Professional Documents

Culture Documents

Saferad Procedure

Uploaded by

Exsan OthmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saferad Procedure

Uploaded by

Exsan OthmanCopyright:

Available Formats

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 1 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

CLIENT

Title:

SAFERAD PROCEDURE

SAFERAD

PROCEDURE

TABLE OF CONTENTS

SECTION

DESCRIPTION

1.0

PURPOSE

2.0

SCOPE

Printed on Monday, August 17, 2015

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 2 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

Title:

SAFERAD PROCEDURE

3.0

RESPONSIBILITY

4.0

DEFINITION

5.0

SAFETY

6.0

PERSONNEL

7.0

PREPARATION

8.0

TOOLS & EQUIPMENT

9.0

PROCEDURE

10.0

ACCEPTANCE CRITERIA

11.0

DOCUMENTATION

12.0

REFERENCES

13.0

ATTACHMENTS

Printed on Monday, August 17, 2015

CLIENT

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 3 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

CLIENT

Title:

SAFERAD PROCEDURE

1.0

PURPOSE

This procedure describes the proper method of carrying out Saferad Testing as described in

Article 2 for examination of materials including castings and welds shall be used together

with Article 1.

2.0 SCOPE

This procedure describes the radiographic methods to be employed by Testex (M) Sdn Bhd

for the Radiographic Inspection of butt welds in accordance with ASME Section V.

3.0 RESPONSIBILITY

3.1

The NDT Supervisor shall possess minimum of Level II in Radiography Testing.

He/she shall be the focal person and will assume total responsibility of the companys

performance during execution of the WORKS. He will also double-up his function as

to oversee and manage the Safety and Quality aspects of the WORKS and Companys

resources.

3.2

The NDT Level II Operators is responsible for performing the activity, preparing the

Activity Report, and evaluate the results.

4.0 DEFINITION

Client Company or organization for whom Testex (M) Sdn Bhd performing the work.

LPTA

Lembaga Periesenan Tenaga Atom, Malaysia (Atomic Energy

Licensing Board)

NDT

Non-Destructive Testing

ASNT

American Society for Non-Destructive Testing

MLVK

Majlis Latihan Vokasional Kebangsaan,Malaysia(National Vocational Training

Council)

PCN

Personnel Certification Scheme for Non-Destructive Testing

CSWIP

Certification Scheme for Weld Inspection Personnel

IQI

Image Quality Indicator

Printed on Monday, August 17, 2015

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 4 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

CLIENT

Title:

SAFERAD PROCEDURE

5.0

SAFETY

5.1

All Radiographic work shall be carried out in accordance with Statutory Safety

Requirements (AELB), Testex (M) Sdn. Bhds Radiation Protection Program/Safety

Standing Instructions that was approved by AELB and Client Regulations. Adherence

to these regulations is mandatory.

5.2 Special precautions must be taken to protect personnel from radiation hazards. The

assigned person performing the examination must be aware of the special precautions,

including barricading of the exposure area.

5.3

The detail work procedures in this program require that all inspection activities be

conducted such that all risks to safety health and the environments are minimized to

an acceptable level. Therefore the following requirement should be met;

i.

Job Safety Analysis (JSA) be undertaken for all inspection work procedures

(Refer to JSA attached).

ii.

Safe work procedures shall be documented for inspection procedures. These

should clearly cover permit requirement, protective equipments and

requirements for working at heights and in confine space areas.

6.0 QUALIFICATION OF PERSONNEL

Radiographic Inspection work shall be carried our by two Radiographers. The technicians

shall be required to hold the followings;

a) Radiographer

A Valid LPTA Radiographer Operator License and a current

Certificate Proficiency in Radiography Level II to a recognize

qualification and certification scheme.

b) Radiographic Interpreter

A current Certificate of Proficiency in Radiography Level II,

Level III, or Radiographic Interpreter to a recognized

qualification and certification scheme.

The following recognized qualification and certification scheme may be used for the purpose

of qualification and certification of personnel:a) ASNT (in accordance with the companys written practice)

b) MLVK

c) PCN/CSWIP

Alternative qualifications shall only be acceptable with the prior consent of the Client and

Companys Level III

.

Printed on Monday, August 17, 2015

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 5 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

CLIENT

Title:

SAFERAD PROCEDURE

7.0

PREPARATION

Saferad (Radiography) Inspection shall only be carried out on welds which has visually

inspected and any remedial work necessary is completed and accepted by the

Client In addition, the Radiographer inspects the weld surface for any

irregularities that may mask or confuse interpretation of the final radiograph.

