Professional Documents

Culture Documents

SikaCarboShearL Pds

Uploaded by

Alexandra NeaguCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SikaCarboShearL Pds

Uploaded by

Alexandra NeaguCopyright:

Available Formats

Product Data Sheet

Edition 05.2014/v1

CSC Master FormatTM 03 25 00

Sika CarboShear L

Sika CarboShear L

Construction

High Performance, Shear Strengthening CFRP Elements

Description

Sika CarboShear L elements are used within a high performance CFRP shear strengthening

system for reinforced concrete structures. The system components consist of:

Sika CarboShear L shaped CFRP elements.

Sikadur 30 structural adhesive for externally-bonded CFRP.

Sika CarboShear L complements the SikaCarboDur composite strengthening system, used

for structural strengthening of bending moments. The efficiency of the Sika CarboShear L

strengthening system has been proven by full-size tests performed in collaboration with the

Swiss Federal Laboratories for Materials Testing and Research, EMPA.

Where to Use

External strengthening against shear forces in cases of:

Increased loads due to

Higher live loads in buildings and on bridges.

Changes of building utilization.

Damaged structural parts due to

Corrosion of the inner shear reinforcement.

Vehicular impact upon structures.

Fire damage of reinforced concrete.

Improvement of serviceability

Stress reduction in steel reinforcement.

Crack width and fatigue reduction.

Change in structural system

Removal of walls, columns or slab sections for openings.

Change in specification

Requirements in the event of earthquakes.

Changed design philosophy.

Design and construction errors such as

Insufficient / inadequate reinforcement.

Advantages

Lightweight.

Non-corrosive.

Very high strength and durability.

Well defined and tested anchorage system.

Outstanding fatigue resistance.

Low profile; can be coated.

Low aesthetic impact.

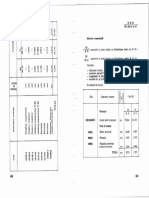

Technical Data

Packaging

Colour/Appearance

Shelf Life

Density

Glass Transition Temperature

Fibre Content

Physical Properties

Sika CarboShear L

Element Dimensions

Cartons of 20 elements or sold individually

Black.

Carbon fibre reinforced polymer with an epoxy matrix. L

shaped elements with a 90 bend. Both faces of the element

are covered with release agent-free peel-ply fabric

Unlimited. Store in dry conditions and away from exposure

to direct sunlight.

1.55 g/cm3 (0.89 oz/in3)

> 80C (160F)

> 56% by volume

Sikadur 301

Consumption

Leg Length

Width

Nominal Thickness

Short

Long

without Peel-ply

mm (in) mm (in)

mm (in)

mm (in)

4/20/50

0.5 kg (1.1 lb)

200 (8)

500 (20)

40 (1.57)

2 (0.0787)

4/30/70

0.6 kg (1.3 lb)

300 (12) 700 (28)

40 (1.57)

2 (0.0787)

4/50/100

0.7 kg (1.5 lb)

500 (20) 1000 (39) 40 (1.57)

2 (0.0787)

4/80/150

1.0 kg (2.2 lb)

800 (32) 1500 (59) 40 (1.57)

2 (0.0787)

Leg length can be cut to measure (by saw or preferably by diamond disk). The inner radius of the bend

zone is 25 mm (1 in).

1 Dependent on the size of anchorage hole, plane- and roughness, actual consumption of adhesive may

differ. (anchor hole: assumption 150 mm depth).

Tensile Strength*

> 1350 MPa (19.67 x 104 psi)

E-Modulus of Elasticity*

> 90 000 MPa (131.18 x 105 psi)

Strain at Break*

>1.30%

*In direction of longitudinal fibres, considering a nominal thickness of 2 mm (0.0787 in).

Product properties are typically averages, obtained under laboratory conditions. Reasonable variations can be expected

on-site due to local factors, including environment, preparation, application, curing and test methods.

Sika CarboShear L

03 25 00 COMPOSITE REINFORCING

3-603

Design

The design procedure may be undertaken in accordance with: the Canadian Building Code

Standard, Design and Construction of Building Components with Fibre-Reinforced Polymers,

CAN/CSA S806-02: ACI 440.2R-08: or the model described in the EMPA Test Report 116/7:

2002.

Additional considerations must include:

Procedure for Condition Determination:

Measurements (geometry, reinforcement, level and evenness of the surface to be strengthened),

quality of the construction material, climatic conditions, use a zoning plan.

