Professional Documents

Culture Documents

A Supply Chain Simulation Model With Customer's Satisfaction

Uploaded by

maherkamelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Supply Chain Simulation Model With Customer's Satisfaction

Uploaded by

maherkamelCopyright:

Available Formats

A Supply Chain Simulation Model with Customers Satisfaction

Jianfeng Li, Yan Lin, Feng Jin

A Supply Chain Simulation Model with Customers Satisfaction

Jianfeng Li, Yan Lin, Feng Jin

Management Science and Engineering , Dalian Maritime University

Dalian city, PR. China

E-mail lijianfeng_vvv@yahoo.com.cn

Abstract

According to the customers satisfaction, this paper establishes a two level supply chain simulation

model through system dynamics (SD) approach, and then, Simulink tool is adopted for that model.

Through the simulation, its shown that improvement of supply chain processs promptness can bring

out the more customers satisfaction, and then, the sale amount is increased. The indirect profit is

gained by means of improving operations efficiency in supply chain. In this way, the simulation about

customer satisfaction is reflected clearly, and that system dynamics simulation model can be helpful for

the supply chain management project.

Keywords: Supply Chain Management, Supply Chain Simulation, System Dynamics

1. Introduction

With the development of economic globalization, supply chain management (SCM) becomes an

important management conception for enterprises in the current vehement environment [1,2]. As what

Wood has stated, since the supply chain represents 60 to 80% of a typical companys cost structure, a

10% reduction can yield a 40 to 50% improvement in pre-tax profits [3]. For SCM, on account of

avoiding large expense for the failure of SCM projects, simulation is a widely and useful method, many

scholars have worked over the supply chain in order to achieve some value things:

Kang Bokyoung applied an new social network analysis method to simulate supply chain integrating

agent-based modeling[4]. Minegishi and Thiel made a system dynamics simulation for a food supply

chain system, that work sheds lighted on the complex nature of this specific type of supply chain and in

particular on the coordination of variables controlling the food production[5]. Adhitya, Arief integrated

dynamic simulation and LCA indicators to bring forward some decision support for green supply chain

operation[6]. Gavirneni, from the viewpoint of information distortion, simulated an overall supply chain

model, that emphasizes the value of information and extended existing inventory theory[7]. Towill from

system dynamics perspective also demonstrated that supply chain integration with exchange of

information was as beneficial as lead time reduction throughout the supply chain via JIT [8].

Dejonckheere examined the beneficial impact of information sharing in multi-tier supply chains and

discovered that information sharing helped to reduce the bullwhip effect in the chains with different

inventory policies [9]. Kumar used six sigma simulation and designed experiment to quantify supply

chain trade-offs and developed a flexible distribution networks[10].

In current simulation literature for SCM, the research on the reflection of customers satisfaction in

the supply chain is very little, in this way, this paper establishes a two level supply chain simulation

model with customers satisfaction through system dynamics, and showing some little improvement of

operations efficiency in supply chain can bring out the change of main customers satisfaction, which

also lead to alternation of other factors, such as sale amount.

The rest of the paper is organized as follows. In section 2, two level supply chain simulation model

using SD method is established. In section 3, Simulink tool is adopted for the above simulation model,

and then, the results expected from the simulation are described. In section4, the Simulation analysis on

customers satisfaction is given out. In section 5, the conclusions are presented finally.

International Journal of Advancements in Computing Technology(IJACT)

Volume4,Number10,June2012

doi:10.4156/ijact.vol4.issue10.15

125

A Supply Chain Simulation Model with Customers Satisfaction

Jianfeng Li, Yan Lin, Feng Jin

2. Supply chain system dynamics model

Through the SD approach, a simple two-stage supply chain model is established, which is shown in

Fig.1. There are four basic roles in supply chain: customer, retailer, manufacturer and supplier. The

retailer orders the goods from the manufacturer and then sales them to customer. The manufacturer

orders relative materials from the supplier. The activities such as ordering, transporting, producing,

stocking and selling are included in that procedure basically.

Manufacturer

Supplier

GMT

CMT

OnM

PM

ComeM

GoM

Retailer

CRT

OnR

InventM

ProdM

CML

GRT

PMT

GoR

ComeR

Sale

PML

CRL

GRV

GMV

GM

FR

Market

Demand

GR

FM

SafM

Customer

InventR

DemRate

SumWeek

SafR

CuRateC or

CuRateG

Figure1. Supply Chain Simulation Model with Customers Satisfaction

The variables in that model are following:

Market: the stochastic total demand in the market.