8.0

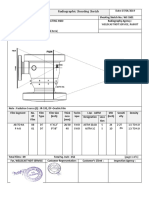

RADIOGRAPHIC TOOLS & EQUIPMENT

For Saferad (Radiography) work, Se-75 Saferad or equivalent Containers and remote

Control Wind outs will be used8.1

LOCATION OF DATUM

All welds will be positively marked datum and each portion under examination

shall be positively identified by marking along the length of the weld.

This may be achieved by taking measurements along the length of the weld from

an agreed datum. For tubular structure, the 'clock face' method shall be employed

and the datum line shall be positioned, as follows:

For horizontal and inclined tubular structure, the datum is the highest point in the

joint when viewed from the lower numbered joint

For vertical tubular structure, the datum is north, when the join is viewed vertically

downwards.

In all cases the datum shall be indelibly marked on the welds. A meter band

incorporating lead numerals along the weld shall be utilized to allow positive

location of any discontinuity.

8.2

CASSETTES

Flexible envelope cassettes shall be used unless specifically stated otherwise.

Ensure close Film-To-Screen and Cassette-To-Object Contact

The use of pre-pack film with integral metal screens may be used with written

agreement from the client

Printed on Monday, August 17, 2015

TestEx

Mechanical Integrity System Manual

CLIENT

Author: Yusoff B Ismail

Page 6 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

Title:

SAFERAD PROCEDURE

8.3

FILM

8.3.1

Type of Film

Radiographs shall be made using industrial radiographic film and shall be

selected from Table I below.

Table 1: Selection of Radiographic Film

Class of Film

Brand

Type

Size of Film used

I

(high sensitive film)

Dupond

Agfa

Kodak

NDT55

D4

MX

4 x 10

4 x 15

14 x 17

II

(sensitive film)

Dupond

Agfa

Kodak

NDT70

D7

CX

4 x 10

4 x 15

14 x 17

Films shall have sufficient length and shall be placed to produced at least 13 mm of film

expose to direct radiation beyond each edge where the weld is terminated

8.3.2

Overlap

If more than one film is required in single exposure, overlapping cassettes

shall be used. Radiographs shall have 25 mm overlap at each end to ensure

that no portion of the joint remains unexamined. There shall be a specific lead

marker visible on both radiographs in the overlap.

8.4

SCREENS

Lead intensifying screens shall be used. The front screen thickness shall normally be

0.125 mm and rear will normally be 0.125 mm.

Screen shall be examined and cleaned on a regular basis (every time before film

loading) for dirt or blemishes that may transfer onto the film thus confusion with and

masking of defect images.

Printed on Monday, August 17, 2015

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 7 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

CLIENT

Title:

SAFERAD PROCEDURE

8.5 GAMMA RAY SOURCE

The Selenium-75, an artificial isotope with a half-life of 119.8 days shall be used.

9.0

8.5.1

Source Size

The size of Se-75 source shall be as per stated in the suppliers decay curves

i.e diameter 3.0 mm, length 3.0 mm and diagonal 4.24 mm

8.5.2

Source Strength

For safety reasons the maximum source strength in every container is limit to

80 curies (3 Tbq)

RADIOGRAPHIC PROCEDURE.

9.1

Radiographic Inspection techniques

Radiographic Inspection techniques shall be carried out in accordance with the

current edition of ASME section V Article 2.

A single-wall exposure technique shall be used for radiography whenever practical.

When it is not practical to use a single-wall technique, a double-wall technique shall

be used. An adequate number of exposures shall be made to demonstrate that the

required coverage has been obtained.

9.1.1

Single-Wall Technique

In the single-wall technique, the radiation passes through on one wall of the

weld (material), which is viewed for acceptance on the radiograph.

9.1.2

Double-Wall Technique.

When it is not practical to use a single-wall technique, one of the following

double-wall techniques shall be used.

a)

Single-Wall Viewing

For materials and for welds in components, a technique may be used in

which the radiation passes through two walls and only the weld

(material) on the film-side wall is viewed for acceptance on the

radiograph. When complete coverage is required for circumferential

welds (materials), a minimum of three exposures taken 120 deg. to

each other shall be made.

b)

Double-Wall Viewing.

For materials and for welds in components 3 1/2 in. (89 mm) or less in

nominal outside diameter, a technique may be used in which the

radiation passes through two walls and the weld (material) in both

walls is viewed for acceptance on the same radiograph. For doublewall viewing, only a source-side IQI shall be used. Care should be

exercised to ensure that the required geometric un-sharpness is not

Printed on Monday, August 17, 2015

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 8 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

CLIENT

Title:

SAFERAD PROCEDURE

exceeded. If the geometric un-sharpness requirement cannot be met,

then single-wall viewing shall be used.

9.3

i.

