Professional Documents

Culture Documents

Environmental Issues in EMS

Uploaded by

papplionCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Environmental Issues in EMS

Uploaded by

papplionCopyright:

Available Formats

As of April 30 2007, this document is NO LONGER IN USE by the

Pollution Prevention and Abatement Handbook

World Bank Group. The new versions of the World Bank Group

WORLD BANK GROUP

Environmental, Health, and Safety Guidelines are available at

Effective July 1998

http://www.ifc.org/ifcext/enviro.nsf/Content/EnvironmentalGuidelines

Electronics Manufacturing

Industry Description and Practices

sides), and multilayer (three or more circuit layers). Board manufacturing is accomplished by

producing patterns of conductive material on a

nonconductive substrate by subtractive or additive processes. (The conductor is usually copper;

the base can be pressed epoxy, Teflon, or glass.)

In the subtractive process, which is the preferred

route, the steps include cleaning and surface

preparation of the base, electroless copperplating,

pattern printing and masking, electroplating, and

etching.

Printed wiring assemblies. Printed wiring assemblies consist of components attached to one or

both sides of the printed circuit board. The attachment may be by through-hole technology, in

which the legs of the components are inserted

through holes in the board and are soldered in

place from underneath, or by surface mount technology (SMT), in which components are attached

to the surface by solder or conductive adhesive.

(The solder is generally a tin-lead alloy.) In

printed circuit boards of all types, drilled holes

may have to be copper-plated to ensure interconnections between the different copper layers.

SMT, which eliminates the drilled holes, allows

much denser packing of components, especially

when components are mounted on both sides. It

also offers higher-speed performance and is gaining over through-hole technology.

The electronics industry includes the manufacture of passive components (resistors, capacitors,

inductors); semiconductor components (discretes,

integrated circuits); printed circuit boards (single

and multilayer boards); and printed wiring assemblies. This chapter addresses the environmental

issues associated with the last three manufacturing processes. The manufacture of passive components is not included because it is similar to

that of semiconductors. (A difference is that passive component manufacturing uses less of the

toxic chemicals employed in doping semiconductor components and more organic solvents, epoxies, plating metals, coatings, and lead.)

Semiconductors. Semiconductors are produced

by treating semiconductor substances with

dopants such as boron or phosphorus atoms to

give them electrical properties. Important semiconductor substances are silicon and gallium arsenide. Manufacturing stages include crystal

growth; acid etch and epitaxy formation; doping

and oxidation; diffusion and ion implantation;

metallization; chemical vapor deposition; die

separation; die attachment; postsolder cleaning;

wire bonding; encapsulation packaging; and final testing, marking, and packaging. Several of

these process steps are repeated several times,

so the actual length of the production chain may

well exceed 100 processing steps. Between the

repetitions, a cleaning step that contributes to the

amount of effluent produced by the process is

often necessary. Production involves carcinogenic

and mutagenic substances and should therefore

be carried out in closed systems.

Printed circuit board (PCB) manufacturing. There

are three types of boards: single sided (circuits

on one side only), double sided (circuits on both

Waste Characteristics

Air Emissions

Potential air emissions from semiconductor manufacturing include toxic, reactive, and hazardous

gases; organic solvents; and particulates from the

process. The changing of gas cylinders may also

result in fugitive emissions of gases. Chemicals

302

Electronics Manufacturing

in use may include hydrogen, silane, arsine, phosphine, diborane, hydrogen chloride, hydrogen

fluoride, dichlorosilane, phosphorous oxychloride, and boron tribromide.

Potential air emissions from the manufacture

of printed circuit boards include sulfuric, hydrochloric, phosphoric, nitric, acetic, and other acids; chlorine; ammonia; and organic solvent

vapors (isopropanol, acetone, trichloroethylene;

n-butyl acetate; xylene; petroleum distillates; and

ozone-depleting substances).

