Professional Documents

Culture Documents

White Topping

Uploaded by

Ankush SehgalCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

White Topping

Uploaded by

Ankush SehgalCopyright:

Available Formats

Whitetopping

Concrete overlay offers cost-effective alternative to asphalt overlay

Concrete overlay on existing distressed and

rutted asphalt pavement is often referred

to as whitetopping. Taking into account

life-cycle costs, whitetopping can be

cost-effective in rehabilitating deteriorated

asphalt pavements.

There are three types of whitetopping:

Ultrathin whitetopping (UTW).

Typically 2 to 4 inches (in) thick, with joint

spacing ranging from 2 to 6 feet (ft), this

type of whitetopping is used primarily for

urban intersections, city streets, and

overall low-volume roads. UTW relies on

its bond to the existing asphalt pavement

for performance.

Contact

Suneel Vanikar

Team Leader, Concrete Pavement

Office of Infrastructure

FHWA

202-366-0120

suneel.vanikar@dot.gov

Whitetopping is gaining popularity at the

national level, and many states are

implementing or experimenting with this

technology.

Whitetopping was first applied in the

United States in 1981 over an existing

asphalt roadway on South 7th Street in

Terre Haute, IN.

Beginning in the early 1990s, demand

for whitetopping technology soared.

Many states started experimenting with

concrete overlays, including California,

Colorado, Florida, Illinois, Iowa,

Kentucky, Massachusetts, Michigan,

Minnesota, Mississippi, Missouri,

Montana, Nevada, and Virginia.

Thin whitetopping (TWT). This type is

4 to 8 inches in thick with joint spacing

from 4 to 12 ft. Like UTW, TWT relies on

the bond with the underlying asphalt

pavement for good performance. TWT is

the most prevalent type of whitetopping

overlay highway agencies use.

Conventional whitetopping. More

than 8 in thick, this type of whitetopped

pavement follows the behavior of a

concrete pavement in terms of

performance.

Continued on

backside

W W W . F H W A . D O T . G O V / H F L

Whitetopping, Continued

The first bonded UTW project was constructed on a landfill disposal facility

near Louisville, KY in 1991. By 1997, 200 UTW projects had been built in

North America.

In 1990, the Colorado Department of Transportation began a series of

successful whitetopping projects using TWT technology, with more than

705,000 square yards of concrete placed to date. In the 1990 project, test

sections (3.5 in and 5 in with 6.5 by 6.5 ft and 12 by 13 ft joint spacing) were

placed directly over existing asphalt pavement on SH 68. These test sections

performed well over 15 years, and cost analysis showed a savings of 11

percent over asphalt replacement.

Thin whitetopping

Over the past 15 years, many research studies have been conducted on TWT and

UTW projects aimed at formulating guidelines for properly designing and

constructing TWT and UTW overlays. Major findings from these studies include

the following:

UTW and TWT concrete overlays behave as partially bonded systems.

A strong bond at the concrete-asphalt interface is essential for good

performance of UTW and TWT. Milling and cleaning the asphalt surface

enhances the bond and improves performance.

Newly paved asphalt pavements (milled or nonmilled) are not recommended

for whitetopping because bonding potential is dramatically reduced.

Tie bars are recommended for longitudinal joints to prevent slab slippage.

Load transfer devices have an insignificant effect on pavement performance

in UTW and TWT pavements.

For more information

WhitetoppingState of Practice, American Concrete Pavement Association, www.acpa,org

Guide to Concrete Overlay Solutions, National Concrete Pavement Technology Center, 2007,http://concreteparking.org/PDFs/guide_concrete_overlays.pdf

Thin and Ultra-Thin Whitetopping, National Cooperative Highway Research Program Synthesis 338, 2009, www.trb.org

W W W . F H W A . D O T . G O V / H F L

You might also like

- White ToppingDocument7 pagesWhite ToppingMuhamMed UvaiZe0% (1)

- White Topping Over Existing RoadsDocument15 pagesWhite Topping Over Existing RoadssaiNo ratings yet

- White ToppingDocument11 pagesWhite ToppingGossetto75% (4)

