless steel stem,

PTFE or TFE seats,

stainless steel vented

ball. MSS SP-110.

Threaded ends.

Ball, Full port, two piece,

600 CWP, bronze body ,

stainless steel stem,

PTFE or TFE seats,

stainless steel vented

ball. MSS SP-110.

Threaded ends.

EXPANSION

-----

-----

-----

-----

DIVISION 22PLUMBING

Page 4 of 13

BGSU Construction Standards

Office of Design & Construction

Bowling Green State University

Schedule of Piping (continued)

SERVICE

PIPE

SIZE

Underground,

Domestic

Water

All

Sizes

Underground

Natural Gas

All

Sizes

MINIMUM

WORKING

PRESSURE &

TEMPERATURE

MATERIALS

JOINT

FITTINGS

UNIONS / FLANGES /

COUPLINGS

GASKETS

150 psig

200F

PVC AWWA

C900

Bell End &

Spigot

Ductile Iron

Push-On

Fittings

Ductile Iron Push-On

Fittings

-----

150 psig

200F

HDPE

SDR11

Butt Fused

HDPE SDR11

HDPE SDR11

-----

150 psig

200F

Polyethylene,

ASTM D2513

SDR11

Socket

Fused or But

Weld

Polyethylene,

ASTM D2683

or ASTM 3261

Polyethylene, ASTM

D2683 or ASTM 3261

----

September 27, 2013

MANUAL ISOLATION

VALVES

Gate, AWWA C509,

OS&Y rising stem, metal

seated. Coating per

AWWA C550. Gray or

ductile-iron body and

bonnet; with bronze, gray

or ductile-iron gate,

resilient seats, bronze

stem, and stem nut

Ball with polyethylene

body and ball, 80 CWP,

Nitrile Stems and Seats

Acetal Stem.

EXPANSION

-----

-----

-----

DIVISION 22PLUMBING

Page 5 of 13

BGSU Construction Standards

Office of Design & Construction

Bowling Green State University

Schedule of Piping (Continued)

SERVICE

CONDITIONS

MATERIALS

Exterior of Building

Underground 15

PVC ASTM D-3034 SDR 35

Hubless ASTM A888 or CISPI 301 cast-iron soil pipe and fittings

Sanitary Waste

Inside Building

Underground 15

PVC Schedule 40 DWV ASTM D-2665. Specify only where elevated waste

water temperatures are not a concern. See notes below.

Hubless ASTM A888 or CISPI 301 cast-iron soil pipe and fittings

Sanitary Waste &

Vent

Inside Building

Aboveground 15

Exterior of Building

Underground 15

Storm

PVC ASTM D-3034 SDR 35

Inside Building

Underground 15

PVC Schedule 40 DWV ASTM D-2665

Inside Building

Aboveground

Hubless ASTM A888 or CISPI 301 cast-iron soil pipe and fittings

2. Sanitary.

a. Fill material around piping below slab shall be compacted granular material to 95

percent-modified proctor.

b. Piping shall not be installed parallel/directly under walls. Minimum parallel

distance from a wall to the pipe shall be 3 feet for repair access.

c. Piping above grade shall be Schedule 40 polyvinyl chloride or cast iron, no hub

with approved hanger spacing.

d. Piping in a plenum shall be cast iron, no hub. Schedule 40 polyvinyl chloride is

not approved for use in a plenum space.

e. Sanitary Piping Avoid the use of cross tees for all branch line. Y fittings are

preferred for cleanout purposes. No tees in lavatory drain piping. Piping in

multistory buildings must be cast iron. Piping in and downstream of Kitchens and

Mechanical Rooms must be cast iron and all PVC connections to this line must

include 3-0 of cast iron at the connection fitting. No hub bands on cast iron pipe

shall be equal to Husky heavy duty, type 304 stainless steel, 4 clamping bands

type.

