Professional Documents

Culture Documents

Paper Related To Biofuel

Uploaded by

fawadazeemqaisraniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Paper Related To Biofuel

Uploaded by

fawadazeemqaisraniCopyright:

Available Formats

Letters

Fuel efficiency and

inefficiency in private

tubewell development

Gert Jan Bom

Solartec, PO Box 1130, Papendrecht, the Netherlands

Frank van Steenbergen

Arcadis Euroconsult, PO Box 441, Arnhem, the Netherlands

1. Introduction

In the last two decades there has been a proliferation of

private groundwater irrigation in India. Estimates put the

figure of diesel pumpsets in India at 6.5 million at present.

To this figure another 11 million pumps with electric motors can be added, mainly operating in areas with deep

aquifers. Similar dramatic increases in private groundwater irrigation have taken place in Pakistan and Bangladesh.

This development has been driven by farmers investment, although a range of public subsidies has accelerated

the pace of groundwater exploitation.

The typical configuration in areas with shallow water

tables in India is that of a centrifugal pump operated with

a 2.5-10 horsepower (hp) (1 hp = 0.746 kW) engine. In

some areas diesel pumpsets have been common from the

beginning. In other areas the failing reliability of rural

power supply has encouraged farmers to replace electric

pumps with diesel pumpsets. A striking feature is that

within this broad category each area has its own typical

irrigation tubewell configuration (size of the engine, capacity of the centrifugal pump, type of well), related to

the depth of the water table, prevailing land ownership,

soil condition and local tradition.

This is not to say that the tubewell configurations are

optimal in terms of fuel consumption or water-saving. In

fact, substantial improvements in well technology,

pumpset design and conveyance systems are possible at

modest cost. These improvements are indicative of the

technological vacuum in which private tubewell development has taken place. In this note evidence on fuel efficiency improvements collected from three districts

(Cooch Behar, Jalpaiguri and Darjeeling) in the northern

part of West Bengal state (known as North Bengal) of

India is presented. After explaining improvements in tubewell configuration, the note concludes with exploring

why the inefficiencies have persisted and have not been

self-corrected.

2. Inefficiencies in pump lift irrigation:

pumpsets, wells and conveyance systems in North

Bengal

Groundwater irrigation has only come to North Bengal

recently. For a long time the cultivation of kharif (the

term used in India for the crop using the south-west monsoon, the end-of-summer rainy season) rain-fed paddy on

46

Energy for Sustainable Development

Figure 1. A modified pumpset with drum cooling and priming pump on

the discharge.

monsoon-inundated land dominated the agricultural economy. In the last two decades the cultivation of wheat,

potatoes and vegetables in the dry winter season has

gained considerable popularity. This required the development of groundwater irrigation facilities. A large number of government programmes set the trend, but

increasingly farmers have invested in shallow tubewells

from their own resources. Diesel pumpsets are most common, as elsewhere in the Terai belt [Shah, no date; Tyagi,

1995], the rich groundwater zone bordering the Himalayan foothills, characterized by high recharge and shallow

water tables.

Investigations and field tests were undertaken under the

North Bengal Terai Development Project to review the

efficiency of the prevalent pumpset configurations in the

region. The investigations discovered that substantial improvements were possible in the configuration of diesel

pumpsets, wells and conveyance systems.

2.1. Improved diesel pumpsets

Most shallow tubewells in the region, but also open wells

and ponds, are operated with 5hp diesel pumpsets. During

field surveys it was found that these pumps were generally oversized (only about 1.5 hp is effectively absorbed

by the pump), overcooled (the operating temperature is

generally only 35C instead of 80C) and that there was

excessive friction loss in the suction pipes due to the inl

Volume III No. 5

January 1997

Letters

stallation of a poorly designed check valve.

Through a series of experiments on existing diesel

pumpsets, a set of modifications appropriate for North

Bengal was developed [Chakraborty et al., 1997]. It was

found that overcooling because of passing pump water

through the engine jacket was best corrected by fitting

thermosyphon drum-cooling. The drum-cooling increased

the engine operating temperature from a low 35C to a

normal level of 80C. This modification reduced the fuel

consumption of the standard pumpset by 13%. Next, removing the check valve from the suction pipe reduced

the hydraulic friction losses, saving another 18% on the

fuel consumption. Finally, to mitigate the effects of the

engine being oversized, the engine speed was decreased

from 1500 to 1100 rpm. This resulted in a further reduction of the fuel consumption by 20%. Total fuel consumption could in this way be reduced from 1 l/h to 0.5 l/h,

while the discharge of the pumpsets remained unchanged.