- White ToppingDocument73 pagesWhite ToppingJavo GuerreroNo ratings yet

- White Topping To B. TDocument12 pagesWhite Topping To B. TMuthusamy ArumugamNo ratings yet

- Highway Development in IndiaDocument51 pagesHighway Development in IndiaRADHESHYAMNo ratings yet

- Transportation Engineering: Efforts By:-Gurpinder Singh Roll No. - 615/17 Submitted To: - Dr. Sanjeev NavalDocument35 pagesTransportation Engineering: Efforts By:-Gurpinder Singh Roll No. - 615/17 Submitted To: - Dr. Sanjeev NavalGurpinder SinghNo ratings yet

- Use of Fly Ash For Road and Embankment Construction CRRI Sudhir MathurDocument72 pagesUse of Fly Ash For Road and Embankment Construction CRRI Sudhir MathurUmer Farooq100% (1)

- Chapter5 Part2Document42 pagesChapter5 Part2Aliya OthmanNo ratings yet

- A Road Building Opportunity PURE - CRETE - Eng - 02252011Document48 pagesA Road Building Opportunity PURE - CRETE - Eng - 02252011PAYLEUNo ratings yet

- 1.2 - Development of RoadsDocument42 pages1.2 - Development of RoadsKirtiyadavNo ratings yet

- Claycrete English v3Document22 pagesClaycrete English v3supernaenergy100% (1)

- 01-Transportation Engg - Prof. AamirDocument69 pages01-Transportation Engg - Prof. AamirChandan KumarNo ratings yet

- Use of Fly Ash For Road and Embankment ConstructionDocument72 pagesUse of Fly Ash For Road and Embankment ConstructionArvind Bajpai50% (2)

- 1 What Is LevelingDocument19 pages1 What Is LevelingAbduraman Isa100% (1)

- Design Problems in Civil EngineeringDocument8 pagesDesign Problems in Civil Engineeringrao159951No ratings yet

- Pavement Design 2013 ProjectDocument58 pagesPavement Design 2013 ProjectEr Mukesh PawarNo ratings yet

- Technolgy Practice Part 1 and CompaniesDocument138 pagesTechnolgy Practice Part 1 and CompaniesKobciye ProductionNo ratings yet

- Pcci 4302 Te I 2Document315 pagesPcci 4302 Te I 2Saranya Godwin50% (2)

- Transpotation - Emulsions For Highway ConstructionDocument20 pagesTranspotation - Emulsions For Highway ConstructionAtish KumarNo ratings yet

- Road Development in IndiaDocument13 pagesRoad Development in IndiaSatish SajjaNo ratings yet

- Earth Compaction EquipmentDocument15 pagesEarth Compaction EquipmentÄmî Îíţ ŚHäh100% (1)

- Rigid Pavements: Ravi Kumar GarreDocument51 pagesRigid Pavements: Ravi Kumar GarreP YADA GIRINo ratings yet

- Comparison Concrete and Asphalt PavementDocument6 pagesComparison Concrete and Asphalt PavementJulius OgowewoNo ratings yet

- Field TripDocument16 pagesField TripChidi HenryNo ratings yet

- Bituminous Roads PDFDocument41 pagesBituminous Roads PDFनोलराज पौडेलNo ratings yet

- Pavement & Green TechnologyDocument12 pagesPavement & Green TechnologyAanchal AroraNo ratings yet

- Unit - I TransportationDocument90 pagesUnit - I TransportationSunil PadmanabhamNo ratings yet

- What Is Highway EngineeringDocument4 pagesWhat Is Highway EngineeringNagesh SinghNo ratings yet

- Construction On Flexible PavementDocument16 pagesConstruction On Flexible PavementABHAY SHRIVASTAVANo ratings yet

- Tests On AggregateDocument94 pagesTests On AggregateRamen KishoreNo ratings yet

- Causeways: Figure 1 Causeways With Low Volume Flow and in FloodDocument14 pagesCauseways: Figure 1 Causeways With Low Volume Flow and in FloodAnil MarsaniNo ratings yet

- How Road Are Being ConstructedDocument4 pagesHow Road Are Being ConstructedDianaDion WintersPolNo ratings yet