September 27, 2013

DIVISION 22PLUMBING

Page 6 of 13

BGSU Construction Standards

Office of Design & Construction

Bowling Green State University

f. Cleanouts in sanitary systems shall be located outside the toilet chase if

accessible or in chase walls if there is not access. They shall be located above

the flood level rim of the highest water closet (minimum 10 inches) but no more

than 24 inches above the finished floor. Cleanouts located in the wall shall be a

no-hub cap with stainless steel band connection. Tap no-hub cap for fastening

over size stainless steel wall plate cleanout cover. Plate access hole must be

made large enough to remove no-hub bands and cap for cleaning out sanitary

piping. Cleanouts shall not be located in main communication areas.

g. Vent Piping PVC is acceptable in non-plenum areas.

h. Vent System Air admittance valves are to be avoided if possible, but are

acceptable where conventional venting is not possible. Follow all requirements

as dictated by The State of Ohio Plumbing Code.

i. Provide information to the Site Design Professional as to the depth of the

sewer(s) exiting the building.

j. Provide information to the Structural Design Professional as to the location and

depths of the sewer in relationship to footings and columns as they pertain to the

project.

3. Acid Waste.

a. Acid waste piping below grade shall be Schedule 40 polypropylene with fusion

joints. All acid waste piping above grade shall be Schedule 40 polypropylene with

mechanical joints. Acid waste piping in a plenum shall be fire and smoke-rated

polyvinylidene fluoride or glass.

b. Acid neutralizing sumps shall be located on the exterior of the building with

access to grade.

4. Roof Drain / Storm.

a. Piping materials shall include Schedule 40 polyvinyl chloride with solvent joints or

cast iron no hub.

b. Fill material around piping below slab shall be compacted granular material to 95

percent-modified proctor. Piping shall not be installed parallel/directly under

walls. Minimum parallel distance from a wall to the pipe shall be 3 feet for repair

access.

c. Piping above grade shall be Schedule 40 polyvinyl chloride or cast iron, no hub,

with approved hanger spacing. Piping above plenum shall be cast iron, no hub.

Schedule 40 polyvinyl chloride is not approved for use in a plenum space.

d. Provide connections to all roof drains.

e. Provide information to the Site Design Professional as to the depth of the

sewer(s) exiting the building.

f. Provide information to the Structural Design Professional as to the location and

depths of the sewer in relationship to footing and column pass as they pertain to

the project.

5. Natural Gas.

a. Gas piping in plenums shall not contain valves or unions.

b. Provide a valve and a dirt leg at each appliance connection.

September 27, 2013

DIVISION 22PLUMBING

Page 7 of 13

BGSU Construction Standards

Office of Design & Construction

Bowling Green State University

c. Natural gas piping to island sinks shall be in an accessible trench in the floor with

a removable cover.

6. Potable Water.

a. All domestic water entering the building must pass through a reduced pressure

backflow preventer to protect the outside water source from contamination in the

building. A main pressure-reducing valve is required if the incoming water

pressure exceeds 80 psi.

b. Water distribution throughout the facility will be through piping systems located

above ceiling areas. Piping installed under slab areas will not be permitted,

unless accessible for maintenance on the system.

c. Domestic water systems within the building shall be copper tubing. The use of

polyvinyl chloride, chlorinated polyvinyl chloride, or polybutylene material will not

be permitted.

d. The required pressure for operation of the furthest fixture from the incoming

service will determine if a pressure booster system will be required.

e. The booster system should be a packaged unit that includes all controls. Provide

a constant-speed duplex pump package with bladder-type compression tank to

meet the flow requirements. It will be necessary to consider the installation of an

emergency power system in order to maintain the operation of the booster

system in the event of power outages, if the building is to be used during

emergency-type occupancies. Coordination with the Electrical Design

Professional will be necessary.

f. Minimum pressure required at the furthest fixture connection shall be 30 psi.

g. The minimum pipe size for potable water piping shall be -inch.

7. Valves

a. All valves shall be of one manufacturer for each type of valve.

b. Isolation valves shall be installed on all equipment.

c. Isolation valves shall be installed on all piping risers inside buildings.

d. Isolation valves shall be installed on supply and return piping at all equipment for

isolation and/or removal and also at all sinks in Residence Halls.

e. Isolation valves will be installed to isolate individual plumbing fixtures and groups

of plumbing fixtures to permit shut down of the fixture or equipment item without

affecting the remainder of the building. Isolation valves shall be provided at each

floor in an accessible chase.

f. The domestic water system valves shall be bronze construction with a ball-type

conventional port or cast iron butterfly valve per piping schedule.

g. All domestic water valves shall be full port ball type on 2 and smaller.