The cost of these modifications on shallow tubewell

pumpsets is Rs. (rupees) 350 (US$ 8). During the irrigation season, this cost can be recovered through fuel savings in 70 running hours, with the diesel fuel costing Rs.

10/l.

A better solution in the long run for the North Bengal

region would be to introduce smaller engines instead of

modified 5 hp engines. In the shallow water tables of the

North Bengal Terai, 3.5 hp pumpsets fit the need much

better. Lower power engines have the additional advantage that their weight is much less (90 kg instead of 220

kg). As a result, transport of pumpsets in the field will

be considerably easier. First tests with a 3.5 hp diesel

engine driving a 363 mm pump (the same pump as is

normally driven by the 5 hp engine) have been positive.

Running at 1000 rpm, the discharge was measured to be

12 l/s at 4m water depth and a fuel consumption of 0.4

l/h, or 20% better than the 5 hp engine under the same

conditions. It is expected that optimisation of the pump

(adapting impeller vane angle) for 1000 rpm will further

reduce the fuel consumption to 0.3 l/h, or 30% of its original level.

2.2. Improved well technology

A variety of well filters is in use in North Bengal. Shallow

76 mm tubewells may have 76 mm galvanized iron, brass,

PVC or bamboo filters. The dynamic water levels vary

from 4 to 5m at extraction rates of 7-10 l/s and static

water levels of 2-3m. Measurements showed resistance of

the filter in general to be excessive (3-4m). As a result

about 40% of the total energy is required just for overcoming the filter resistance. Because the well pipes in this

area also serve as the suction pipe for the pump (Figure

3), the dynamic water level is measured in an observation

well at 30 cm distance. For establishing the filter resistance, a vacuum gauge is mounted on the well pipe where

it comes above ground and the difference between the

vacuum gauge reading (corrected for friction loss and velocity head) and the dynamic water level gives the filter

resistance.

The cause of the high filter resistance lies partly in a

faulty design (too small slot size of filter and insufficient

Energy for Sustainable Development

Figure 2. Fuel consumption versus discharge for each modification on a

shallow tubewell pumpset, with static water level at 3m and dynamic water

level at 4.5m.

Figure 3. A typical well configuration in North Bengal with the well pipe

doubling as suction pipe.

total open area) and partly in lack of development of the

well after construction. Most wells are made without a

gravel pack and have very small slot sizes (0.2 mm is

common) to avoid sand entering the well. The total filter

capacity (open area) however is usually insufficient. As

a result the velocity of the water entering the filter is too

high (exceeding the recommended maximum of 3 cm/s),

which propels small particles towards the well. This ultimately clogs the filter. A second reason for the high filter

resistance is the inadequate development of the well after

construction. Cowdung is commonly used both as slurry

as well as to stabilize the borehole during drilling, but

after development the well is not properly flushed and the

cowdung partially blocks the filter slots, thus setting a

process of further clogging in motion. Moreover, no gradation of material around the screens takes place. Ideally

an outer layer of coarse material should evolve. This does

not happen, because the small slot size does not allow

l

Volume III No. 5

January 1997

47

Letters

Figure 4. Preparation of a mosquito net filter of 3.7m length and 76 mm

diameter.

Table 1. Comparison between netting filters and PVC or brass filters

Filter

PVC

Bamboo/netting

Diameter (mm)

76

76

Slot size (mm)

0.2

Filter length (m)

Static water level (m)

7.5

12

2400

1500

Yield with 5hp pump (l/s)

Total cost for 10m depth (Rs.)

the small particles to be pumped away.

Experiments in North Bengal with improved well design (mosquito net filter combined with PVC plain pipes)

plus post-construction development have already resulted

in wells with 70% less filter resistance (from 3m down

to 1m resistance), giving an additional fuel-saving (on top

of what is achieved by improving the pumpset) of about

30%. The cost of improved wells using bamboo filters

with mosquito netting is considerably less than for wells

with modern filters such as slotted PVC or brass.

While this would work for new wells, for existing wells

rehabilitation is an attractive, though still uncertain, option [van Herwijnen and Ray, 1997]. By surging (moving

a piston up and down in the well pipe) and jetting (recirculating well water with a pump and directing a concentrated water jet at the filter inner surface) the well

discharge improves by about 20% (corresponding to 20%

decrease in fuel consumption). The cost of this operation

is Rs. 100. If this is done after modifying the pumpset,

the incremental fuel saving of 20% amounts to a saving

of Rs. 1.10/h. This investment is recovered in 90 running

hours.

