Professional Documents

Culture Documents

Dri Equipment Breakdown Analysis Report: Date: - 19/05/2015

Uploaded by

abhinay02meOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dri Equipment Breakdown Analysis Report: Date: - 19/05/2015

Uploaded by

abhinay02meCopyright:

Available Formats

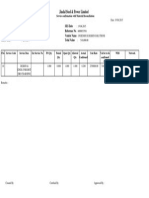

DRI EQUIPMENT BREAKDOWN analysis REPORT

Date: 19/05/2015

Name and Tag no. of the equipment: - PROCESS GAS COMPRESSOR STAGE 1

(CP-A 57)

Short Details of Equipment:1) Driven by a motor of 8.5 MW (1480 RPM).

2) An intermediate gear box (multiplier) having double helical gears (Herringbone

gear).

3) A cantilever supported rotor having two journal bearings at its DE & NDE side

and a thrust

bearing in between them and running at 5600 RPM.

4) It is a centrifugal compressor.

Lubrication Details:- Oil lubricated ( Servo Press Gr. T-32) by a centralized lube oil

system.

Breakdown Downtime:

Started from 2200 hrs on May 5th, 2015

Ended at 2130 hrs on May 9th, 2015.

Actual downtime: 96 hrs/5760 minutes

Probable causes of breakdown:1)

2)

3)

4)

5)

6)

7)

8)

Rotor unbalance.

Journal bearing failure.

Oil contamination with water or due to wear & tear.

At a sudden jerk on rotor due to plant tripping can budge the axial float of the

impeller.

Motor can also encounter some problems.

Wear and tear in gear box.

Couple unbalances.

Structural looseness.

DRI EQUIPMENT BREAKDOWN analysis REPORT

CBM Report:- Vibration readings ( Velocity RMS-mm/sec)

LOCATION

MOTOR

NDE

02.05.15

After

Maintenance

09.05.15 at

09:20 PM

10.05.15

16.05.15

2.3

2.6

2.6

2.4

1.2

0.9

0.7

1.4

1.0

0.8

0.8

1.1

0.6

0.7

1.5

0.6

2.0

1.5

0.9

1.4

1.1

0.7

1.0

0.9

0.8

0.7

0.9

1.1

0.7

1.3

1.0

0.9

0.8

0.6

0.9

0.6

0.6

1.0

0.9

1.9

1.2

0.9

1.7

0.8

1.0

1.1

1.0

1.0

0.9

1.1

1.1

1.0

1.0

1.3

1.2

0.8

0.7

0.9

0.6

0.8

1.5

0.6

2.0

1.4

0.8

1.7

1.5

0.8

0.9

0.6

0.6

0.7

0.7

1.2

0.9

1.1

1.3

1.1

0.8

0.8

0.9

0.6

0.8

1.4

0.8

2.2

1.4

1.0

1.4

1.3

0.7

0.9

0.6

0.5

0.7

0.8

DIRECTIO

N

CLASS &

LIMITS AS

PER ISO

10816

A

H

MOTOR DE

V

A

GEARBOX

I/P DE

GEARBOX

I/P NDE

GEARBOX

O/P DE

GEARBOX

O/P NDE

COMPRESS

OR DE

COMPRESS

OR NDE

H

V

A

H

V

A

H

V

A

H

V

A

H

V

A

H

V

A

Class 3

&

11.2mm/

sec

Compressor trial was taken thrice but tripped on every trial due to high

vibration in DE bearing , magnitude being measured as 10.82 mils, 6.6

mm/sec(11.2 mils), 13.4 mm/sec(13.25 mils) respectively. So the spectrums

could not be recorded at the time of conducting trial but after the corrective

measures the spectrums were recorded which can be referred in the next

section the report.

DRI EQUIPMENT BREAKDOWN analysis REPORT

Prompt Action Taken:1) On the basis of jamming problem reported by operation crew in plant start up

after a short duration S/D, motor to gear box and gear box to compressor decoupling done and each drive is independently rotated manually and

observed that all three drives i.e. motor, gear box and compressor were

freely rotating without any obstruction.