Construction

Anchorage Forces:

Anchorage zone: The longer leg of the plate is anchored with Sikadur 30 in the compression

slab of the structure. The anchorage length has the following influence on the pull-out force

of the plate:

Anchorage length

mm (in)

Pull-out force*

kN (lbf)

Rel. pull-out force

(% of breaking load)

100 (4)

approx. 77 (17310)

approx. 60

150 (6)

200 (8)

approx. 100 (22480)

approx. 120 (26977)

approx. 80

approx. 95

Bend Zone

The length of the two shorter ends bonded on each other to a U has the following influence

on the breaking load:

Overlapping zone length

mm (in)

150 (6)

225 (9)

300 (12)

Average failure force*

kN (lbf)

67 (15062)

69 (15511)

74 (16635)

Efficiency (% of ultimate

tensile force of the plate)

53

55

59

*These numbers are test results. For design values consult the above mentioned EMPA Test

Report 116/7, 2002. A value of 45 kN (10116 lbf) per Sika CarboShear L element can be

chosen as estimation for feasibility study purposes.

How to Use

Surface

Preparation

Sikadur 30

Adhesive

Preparation

Prepare the surface on the side and underside of the web by sandblasting or other appropriate

mechanical means to provide an open roughened texture, conforming to ICRI CSP-5. Remove

dust and loose particles by means of an industrial vacuum cleaner. The resultant concrete

substrate must be clean, oil, grease-free and dry (max. surface moisture content 4% by

weight).

The adhesive strength of the concrete must be verified after surface preparation by random pull

off tests conducted to ACI 503R, at the discretion of the engineer. A mean tensile strength of

2 MPa (290 psi) and a minimum tensile strength of 1.5 MPa (218 psi) with concrete substrate

failure is required before proceeding.

The evenness of the surface is checked with a straight edged ruler. The maximum permissible

tolerance over a length of 0.5 m (1.64 ft) is 2.5 mm (0.098 in). Greater unevenness must be

levelled using Sikadur 30 structural adhesive and clean oven-dried silica sand (mixed in a

ratio of 1:1 parts by volume).

The edge of the web (later the position of the bend in the Sika CarboShear L element) must

be levelled or rounded to fit the inner 25 mm (1 in) radius of the Sika CarboShear L element.

This can be done by grinding.

Consult Sikadur 30 Product Data Sheet for information on mixing and application of the

adhesive for bending reinforcement.

Sika CarboShear L Peel-ply fabric must be carefully removed from both sides of the Sika CarboShear L element

up to the intended cutting point. Ensure that the profile remains clean and free from loose

Preparation

friable material and contaminants.

Sika CarboShear L elements can then be cut using a saw or diamond cutting disk to suit the

dimensions of the structure being strengthened.

The day before the installation of the L-shaped profile, CFRP surfaces must be wiped clean

using a clean, lint free white cloth and acetone until all residual carbon dust and glue are

removed (i.e. white cloth remains white after wiping the laminate). The end to be anchored must

then be coated on both sides with Sikadur 30 to the required anchoring length plus 10 mm

(3/8 in). The adhesive is applied with a tooth-trowel (5 mm [3/16 in]) with the grooves at right

angles to the direction of the fibres.

Sika CarboShear L

03 25 00 COMPOSITE REINFORCING

3-603

Construction

Sika CarboShear

L Installation

If anchoring into the compression slab, the pre-drilled holes must be completely filled with

Sikadur 30 structural adhesive, applied using a bulk caulking dispenser or from a cartridge

gun, fitted with a hose or tube.

Alternatively, drill 3 parallel holes of 25 mm (1 in) diameter at 10 - 15 mm (3/8 to 5/8 in) intervals,

forming an oblong hole of about 50 mm (2 in) in length.

Remove dust, dirt and moisture from the hole. Let the surfaces within the hole dry.

Take care to drill the holes close to the web to allow bonding of the Sika CarboShear L shaped

elements with an adhesive layer of minimal thickness.

Having removed the peel-ply fabric and acetone wiped the Sika CarboShear L elements,

apply Sikadur 30 in an apex shape to the inner face of the CFRP element and at the same

time to the grooves of the anchor length, prepared in advance to avoid air entrapment in the

anchoring adhesive.

Spread a thin filler coat of Sikadur 30 onto the prepared concrete surface. Apply a substantial

amount of Sikadur 30 to the edge of the structure in order to avoid any risk of gap in the layer

of adhesive.