Demand : the demand of customer in that supply chain.

DemRate: the rate of total demand for that customer.

CuRateC or CuRateG: the increasing or decreasing change rate of demand on account of

customers satisfaction.

SumWeek: the sum of demands for customer in a week

InventR or InventM: the inventory level for the retailer or manufacturer.

OnR or OnM: the stock of goods on the route for the retailer or manufacturer.

PM: the stock of goods produced by the manufacturer.

GoR or GoM: the goods flow from manufacturer or supplier.

ComeR or ComeM: the goods flow coming to the retailer or manufacturer.

ProdM: the goods flow that manufacturer produces.

GMT, CMT or PMT: the delay of ordering, transporting or producing for manufacturer.

GRT or CRT: the delay of ordering or transporting for retailer.

CML or PML: the limit of transporting or producing for manufacturer.

CRL: the limit of transporting capability for the retailer.

FR or FM: the forecasting value of selling goods for retailer of manufacturer.

SafR or SafM: the safety coefficient for the retailer or manufacturer.

GR or GM: the attending ordering amount for retailer or manufacturer.

Sale: the selling goods flow to the customer.

Here, the demand of customer in the market (Market) is stochastic, and the demand in that supply

chain is some part of the total demand in the market (Market*DemRate). The sale amount fulfilling

customers satisfaction depends on the retailers inventory level, in this way, the sale amount is the

minimum between the demand and the inventor level of retailer(InventR) in a special time t

(fundamental simple time). Supposing when the sale amount can meet the demand of the customer, the

number of customers buying in that supply chain will increase next time (CuRateC), otherwise the

number of customers will decreases (CuRateG).

The retailer makes ordering decision through exponential smoothing method according to the

summation of sale value over some time before, such as a week(SumWeek), Whats more, in order to

126

A Supply Chain Simulation Model with Customers Satisfaction

Jianfeng Li, Yan Lin, Feng Jin

guarantee the enough inventories to fulfill the customer satisfaction, the retailer multiplies the

forecasting value through exponential smoothing method by a safety coefficient(SafR) and considers

that multiplied value as the forecasting sale amount next period(FR). Then, the retailer subtracts

amount of the goods on the route(OnR) and inventory amount(InventR) from that forecasting sale

amount to order from the manufacturer. If the result is larger than zero, the retailer orders that amount,

else doesnt order. The real ordering goods amount (GoR) is depended on the inventory level (InventM)

of manufacturer. The same is the manufacturer. The variable FM is the forecasting value through

exponential smoothing method, variable SafM is the safety coefficient, and GM is the ordering value

for the manufacturer, in which, goods on the route(OnM), inventory amount(inventM), and the goods

produced by manufacturer(PM) is also needed to subtract. However, the ordering amount from the

supplier is not under the control (GoM). i.e. the supplier can supply any ordering amount that the

manufacturer needs.

When the material goods flows in the supply chain, it will cost some time (CRT, CMT or

PMT), so is the ordering information exchanges (GRT or GMT), whichs more, the amount flow

of transportation (ComeM or ComeR) and production (ProdM) are limited by their ability (CML,

CRL and PML) on account of some reason, such as manufacturer cant produce enough goods

by machine in a fundamental simple time. In this way, the material is flowing over the supply

chain continuously, and a supply chain simulation model with customers satisfaction is

established.

3. Simulation through simulink

Simulink tool is adopted for the above SD simulation model (Fig.2), which is an environment for

multi-domain simulation and model-based design for dynamic and embedded systems.

In

Out

SumWeek

SumWeek

In

-K-

Market

Market

Demand

FR

Sub_Exponential

Smoothing_R SafR

Sub_SignalStatistic

Demand

Out

FRS

Signal

Random

Sale

MarkRateR

GR

FRS

Sub_Customer

Limit

signal

Out

In

Lev el

Sale

Inv entR

Lev el

ComeR

Out

GRT

CRL

Sub_OnR

Sub_InventR

-1

Z

GR

Divide

Sale

Limit

CRL

In

FMS

Limit

In

Out

GoR

Inv entM

Lev el

FMS

Sub_InventM

0

PML

ProdM

Out

Limit

PML

In

Sub_PM

FM

Out

In

Sub_Exponential

Smoothing_M

GM

OnM

PM

Lev el

PM

-KSafM

GM

CML

OnM

ComeM

Lev el

Out

Limit

In

GMT

CML

-1

Z

GMZ

GMZ

Sub_OnM

Figure2. Supply Chain Simulation through Simulink

There are mainly five kinds of subsystem:

(a) Subsystem for signal statistic

The Sub_SignalStatistic module in Fig.3 is this kind of subsystem, which is for calculating the

demands in some time before. In this module, input is the customers stochastic demands and output is

127

A Supply Chain Simulation Model with Customers Satisfaction

Jianfeng Li, Yan Lin, Feng Jin

the summation of demands in some periods. Supposing the retailer orders the goods from the

manufacturer every week, it must calculate the summation of demands this week, and then consider

that statistic amount as some basis to forecast the probability sale amount next week. A summation

pulse signal every 7 day is produced in this subsystem.

In

1

K Ts

MATLAB

Function

z-1

mod1

Discrete-Time

Integrator

Clock1

Sum

Switch3

== 0

Compare

To Zero

Constant

Zero-Order

Hold

Out

SumWeek

Figure3. Subsystem for Signal Statistic

(b) Subsystem for transportation or production

The modules of Sub_OnR, Sub_OnM and Sub_PM in Fig.2 belong to this kind of subsystem, which

is for describing output and level condition of transportation or production. In those modules, Inputs

are some material inflow and capability limit, and outputs are material outflow and the stocking level,

such as the goods on the route and the goods which is being produced. Here, there are some delays in

transportation and production in supply chain and the FIFO rule is adopted to shown in that procedure,

which is shown in Fig.4.

OnR

In1

Out1

In2

Level

GoR

OnLine1

1

Limit

Out

Subtract3

2

In

Switch2

-1

Z

Subtract2

CMT

[0]

IC2

Memory2

1

1

In1

Out1

Subtract1

2

In2

[0]

IC1

Memory1

Figure4. Subsystem for Transportation or Production

(C) Subsystem for signal statistic

The modules of Sub_ExponentialSmoothing_R and Sub_ExponentialSmoothing_M in Fig.3 belong

to this kind of subsystem, which are made in order to forecast the sale amount next week. Here,

exponential smoothing method is adopted. Here supposing the smoothing factor 0.6 .The

exponential smoothing module is shown in Fig.5, through that, the forecasting sale value is output, and

then, supposing safety coefficient SafR and SafM are both 1.05, the retailer and manufacturer considers

that multiplication as the needed sale amount next week.

128

A Supply Chain Simulation Model with Customers Satisfaction

Jianfeng Li, Yan Lin, Feng Jin

Yt

1

In

0.6

Subtract

-7

Z

CofR

Clock1

FR

Switch1(7) Zero-OrderInteger Delay(7)

Hold1

St

1

Out

Figure5. Subsystem for Exponential Smoothing

(d) Subsystem for the inventory

The modules of Sub_InventR and Sub_InventM in Fig.2 belong to this kind of subsystem, which is

mainly for showing the change of the inventory level and the selling status to customer or retailer. In

those modules, the inputs are the coming goods and the capability limit, and outputs are inventory level

and sale amount really. Here because there is no time delay for inputting, transmitting and outputting

the goods in the storehouses of the retailer and manufacturer, the blending rule is adopted in those

modules, i.e. any goods are picking up at the equal possibility only if they are inputs into the

storehouse, which is shown in Fig.6.

1

signal

1

2

Limit

ComeR

Out

Subtract3

Switch1

2

In

Subtract2

[0]

IC1

InventR

3

Level

Memory1

Figure6. Subsystem for the inventory

(e) Subsystem for customer

Sub_Customer system is the most important and designed for customers satisfaction. (Fig,7). In

this subsystem, the demand is changed in the percent of CuRateC or CuRateG next time with signal,

which is the difference between inventory and customers demand. when the sale amount can meet the

demand of the customer, the number of customers buying in that supply chain will increase next time

(CuRateC), otherwise the number of customers will decreases (CuRateG). Whats more, the

proportion of sale amount to the demand in supply chain is considered as the symbol of customers

satisfaction in some degree. (SatiR).