Rectifications and Corrections done:-

S. No

Date

05/05/1

5

06/05/1

5

06/05/1

5

06/05/1

5

07/05/1

5

07/05/1

5

08/05/1

5

09/05/1

5

Description of Job

Reported that PGC 1 is not rotating, decided to rotate manually

but in vain, then motor to g/box & g/box to compressor decoupled

& all 3 equipments found free.

Chain block fixed, and cleaning done around the gearbox and

compressor. Clamp fixing on motor side. Solo run taken in slow

speed, after that clamp removed and solo run in full speed take,

running normal.

PGC-1 motor to gear box coupling done after solo run & after

electrical clearance .Hand over to Prod at 8:30PM, Comp Started

at 9PM, But after 45 Sec Running Comp got tripped due to High

Vibration in DE bearing, Instrument person are checking

PG Compressor no.1 started twice in a shift, but tripped due to

high vibration in DE bearing. Chain block shifted and fixed at

compressor. Compressor coupling guard removed

Coupling inspected and found one bolt missing and one bolt loose

towards gear-box side of high speed coupling. Same replaced with

new one. Compressor started two times but both times tripped on

higher vibration.

Compressor to gear-box decoupled. Bearing to be inspected.

All lube oil fittings removed and blind fixed. CMP bearing cover

bolt removed & Kept in Position.

DE bearing removed after removing the cover, one nozzle

fabricated with v/v and metallic hose fixed to arrest CO leakage.

All three bearing removed, cleaned and inspected, journal pads all

dimensions recorded and fixed back. Casing and all lube oil

fittings put back at their respective positions. Lube oil started at

5.30 am. Motor to G/B coupled back.

Motor to gear box alignment checked and found O.K. Clearance

given for Motor gearbox trial. Max vibration of 2.8mm/sec

observed on Motor and 1.2mm/sec on gearbox. To mark magnetic

center, motor to gearbox again decoupled to take motor solo run.

Rotor axial float also checked and found 0.28 mm on either side.

DRI EQUIPMENT BREAKDOWN analysis REPORT

09/05/1

5

Motor forced to stop at magnetic center. Motor to gear box and

gear box to compressor coupling done. Seals piping mounted.

Both coupling guards mounted. Chain block removed and kept

aside.

Compressor started and running normal with 1.6 mm/sec

vibrations.

SPECTRUMS FOR REFERENCE:Compressor DE H:-

v rms [mm/s]

0.70

PGC 1\COMPR E SSOR \COMP DE H\6000 R PM\Spectrum 5/16/2015 10:59:18 AM

0.65

(88.50 / 0.59)

0.60

M

D

0.55

0.50

0.45

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0.00

0

200

400

600

800

1000

1200

1400

1600

1800

2000

f [Hz]

DRI EQUIPMENT BREAKDOWN analysis REPORT

Compressor DE V:-

v rms [mm/s]

0.80

PGC 1\COMPRE SSOR\COMP DE V\6000 RPM\Spectrum 5/16/2015 10:59:33 AM

(1063.00 / 0.71)

0.75

M

0.70

0.65

0.60

0.55

0.50

0.45

(88.50 / 0.38)

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0.00

0

500

1000

1500

Compressor DE A:-

2000

2500

3000

f [Hz]

DRI EQUIPMENT BREAKDOWN analysis REPORT

v rms [mm/s]

1.6

PGC 1\COMPR E SSOR \COMP DE A\6000 R PM\Spectrum 5/16/2015 10:59:46 AM

1.5

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

(88.50 / 0.34)

0.4

0.3

0.2

0.1

0.0

0

500

1000

1500

2000

2500

3000

f [Hz]

Compressor NDE H:

v rms [mm/s]

0.40

PGC 1\COMPR E SSOR \COMP NDE H\6000 RPM\Spectrum 5/16/2015 11:00:49 AM

0.38

0.36

(88.50 / 0.33)

0.34

0.32

0.30

0.28

0.26

0.24

0.22

0.20

(1063.50 / 0.17)

0.18

0.16

0.14

0.12

0.10

0.08

0.06

0.04

0.02

0.00

0

500

1000

1500

2000

2500

3000

f [Hz]