221006 - PLUMBING SPECIALTIES

1. Floor Drain - FD

a. Floor drains shall be installed in each large group restroom, locker room,

mechanical room, and kitchen area. Provide a sediment bucket in the floor drain

if conditions exist where solids may enter the drain only. Sediment buckets are

September 27, 2013

DIVISION 22PLUMBING

Page 8 of 13

BGSU Construction Standards

Office of Design & Construction

Bowling Green State University

not to be specified for most applications other than special applications where

required.

b. Trap primers will be required where the water in a floor drain could dry up in the

trap seal and permit sewer gases into the building. Trap primers shall be

accessible for repair.

c. All floor drain outlets - non shower drain, shall be a minimum of 3-inch.

2. Roof Drain RD

a. Cast iron body, receiver, extension for roof insulation, underdeck clamp and ply

cone.

3. Wall Hydrant WH

a. Outside wall hydrants, shall be loose key wall type, freezeproof, with vacuum

breaker.

b. Provide at intervals not to exceed 75 feet between hydrants.

4. Sanitary and storm sewer cleanouts shall be installed at 50 feet on center and at

changes in direction of 90 degrees or more, at the bottom of vertical risers and as

the sewer exits the building.

5. Install a cold/hot water stainless steel hose box in each large group restroom/shower

room. The hose box shall be recessed in wall with integral key lockable door. Hose

box shall be equal to Acorn type.

6. Reduced pressure backflow preventers are required on the water supplies to each

HVAC makeup water system.

7. A water pressure reducing station requiring 2 pressure reducing valves sized for 1/3

and 2/3 flow shall maintain the water pressure in the building to a maximum of 80

psi, if the incoming water pressure can exceed 80 psi.

8. Relief valves shall be piped to discharge in a floor drain with funnel, with only one

elbow. If more than one elbow is required, a union shall be installed close to the

valve to facilitate easy replacement. In no cases shall there be more than three

elbows from valve to point of discharge.

9. Water hammer arresters shall be installed at all major fixture groupings and

wherever there is a potential for water hammer. Water hammer arrestors shall be

installed in an accessible location or accessible via access panel where required.

10. Drain valves shall be installed at all low points in the system to facilitate drainage

and shall incorporate threaded hose adapter with chained end cap.

223000 PLUMBING EQUIPMENT

1. Simplex Clear Water Lift Station

a. Pump to be complete with built-in capacitor and starting switch, #303 Stainless

Steel shaft, ball bearings, mechanical seal and strainer.

b. NEMA alarm panel including cable, float, alarm light and alarm horn with

silencing switch. A separate 115 volt power source shall be furnished for this

alarm panel.

c. Control system with control box, two float switches with cable and a heavy duty

contactor.

September 27, 2013

DIVISION 22PLUMBING

Page 9 of 13

BGSU Construction Standards

Office of Design & Construction

Bowling Green State University

2.

3.

4.

5.

d. Clear water sump shall be cast iron with tapped flanged or precast reinforced

concrete or high strength plastic fiberglass reinforced.

e. Pump shall be screenless non-clog submersible sewage lift pump. NEMA 6 air

filled submersible type having cast iron shell with special fin cooling to permit

continuous operation while running dry. Pump shall have an oil filled seal

chamber with two (2) mechanical seals.

f. Control system shall include sealed mercury switches in a polypropylene float set

at the NEMA 1, simplex control panel, one (1) fusible disconnect switch, one (1)

magnetic starter one (1) overload reset button, one (1) running light for pump

motor, one (1) control circuit transformer, one (1) Test-Off-Automatic selector

switch, alarm light and alarm horn with silencing switch.

g. Clear water sump shall be cast iron with tapped flanged or precast reinforced

concrete, high strength plastic fiberglass reinforced.

Sanitary Waste Equipment

a. Kitchen Grease Interceptor

i. Exterior Interceptor; Prefabricated concrete reinforced tank, minimum 3 thick

of 4500 psi reinforced concrete with 6 x 6 ten gauge mesh.

ii. Interior Interceptor: Acid resisting epoxy coated interior and exterior grease

trap, internal air relief by-pass, bronze cleanout plug, visible double wall trap

seal, gas and watertight gasketed non-skid cover with stainless steel fasteners.

Simplex Sanitary Lift Station (Clear Water Only)

a. Pump to be complete with built-in capacitor and starting switch, #303 Stainless

Steel shaft, ball bearings, mechanical seal and strainer.

b. NEMA 1 alarm panel including cable, float, alarm light and alarm horn with

silencing switch.

c. Control system with control box, two float switches with cable and a heavy duty

contactor.

d. Sanitary sump shall be cast iron with tapped flange or precast reinforced

concrete or high strength plastic fiberglass reinforced supply gasketed fittings to

seal gas-tight all pipes, wires, etc. that penetrate the sump cover.