-C-

DemRate

Market

Product

Demand

Product1

Market

-C-

-1

Z

-C-

Integer Del ay2

Si gnal

Si gnal

Demand

-CuRate

1+CuRateC

IC1

1-CuRateG

Sati R

3

Sal e

Figure7. Subsystem for the customer

Divide

129

A Supply Chain Simulation Model with Customers Satisfaction

Jianfeng Li, Yan Lin, Feng Jin

4. Simulation analysis on customers satisfaction

In this simulation system, the simulation start time is 0 and stop time is 70, the solver type is Fixedstep, the solver is adopted in discrete solver, and the fix-step size (fundamental sample time) is 1. The

goods for transportation is stochastic between 0 and 1. Some other variables are determined below:

OnM 0 PM 0 InventM 0 OnR0 InventR0

(1)

PML CML 0.8

(2)

CMT PMT CRT 2

(3)

SafM SafR 1.05

(4)

DemRate 0.5

(5)

CuRateC 0.01

(6)

CuRateG 0.02

(7)

GRT 2

(8)

GMT 2

(9)

In the simulation, the random demand of customer in the market (Market) is shown as follow (Fig.8),

which is between 0 and 0.1 (the sale amount unit is 10 thousand).

Figure8. The random demand of customer in the market

Some proportion (Market*DemRate) of that total demand in the market is considered as the demand

in the supply chain. Whats more, it can be changed with the need gratification or not. Supposing there

are some methods of SCM for improving information exchange quickness in the supply chain, in

which the GRT and GMT both decrease from 2 to 1 (lineo to line*), the relative changes for two

enterprises are shown as follows:

(a) The Change of Sale

The total sale amount in the supply chain increases a little, which is up from 1.1924 unit to 1.2585

unit in the simulation time (0~70). It means that improvement of information exchange can promote

the cycle in supply chain and facilitate the sale amount (Fig9).

130

A Supply Chain Simulation Model with Customers Satisfaction

Jianfeng Li, Yan Lin, Feng Jin

Figure9. The sale amount in the supply chain

(b) The Change of Signal

The Signal is the difference between inventory and demand. When the information exchange is

improved in supply chain, its shown clearly that the inventory of retail can be more enough to fulfill

the demand of the customers (Fig10).

Figure10. The signal in the supply chain

(b) The Change of Satisfaction

The satisfaction (SatiR) is simply expressed by the proportion of sale amount (fulfilling demand) to

the demand in supply chain. Its shown clearly that quickness of information exchange can make

enough good sold to promote the customers satisfaction (Fig11).

Figure11. The satisfaction in the supply chain

131

A Supply Chain Simulation Model with Customers Satisfaction

Jianfeng Li, Yan Lin, Feng Jin

In a word, its shown clearly from the above, that data represented by the line * is better, in

which, the retailer can sell more goods(Sale), the signal reflecting shortage is less(Signal), and

the customers satisfaction is higher(SatiR). That means the improvement of supply chain

processs promptness can bring out the more customers satisfaction, and then, the sale amount

is increased. The indirect profit is gained by means of improving operations efficiency in

supply chain.

5. Conclusion

This paper establishes a supply chain simulation model with customers satisfaction through

the system dynamics approach, and then, Simulink tool is adopted for that model. Through the

simulation, it can be seen clearly that the value of information is emphasized and customers

satisfaction can be increased by improving supply chain processs promptness, and the

information exchanges quickness can bring out large profit indirectly.

6. Acknowledgements

The authors would like to thank peer reviewers for commenting this article. This work is

supported by the National Natural Science Foundation of China (70801007, 71072124), the

Fundamental Research Funds for the Central Universities (2011QN034, 2011JC008 and

2011QN158), DLMU Outstanding scientific and technological innovation team training fund

(2012TD019)

7. References

[1] HsuHao Tsai, YenPing Chi, "Trend Analysis of Supply Chain Management by Bibliometric

Methodology", JDCTA, Vol. 5, No. 1, pp. 285-295, 2011

[2] Xing Zhang, Qiuhong Zhao, Guoping Xia, "Research on Integrated Optimization Problem in a

Multi-product Supply Chain Based on Markov Decision Processes", JCIT, Vol. 7, No. 1, pp. 45 53, 2012.

[3] Amrik S Sohal, Damien J Power, Mile Terziovski, Supply chain management in Australian

manufacturingtwo case studies. Computers & Industrial Engineering, Vol. 43, Issues 1-2, 1

July, pp.97-109, 2002.

[4] Kang Bokyoung, Kim Dongsoo,Kang SukHo, Supply chain simulation integrating agent-based

modeling with social network analysis: A conceptual framework, ICIC Express Letters, v 6, n 4,

pp 1115-1120, April, 2012.