DRI EQUIPMENT BREAKDOWN analysis REPORT

Compressor NDE V:v rms [mm/s]

0.70

PGC 1\COMPR E SSOR \COMP NDE V\6000 R PM\Spectrum 5/16/2015 11:01:03 AM

0.65

0.60

(88.50 / 0.55)

0.55

0.50

0.45

0.40

0.35

0.30

0.25

(1063.50 / 0.18)

0.20

0.15

0.10

0.05

0.00

0

500

1000

1500

Compressor NDE A:-

2000

2500

3000

f [Hz]

DRI EQUIPMENT BREAKDOWN analysis REPORT

v rms [mm/s]

0.65

PGC 1\COMPRE SSOR\COMP NDE A\6000 RPM\Spectrum 5/16/2015 11:01:18 AM

0.60

(1063.50 / 0.55)

M

0.55

0.50

0.45

(88.50 / 0.36)

0.40

0.35

0.30

0.25

0.20

0.15

0.10

0.05

0.00

0

500

1000

1500

2000

2500

3000

f [Hz]

Present Health Status:NORMAL, As per ISO standards present vibration levels are in satisfactory

zone.

Root Causes of Breakdown:-

Recommendations & Suggestions for future: Monitor the vibration trend levels for further course of action.

Oil sampling should be done at periodic intervals.

PMI( Preventive Maintenance Inspection) of compressor should be

done at particular intervals as per Preventive maintenance schedule.

You might also like

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- GM 6t70 UpdatesDocument45 pagesGM 6t70 UpdatesThePokeOne100% (9)

- Eightspeed Guide 2022 CompressedDocument14 pagesEightspeed Guide 2022 CompressedCarlos0% (1)

- All About AL4-Gear BoxDocument23 pagesAll About AL4-Gear BoxAhmed Fotoh97% (39)

- 2AZ-FE Engine MechanicalDocument127 pages2AZ-FE Engine Mechanical胡瑞麟82% (22)

- 2az Fe Engine Mechanical-1Document290 pages2az Fe Engine Mechanical-1Diego Falconi100% (2)

- Kia Sorento Engine (XM) InfoDocument61 pagesKia Sorento Engine (XM) Inforeluma0% (1)

- 2GR-FE Engine MechanicalDocument156 pages2GR-FE Engine MechanicalLuks Fernandez100% (7)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Engine Mechanical PDFDocument115 pagesEngine Mechanical PDFAndrey GladyshevNo ratings yet

- 78 Dt400e DT250E ManualDocument18 pages78 Dt400e DT250E Manualdisgustipate0% (1)

- A CASE STUDY ON ROTOR DAMAGE DUE TO ELECTROMAGNETIC SHAFT CURRENTS - Singh PDFDocument13 pagesA CASE STUDY ON ROTOR DAMAGE DUE TO ELECTROMAGNETIC SHAFT CURRENTS - Singh PDFJose PradoNo ratings yet

- Automotive Air Conditioning and Climate Control SystemsFrom EverandAutomotive Air Conditioning and Climate Control SystemsRating: 4 out of 5 stars4/5 (6)

- Shaper Gear CuttingDocument4 pagesShaper Gear Cuttingnevadablue100% (4)

- Basic Signal Procesing For Vibration Data CollecitonDocument9 pagesBasic Signal Procesing For Vibration Data CollecitonMohd Asiren Mohd Sharif100% (1)

- A960e VB BreakdownDocument15 pagesA960e VB BreakdownDavid Chalker0% (2)

- Auditing RacfDocument57 pagesAuditing Racfசிங்கார வேலன்No ratings yet

- P6V7-Case Study ProjectDocument43 pagesP6V7-Case Study Projectabhinay02meNo ratings yet

- Test Transmision 420E CatDocument8 pagesTest Transmision 420E CatEdin Raul Yalle RafaelNo ratings yet

- JM Engine 20040209Document43 pagesJM Engine 20040209wreckedweasel100% (2)

- J24B EngineDocument196 pagesJ24B EngineLeonel Dominguez100% (2)