For welds, the radiation beam may be offset from the plane of

the weld at an angle sufficient to separate the images of the

source-side and film-side portions of the weld so that there is

no overlap of the areas to be interpreted. When complete

coverage is required, a minimum of two exposures taken 90

deg to each other shall be made for each joint.

ii.

As an alternative, the weld may be radiograph with the

radiation beam positioned so that the images of both walls are

superimposed. When complete coverage is required, a

minimum of three exposures taken at either 60 deg or 120

deg to each other shall be made for each joint.

iii.

Additional exposures shall be made if the required

radiographic coverage cannot be obtained using the minimum

number of exposures indicated in (i) or (ii) above.

GEOMETRIC RELATIONSHIPS

9.3.1 The geometric un-sharpness of the radiograph shall be determined in

accordance in accordance with:Geometric un-sharpness,

Ug = Fd/(S-d)

Where Ug - geometric un-sharpness

F - focal spot size of source size

d - object to film distance

S - focal spot-to-film distance (x-ray) or source-to-film distance

(Gamma Ray)

9.3.2

Geometric Un-sharpness of the radiograph shall not exceed the Ug value in

table 2 below and the value of geometric un-sharpness shall be recorded in the

report.

Table 2: Maximum Geometric Un-sharpness

Material Thickness, mm

Under 50.8

50.8 through 76.2

Over 76.2 through 101.6

Greater than 101.6

Ug Maximum, mm

0.51

0.76

1.02

1.78

Printed on Monday, August 17, 2015

Mechanical Integrity System Manual

TestEx

Author: Yusoff B Ismail

Page 9 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

CLIENT

Title:

SAFERAD PROCEDURE

Material thickness is the thickness on which the IQI is based. This shall be the base metal or

parent metal plus the maximum allowable reinforcement. For welds at transition thickness,

material thickness shall be the thinner base metal.

9.4

IMAGE QUALITY INDICATORS (IQI)

9.4.1

Selection of IQI

The IQI provides a guide to the quality of radiographs produced and shall

be appropriately chosen from one of the types recommended in ASME

Section V Article 2 (As per Table 3 & 3a below).

Table 3: Wire IQI Designation, Wire Diameter And Wire Identity

Set A

Set B

Set C

Set D

Wire

Diameter,

in

Mm

Wire

Identity

Wire

Diameter,

in

mm

Wire

Identity

Wire

Diameter,

in

mm

Wire

Identity

Wire

Diameter,

in

mm

Wire

Identity

0.0032

0.004

0.005

0.0063

0.008

0.010

0.08

0.01

0.13

0.16

0.20

0.25

1

2

3

4

5

6

0.010

0.013

0.016

0.020

0.025

0.032

0.25

0.33

0.41

0.51

0.64

0.81

6

7

8

9

10

11

0.032

0.040

0.050

0.063

0.080

0.100

0.81

1.02

1.27

1.60

2.03

2.54

11

12

13

14

15

16

0.100

0.126

0.160

0.200

0.250

0.320

2.54

3.20

4.06

5.08

6.35

8.13

16

17

18

19

20

21

Table 3a: IQI Selection

________________________________________________________________________________

_

IQI

Source Side

Material Thickness Range

In.

mm

Hole-Type

Designation

Wire-Type

Essential

Film Side

Hole-Type

Designation

Wire-Type

Essential Wire

Up to 0.25, incl.

Up to 6.4, incl.

12

5

10

4

Over 0.25 through 0.375

Over 6.4 through 9.5

15

6

12

5

Over 0.375 through 0.50

Over 9.5 through 12.7

17

7

15

6

Over 0.50 through 0.75

Over 12.7 through 19.0

20

8

17

7

Over 0.75 through 1.00

Over 19.0 through 25.4

25

9

20

8

Over 1.00 through 1.50

Over 25.4 through 38.1

30

10

25

9

Over 1.50 through 2.00

Over 38.1 through 50.8

35

11

30

10

Over 2.00 through 2.50

Over 50.8 through 63.5

40

12

35

11

Over 2.50 through 4.00

Over 63.5 through 101.6

50

13

40

12

Over 4.00 through 6.00

Over 101.6 through 152.4

60

14

50

13

Over 6.00 through 8.00

Over 152.4 through 203.2

80

16

60

14

Over 8.00 through 10.00

Over 203.2 through 254.0

100

17

80

16

Over 10.00 through 12.00

Over 254.0 through 304.0

120

18

100

17

Over 12.00 through 16.00

Over 304.0 through 406.4

160

20

120

18

Over 16.00 through 20.00

Over 406.4 through 508.0

200

21

160

20

_________________________________________________________________________________________________________________________

Printed on Monday, August 17, 2015

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 10 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

CLIENT

Title:

SAFERAD PROCEDURE

a)

Source Side IQI(s)

The IQI(s) shall be placed on the source side of the part being examined, except in the

condition described in 12.2 b.

b)

Film Side IQI(s)

Where inaccessibility prevents hand placing the IQI(s) on the source side it shall be

placed on the film side in contact with the part being examined. A lead letter 'F at

least as high as the IQI identification numbers) shall be paced adjacent the IQI(s).