Simplex Sanitary Lift Station

a. Heavy duty screenless non-clog submersible sewage lift pumps. NEMA 6 air

filled submersible type having cast iron shell with special fin cooling to permit

continuous operation while running dry, oil filled seal chamber with two (2)

mechanical seals, capable of passing 2 solids.

b. Control system shall include sealed mercury switches in a polypropylene float

set, NEMA 1 simplex control panel, one (1) fusible disconnect switch, one (1)

magnetic starter, one (1) overload reset button, one (1) running light for pump

motor, one (1) control circuit transformer, one (1) Test-Off-Automatic selector

switch, alarm light mounted on the panel door and a NEMA 1 alarm panel.

c. Sump shall be cast iron with tapped flange or precast reinforced concrete or high

strength plastic fiberglass reinforced, supply gasketed fittings to seal gas-tight all

pipes.

Domestic Hot Water Heating

September 27, 2013

DIVISION 22PLUMBING

Page 10 of 13

BGSU Construction Standards

Office of Design & Construction

Bowling Green State University

a. Steam

i.

Buildings connected to the campus steam distribution system shall utilize

semi-instantaneous steam domestic water heaters.

ii.

Domestic hot water heat exchangers shall be installed in pairs when

possible to maintain hot water production during cleaning. This is

especially critical in laboratory buildings and residence halls. Each heat

exchanger shall be sized to handle at least two thirds of the total peak load.

b. Natural Gas

i.

Utilize natural gas fired domestic water heaters where campus steam is not

available.

ii.

Provide water heaters with Performance Efficiencies not less than

prescribed in ASHRAE 90A, Energy Conservation in New Building

Design.

c. Electric domestic water heaters shall not be permitted unless supported by an

economic evaluation incorporating first cost, operating costs and life cycle costs.

d. Instantaneous water heaters are not permitted as a primary source. For

incidental use, sporadic equipment demands, or remote individual fixtures (i.e.

lavatory, sink, shower, service sink), the use of instantaneous water heaters is

permitted. Point of use instantaneous water heaters are permitted for use at

emergency fixtures to supply tepid water immediately at the emergency fixture

or group of emergency fixtures.

e. The use of thermostatic mixing valves is required to maintain hot water

temperature consistent with the plumbing code requirement to hand washing

sinks and showers. Use of a single valve tempering device is preferred. Other

devices will be considered for use, but approval by BGSU is required. Selection

of tempering devices shall be chosen with consideration of the high mineral

content of the city of Bowling Green water provided to the BGSU Main Campus.

Provide shut off valves, unions and check valves on all incoming and outgoing

piping. Provide a bypass line with shut off valve to allow removal of the mixing

valve while maintaining hot water in service.

f. The domestic hot water system shall use a maintenance free (no oil) recirculation pump to keep the mains warm at all times. The use of heating cable

is not acceptable. The on/off operation of the domestic hot water re-circulation

pumps shall be controlled by a time clock or the temperature control system.

g. Piping to semi-instantaneous heaters shall be installed in a manner to have clear

access for tube repairs and cleaning. Valving shall allow servicing of one heater

while the other remains active. Piping connections to heaters shall be made with

copper/brass flanged connections to avoid corosion and allow easy removal,

h. A bladder type expansion tank shall be installed on all domestic hot water

systems. Expansion tank to be tagged for system operating pressure.

224000 - PLUMBING FIXTURES

1. General

September 27, 2013

DIVISION 22PLUMBING

Page 11 of 13

BGSU Construction Standards

Office of Design & Construction

Bowling Green State University

a. All plumbing fixtures shall be of one manufacturer insofar as possible and white

in color.

b. Set floor sinks in leveling bed of cement grout.

c. Water supply (hot and/or cold) to lavatories, sinks, drinking fountains, etc., shall

have angle stops with loose key handles in an accessible location.

d. Install escutcheons at each wall, floor and ceiling penetration in exposed finished

locations and within cabinets and millwork.

e. Seal fixtures to walls, floors and counters using a sanitary-type, one-part, mildewresistant, silicone sealant with sealant.