In the manufacture of printed wiring assemblies,

air emissions may include organic solvent vapors

and fumes from the soldering process, including

aldehydes, flux vapors, organic acids, and so on.

Throughout the electronics manufacturing

sector, chlorofluorocarbons (CFCs) have been a

preferred organic solvent for a variety of applications. CFCs are ozone-depleting substances

(ODSs). Their production in and import into developing countries will soon be banned.

Hydrochlorofluorocarbons (HCFCs) have been

developed as a substitute for CFCs, but they too

are ODSs and will be phased out. Methyl chloroform, another organic solvent, has also been used

by the electronics industry; it too is an ODS and

is being eliminated globally on the same schedule as CFCs. Chlorobromomethane and n-propyl

bromide are also unacceptable because of their

high ozone-depleting potential.

Effluents

Effluents from the manufacture of semiconductors

may have a low pH from hydrofluoric, hydrochloric, and sulfuric acids (the major contributors to low pH) and may contain organic solvents,

phosphorous oxychloride (which decomposes in

water to form phosphoric and hydrochloric acids), acetate, metals, and fluorides.

Effluents from the manufacture of printed circuit boards may contain organic solvents, vinyl

polymers; stannic oxide; metals such as copper,

nickel, iron, chromium, tin, lead, palladium, and

gold; cyanides (because some metals may be

complexed with chelating agents); sulfates; fluorides and fluoroborates; ammonia; and acids.

Effluents from printed wiring assemblies may

contain acids, alkalis, fluxes, metals, organic solvents, and, where electroplating is involved,

metals, fluorides, cyanides, and sulfates.

303

Solid and Hazardous Wastes

Solid and hazardous wastes from semiconductor

manufacture may include heavy metals, solder

dross (solder pot skimmings), arsenic, spent epoxy, and waste organic solvents (contributing the

largest volume of waste). In printed circuit board

operations, solid wastes may include scrap board

materials, plating and hydroxide sludges, and

inks. In the manufacture of printed wiring assemblies, solid wastes may include solder dross, scrap

boards, components, organic solvents, and metals. Boards may also be treated with brominated

flame retardants, which may pose some environmental risk when boards are disposed of in landfills. All conventional electronics present

additional hazards in landfills because of the

presence of lead in cathode-ray tube envelopes

and in solder, as well as lead and other metal salts,

particularly if they have not been cleaned in a

postsoldering operation.

All three manufacturing processes may generate sludges containing heavy metals from

wastewater treatment plants. Organic solvent

residues also require management and disposal.

Pollution Prevention and Control

Semiconductor Industry

Measures such as plasma etching of silicon nitride (a dry process) in metal oxide semiconductor (MOS) technology replace the hot corrosive

phosphoric acid (H3PO4) wet process and offer

reductions in generated waste and better safety

for workers while reducing the number of processing steps. Because of the reaction of the

plasma with the substrate, several substances are

formed that are regarded as carcinogenic or mutagenic and that may pose a danger to maintenance personnel. Risks are minimized by

sweeping equipment with nitrogen before opening it. A gas mask with breathing equipment

should be worn by personnel during repair and

maintenance.

Printed Circuit Board Manufacturing

A number of process alternatives exist for the

manufacture of printed circuit boards. These include:

304

PROJECT GUIDELINES: INDUSTRY SECTOR GUIDELINES

In board manufacture: SMT rather than plated

through-hole technology; injection molded

substrate; additive plating

In cleaning and surface preparation: use of

nonchelating cleaners; extension of bath life;

improvement of rinse efficiency; countercurrent cleaning; recycling and reuse of cleaners

and rinses

In pattern printing and masking: aqueous

processable resist; screen printing to replace

photolithography; dry photoresist; recycling

and reuse of photoresist strippers; segregation

of streams; recovery of metals

For electroplating and electroless plating: replacement of these processes by mechanical

board production; use of noncyanide baths;

extension of bath life; recycling and reuse of

cleaners and rinses; improvement of rinse efficiency; countercurrent rinsing; segregation of

streams; recovery of metals

In etching: use of differential plating; use of

nonchelated etchants and nonchrome etchant;

use of pattern instead of panel plating; use of

additive instead of subtractive processes; recycling and reuse of etchants.