Radiography shall be performed with a technique of sufficient sensitivity to display the IQI image

and the designated or smallest wire for required sensitivity, which are essential indications of the

image quality of the radiograph. The radiographs shall also display the identifying number and

letters.

9.4.2

Number of Image Quality Indicator (IQI)

IQI shall show clearly on each radiograph. For a radiograph represents 255

mm or greater of weld length, two IQIs shall be placed; one at each end of the

weld length. For radiograph represents less than 255mm of weld length, one

IQI shall be placed at any end of the weld length. IQI shall be perpendicular to

the joint with the smallest wire on the outer edge of the area being

radiographed.

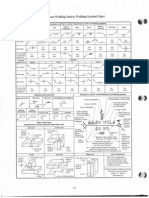

Figure 1 and Figure 2 illustrate the arrangement of lQI(s) locations.

For tubular structure, the following exception minimum number and required

locations of IQI shall be followed:-

a)

Where the source is located at the center of the tubular structure and

one or more film holders are used for a single exposure of complete

circumference

(Panoramic Technique), at least three Image Quality Indicator (IQI)

shall be spaced approximately 120 apart

b)

Where the source is placed at the center of the component (SingleWall Single-Image Viewing) and four or more film holders are used

for a single exposure of a section of the circumference, at least three

Image Quality Indicator (IQI) shall be used. One IQI shall be placed at

the center of the section exposed and one each at the end.

c)

Where the source is located on the axis of the object (Double-Wall

Single Viewing Technique) and four or more film holders are used for

an exposure of a circumferential weld, at least three Image Quality

Indicator (IQI) shall be used. One IQI shall be in the approximate

center of the section exposed and one at each end.

Printed on Monday, August 17, 2015

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 11 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

CLIENT

Title:

SAFERAD PROCEDURE

9.5

SENSITIVITY

The required sensitivity for each radiograph shall be based on ASME Standard as in

Table 3a Wire Type IQI. Radiography shall be performed with a technique of

sufficient sensitivity to display the designated the essential wire of a wire IQI. The

radiographs shall also display the IQI identifying numbers and letters

9.6

FILM DENSITY

For each radiograph made, film Density will be measured adjacent to the designated

wire of a wire IQI and the area of interest shall be 1.8 minimum for single film

viewing for radiographs made with an X-ray source and 2.0 minimum for radiographs

made with a gamma ray source. The maximum density shall be 4.0 for either single of

composite viewing.

9.7

EXCESSIVE BACKSCATTER

A lead symbol B with dimensions of in. (13 mm) in height and 1/16 in. (1.6 mm)

in thickness, shall be attached to the back of each film holder during each exposure to

determine if backscatter radiation is exposing the film. If a light image of the B,

appears on a darker background of the radiograph, protection from backscatter is

insufficient and the radiograph shall be considered unacceptable. A dark image of the

B on a background is not cause for rejection.

9.8

FILM PROCESSING

This shall be carried out in accordance with the recognized good practice. Processing

shall be carried out using the standard developer and fixer solutions, and shall be in

accordance with manufacturers recommendationsThe performance of the processing will be checked daily using control strips of X-ray

film exposed to a known density change is marked on a process control chart. Upper

and lower limits are marked on the chart to provide controls against which the plot

can be monitored. The results are interpreted and corrective action taken if necessary.

The radiographs will be free from imperfections due to processing or any other

defects that would interfere with interpretation.

Printed on Monday, August 17, 2015

TestEx

Mechanical Integrity System Manual

CLIENT

Author: Yusoff B Ismail

Page 12 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

Title:

SAFERAD PROCEDURE

9.8.1

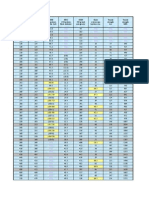

Developing Time/Temperature

Time and temperature are important factors in development. Typically, a

temperature of 68 oF (20 oC) is used with a development time of between 5

and 8 minutes. As the temperature of the solution is increased, the speed at

which the alkali penetrates is also increased. The details of developing time is

as tabulated in Table 4.