[5] Shotaro Minegishi, Daniel Thiel, System dynamics modeling and simulation of a particular food

supply chain, Simulation Practice and Theory, Vol.8, No 5, pp.321-339, 2000.

[6] Adhitya Arief, Halim Iskandar, Srinivasan Rajagopalan, Decision support for green supply chain

operations by integrating dynamic simulation and LCA indicators: Diaper case study.

Environmental Science and Technology, v 45, n 23, pp 10178-10185, December 1, 2011.

[7] Srinagesh Gavirneni, Roman Kapuscinski, Sridhar Tayur, Value of information in capacitated

supply chains, Management Science. Vol.45, No.1, pp.1624, 1999.

[8] Denis Towill, Mohamed M Naim, Joakim Wikner, Industrial dynamics simulation models in the

design of supply chains, International Journal of Physical Distribution and Logistics

Management, Vol.22, No.5, pp.313, 1992.

[9] Jeroen Dejonckheere, Stephen M Disney, Lambrecht Marc, Denis Towill, The impact of

information enrichment on the Bullwhip effect in supply chains: a control theoretic approach,

European Journal of Operations Research, Vol.153, No.3, pp727750, 2004.

[10] Sammeer Kumar, Marietsa L McCreary, Daniel A Nottestad. Quantifying Supply Chain Tradeoffs Using Six Sigma, Simulation, and Designed Experiments to Develop a Flexible Distribution

Network, Quality Engineering, v 23, n 2, p 180-203, April-June 2011.

132

You might also like

- How to Optimise Your Supply Chain to Make Your Firm Competitive!From EverandHow to Optimise Your Supply Chain to Make Your Firm Competitive!Rating: 1 out of 5 stars1/5 (1)

- Supply Chain AnalyticsDocument7 pagesSupply Chain Analyticskirtiraj sahooNo ratings yet

- Supply Chain ManagementDocument15 pagesSupply Chain ManagementAankit Kumar Jain Dugar100% (1)

- Supply Chain ManagementDocument14 pagesSupply Chain Managementعبد المجيد ياسر عبد المجيد غانمNo ratings yet

- Enterprise Resource Planning: Mid Term SubmisionDocument12 pagesEnterprise Resource Planning: Mid Term SubmisionShruti SharmaNo ratings yet

- OM M5 SCM M5 NotesDocument33 pagesOM M5 SCM M5 NotesChandan SainiNo ratings yet

- Developing Model For Supply Chain Management - The Case of CroatiaDocument5 pagesDeveloping Model For Supply Chain Management - The Case of CroatiaXFiremanxNo ratings yet

- SCM Summaries Karthik Sai DhanduDocument9 pagesSCM Summaries Karthik Sai DhanduKarthik SaiNo ratings yet

- SCM Notes Sunil ChopraDocument9 pagesSCM Notes Sunil ChopraRohit singhNo ratings yet

- SC Strategy1 MidDocument14 pagesSC Strategy1 MidaliNo ratings yet

- Role of Quick Response To Supply ChainDocument15 pagesRole of Quick Response To Supply ChainSanuwar RashidNo ratings yet

- SCM Notes Sunil ChopraDocument9 pagesSCM Notes Sunil ChopraGangadhar100% (1)

- SCM PrinciplesDocument35 pagesSCM PrinciplesSRanizaiNo ratings yet

- Distribution & Logistics Management V3Document5 pagesDistribution & Logistics Management V3solvedcareNo ratings yet

- Supply ChainDocument8 pagesSupply ChainŠ Òű VïķNo ratings yet

- Analysis of Permissible Delay in Payment Policy For Sustainable Business DevelopmentDocument7 pagesAnalysis of Permissible Delay in Payment Policy For Sustainable Business Developmentieom2012No ratings yet

- Supply Chain TerminologyDocument5 pagesSupply Chain TerminologyMehroz KhanNo ratings yet

- IT Enabled Supply Chain Management.Document46 pagesIT Enabled Supply Chain Management.anampatelNo ratings yet

- Indroduction To Supply Chain 1Document38 pagesIndroduction To Supply Chain 1Tansen John100% (2)

- Global Supply Chain Management Notes-Msc Procurement and Logistics-Sept, 2023Document85 pagesGlobal Supply Chain Management Notes-Msc Procurement and Logistics-Sept, 2023hassan28sepNo ratings yet