- Basic HydraulicsDocument53 pagesBasic Hydraulicsabhinay02meNo ratings yet

- Hanbell Service ManualDocument80 pagesHanbell Service ManualStephen Marcus100% (2)

- Cylinder Head - Install: Cerrar SIS Pantalla AnteriorDocument21 pagesCylinder Head - Install: Cerrar SIS Pantalla AnteriorReymundo Enrique Dominguez Hernandez100% (1)

- Demo Service Manual Cat 120KDocument41 pagesDemo Service Manual Cat 120KJimmy Jimmy100% (2)

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Carte Tehnica Excavator VolvoDocument12 pagesCarte Tehnica Excavator VolvoCiufudean AdrianNo ratings yet

- Yamaha TT600K Service ManualDocument168 pagesYamaha TT600K Service ManualErko Sinisalu100% (1)

- ASTM E1417 Penetrant Testing - 9 PDFDocument11 pagesASTM E1417 Penetrant Testing - 9 PDFbikaNo ratings yet

- Hot Work ProcedureDocument10 pagesHot Work ProcedureOws AnishNo ratings yet

- ME Manual AppendixDocument641 pagesME Manual AppendixAnonymous uTO1WI0% (1)

- DG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsDocument11 pagesDG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsMugeshNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Enticer ManualDocument122 pagesEnticer Manualdhaze14No ratings yet

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Psychrometrics FormulaeDocument5 pagesPsychrometrics Formulaetmy3dataNo ratings yet

- SB1208 - ZF As Tronic - Clutch Component LubricationDocument12 pagesSB1208 - ZF As Tronic - Clutch Component LubricationCarlos José FariaNo ratings yet

- August QuestionsDocument8 pagesAugust Questionsbaba maachoNo ratings yet

- Yamaha Exciter 440 EX440 1980Document18 pagesYamaha Exciter 440 EX440 1980mkaukolaNo ratings yet

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Steering System PDFDocument12 pagesSteering System PDFGeorge Guerrero100% (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Minimum Load For Empty Minimum Load For OperatingDocument6 pagesMinimum Load For Empty Minimum Load For OperatingjitendraNo ratings yet

- Manituo Maniscopic Tyre HandlerDocument14 pagesManituo Maniscopic Tyre Handlermohanngp100% (2)

- Grafica de Medidas para Recesion de Valvulas G3400Document3 pagesGrafica de Medidas para Recesion de Valvulas G3400carlos angelNo ratings yet

- Mep Ques PDFDocument19 pagesMep Ques PDFMoryz PandeyNo ratings yet

- Hand Over 4 22Document2 pagesHand Over 4 22Ahmed AlwakeelNo ratings yet

- Spark T4 Engine1 (0-30)Document31 pagesSpark T4 Engine1 (0-30)Çàřļōş Ǡǹȡȓȇș Preciado100% (1)

- Mom VoithDocument5 pagesMom Voithapi-19984595No ratings yet

- Technical Inforinforme Tecnico Falla CilidrosDocument1 pageTechnical Inforinforme Tecnico Falla CilidrosJulio Palacios VeraNo ratings yet

- CamryShiftFlare TSIBDocument6 pagesCamryShiftFlare TSIBVadim Urupa100% (2)

- Eccentric Weight Housing Oil - Change: Operation and Maintenance ManualDocument3 pagesEccentric Weight Housing Oil - Change: Operation and Maintenance ManualLuis AugustoNo ratings yet

- 1983 Data-Tech Chevrolet S10 2.8L Vin B Especificaciones de Motor EspecificacionesDocument24 pages1983 Data-Tech Chevrolet S10 2.8L Vin B Especificaciones de Motor EspecificacionesRubenNo ratings yet

- Daily Report - of June 2012Document72 pagesDaily Report - of June 2012masudalamNo ratings yet

- Peroidic Maintenance ServicesDocument43 pagesPeroidic Maintenance Servicesthawatchai11222512No ratings yet