Metal recovery by regenerative electrowinning

results in a near-zero effluent discharge for segregated metal-bearing streams. Heavy metals are

recovered to metal sheets, which eliminates 95%

of sludge disposal. Metal-bearing sludges that are

not treated for recovery of metals should be disposed of in secure landfills.

Printed Wiring Assemblies

In the printed wiring assembly process, nonozone-depleting alternatives are readily available

for cleaning printed wiring assemblies. These alternatives include other organic solvents, hydrocarbon/surfactant blends, alcohols, and organic

solvent blends, as well as aqueous and semiaqueous processes. More important, the industry has shown that even sophisticated printed

wiring assemblies intended for military uses

(where specifications are very exacting) can be

made without cleaning by using low-residue

fluxes that leave very little in the way of contamination on the boards. The no-clean concept

does away with the use of organic solvents and

the need to dispose of organic solvent waste,

eliminates a process step and the corresponding equipment, and has been shown to give

adequate product quality according to the

application.

General

Organic solvent losses can be reduced by conservation and recycling, using closed-loop delivery

systems, hoods, fans, and stills. Installation of

activated carbon systems can achieve up to 90%

capture and recycle of organic solvents used in

the system. All solvents and hazardous chemicals (including wastes) require appropriate safe

storage to prevent spills and accidental discharges. All tanks, pipework, and other containers should be situated over spill containment trays

with dimensions large enough to contain the total volume of liquid over them. Containment facilities must resist all chemical attack from the

products. In lieu of containment facilities, the floor

and walls, to a reasonable height, may be treated

(e.g., by an epoxy product, where chemically appropriate) to prevent the possibility of leakage of

accidental spills into the ground, and there should

be doorsills. (Untreated cement or concrete or

grouted tile floors are permeable.) It is unacceptable to have a drain in the floor of any shop where

chemicals of any description are used or stored,

except where such a drain leads to an adequate

water-treatment plant capable of rendering used

or stored chemicals in its catchment area.

Waste organic solvents should be sent to a solvent recycling operation for reconstitution and

reuse. Where recycling facilities are not available,

waste solvents may need to be incinerated or

destroyed as appropriate for their chemical composition.

Target Pollution Loads

Implementation of cleaner production processes

and pollution prevention measures can yield both

economic and environmental benefits. The following production-related targets can be

achieved by measures such as those described in

the previous section.

Ozone-depleting substances are not to be used

in production operations unless no proven alternative exists. Discharges of organic solvents

should be minimized, and alternative technolo-

Electronics Manufacturing

gies should be considered where available. Solder dross should not be sent to landfills. (Waste

can be sent to suppliers or approved waste recyclers for recovery of the lead and tin content of

the dross.) Scrap boards and assemblies having

soldered components should have their components and solder connections removed before

they are sent to landfills or recycled for other uses.

Treatment Technologies

Wet scrubbers, point-of-use control systems, and

volatile organic compound (VOC) control units

are used to control toxic and hazardous emissions

of the chemicals used in semiconductor manufacturing. It is often appropriate to scrub acid and

alkaline waste gases in separate scrubbers because different scrubber liquids can then be used,

resulting in higher removal efficiencies.

Air emission concentrations of chemicals such

as arsine, diborane, phosphine, silane, and other

chemicals used in the process should be reduced

below worker health levels for plant operations.