Table 4:

Developer Temperature

(oC )

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

9.9

Standard Developing Time

Developer Temperature

(oF )

61

63

64

66

68

70

72

73

75

77

79

81

82

84

86

88

90

91

93

Developer Time

(minutes)

7.0

6.5

6.0

5.5

5.0

4.5

4.0

3.8

3.5

3.3

3.0

2.8

2.5

2.3

2.0

1.8

1.5

1.3

1.0

FILM IDENTIFICATION

Each film will be identified by the use of lead symbols to indicate the following

minimum information:a)

The job or work-piece

b)

The joint

c)

The section of the joint

d)

The date of the test

e)

The welder identification

9.10

.

VIEWING CONDITION

Printed on Monday, August 17, 2015

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 13 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

CLIENT

Title:

SAFERAD PROCEDURE

The radiographs shall be examined in a darkened room. The radiograph viewer shall

provide a light source sufficient for the essential IQI wire/hole to be visible for the

specific density range. The light from around the outer edges of the radiographs will

be masked.

9.11INTERPRETATION OF RADIOGRAPHS

A calibrated densitometer or calibrated density strip will be kept in close proximity to

the viewer and a spot high-density illuminator will be available. All comments with

regard to film quality and interpretation will recorded on the film folder and on the

radiographic report form.

The density of density strips and densitometer calibration shall be verified by

comparison with a calibrated step wedge film traceable to a national standard. The

densitometer shall be calibrated in accordance with paragraph 5 of ASTM E-1079,

calibration of Transmission Densitometers.

Indication from defects shall be assessed in accordance with the requirements of the

latest edition Referencing Code section.

10.0

11.0

ACCEPTANCE CRITERIA

10.1

For the Pressure Vessel, the Acceptance criteria shall be in accordance to ASME VIII

Division 1 Appendix 4. Rounded indications charts acceptance standard for

radiographically determined rounded indications in welds.

10.2

For piping, the acceptance criteria shall be in accordance to ANSI B31.3 Table

341.3.2.

DOCUMENTATION/RADIOGRAPHIC REPORT

11.1

Written reports shall be prepared giving the results of all performed using the Testex

(M) Sdn Bhd Radiographic Form.

11.2The findings shall be reported in the Report format supported with the sketch shows the

defect location and depth (if any). The reports shall be submitted to the Client's

Inspector for approval.

12.0

.

REFERENCES.

Printed on Monday, August 17, 2015

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 14 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

Title:

SAFERAD PROCEDURE

ASME Section V Article 2

SNT-TC-1A- Qualification of personnel

Atomic Energy Licensing Act, Malaysia, 1984.

Ionizing Radiation Regulation (licensing) Malaysia, 1986

Ionizing Radiation Regulation (Basic Safety Standard) Malaysia, 1988

Ionizing Radiation Regulation (Transportation) Malaysia, 1989

13.0

ATTACHMENTS

13.1

Appendices

13.2

Inspection and Testing Activity Report Form

13.3

Revision History (If any)

Printed on Monday, August 17, 2015

CLIENT

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 15 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

Title:

SAFERAD PROCEDURE

Printed on Monday, August 17, 2015

CLIENT

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 16 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

Title:

SAFERAD PROCEDURE

Printed on Monday, August 17, 2015

CLIENT

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 17 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

Title:

SAFERAD PROCEDURE

Printed on Monday, August 17, 2015

CLIENT

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 18 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

Title:

SAFERAD PROCEDURE

ISSUE AND REVISION STATUS

.

Printed on Monday, August 17, 2015

CLIENT

TestEx

Mechanical Integrity System Manual

Author: Yusoff B Ismail

Page 19 of 19

Doc No.:

MI-30570

TESB-INSP-10001

MIIST

Approved by

Issue (Rev.) 3

JANUARY 15, 2010 (a)

CLIENT

Title:

SAFERAD PROCEDURE

Revision Status

Text Amended

Revision 0

Original Text

15.04.1999

Yusoff Ismail

Revision 1

Add Para 3.0, 5.0 &

9.0

15.06.2003

Yusoff Ismail

Revision 2

Para 5.0, 8.0 & 9.0

15.09.2003

Yusoff Ismail

Revision 3

Para 8.0

15.01.2010

Yusoff Ismail

Printed on Monday, August 17, 2015

Date

Authorized

You might also like

- High Temperature Ultrasonic ScanningDocument7 pagesHigh Temperature Ultrasonic ScanningscribdmustaphaNo ratings yet

- Radiography Test Procedure Part - 1Document21 pagesRadiography Test Procedure Part - 1Ahmed Lepda100% (1)

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989From EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookNo ratings yet

- BarcDocument15 pagesBarcsojeck0% (1)

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- Standard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodDocument7 pagesStandard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodMauricio FernándezNo ratings yet

- The AnswerDocument24 pagesThe AnswerrezokaNo ratings yet

- En 14096-1 Final DraftDocument11 pagesEn 14096-1 Final Draftrizwankhanzhi100% (1)