- Modelling and SimulationDocument13 pagesModelling and Simulationsuresh_ramanujam007100% (1)

- Supply Chain Management Training Kit v5.0Document59 pagesSupply Chain Management Training Kit v5.0Ajay ThakralNo ratings yet

- Assignment On Supply Chain ManagementDocument19 pagesAssignment On Supply Chain ManagementRayan Karim85% (27)

- Chapter 1: Understanding The Supply ChainDocument5 pagesChapter 1: Understanding The Supply ChainFidan MehdizadəNo ratings yet

- Chapter 1-Understanding The Supply ChainDocument3 pagesChapter 1-Understanding The Supply ChainShashank nayakNo ratings yet

- Supply Chain ManagementDocument11 pagesSupply Chain ManagementMd NematullahNo ratings yet

- Serviano-ms1-Finals Module-Leganes-Bsa 2 - A DDocument33 pagesServiano-ms1-Finals Module-Leganes-Bsa 2 - A DlykaaajaneNo ratings yet

- 13 TH INRODUCTION TO SCMDocument22 pages13 TH INRODUCTION TO SCMAkshil NagdaNo ratings yet

- Read 2 - Survival AnalysisDocument18 pagesRead 2 - Survival AnalysisAndy HuNo ratings yet

- SUPPLY CHAIN MANAGEMENT MCQsDocument5 pagesSUPPLY CHAIN MANAGEMENT MCQsAsha Sharmi100% (2)

- Push Process and 2. Pull ProcessDocument11 pagesPush Process and 2. Pull ProcessrakeshNo ratings yet

- Partcipacion 3..Document11 pagesPartcipacion 3..Ivonne CMNo ratings yet

- MM ZG621 Ec-2r First Sem 2022-2023Document30 pagesMM ZG621 Ec-2r First Sem 2022-2023shahul hameedNo ratings yet

- Ata Allah Taleizadeh, Iman Shokr and Fariborz JoaliDocument31 pagesAta Allah Taleizadeh, Iman Shokr and Fariborz JoaliNafiz AlamNo ratings yet

- Supply Chain MnagementDocument5 pagesSupply Chain MnagementDanish AhsanNo ratings yet

- Design For Supply ChainDocument15 pagesDesign For Supply ChainSuryakant GideNo ratings yet

- Reviewed Ds Project Report For Group 2Document19 pagesReviewed Ds Project Report For Group 2Daddy MewariNo ratings yet

- Logistics and Supply ChainDocument54 pagesLogistics and Supply Chainshouvik chouduryNo ratings yet

- Supply Chain Management of Coca-ColaDocument20 pagesSupply Chain Management of Coca-ColaAditya Dethe85% (33)

- An Optimized Supply Chain Planning Model For Manufacture Company Based On JITDocument5 pagesAn Optimized Supply Chain Planning Model For Manufacture Company Based On JITAmit KapoorNo ratings yet

- Bullwhip Effect and Supply Chain Modelling and Analysis Using CPN ToolsDocument13 pagesBullwhip Effect and Supply Chain Modelling and Analysis Using CPN ToolsBiljana PanicNo ratings yet

- 01 Introduction To Supply Chain ManagementDocument110 pages01 Introduction To Supply Chain ManagementSudhir Patel100% (4)

- Chapter 7 - Demand Management and Customer ServiceDocument61 pagesChapter 7 - Demand Management and Customer ServiceArmanNo ratings yet

- Agent-Based Simulation Model of Single Point Inventory SystemDocument7 pagesAgent-Based Simulation Model of Single Point Inventory SystemHadiBiesNo ratings yet

- Ch01-Discussion Questions and AnswersDocument3 pagesCh01-Discussion Questions and Answerseeman kNo ratings yet

- Assignment 2 - Supply ChainDocument5 pagesAssignment 2 - Supply ChainHeena SharmaNo ratings yet

- Bullwhip Effect and Supply Chain Modelling and Analysis Using CPN ToolsDocument16 pagesBullwhip Effect and Supply Chain Modelling and Analysis Using CPN Toolsshmuup1No ratings yet

- SCM WRT Oracle AppsDocument6 pagesSCM WRT Oracle AppsRabindra P.SinghNo ratings yet

- SCMDocument181 pagesSCMJeremy Taylor50% (2)

- Supply Chain ManagementDocument27 pagesSupply Chain ManagementParth Kapoor100% (1)