Because of the many chemicals used in the electronics industry, wastewater segregation simplifies waste treatment and allows recovery and

reuse of materials. Organic wastes are collected

separately from wastewater systems. (Note that

solvent used in the semiconductor industry

cannot be readily recycled because much of it

is generated from complex mixtures such as photoresist.) Acids and alkalis are sent to onsite

wastewater treatment facilities for neutralization,

after segregation of heavy-metal-bearing streams

for separate treatment. Fluoride-bearing streams

in a semiconductor plant are segregated and

treated on site or sent off site for treatment or

disposal. Treatment steps for effluents from the

electronics industry may include precipitation,

coagulation, sedimentation, sludge dewatering,

ion exchange, filtering, membrane purification

and separation, and neutralization, depending on

the particular stream. Sanitary wastes are treated

separately (primary and secondary treatment

followed by disinfection) or discharged to a municipal treatment system.

Emissions Guidelines

Emissions levels for the design and operation of

each project must be established through the en-

305

vironmental assessment (EA) process on the basis of country legislation and the Pollution Prevention and Abatement Handbook, as applied to

local conditions. The emissions levels selected

must be justified in the EA and acceptable to the

World Bank Group.

The guidelines given below present emissions

levels normally acceptable to the World Bank

Group in making decisions regarding provision

of World Bank Group assistance. Any deviations

from these levels must be described in the World

Bank Group project documentation. The emissions levels given here can be consistently

achieved by well-designed, well-operated, and

well-maintained pollution control systems.

The guidelines are expressed as concentrations

to facilitate monitoring. Dilution of air emissions

or effluents to achieve these guidelines is unacceptable.

All of the maximum levels should be achieved

for at least 95% of the time that the plant or unit

is operating, to be calculated as a proportion of

annual operating hours.

Air Emissions

The air emissions levels presented in Table 1

should be achieved.

Liquid Effluents

The effluent levels presented in Table 2 should

be achieved.

Ambient Noise

Noise abatement measures should achieve either

the levels given below or a maximum increase in

background levels of 3 decibels (measured on the

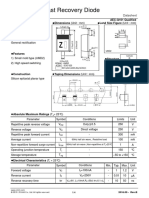

Table 1. Air Emissions from Electronics

Manufacturing

(milligrams per normal cubic meter)

Parameter

VOC

Phosphine

Arsine

Hydrogen fluoride

Hydrogen chloride

Maximum value

20

1

1

5

10

306

PROJECT GUIDELINES: INDUSTRY SECTOR GUIDELINES

Table 2. Effluents from Electronics

Manufacturing

(milligrams per liter, except for pH )

Parameter

Maximum value

pH

BOD

TSS

Maximum

Monthly average

Oil and grease

Phosphorus

Fluoride

Ammonia

Cyanide

Total

Free

Total chlorocarbons and

hydrochlorocarbons

Metals, total

Arsenic

Chromium, hexavalent

Cadmium

Copper

Lead

Mercury

Nickel

Tin

69

50

50

20

10

5.0

20

10

cess. Effluents should be monitored continuously

for pH, and other parameters should be tested

once a month.

Monitoring data should be analyzed and reviewed at regular intervals and compared with

the operating standards so that any necessary

corrective actions can be taken. Records of monitoring results should be kept in an acceptable

format. The results should be reported to the

responsible authorities and relevant parties, as

required.

Key Issues

1.0

0.1

The key production and control practices that will

lead to compliance with emissions requirements

can be summarized as follows:

0.5

10

0.1

0.1

0.1

0.5

0.1

0.01

0.5

2.0

Cylinders of toxic gases should be well secured

Note: Effluent requirements are for direct discharge to surface

waters.

A scale) [dB(A)]. Measurements are to be taken

at noise receptors located outside the project

property boundary.

Receptor

Residential,

institutional,

educational

Industrial,

commercial

Maximum allowable log

equivalent (hourly

measurements), in dB(A)

Day

Night

(07:0022:00) (22:0007:00)

55

45

70

70

and fitted with leak detection devices as appropriate. Well-designed emergency preparedness programs are required. Note that fugitive

emissions occurring when gas cylinders are

changed do not normally require capture for

treatment, but appropriate safety precautions

are expected to be in place.