Holding the CFRP elements slightly obliquely, push the long Sika CarboShear L legs of the

first side of the web into the boreholes filled with Sikadur 30. When the anchor length is almost

reached, press the element firmly onto the filler coat on the substrate, using a rubber roller to

bed the element and evacuate any air. Subsequently remove excess of Sikadur 30 with a cloth

and scraper from the overlap zone on the underside of the web.

Sika CarboShear L elements on the opposite side are applied exactly the same way as on the

first side. The exposed surface of the shorter leg of the plate of the web side have to be primed

with Sikadur 30 first, in order to ensure that the plates remain in place. Remove excessive

adhesive with a tongue shaped spatula.

Do not disturb during the curing period. Once cured, the elements can be protected from ultraviolet light by over-coating, for example with Sikagard 550 W Elastic or Sikagard Color A50

Lo-VOC.

Limitation

Design calculations must be made and certified by an independent, licensed professional

engineer. Sika Canada cannot and will not determine the locations, spacing nor orientation

of the Sika CarboShear L elements on the actual project. Design guidelines are available

through contact with Sika Canada Technical Services.

The required mean adhesive (tensile) strength of the prepared concrete substrate must be

2 MPa (290 psi), with a minimum 1.5 MPa (218 psi).

Maximum admissible working temperature: 50C (122F).

Minimum application temperature: 10C (50F).

Maximum substrate moisture content: 4% by weight.

Ambient and substrate temperature during application must be at least 3C (6F) above dew

point.

Sika CarboShear L systems must be protected against continuous exposure to direct

sunlight.

Health and Safety

Information

For information and advice on the safe handling, storage and disposal of chemical products,

users should refer to the most recent Material Safety Data Sheet containing physical,

ecological, toxicological and other safety-related data.

KEEP OUT OF REACH OF CHILDREN

FOR INDUSTRIAL USE ONLY

The information, and in particular, the recommendations relating to the application and end-use of Sika products, are given in

good faith based on Sikas current knowledge and experience of the products when properly stored, handled and applied under

normal conditions, within their shelf life. In practice, the differences in materials, substrates and actual site conditions are such that

no warranty in respect of merchantability or of fitness for a particular purpose, nor any liability arising out of any legal relationship

whatsoever, can be inferred either from this information, or from any recommendations, or from any other advice offered. The

proprietary rights of third parties must be observed. All orders are accepted subject to our current terms of sale and delivery. Users

should always refer to the most recent issue of the Product Data Sheet for the product concerned, copies of which will be supplied

on request or can be accessed in the Internet under www.sika.ca.

Sika Canada Inc.

Head Office

601 Delmar Avenue

Pointe-Claire, Quebec

H9R 4A9

Other locations

Toronto

Edmonton

Vancouver

1-800-933-SIKA

www.sika.ca

An ISO 9001 certified company

Pointe-Claire: ISO 14001 certified EMS

Sika CarboShear L

03 25 00 COMPOSITE REINFORCING

3-603

Construction

Sika CarboShear L

03 25 00 COMPOSITE REINFORCING

3-603

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- (PPT) Eurocode 2 Design of Concrete Structures EN1992-1-1 (Walraven)Document173 pages(PPT) Eurocode 2 Design of Concrete Structures EN1992-1-1 (Walraven)Gregory SimmonNo ratings yet

- (PPT) Eurocode 2 Design of Concrete Structures EN1992-1-1 (Walraven)Document173 pages(PPT) Eurocode 2 Design of Concrete Structures EN1992-1-1 (Walraven)Gregory SimmonNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pricing Strategies of Reliance TelecomDocument37 pagesPricing Strategies of Reliance Telecomvenkataswamynath channa100% (9)

- F ArmDocument6 pagesF ArmAlexandra NeaguNo ratings yet

- Seismic Response of Elevated Liquid Storage Steel TanksDocument6 pagesSeismic Response of Elevated Liquid Storage Steel TanksAlexandra NeaguNo ratings yet

- 1004 1188Document93 pages1004 1188Alexandra NeaguNo ratings yet

- The Arrival of British Standards For Concrete: RepairDocument4 pagesThe Arrival of British Standards For Concrete: RepairAlexandra NeaguNo ratings yet