- Fasnt - Ultrasonic Testing TestDocument3 pagesFasnt - Ultrasonic Testing TestaravindanNo ratings yet

- Thickness Gauging Level 2 (Questions & Answers)Document3 pagesThickness Gauging Level 2 (Questions & Answers)kingston100% (2)

- LPT Spe QB 2Document6 pagesLPT Spe QB 2Aruchamy SelvakumarNo ratings yet

- Splimentry RT Level IIIDocument6 pagesSplimentry RT Level IIIRahul Musale100% (1)

- Form PAUTDocument1 pageForm PAUTLuong Ho VuNo ratings yet

- Radiograph FormulaDocument2 pagesRadiograph Formulaहेमंत कुमार मीणाNo ratings yet

- Ultrasonic Examination Based Acceptance CriteriaDocument2 pagesUltrasonic Examination Based Acceptance CriteriaAngelTinocoNo ratings yet

- PAUT Procedure EEISDocument13 pagesPAUT Procedure EEISZakirUllahNo ratings yet

- Radiographic Testing (RT) Level - 2 Specific Exam-2Document7 pagesRadiographic Testing (RT) Level - 2 Specific Exam-2Mohammed Aljawhar100% (1)

- 4#600 Body RSSDocument1 page4#600 Body RSSRavi patelNo ratings yet

- Radiography Testing Level I and II PDFDocument87 pagesRadiography Testing Level I and II PDFIdeal NaradmuniNo ratings yet

- PCN Training and Certification of PCN Level 2 and 3 Course Brochure - BIT - BINDT, 2020Document13 pagesPCN Training and Certification of PCN Level 2 and 3 Course Brochure - BIT - BINDT, 2020AMITNo ratings yet

- Proc. For Radiographic Profile Thk. MeasurementDocument7 pagesProc. For Radiographic Profile Thk. MeasurementSergey KichenkoNo ratings yet

- Lesson 3 - IsO 9712Document13 pagesLesson 3 - IsO 9712Abdelaziz AbdoNo ratings yet

- Small Diameter Tube and Pipe Inspection With Phased Array PDFDocument7 pagesSmall Diameter Tube and Pipe Inspection With Phased Array PDFAlanka PrasadNo ratings yet

- N F: NFT S C: EAR Ield Tandard Alibration TubeDocument1 pageN F: NFT S C: EAR Ield Tandard Alibration TubeMahmood KhanNo ratings yet

- UT AssessmentDocument1 pageUT AssessmentSantanu SahaNo ratings yet

- Safety-Model QuestionsDocument4 pagesSafety-Model QuestionsraofrhanNo ratings yet

- PCN ISO 9712 NDT Training and Certification Level 1 2 and 3 Course Brochure 2021 BIT Chennai IndiaDocument17 pagesPCN ISO 9712 NDT Training and Certification Level 1 2 and 3 Course Brochure 2021 BIT Chennai IndiaAMITNo ratings yet

- PRR CalculationDocument4 pagesPRR CalculationnavitaNo ratings yet

- RT Formulas For CalculationsDocument4 pagesRT Formulas For CalculationsdanemsalNo ratings yet

- Evaluation For Paut ASME 8 DIV 2Document3 pagesEvaluation For Paut ASME 8 DIV 2Woodrow FoxNo ratings yet

- DAC Block Details PDFDocument2 pagesDAC Block Details PDFShrikant UtekarNo ratings yet

- GE Hardness-testing-FAQ MIC 10Document19 pagesGE Hardness-testing-FAQ MIC 10Harshit MehtaNo ratings yet

- 3.3.3-Fillet Weld Design 9th Mar 21Document40 pages3.3.3-Fillet Weld Design 9th Mar 21Vivek kmNo ratings yet

- Api Ut Thickness Procedure PDFDocument7 pagesApi Ut Thickness Procedure PDFShreekanthKannathNo ratings yet

- UT Formula SheetDocument2 pagesUT Formula SheetOktayKulNo ratings yet

- Asme NDT MethodDocument1 pageAsme NDT Methodkinglordofato100% (1)

- Liquid Penetrant Testing ProcedureDocument2 pagesLiquid Penetrant Testing ProcedureManivannanMudhaliarNo ratings yet

- Multiple Choice 7 Mechanical TestingDocument5 pagesMultiple Choice 7 Mechanical TestingChandra MohanNo ratings yet

- APIRP586 Sec 1 Heat Exch Tubing InspsecondballottrackDocument48 pagesAPIRP586 Sec 1 Heat Exch Tubing InspsecondballottrackUsman NaseemNo ratings yet

- GE Mentor EM Weld BrochureDocument6 pagesGE Mentor EM Weld BrochuredimachampionNo ratings yet