- Pavement Design Kiran BiradarDocument18 pagesPavement Design Kiran BiradarSudipto PaulNo ratings yet

- Cement StabilisationDocument9 pagesCement StabilisationRoddy TeeNo ratings yet

- CENG 6305 - Chapter 4 - Granular Pavement Materials PDFDocument65 pagesCENG 6305 - Chapter 4 - Granular Pavement Materials PDFadane mekonnenNo ratings yet

- Investigation Into Courses of Pavement FailureDocument59 pagesInvestigation Into Courses of Pavement FailureAhmed BinNo ratings yet

- Bituminous Construction TypesDocument3 pagesBituminous Construction TypesSiya Fal DesaiNo ratings yet

- A Research Paper On Porous Asphalt PavementDocument6 pagesA Research Paper On Porous Asphalt PavementEditor IJTSRDNo ratings yet

- Types of PavementsDocument17 pagesTypes of PavementsPereira KastroNo ratings yet

- Importance of Roads in IndiaDocument8 pagesImportance of Roads in IndiaShubham NandedkarNo ratings yet

- ChaptersDocument79 pagesChaptersMay JangkumNo ratings yet

- Flexible PavementsDocument13 pagesFlexible PavementsAhmad NajiNo ratings yet

- Road Construction Inplant TrainingDocument31 pagesRoad Construction Inplant TrainingAditya ChopraNo ratings yet

- Stone Matrix Asphalt Pavement 1Document26 pagesStone Matrix Asphalt Pavement 1JAYBHAY BHAGWATNo ratings yet

- Indrustrial Traning PWD HimachalDocument194 pagesIndrustrial Traning PWD HimachalkamalNo ratings yet

- Road Note 8 (Sub Soil Drainage)Document25 pagesRoad Note 8 (Sub Soil Drainage)Someshwar Rao ThakkallapallyNo ratings yet

- Road Survey and Quantity CalculationDocument25 pagesRoad Survey and Quantity CalculationHarish joshiNo ratings yet

- Advantages of Cement Concrete RoadDocument8 pagesAdvantages of Cement Concrete RoadBiswanath PanigrahiNo ratings yet

- Ultra Thin WhitetoppingDocument36 pagesUltra Thin Whitetoppingshamkumavat50% (4)

- On Modified BitumenDocument19 pagesOn Modified BitumenTejeshwini SNo ratings yet

- TERRAZYMEDocument36 pagesTERRAZYMEJean MbuNo ratings yet

- Perpetual Flexible Pavements: Pavements of Future: Sanjay GargDocument17 pagesPerpetual Flexible Pavements: Pavements of Future: Sanjay GargDidier BellonNo ratings yet

- 4 Inverted Pavement SystemsDocument10 pages4 Inverted Pavement SystemsprmraoNo ratings yet

- Flexible Pavement: Click To Edit Master Title StyleDocument13 pagesFlexible Pavement: Click To Edit Master Title StyleFaisal SharifNo ratings yet

- On Fly Ash by Sumit SumanDocument20 pagesOn Fly Ash by Sumit SumanSumit Suman100% (3)

- 7.0 Super Elevation DesignDocument15 pages7.0 Super Elevation DesignGerald MagingaNo ratings yet

- Guidelines From MSRDC PDFDocument15 pagesGuidelines From MSRDC PDFSreekanth SattirajuNo ratings yet

- Ultra Thin White ToppingDocument17 pagesUltra Thin White ToppingAthira SurendranNo ratings yet

- Utwt ReportDocument3 pagesUtwt ReportSrujan MeshramNo ratings yet

- Websphere Business Modeler TutorialDocument46 pagesWebsphere Business Modeler TutorialIda MariaNo ratings yet

- Maruti Bba Project For MarketingDocument92 pagesMaruti Bba Project For Marketingkaushal244256% (9)

- Document For AgileDocument5 pagesDocument For Agilemohan1221itNo ratings yet

- FDA GMP GuidelinesDocument7 pagesFDA GMP Guidelinesm_ihab777629No ratings yet

- BS IEC 61882 - 2001 - Hazard and Operability StudiesDocument60 pagesBS IEC 61882 - 2001 - Hazard and Operability Studiesd-fbuser-230265495100% (2)