- 2.engine AssemblyDocument126 pages2.engine AssemblyWissem RatelNo ratings yet

- EASA TCDS E.005 (IM) Teledyne Continental IO 360 Series Engines 01 31032004Document24 pagesEASA TCDS E.005 (IM) Teledyne Continental IO 360 Series Engines 01 31032004Ken VanNo ratings yet

- Weber 3236 AdjustDocument1 pageWeber 3236 AdjustNarendra WijayasuriyaNo ratings yet

- Omml 7 201 300 B enDocument7 pagesOmml 7 201 300 B enEngr Mohammed UsmaniaNo ratings yet

- 1328699325305-Gr B Ans PT 2Document93 pages1328699325305-Gr B Ans PT 2Sankati SrinivasNo ratings yet

- Presiones 988bDocument24 pagesPresiones 988bMarielisa Zertuche FloresNo ratings yet

- Engine Mechanical ECHO 2002Document85 pagesEngine Mechanical ECHO 2002Tomas Dominguez100% (1)

- Valve Lash 1Document4 pagesValve Lash 1Daniel TekleNo ratings yet

- File - 20220609 - 210203 - Ce Handing Over NotesDocument5 pagesFile - 20220609 - 210203 - Ce Handing Over NotesPhuc ChuNo ratings yet

- Technical Note 3562A XG0NDocument120 pagesTechnical Note 3562A XG0NEeepsNo ratings yet

- Total Service: CharacteristicsDocument4 pagesTotal Service: Characteristicsbeu catalinNo ratings yet

- 5 (A) BankDocument11 pages5 (A) BankRaj MohammadNo ratings yet

- Fes PresenationDocument24 pagesFes PresenationIDRISSA MUSSANo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Coupler Shaft AssemblyDocument2 pagesCoupler Shaft Assemblyabhinay02meNo ratings yet

- Table of ContentsDocument3 pagesTable of Contentsabhinay02meNo ratings yet

- Do Not Scale: PP1 PP2 ANG2-7a-ME-DE-05-17-10048-01 C.007542 C.008627 ANG2-07-ME-DE-05-17-10048-01Document1 pageDo Not Scale: PP1 PP2 ANG2-7a-ME-DE-05-17-10048-01 C.007542 C.008627 ANG2-07-ME-DE-05-17-10048-01abhinay02meNo ratings yet

- PR 368 101.12044Document1 pagePR 368 101.12044abhinay02meNo ratings yet

- Current Booking Current Booking: Print ERS Without Advertisements (X)Document2 pagesCurrent Booking Current Booking: Print ERS Without Advertisements (X)abhinay02meNo ratings yet

- JSPL/Angul/SMS Project/24-10-2019/105513: ApprovedDocument3 pagesJSPL/Angul/SMS Project/24-10-2019/105513: Approvedabhinay02meNo ratings yet

- Tutorial 4: NVH: Modal Correlation (MAC)Document9 pagesTutorial 4: NVH: Modal Correlation (MAC)abhinay02meNo ratings yet

- Jindal Steel & Power LimitedDocument1 pageJindal Steel & Power Limitedabhinay02meNo ratings yet

- 17 20 000 - r2 170t X 8 5m Span Trolley Arrangement-ModelDocument1 page17 20 000 - r2 170t X 8 5m Span Trolley Arrangement-Modelabhinay02meNo ratings yet

- HM DeS KRDocument12 pagesHM DeS KRabhinay02meNo ratings yet

- PR 368 101.12044Document1 pagePR 368 101.12044abhinay02meNo ratings yet

- Jindal Steel & Power Limited Purchase Requisition Receiving Plant: Jindal Steel PlantDocument1 pageJindal Steel & Power Limited Purchase Requisition Receiving Plant: Jindal Steel Plantabhinay02meNo ratings yet

- Jindal Steel & Power Limited Purchase Requisition Receiving Plant: Jindal Steel PlantDocument1 pageJindal Steel & Power Limited Purchase Requisition Receiving Plant: Jindal Steel Plantabhinay02meNo ratings yet

- HVWS SystemDocument1 pageHVWS Systemabhinay02meNo ratings yet

- Jindal Steel & Power LimitedDocument1 pageJindal Steel & Power Limitedabhinay02meNo ratings yet