No ozone-depleting chemicals should be used

in the process unless no proven alternatives

are available.

Equipment, such as refrigeration equipment,

containing ozone-depleting chemicals should

not be purchased unless no other option is

available

Toxic and hazardous sludges and waste materials must be treated and disposed of or sent

to approved waste disposal or recycling

operations

Where liquid chemicals are employed, the

plant, including loading and unloading areas,

should be designed to minimize evaporation

(other than water) and to eliminate all risk of

chemicals entering the ground or any watercourse or sewerage system in the event of an

accidental leak or spill.

Monitoring and Reporting

Source

Monitoring of sources of toxic emissions (such

as the toxic gases used in the semiconductor industry, should be continuous and part of the pro-

World Bank. 1997. Industrial Pollution Prevention and

Abatement: Electronics Manufacturing. Draft Technical Background Document. Environment Department, Washington, D.C.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Smartphone 4G Handset Repairing SyllabusDocument11 pagesSmartphone 4G Handset Repairing SyllabusVaibhav jagtap0% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- IQA Auditor TrainingDocument112 pagesIQA Auditor Trainingpapplion100% (5)

- ASCEN SMT Conveyor List 0Document22 pagesASCEN SMT Conveyor List 0Igur EuiNo ratings yet

- Customer Complaint HandlingDocument7 pagesCustomer Complaint HandlingpapplionNo ratings yet

- DG2IAQ Modification Sheet President LincolnDocument11 pagesDG2IAQ Modification Sheet President LincolnSalvador Lopez BoschNo ratings yet

- AEC Q200 Rev C CompleteDocument119 pagesAEC Q200 Rev C Completekalisto88100% (1)

- Control Plan For Lighting ProductDocument6 pagesControl Plan For Lighting ProductpapplionNo ratings yet

- ASQ Auditing HandbookDocument6 pagesASQ Auditing Handbookpapplion0% (5)

- 19 Internal Audit Check ListDocument6 pages19 Internal Audit Check ListpapplionNo ratings yet

- Improving Wave Soldering MachineDocument49 pagesImproving Wave Soldering MachinedangmiuNo ratings yet

- Component Shelf Life 8a GEDocument35 pagesComponent Shelf Life 8a GEpapplionNo ratings yet

- Ipc D 325aDocument6 pagesIpc D 325apapplion0% (1)

- Apex Expo 2013 Show DirectoryDocument151 pagesApex Expo 2013 Show DirectoryAman KumarNo ratings yet

- ISO 9001:2008 Management Review Meeting Sep. 2014Document44 pagesISO 9001:2008 Management Review Meeting Sep. 2014papplionNo ratings yet

- Intertek - Ingress - Protection - Rev2013Document8 pagesIntertek - Ingress - Protection - Rev2013papplionNo ratings yet

- Improve Yields Using Root Cause - PPTDocument39 pagesImprove Yields Using Root Cause - PPTpapplionNo ratings yet

- 04 Tightening Reliability PDFDocument22 pages04 Tightening Reliability PDFpapplionNo ratings yet

- Street Light RelibilityDocument7 pagesStreet Light RelibilitypapplionNo ratings yet

- 03 Inspecting Tightening Torque PDFDocument4 pages03 Inspecting Tightening Torque PDFpapplionNo ratings yet

- A Chameleon: by Anton ChekhovDocument3 pagesA Chameleon: by Anton ChekhovpapplionNo ratings yet

- Performance Measurement of R&D Projects in A Multi Project Concurrent Engineering EnvironmentDocument13 pagesPerformance Measurement of R&D Projects in A Multi Project Concurrent Engineering EnvironmentpapplionNo ratings yet

- SRG Audit 2014 Assessment For SQE 09102015Document168 pagesSRG Audit 2014 Assessment For SQE 09102015papplion100% (1)

- Porter's Five Forces - SRTDocument19 pagesPorter's Five Forces - SRTpapplionNo ratings yet