- SCM in RetailingDocument67 pagesSCM in RetailingKaran MagoNo ratings yet

- SCM - Important TopicsDocument21 pagesSCM - Important TopicsAbdullah HameedNo ratings yet

- SCM MidtermDocument4 pagesSCM MidtermShershah AdnanNo ratings yet

- The Implementation of Vendor Managed Inventory inDocument6 pagesThe Implementation of Vendor Managed Inventory inshreya bhagatNo ratings yet

- Shruti Assignment 4,5Document20 pagesShruti Assignment 4,5Shruti SuryawanshiNo ratings yet

- An Introduction to Global Supply Chain Management: What Every Manager Needs to UnderstandFrom EverandAn Introduction to Global Supply Chain Management: What Every Manager Needs to UnderstandNo ratings yet

- Marketing Analytics: Data-Driven Techniques with Microsoft ExcelFrom EverandMarketing Analytics: Data-Driven Techniques with Microsoft ExcelRating: 4.5 out of 5 stars4.5/5 (2)

- Essentials of Supply Chain ManagementFrom EverandEssentials of Supply Chain ManagementRating: 2.5 out of 5 stars2.5/5 (2)

- Inspection, Quality Control, and Assurance SHEET (1) : 6-If The Mean Value of The Measured Stress Was 15 KG/MMDocument1 pageInspection, Quality Control, and Assurance SHEET (1) : 6-If The Mean Value of The Measured Stress Was 15 KG/MMmaherkamelNo ratings yet

- Introduction To Six SigmaDocument30 pagesIntroduction To Six SigmaadysubagyaNo ratings yet

- Beyond Taguchi's Concept of The Quality Loss Function: Atul Dev, Pankaj JhaDocument5 pagesBeyond Taguchi's Concept of The Quality Loss Function: Atul Dev, Pankaj JhamaherkamelNo ratings yet

- 8 QualityDocument26 pages8 QualitymaherkamelNo ratings yet

- PQ Unit-IiDocument6 pagesPQ Unit-IimaherkamelNo ratings yet

- GE2022 TQM Notes 2 PDFDocument15 pagesGE2022 TQM Notes 2 PDFBalakumar MurugesanNo ratings yet

- Quality Assurance and Quality ControlDocument17 pagesQuality Assurance and Quality Controltraslie0% (1)

- Pareto and QualityDocument1 pagePareto and QualitymaherkamelNo ratings yet

- Forming 2 PDFDocument43 pagesForming 2 PDFNeoXana01No ratings yet

- Gage R&RDocument24 pagesGage R&ROMAR CECEÑASNo ratings yet

- The Quality Improvement Model: Is Process Capable?Document19 pagesThe Quality Improvement Model: Is Process Capable?maherkamelNo ratings yet

- Attributes Data: Binomial and Poisson DataDocument31 pagesAttributes Data: Binomial and Poisson DatamaherkamelNo ratings yet

- Chapter 9Document9 pagesChapter 9Rasha Abduldaiem ElmalikNo ratings yet

- ISO History (Brief) and Basic FactsDocument9 pagesISO History (Brief) and Basic FactsmaherkamelNo ratings yet

- Acceptance SamplingDocument19 pagesAcceptance Samplingpm3dNo ratings yet

- Basic Chart ConceptsDocument13 pagesBasic Chart ConceptsmaherkamelNo ratings yet

- Acceptance SamplingDocument19 pagesAcceptance Samplingpm3dNo ratings yet

- Chapter 9Document9 pagesChapter 9Rasha Abduldaiem ElmalikNo ratings yet

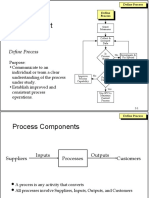

- Basics of Defining ProcessesDocument18 pagesBasics of Defining Processesmaherkamel100% (1)

- HW1 2Document2 pagesHW1 2maherkamelNo ratings yet

- Course 649Document2 pagesCourse 649jambu99No ratings yet

- Basics 1Document7 pagesBasics 1maherkamelNo ratings yet

- HW3 ADocument2 pagesHW3 Ajambu99No ratings yet

- Me338 10Document2 pagesMe338 10maherkamelNo ratings yet

- Quality Lecture NotesDocument23 pagesQuality Lecture NotesmaherkamelNo ratings yet