2. Shower drain traps shall be 4 diameter only, no exceptions. 3 acceptable if space

limitations dictate. Shower drain shall have square 6x6 nickel bronze top. All

shower drain traps shall be accessible for removal and cleaning. Use access panels

where necessary.

a. Lavatory drains shall be separately piped to main horizontal branches only.

Combining two or more lavatories to one drop to main is not allowed.

b. All lavatories and sink traps shall have cleanouts in bottom of trap.

3. Water closets shall be china, white, standard flush valve, wall hung only, siphon jet

design and low water consumption type. Floor set toilets shall only be used in

situations where there are no other options to provide wall hung type. Approval to

use floor set toilets will still be required. Provide hard wired sensor flush valves for

most Campus buildings except residence halls. Residence Halls shall have manual

flush valves unless prior approval is given to use other type devices.

4. Toilets seats.

a. Black seats shall be used with open front without cover. In special

circumstances, possibly some residence halls, white seats may be used if

approved by owner only.

b. Commercial, heavy duty solid plastic, elongated, self-sustaining check hinges.

5. Urinals shall be china, white, standard flush valve, wall hung, and low water

consumption type. Provide hard wired sensor flush valves for most Campus

buildings except residence halls. Residence Halls shall have manual flush valves

unless prior approval is given to use other type devices.

6. Lavatories except in Residence Halls shall have AC powered infrared faucet with the

electronics/solenoid built into the spout. Temperature control shall be integral with

the faucet or remote mixed.

7. Lavatories in Residence Halls shall have separate lever handles for hot and cold

water. Single lever faucets shall be avoided due to the likelihood of

damage/vandalization.

8. All lavatory drains shall be grid type. Pop up style drains are not acceptable unless

approved by owner.

9. All lavatory and shower faucets shall be ADA compliant, non-wrist blade type if at all

possible.

10. Showers shall have a hot and cold, single lever pressure balancing valve with a

vandal-resistant head and a stainless steel if available/metal wall plate. Plastic wall

plates are not acceptable and long length single arm temperature adjusting handles

September 27, 2013

DIVISION 22PLUMBING

Page 12 of 13

BGSU Construction Standards

Office of Design & Construction

Bowling Green State University

should be avoided. (Note: all shower valves shall have both check and stop valves

on the cold and hot water connections to the valves and preferably loose rather than

integral to the valves.)

11. Residence Halls drinking water coolers/fountains shall be handicap accessible and

fully recessed. Details are available from The BGSU Office of Design and

Construction.

12. Water cooler with bottle filling station shall be ADA compliant, stainless steel with

integral drain, 1.5 gpm with 20-second auto shut-off.

13. Stainless steel sinks when specified shall be 18-gauge, 302 or 304 stainless steel.

14. Service sinks shall be floor-mounted, molded stone, 10 inches high, with a wallmounted faucet.

15. Science lab sinks shall be connected with acid-resistant material. The science

casework manufacturer shall provide sinks.

16. All plumbing fixtures and trim designed or designated for use by the handicapped

shall meet the Americans with Disabilities Act guidelines.

17. All lavatories, water closets, and urinals shall have wall carriers.

End of Section

September 27, 2013

DIVISION 22PLUMBING

Page 13 of 13

You might also like

- 22 05 16-Expansion Fittings and Loops For Plumbing PipingDocument8 pages22 05 16-Expansion Fittings and Loops For Plumbing PipingMahmoud GwailyNo ratings yet

- 1113 DWSDWSDDocument53 pages1113 DWSDWSDenjoygurujiNo ratings yet

- HVAC Ducts and CasingsDocument10 pagesHVAC Ducts and CasingsmanikantanNo ratings yet

- SECTION 22 05 29 Hangers and Supports For Plumbing Piping and EquipmentDocument6 pagesSECTION 22 05 29 Hangers and Supports For Plumbing Piping and Equipmentmichael_george291616No ratings yet

- Hvac PipingDocument6 pagesHvac PipingSkylarNo ratings yet

- Sewage Forcemain DesignDocument9 pagesSewage Forcemain DesignMarlon A. MendozaNo ratings yet

- 15890Document15 pages15890uddinnadeemNo ratings yet

- Valve Procurement SpecsDocument39 pagesValve Procurement Specsjoseph.maquez24100% (2)

- Steel Water Pipe Specs 06Document7 pagesSteel Water Pipe Specs 06Astri NgentNo ratings yet