- Internal Clearance - Types and NormsDocument6 pagesInternal Clearance - Types and Normsabhinay02meNo ratings yet

- End Valve PG 1Document1 pageEnd Valve PG 1abhinay02meNo ratings yet

- Jindal Steel & Power Limited: General NFADocument2 pagesJindal Steel & Power Limited: General NFAabhinay02meNo ratings yet

- Biomimetics: Lessons From Nature - An OverviewDocument42 pagesBiomimetics: Lessons From Nature - An Overviewabhinay02meNo ratings yet

- Welder and Welding Operator Qualification Test Record (Asme Ix Code)Document1 pageWelder and Welding Operator Qualification Test Record (Asme Ix Code)Neil TaneoNo ratings yet

- Feslog - 1508161122 - Fiat Doblo' (Type 223) Cargo 1.3 Mjet 16vDocument19 pagesFeslog - 1508161122 - Fiat Doblo' (Type 223) Cargo 1.3 Mjet 16vraulUTCNNo ratings yet

- Fourier Series - MATLAB & Simulink PDFDocument7 pagesFourier Series - MATLAB & Simulink PDFWanderson Antonio Sousa SilvaNo ratings yet

- System Theory - Model ExamDocument2 pagesSystem Theory - Model ExamrajapandiyaNo ratings yet

- Overview of Ultrasound Detection Technologies For Photoacoustic ImagingDocument24 pagesOverview of Ultrasound Detection Technologies For Photoacoustic ImagingShuvam5 GuptaNo ratings yet

- Service Manual: Model Code - Kib19Bp3-CmgDocument11 pagesService Manual: Model Code - Kib19Bp3-Cmgpravin jadavNo ratings yet

- T620 Plus DisassemblyDocument25 pagesT620 Plus DisassemblycdgmatNo ratings yet

- Data Warehousing Quick GuideDocument66 pagesData Warehousing Quick Guidejacktheking2010No ratings yet

- Ups and Stabilizer Assembling UnitDocument28 pagesUps and Stabilizer Assembling UnitIPro PkNo ratings yet

- 24 - Article - $mbps Vs $MHZ Why Is This ImportantDocument2 pages24 - Article - $mbps Vs $MHZ Why Is This ImportantShiraz SiddiqNo ratings yet

- K.analysis of The Articulated Robotic Arm (TITLE DEFENCE)Document22 pagesK.analysis of The Articulated Robotic Arm (TITLE DEFENCE)sky4sterNo ratings yet

- Manufacturer'S Test Certificate: National Builtech Trading and Contracting CoDocument1 pageManufacturer'S Test Certificate: National Builtech Trading and Contracting CoQc QatarNo ratings yet

- Fastening SystemsDocument74 pagesFastening SystemsskyvaneNo ratings yet

- TYBTech Syllabus MechanicalDocument49 pagesTYBTech Syllabus MechanicalswapnillkNo ratings yet

- Design of Earth-Quake Resistant Multi Storied RCC Building On A Sloping GroundDocument24 pagesDesign of Earth-Quake Resistant Multi Storied RCC Building On A Sloping GroundKakula SasidharNo ratings yet

- Flexibility and Safety: BERNSTEIN Safety Hinge SwitchesDocument12 pagesFlexibility and Safety: BERNSTEIN Safety Hinge SwitchespiterNo ratings yet

- Comb - Chemkin - Format PDFDocument5 pagesComb - Chemkin - Format PDFMUHAMMAD FAREEZ IZWAN BIN ABDUL JALILNo ratings yet

- CM P1CM EP1 Operation ManualDocument24 pagesCM P1CM EP1 Operation Manualnguyen vuNo ratings yet

- Fuel Consumption Hyster Rev3Document7 pagesFuel Consumption Hyster Rev3crash2804No ratings yet

- Física Práctica 1 MRUDocument5 pagesFísica Práctica 1 MRUPolet BarrionuevoNo ratings yet

- Excel ExercisesDocument37 pagesExcel ExercisesBERNIELLE DAVE FALDASNo ratings yet