- Six SigmaDocument9 pagesSix SigmapapplionNo ratings yet

- Basic Communication Skills 198Document16 pagesBasic Communication Skills 198BKALATHOTI9666No ratings yet

- Usb-Synth-Assembly 20v2 05 PDFDocument30 pagesUsb-Synth-Assembly 20v2 05 PDFyo8rzeNo ratings yet

- Do Mai Lam PHD Thesis. Vapor Phase SolderingDocument105 pagesDo Mai Lam PHD Thesis. Vapor Phase SolderingDo Mai LamNo ratings yet

- POPTRONICS Capacitance MeterDocument11 pagesPOPTRONICS Capacitance Metermiguel_gonzalez_33No ratings yet

- IRFR 420-IRFU 420-SiHFR420-SiHFU420 - MosfetDocument11 pagesIRFR 420-IRFU 420-SiHFR420-SiHFU420 - MosfetTiago LeonhardtNo ratings yet

- GSM Phone Repairs & Maintenance Training: Program ObjectiveDocument34 pagesGSM Phone Repairs & Maintenance Training: Program ObjectiveDahiru MahmudNo ratings yet

- BK 8309Document64 pagesBK 8309Dragan LazicNo ratings yet

- Kem R7005 Uc2 Ud2-541010Document18 pagesKem R7005 Uc2 Ud2-541010Anonymous C6Vaod9No ratings yet

- Littelfuse - TVS - Diode - SMBJ - Datasheet PDFDocument6 pagesLittelfuse - TVS - Diode - SMBJ - Datasheet PDFsamuelborgesNo ratings yet

- Joint Industry Standard: Solderability Tests For Printed BoardsDocument3 pagesJoint Industry Standard: Solderability Tests For Printed BoardsMuhammad Umar TariqNo ratings yet

- IPC-SM-785: Guidelines For Accelerated Reliability Testing of Surface Mount Solder AttachmentsDocument3 pagesIPC-SM-785: Guidelines For Accelerated Reliability Testing of Surface Mount Solder AttachmentsAfzal ImamNo ratings yet

- Low Current SMD LED PDFDocument6 pagesLow Current SMD LED PDFDouglas BeltránNo ratings yet

- CQ tv236 PDFDocument40 pagesCQ tv236 PDFbarbarianaterNo ratings yet

- Circuits Assembly - December 2008Document54 pagesCircuits Assembly - December 2008upmg100% (5)

- Diodo RB751V-40 - NC DatasheetDocument4 pagesDiodo RB751V-40 - NC DatasheetAlexander PeñaNo ratings yet

- Super Fast Recovery Diode: Rf01Vm2SfhDocument6 pagesSuper Fast Recovery Diode: Rf01Vm2SfhYogi SaputraNo ratings yet

- Capacitor Tantalio SMT 1206KEM T2005 T491Document24 pagesCapacitor Tantalio SMT 1206KEM T2005 T491Jeziel Vazquez NavaNo ratings yet

- Vitec Current SensingDocument32 pagesVitec Current SensingKhalid Khassawneh100% (1)

- DatasheetDocument36 pagesDatasheetArita SargNo ratings yet

- Data Sheet: TEA5591ADocument14 pagesData Sheet: TEA5591AmplennaNo ratings yet

- How To Use SMT Red GlueDocument3 pagesHow To Use SMT Red GlueShamsur RahmanNo ratings yet

- Electromagnetic Simulation Workflow For RF Modules in The Age of LTEDocument4 pagesElectromagnetic Simulation Workflow For RF Modules in The Age of LTEarushi sharmaNo ratings yet

- SiliconDocument56 pagesSiliconLuan MinhNo ratings yet

- IoT in Electronics Manufacturing (White Paper)Document17 pagesIoT in Electronics Manufacturing (White Paper)John JalaniNo ratings yet

- WS2815 LED DatasheetDocument8 pagesWS2815 LED DatasheetDaisyNo ratings yet