- Specification For Auto LPG Dispensing StationDocument5 pagesSpecification For Auto LPG Dispensing StationShyBokxNo ratings yet

- Pghu Eh Lspds 002004 Rev 0Document43 pagesPghu Eh Lspds 002004 Rev 0BhoyPachoNo ratings yet

- Part 1 - General: SECTION 21 13 13 Wet-Pipe Sprinkler SystemsDocument16 pagesPart 1 - General: SECTION 21 13 13 Wet-Pipe Sprinkler SystemsNelson VargasNo ratings yet

- Expansion Compensation For PlumbingDocument6 pagesExpansion Compensation For Plumbingabdullah sahibNo ratings yet

- MechanicalDocument173 pagesMechanicalKerx EndranoNo ratings yet

- Specification LPG ServicesDocument12 pagesSpecification LPG ServicesDak SerikNo ratings yet

- 15510Document13 pages15510mahaboobptmNo ratings yet

- Natural Gas PipingDocument3 pagesNatural Gas PipingRezaNo ratings yet

- Hangers and Supports For Hvac Piping and EquipmentDocument10 pagesHangers and Supports For Hvac Piping and EquipmentAmeen Mohamed Ali SanadNo ratings yet

- 22 11 17 - Gas Pipe and AppurtenancesDocument7 pages22 11 17 - Gas Pipe and AppurtenancesTeguh SetionoNo ratings yet

- المواسيرDocument15 pagesالمواسيرshamashergyNo ratings yet

- BK - TNG 001 TS PI SP 001 Piping Material Specification Rev.1Document45 pagesBK - TNG 001 TS PI SP 001 Piping Material Specification Rev.1Kev Tra100% (1)

- 15510Document13 pages15510uddinnadeemNo ratings yet

- PipingDocument7 pagesPipingAshar HassanNo ratings yet

- Piping BasisDocument32 pagesPiping Basislowermine100% (2)

- DR Engp 1.1 R13Document2,070 pagesDR Engp 1.1 R13Revair CostaNo ratings yet

- GSDocument58 pagesGSSalimNo ratings yet

- STD 15080Document4 pagesSTD 15080dineshinnaci123No ratings yet

- Pipe Supports Design CriteriaDocument11 pagesPipe Supports Design CriteriaJaykumar75% (4)

- SF - Domestic Water PipingDocument16 pagesSF - Domestic Water PipingJahat AtencioNo ratings yet

- BK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Document45 pagesBK TNG 001 TS PI SP 001 - Piping Specification - Rev 2Kev TraNo ratings yet

- 0032 50 L SP 015 A4 Specification For Insulating JointDocument8 pages0032 50 L SP 015 A4 Specification For Insulating JointArie SinardiNo ratings yet

- Piping ConstructionDocument17 pagesPiping Constructionadel rihana100% (1)

- Ductile Iron CastingsDocument6 pagesDuctile Iron CastingsSusan Sue Berrospi MerinoNo ratings yet

- Spec Pe Pipe Tubing Fittings WaterDocument12 pagesSpec Pe Pipe Tubing Fittings WatersabahiraqNo ratings yet

- 01LK0F01Document4 pages01LK0F01raobabar21No ratings yet

- Pipe and Pipe FittingsDocument21 pagesPipe and Pipe FittingsAdamNo ratings yet

- Piping SpecDocument355 pagesPiping Speclcaron44100% (1)

- Duct Accessories - RevDocument5 pagesDuct Accessories - RevLuis Gabriel BautistaNo ratings yet

- Steam and Steam Condensate PDocument14 pagesSteam and Steam Condensate PDanny BoysieNo ratings yet

- 15890Document9 pages15890singh1984_09No ratings yet

- Pipelines Process PipingDocument16 pagesPipelines Process PipingmariomatoNo ratings yet

- Corporation: Seamless PipeDocument8 pagesCorporation: Seamless PipeGuru Raja Ragavendran NagarajanNo ratings yet

- 03 Appendix A WL-22-05Document5 pages03 Appendix A WL-22-05pepeNo ratings yet

- Ductworks - RevDocument6 pagesDuctworks - RevLuis Gabriel BautistaNo ratings yet

- 23 11 23 Facility Natural-Gas PipingDocument19 pages23 11 23 Facility Natural-Gas PipingKak SofiNo ratings yet