- Clamp Ring Closures: Sizes: 4-Inch and LargerDocument4 pagesClamp Ring Closures: Sizes: 4-Inch and LargerFilipNo ratings yet

- Laporan Luaran Prosiding Internasional - SUPIYANDI - Tomuan HolbungDocument83 pagesLaporan Luaran Prosiding Internasional - SUPIYANDI - Tomuan HolbungIka Devi PerwitasariNo ratings yet

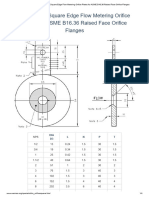

- Wermac - Dimensions of Square Edge Flow Metering Orifice Plates For ASME B16.36 Raised Face Orifice FlangesDocument4 pagesWermac - Dimensions of Square Edge Flow Metering Orifice Plates For ASME B16.36 Raised Face Orifice Flangestechnicalei sulfindoNo ratings yet

- SAP ABAP Interview QuestionsDocument9 pagesSAP ABAP Interview QuestionsJo MallickNo ratings yet

- IT7021 Software Testing UGDocument2 pagesIT7021 Software Testing UGSaraswathy KNo ratings yet

- TMC 2007 Technical BackgroundDocument27 pagesTMC 2007 Technical Backgroundluigi_mattoNo ratings yet

- SB805-10800-203 (Sky497)Document4 pagesSB805-10800-203 (Sky497)Gerhard MNo ratings yet

- Motivation LetterDocument2 pagesMotivation LetterSUNNY KUMARNo ratings yet

- HNK NT VTC Vert Lathes PDFDocument16 pagesHNK NT VTC Vert Lathes PDFs_barriosNo ratings yet

- IRITS-0617-034 HLA Heatless Desiccant Air DryerDocument2 pagesIRITS-0617-034 HLA Heatless Desiccant Air DryerEddie SantillánNo ratings yet

- Purchase Order Approval Using Approval Management Engine (AME)Document44 pagesPurchase Order Approval Using Approval Management Engine (AME)skumaaranNo ratings yet

- Applying eTOM (Enhanced Telecom Operations Map) Framework To Non-Telecommunications Service Companies - An Product/Service/Solution Innovation ExampleDocument45 pagesApplying eTOM (Enhanced Telecom Operations Map) Framework To Non-Telecommunications Service Companies - An Product/Service/Solution Innovation ExampleorigigiNo ratings yet

- Brosur Kitarack 2022Document2 pagesBrosur Kitarack 2022Yulianto WangNo ratings yet

- Tech Spec 132KV LineDocument285 pagesTech Spec 132KV LineSanjay Rout0% (1)

- Week 2 Teradata Practice Exercises GuideDocument7 pagesWeek 2 Teradata Practice Exercises GuideFelicia Cristina Gune50% (2)

- Ejot - Delta PT DsDocument2 pagesEjot - Delta PT DsLucas VeronaNo ratings yet

- Manufacturing Processes Ch.6 (20) Sheet Metal WorkingDocument73 pagesManufacturing Processes Ch.6 (20) Sheet Metal Workingashoku24007100% (1)

- Transportation Manager or International Manager or Logistics SupDocument3 pagesTransportation Manager or International Manager or Logistics Supapi-78592002No ratings yet

- IJ GIS en - CompressedDocument24 pagesIJ GIS en - CompressedpopaminoNo ratings yet

- Lean Think PDFDocument13 pagesLean Think PDFசரவணகுமார் மாரியப்பன்No ratings yet

- Mississippi Drivers Manual - 2013Document85 pagesMississippi Drivers Manual - 2013DMV_exam_GUIDE_comNo ratings yet

- Mj19 Sample Apm QuestionsDocument9 pagesMj19 Sample Apm QuestionsAakash AadeezNo ratings yet

- GT 0715Document84 pagesGT 0715Erhan GencNo ratings yet

- SimHydraulics InformationDocument2 pagesSimHydraulics InformationjcvoscribNo ratings yet

- Sap MM and SD Module CodesDocument48 pagesSap MM and SD Module Codesvishal_160184No ratings yet