- 488 575 PDFDocument44 pages488 575 PDFAlexandra NeaguNo ratings yet

- 306 487Document91 pages306 487Alexandra NeaguNo ratings yet

- Tutorial PlanDocument23 pagesTutorial PlanPraveen KumarNo ratings yet

- ANSI-ISA-75.08.02-2003 - Face-to-Face Dimensions For Flangeless Control Valves (Classes 150, 300, and 600)Document16 pagesANSI-ISA-75.08.02-2003 - Face-to-Face Dimensions For Flangeless Control Valves (Classes 150, 300, and 600)lionking1No ratings yet

- Model LD - Large DC Volt/Current/Process Display: General Description SpecificationsDocument16 pagesModel LD - Large DC Volt/Current/Process Display: General Description SpecificationsRafael LinarezNo ratings yet

- Assessment 1 (Short Answer) SITXWHS007Document14 pagesAssessment 1 (Short Answer) SITXWHS007littleberryzaoNo ratings yet

- Diaphragm Valves: A Class of Their OwnDocument9 pagesDiaphragm Valves: A Class of Their OwnROMNANo ratings yet

- Bugs 6 EjerciciosDocument33 pagesBugs 6 EjerciciosmoncaciNo ratings yet

- KUBOTA KC250H DUMPER Service Repair Manual PDFDocument13 pagesKUBOTA KC250H DUMPER Service Repair Manual PDFufjjdjfkskemmdNo ratings yet

- Zimbra Os Admin GuideDocument180 pagesZimbra Os Admin Guideneoman552No ratings yet

- Mapeplan Gb5-2016 LowDocument46 pagesMapeplan Gb5-2016 LowMohamed Ismail ShehabNo ratings yet

- Enable LDAPS On Windows IISDocument5 pagesEnable LDAPS On Windows IISFahad ShaikhNo ratings yet

- Fancyvrb PDFDocument73 pagesFancyvrb PDFdart13No ratings yet

- OE Friction Catalog Summer 2013Document74 pagesOE Friction Catalog Summer 2013robertoperez525No ratings yet

- CHE70 1 Exercises Quizzes NOV 8Document6 pagesCHE70 1 Exercises Quizzes NOV 8rickiegasparNo ratings yet

- Mismatch Defect in ERW Steel Tubes: September 2014Document5 pagesMismatch Defect in ERW Steel Tubes: September 2014Riza KhanNo ratings yet

- 9 InsulatorDocument39 pages9 InsulatorLeo KhkNo ratings yet

- Point Naming Standards: by James F. Butler, Member ASHRAE and Robert Veelenturf, P.EDocument6 pagesPoint Naming Standards: by James F. Butler, Member ASHRAE and Robert Veelenturf, P.Estatic245No ratings yet

- CV - Edson C Ayuste - Senior Instrument Engineer - March2018Document8 pagesCV - Edson C Ayuste - Senior Instrument Engineer - March2018Edson AyusteNo ratings yet

- Powerpac HC Power Supply: Instruction ManualDocument26 pagesPowerpac HC Power Supply: Instruction ManualSebastian Martinez CuautencoNo ratings yet

- Field Installation, Inspection and Test Plan. Storage TankDocument3 pagesField Installation, Inspection and Test Plan. Storage Tanknur hudaNo ratings yet

- SR30 - Modbus MapDocument9 pagesSR30 - Modbus MapMuathNo ratings yet

- Identity Based Networking Services (IBNS) 2.0 - New Style 802.1X and MoreDocument68 pagesIdentity Based Networking Services (IBNS) 2.0 - New Style 802.1X and MoreWilliam NogueiraNo ratings yet

- Hydraulic Lab 1Document12 pagesHydraulic Lab 1Afiq HamidiNo ratings yet

- Nor GrenDocument4 pagesNor GrenefrenNo ratings yet

- MVC AuthorisationDocument14 pagesMVC AuthorisationAmareswara RaoNo ratings yet

- 110707Document39 pages110707pac100% (8)

- Competency Presentation 1-9Document6 pagesCompetency Presentation 1-9api-483891682No ratings yet

- BS 10 Flange PDFDocument6 pagesBS 10 Flange PDFmozammilNo ratings yet

- Minggu 4 - JavascriptDocument58 pagesMinggu 4 - Javascriptcikiaaulia anisNo ratings yet

- Catalog-Ekarat Solar 200 W Module-MonoDocument2 pagesCatalog-Ekarat Solar 200 W Module-MonoFalcon EgyNo ratings yet