- 1/27/2019 /conversion/tmp/scratch/407716113Document10 pages1/27/2019 /conversion/tmp/scratch/407716113Maki DizonNo ratings yet

- ASTM C1063-12a - Standard Specification For Installation of Lathing and Furring To Receive Interior and Exterior Portland Cement Based Plaster PDFDocument12 pagesASTM C1063-12a - Standard Specification For Installation of Lathing and Furring To Receive Interior and Exterior Portland Cement Based Plaster PDFibrahim100% (2)

- Mat 15 01Document6 pagesMat 15 01Sergio SmithNo ratings yet

- Division 23 - Heating, Ventilating, and Air-Conditioning (Hvac) Section 230529 - Hangers and Supports For Hvac Piping and EquipmentDocument14 pagesDivision 23 - Heating, Ventilating, and Air-Conditioning (Hvac) Section 230529 - Hangers and Supports For Hvac Piping and EquipmentAhmed EbrahimNo ratings yet

- Cement-Mortar Lined & Coated Steel PipeDocument5 pagesCement-Mortar Lined & Coated Steel Pipenay denNo ratings yet

- 2150 Attachment 13 - Minimum Piping DesiDocument24 pages2150 Attachment 13 - Minimum Piping Desidimdaliak_985662241100% (1)

- Hydronic Piping GuidespecDocument16 pagesHydronic Piping GuidespecTom ZimmerNo ratings yet

- Project Standard Specification: Hydronic Piping 15181 - Page 1/12Document12 pagesProject Standard Specification: Hydronic Piping 15181 - Page 1/12adel rihanaNo ratings yet

- Plug ValvesDocument14 pagesPlug Valvesashish.mathur1100% (1)

- Gas Systems For Laboratory Facilities - 1.12.15Document8 pagesGas Systems For Laboratory Facilities - 1.12.15Carl CrowNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Karate SamratDocument46 pagesKarate SamratAbhilashaVermaNo ratings yet

- Date 1Document1 pageDate 1Ritesh JainNo ratings yet

- Gate Pile DistanceDocument1 pageGate Pile DistanceRitesh JainNo ratings yet

- Sanitaryware 07 2013Document55 pagesSanitaryware 07 2013Ritesh JainNo ratings yet

- SET3Document30 pagesSET3Ritesh JainNo ratings yet

- MB0053 International Business ManagementDocument2 pagesMB0053 International Business ManagementRitesh JainNo ratings yet

- Your Faith Fully Reena Rai W/o Mr. Anil Rai C-565 Sarvdharam Colony C-Sector Kolar Road Bhopal. Date:-09.02.2013Document2 pagesYour Faith Fully Reena Rai W/o Mr. Anil Rai C-565 Sarvdharam Colony C-Sector Kolar Road Bhopal. Date:-09.02.2013Ritesh JainNo ratings yet

- Q 2Document1 pageQ 2Ritesh JainNo ratings yet

- Estimate 2 Lacs Add - AltDocument1 pageEstimate 2 Lacs Add - AltRitesh JainNo ratings yet

- Your Faith Fully Reena Rai W/o Mr. Anil Rai C-565 Sarvdharam Colony C-Sector Kolar Road Bhopal. Date:-09.02.2013Document2 pagesYour Faith Fully Reena Rai W/o Mr. Anil Rai C-565 Sarvdharam Colony C-Sector Kolar Road Bhopal. Date:-09.02.2013Ritesh JainNo ratings yet

- 1 How Do You Change Manager Recognize Resistance Employees To Change?Document1 page1 How Do You Change Manager Recognize Resistance Employees To Change?Ritesh JainNo ratings yet

- 4 Cor 92 Lacs B1 16 Jan 2011Document98 pages4 Cor 92 Lacs B1 16 Jan 2011Ritesh JainNo ratings yet

- PM0013 Fall Drive Assignment 2012Document2 pagesPM0013 Fall Drive Assignment 2012Ritesh JainNo ratings yet

- Plan SirlDocument1 pagePlan SirlRitesh JainNo ratings yet

- MB0043Document2 pagesMB0043Ritesh JainNo ratings yet

- Letter Head2Document1 pageLetter Head2Ritesh JainNo ratings yet

- Earth Pressure Coefficients CalculationsDocument34 pagesEarth Pressure Coefficients CalculationsthumatimadhusudhanNo ratings yet

- Introduction To Materials TestingDocument6 pagesIntroduction To Materials Testinggosaye desalegnNo ratings yet