- Me423 PDFDocument2 pagesMe423 PDFmaherkamelNo ratings yet

- HW 1Document2 pagesHW 1maherkamelNo ratings yet

- Mechanics 2Document14 pagesMechanics 2maherkamelNo ratings yet

- ChatterDocument9 pagesChattermaherkamelNo ratings yet

- QM in Library PDFDocument25 pagesQM in Library PDFgaurav sharmaNo ratings yet

- LogExportTool Use Guide For BeneVisionDocument23 pagesLogExportTool Use Guide For BeneVisionVivek Singh ChauhanNo ratings yet

- Stress Gradients in AlbertaDocument22 pagesStress Gradients in AlbertaBehzadDastjerdyNo ratings yet

- Design Calculation of PavementDocument4 pagesDesign Calculation of Pavementorode franklyn100% (1)

- Elysium TranslatorDocument24 pagesElysium Translatorfilip_bonacic3908No ratings yet

- An Analysis of Stravinsky's Symphony of Psalms Focusing On Tonality and HarmonyDocument68 pagesAn Analysis of Stravinsky's Symphony of Psalms Focusing On Tonality and Harmonyr-c-a-d100% (2)

- BS en 10028-1Document24 pagesBS en 10028-1Andrei Balázs100% (1)

- 21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Document28 pages21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Mehdi SoltaniNo ratings yet

- Dot 57406 DS1Document172 pagesDot 57406 DS1Carlos FernandezNo ratings yet

- Vdot Training TabelDocument7 pagesVdot Training TabelVarto RazvanNo ratings yet

- Report On Earthquake Resistance Design of Building StructureDocument40 pagesReport On Earthquake Resistance Design of Building Structuremandira maharjanNo ratings yet

- Homework - Cardinal NumbersDocument2 pagesHomework - Cardinal NumbersMAELSASANo ratings yet

- Ecs448 Chapter 5a ArchDocument28 pagesEcs448 Chapter 5a Archdixn__No ratings yet

- Cabinas de Bioseguridad HealforceDocument8 pagesCabinas de Bioseguridad HealforceJose HurtadoNo ratings yet

- Scania SOPS ParametersDocument32 pagesScania SOPS Parametersjose breno vieira silva89% (19)

- RFID Adoption by Supply Chain Organizations in MalaysiaDocument5 pagesRFID Adoption by Supply Chain Organizations in MalaysiaWalid GradaNo ratings yet

- F325 Redox Equations and TitrationsDocument9 pagesF325 Redox Equations and TitrationsDoc_Croc100% (1)

- Users Manual ACS 501 PDFDocument94 pagesUsers Manual ACS 501 PDFmodelador3dNo ratings yet

- Python (Dictionary)Document54 pagesPython (Dictionary)shahrukhkr.gptNo ratings yet

- DSA Lab1Document22 pagesDSA Lab1dukeyasser107967No ratings yet

- Statistics Fall2013 - Final Sample Test 01Document7 pagesStatistics Fall2013 - Final Sample Test 01Thanh VyNo ratings yet

- Polymers 14 03693 v2Document20 pagesPolymers 14 03693 v2Abd BAGHADNo ratings yet

- New Microsoft Office Word DocumentDocument20 pagesNew Microsoft Office Word DocumentVinay KumarNo ratings yet

- W 9540Document6 pagesW 9540imharveNo ratings yet

- Object Kpis For The Digital Transformation: June 2020Document12 pagesObject Kpis For The Digital Transformation: June 2020MUHAMMAD FIKRI DEVIANESNo ratings yet

- CNS TechnicianDocument2 pagesCNS TechnicianSohailNo ratings yet

- Comparative Analysis of Public and Private Educational Institutions: A Case Study of District Vehari-PakistanDocument10 pagesComparative Analysis of Public and Private Educational Institutions: A Case Study of District Vehari-PakistannithyaNo ratings yet

- Eaton 10 Speed Service ManualDocument186 pagesEaton 10 Speed Service ManualKeith McCann100% (1)

- Lincoln Douglas Debate TextbookDocument115 pagesLincoln Douglas Debate TextbookRogelio Aurelio Rojas ReyesNo ratings yet

- 2020 Specimen Paper 1Document16 pages2020 Specimen Paper 1YuanWei SiowNo ratings yet

- IS30 IS50 WM CWL WM-L Schnittstellendoku enDocument250 pagesIS30 IS50 WM CWL WM-L Schnittstellendoku enspidigeNo ratings yet