- Tutorial IIIDocument21 pagesTutorial IIIravindra_jivaniNo ratings yet

- Asme V Ob JKDocument16 pagesAsme V Ob JKBoon India TrichyNo ratings yet

- Product TechnologyDocument138 pagesProduct TechnologyRaja SekarNo ratings yet

- MIL-STD-453 Xray InspectionDocument33 pagesMIL-STD-453 Xray InspectionMClarkNo ratings yet

- National Step Tablet Vs Step Wedge Comparision FilmDocument4 pagesNational Step Tablet Vs Step Wedge Comparision FilmManivannanMudhaliarNo ratings yet

- Jireh Circ It ScannerDocument2 pagesJireh Circ It ScannerMarcos Kaian Moraes RodriguesNo ratings yet

- API UT21 ThicknessProcedure 20190304Document7 pagesAPI UT21 ThicknessProcedure 20190304michaelNo ratings yet

- Astm E1065 E1065m 20Document10 pagesAstm E1065 E1065m 20Mohamed AboelkhierNo ratings yet

- SOP-030 - Rev0 Mic10 Mic20Document2 pagesSOP-030 - Rev0 Mic10 Mic20Stephen LewellenNo ratings yet

- As1710 VS En10160Document1 pageAs1710 VS En10160Biju_PottayilNo ratings yet

- Inspection Report Bifab Ut On Duplex Stainless Steel Piping PDFDocument11 pagesInspection Report Bifab Ut On Duplex Stainless Steel Piping PDFquiron2014No ratings yet

- 7.5CCEV-35-16-A15 Esp 12,5 MM 1 Grupo Index - 20 MM Raiz 40-60° COBRADocument2 pages7.5CCEV-35-16-A15 Esp 12,5 MM 1 Grupo Index - 20 MM Raiz 40-60° COBRAwilfran villegasNo ratings yet

- 38 MM DAC Block - Master SUDHANDocument5 pages38 MM DAC Block - Master SUDHANmaxpan maxNo ratings yet

- Asme Piping Block (Ut+Paut)Document1 pageAsme Piping Block (Ut+Paut)Muhammed Abo-FandoodNo ratings yet

- Se 273Document4 pagesSe 273solrac4371No ratings yet

- RT Procedure GeneralDocument18 pagesRT Procedure GeneralvsnaiduqcNo ratings yet

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6No ratings yet

- Radiography Test Inspection Free NDT Sample ProcedureDocument4 pagesRadiography Test Inspection Free NDT Sample ProcedureMohamed Tarek Hamam0% (1)

- A-Health Advance - Application Form With InstructionsDocument14 pagesA-Health Advance - Application Form With InstructionsExsan OthmanNo ratings yet

- Remote Field Eddy CurrentDocument4 pagesRemote Field Eddy CurrentExsan OthmanNo ratings yet

- A-Health Advance-I Premium RatesDocument2 pagesA-Health Advance-I Premium RatesExsan OthmanNo ratings yet

- Asmt C 795Document4 pagesAsmt C 795Exsan OthmanNo ratings yet

- Astm C 692 PDFDocument7 pagesAstm C 692 PDFExsan Othman100% (1)

- Engineering Your Future PDFDocument605 pagesEngineering Your Future PDFExsan OthmanNo ratings yet

- Astm C 871Document5 pagesAstm C 871Exsan Othman100% (2)

- Calculation Minimum Required Thickness For Bending Pipe r2Document11 pagesCalculation Minimum Required Thickness For Bending Pipe r2Exsan OthmanNo ratings yet

- AWS Weld Symbol ChartDocument1 pageAWS Weld Symbol ChartExsan OthmanNo ratings yet

- Calculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Document6 pagesCalculation Minimum Required Thickness For Straight Pipe 8inch Leak May10Exsan OthmanNo ratings yet

- MaterialsDocument181 pagesMaterialsExsan OthmanNo ratings yet

- Chat For Organization of CodeDocument1 pageChat For Organization of CodeExsan OthmanNo ratings yet

- AWS Specifications For Filler MaterialDocument9 pagesAWS Specifications For Filler MaterialExsan OthmanNo ratings yet

- Pipeline DataDocument4 pagesPipeline DataExsan OthmanNo ratings yet

- Piping TableDocument59 pagesPiping TableExsan Othman100% (1)

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariNo ratings yet

- Hardness Conversion For Ferrous AlloysDocument2 pagesHardness Conversion For Ferrous AlloysExsan OthmanNo ratings yet

- Hemispherical Head Design Tool: Pressure Vessel Engineering LTDDocument1 pageHemispherical Head Design Tool: Pressure Vessel Engineering LTDExsan OthmanNo ratings yet