- Assignment 10 PDFDocument2 pagesAssignment 10 PDFarchies iescaNo ratings yet

- Bowles J. E. - FDN - Analysis & DSNDocument2 pagesBowles J. E. - FDN - Analysis & DSNharishNo ratings yet

- (Cementitious) Stocrete 4222Document2 pages(Cementitious) Stocrete 4222ginasuhandiniNo ratings yet

- Fisher Globe Valve Selection GuideDocument12 pagesFisher Globe Valve Selection GuideAmiroucheBenlakehalNo ratings yet

- Comp - Statement of Lab EquipmentsDocument8 pagesComp - Statement of Lab EquipmentsKumar gsNo ratings yet

- KAT NX KSA 2020 EN WebDocument220 pagesKAT NX KSA 2020 EN WebSULISTYOWATINo ratings yet

- AVANTI Product Catalogue 2014 EnglishDocument36 pagesAVANTI Product Catalogue 2014 EnglishArouna GoudiabyNo ratings yet

- Chicago School Louis SullivanDocument19 pagesChicago School Louis SullivanKumar SatyamNo ratings yet

- Finishes 4 - ExternalDocument24 pagesFinishes 4 - ExternalMuhammad FakhriNo ratings yet

- Poulos 2018 Subgrade PDFDocument7 pagesPoulos 2018 Subgrade PDFWeimar Garcia0% (1)

- Structural Design PDFDocument683 pagesStructural Design PDFKanenus B Finfinnee100% (1)

- Poliuretano Inyección Hidrofobico 10L Catalizador FichaDocument5 pagesPoliuretano Inyección Hidrofobico 10L Catalizador FichaVictor Hugo Opazo CarreñoNo ratings yet

- A6V10069593 - Linear Smoke Detector - BR - Linearer Rauchmelder - BR - enDocument8 pagesA6V10069593 - Linear Smoke Detector - BR - Linearer Rauchmelder - BR - enVladimir BukaricaNo ratings yet

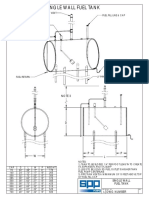

- Deposito Diessel-Newberry - Data Sheet - Drawing - Single Fuel Tank PDFDocument4 pagesDeposito Diessel-Newberry - Data Sheet - Drawing - Single Fuel Tank PDFRolan PonceNo ratings yet

- Measurement of in Situ Shear Strength of Rock Mass: Rajbal SinghDocument12 pagesMeasurement of in Situ Shear Strength of Rock Mass: Rajbal SinghManish Kumar SinghNo ratings yet

- Frigidaire Frs26zsh Manual SuplementarioDocument21 pagesFrigidaire Frs26zsh Manual SuplementarioFernando lobo100% (1)

- Hemp LimeDocument18 pagesHemp LimePranav Chovatiya0% (1)

- Abstract Municipal RoadsDocument8 pagesAbstract Municipal RoadsYhanilyn MasacoteNo ratings yet

- Residential Construction in The UAE To 2019 Market ForecastDocument8 pagesResidential Construction in The UAE To 2019 Market Forecastnitika6390No ratings yet

- Design ConstrDocument36 pagesDesign ConstrgrigoregrigoreNo ratings yet

- Mix CalculationDocument8 pagesMix CalculationPrasanna KumarNo ratings yet

- Site Inspection ReportDocument45 pagesSite Inspection ReportAhmad HasnanNo ratings yet

- Factors Influencing Project Delay: A Case Study of The Vale Malaysia Minerals Project (VMMP)Document8 pagesFactors Influencing Project Delay: A Case Study of The Vale Malaysia Minerals Project (VMMP)LOKESH KUMAR SINHANo ratings yet

- Pizza OvenDocument8 pagesPizza OvenNebojsa GolubovicNo ratings yet

- Construction Materials BrochureDocument12 pagesConstruction Materials BrochurejanakarajNo ratings yet

- Capitol Steel Corporation-RSB PDFDocument1 pageCapitol Steel Corporation-RSB PDFeg choloNo ratings yet

- Earthquake Resistant Structure - NOTES 3rd YR V SEMDocument12 pagesEarthquake Resistant Structure - NOTES 3rd YR V SEMrutuja100% (1)

- Cere 131.2 EditedDocument3 pagesCere 131.2 EditedMary Elizabeth SolasNo ratings yet