- I) Example of Water-Tube Boiler A) Horizontal Straight Tube BoilerDocument1 pageI) Example of Water-Tube Boiler A) Horizontal Straight Tube BoilerExsan OthmanNo ratings yet

- Actvities On Boiler Maintenance: I. FurnaceDocument5 pagesActvities On Boiler Maintenance: I. FurnaceExsan OthmanNo ratings yet

- Boiler Feedwater ControlDocument6 pagesBoiler Feedwater ControlExsan OthmanNo ratings yet

- 27h Radiography PermitDocument1 page27h Radiography PermitMohammed MinhajNo ratings yet

- KOST-NDT-RTP-02 ASME B31.3 Process Piping PDFDocument20 pagesKOST-NDT-RTP-02 ASME B31.3 Process Piping PDFmuhammad faizNo ratings yet

- Radiation Emergency PlanDocument31 pagesRadiation Emergency PlanBenasher IbrahimNo ratings yet

- Rtfi BookDocument82 pagesRtfi Bookmaheshmalaichamy007100% (4)

- Sample RT Report PipelineDocument1 pageSample RT Report Pipelinekhalid hidayatullahNo ratings yet

- Damage Assessment & Evaluation of StructuresDocument18 pagesDamage Assessment & Evaluation of StructuresHarrajdeep SinghNo ratings yet

- Practical NonDestructive TestingDocument7 pagesPractical NonDestructive TestingHamid JahangirNo ratings yet

- As 2177-2006 Non-Destructive Testing - Radiography of Welded Butt Joints in MetalDocument8 pagesAs 2177-2006 Non-Destructive Testing - Radiography of Welded Butt Joints in MetalSAI Global - APAC100% (1)

- Emergency Response Plan and PreparednessDocument7 pagesEmergency Response Plan and Preparednessradha krishnaNo ratings yet

- PTW TestDocument11 pagesPTW TestInstrument WaveNo ratings yet

- Hazard Identification and Risk Assessment Radiography Test: Project: Report No: Client: Location: Consultant: DateDocument4 pagesHazard Identification and Risk Assessment Radiography Test: Project: Report No: Client: Location: Consultant: DateSiva RajNo ratings yet

- Astm 608 PDFDocument6 pagesAstm 608 PDFIslam FawzyNo ratings yet

- Me6019 Ndt-Notes-Unit-1 1Document29 pagesMe6019 Ndt-Notes-Unit-1 1kamala joseNo ratings yet

- Minutes of Pre-Bid Meeting & Scope of WorkDocument7 pagesMinutes of Pre-Bid Meeting & Scope of WorkAlmario Sagun100% (1)

- NG-018-XX-PNL-431203 - Rev07 NDT MatricesDocument20 pagesNG-018-XX-PNL-431203 - Rev07 NDT MatricesFolarin Ayodeji100% (1)

- EHSMS Performance and Incident ReportingDocument38 pagesEHSMS Performance and Incident ReportingravimanasNo ratings yet

- India PCN Course Exam FeeDocument3 pagesIndia PCN Course Exam FeeJames100% (1)

- Ayush Walke Micro Project - NON-DESTRUCTIVE TESTDocument23 pagesAyush Walke Micro Project - NON-DESTRUCTIVE TESTYash ChahandeNo ratings yet

- OHSEC Permit System Rev 03Document91 pagesOHSEC Permit System Rev 03Avietcs MeiNo ratings yet

- Pipeline Welding InspectionDocument4 pagesPipeline Welding InspectionRizky TrianandaNo ratings yet

- Radiography in Modern IndustryDocument212 pagesRadiography in Modern IndustryMohammed Abdul Sayeed50% (2)

- LEVEL III EXAMS Topical OutlinesDocument6 pagesLEVEL III EXAMS Topical OutlinesRamonS.FernandezOrozco100% (1)

- IACS - REC - 20 NDT of Ship Hull Steel StructuresDocument11 pagesIACS - REC - 20 NDT of Ship Hull Steel Structuresalinor_tnNo ratings yet

- JSA For Radiography WorkDocument2 pagesJSA For Radiography Workwahyu nugrohoNo ratings yet

- HB RT InterpretationDocument46 pagesHB RT InterpretationespinozcristianNo ratings yet

- NDT Radiographic TestingDocument93 pagesNDT Radiographic TestingMuhammad Rizal PambudiNo ratings yet

- Twi India Cswip Fee 2017Document4 pagesTwi India Cswip Fee 2017kamal100% (1)

- X Ray TestingDocument24 pagesX Ray Testingapi-27176519100% (6)

- Catalog TDocument56 pagesCatalog TMuhammed ajmal100% (1)