Apart from the fuel saving, a second benefit of the well

improvements is that increased discharge will reduce the

steady state losses of the water conveyance channels

(discussed next).

2.3. Improved conveyance

Typically, the water pumped from shallow tubewells

48

Energy for Sustainable Development

(drilled wells) or pump dug wells (91 cm diameter open

wells) is conveyed through makeshift earthen field channels. The water losses in these earthen channels are considerable. Measurements in North Bengal show that,

depending on the quality of the channel, losses can be as

high as 53% per 100m [van Raalten, 1996]. Such high

losses are mainly attributed to overtopping of undersized

earthen channels. Yet even where the earthen channels

have sufficient freeboard, conveyance losses are significant. They come in two categories. First are the steady

state losses that result from the seepage from the porous

earthen channels. In small-scale lift irrigation the flows

are usually 6-15 l/s. At these relatively established earthen

channels they were measured as 6% per 100m of the flow.

The second category are transient or start-up losses that

are related to the wetting of the dry perimeter of the

earthen channel. Each time the irrigation flow is started

it will take time and water before the water starts to flow

in the channel. In small-scale lift irrigation water is usually started frequently, but for short durations. Obviously,

transient losses depend on the duration and number of

flows. Where water flows are started 30 times annually

and last 2.1h each, transient losses have been measured

at 8.4-10% of the flow per 100m. In intermittent groundwater irrigation transient losses are therefore high, much

higher than in a constant flow situation, characteristic for

surface irrigation. The combined transient and steady state

losses are then at least 15% per 100m, but much higher

in the case of undersized channels.

As a remedy, farmers have adopted polyethylene tubes

(leaflet hoses) as a superior alternative means of water

conveyance in various parts of North Bengal. Intriguingly,

areas where the leaflet hoses are widely accepted are

found right next to areas where they are unknown. The

usual length of the polyethylene tubes is 100-300m. They

weigh 15 kg for 100m length and are available for Rs.

7/m. Depending on the intensity of usage the tubes last

1 to 2 years. There is a thriving market for renting polyethylene tubes. Whereas hire charges for a pump set (including fuel) are typically Rs. 30/h in North Bengal, the

rent for a polyethylene pipe is usually Rs. 5/h. There are

significant advantages to using the polyethylene pipes.

Apart from the minimization of steady state and transient

water losses, the pipes allow the irrigation of higher areas

and do not require land, unlike field channels.

Attaching a polyethylene tube to the delivery pipe of

the pumpset (which has a diameter of 63 or 76 mm), however, increases the delivery head and results in a higher

consumption of diesel per unit volume of water lifted.

The attachment of 100m of polyethylene tube of 102 mm

diameter has been measured to require 11% more diesel

for a given quantity of water lifted. This is more than

compensated by a reduction in the hours of pumping, because water losses even in well-prepared channels are

15% per 100m. However, where 76 mm diameter tubes

are used, as is more common in North Bengal, the increase in delivery head is much more and diesel consumption shoots up by 48% for a 100m tube [van Raalten,

1997].

l

Volume III No. 5

January 1997

Letters

Apart from the polyethylene tubes a number of new

low-cost open-channel technologies have been tried in

North Bengal. The technology that got the most favorable

response from farmers was the soil cement channel. The

soil cement channel is made of a 1:1:4 mixture of sand,

cement and soil and has a thickness of 25 mm. The cost

per m for a channel carrying 15 l/s is Rs. 50. The advantage over the concrete-lined channels, introduced in a

number of government programs, is the low cost (20% of

the costs of a brick-lined channel) and its adaptability to

skills of village masons.

2.4. Combined improvements

The combined improvements in well, pump and conveyance technology in North Bengal translate into a 70% saving in fuel required for a given volume of water (Table

2). Investigations in other parts of South Asia indicate

that savings of 40% are possible elsewhere too, using a

different, location-specific, package of modifications. In

a study in Gujarat state of India [Patel, 1988] a number

of changes to the electric pumps were introduced, resulting in 20-50% savings. Work by Enercon in Pakistan [Reinemann and Saqib, 1991] indicated that the overall

efficiencies of tubewells are only 30% of what is achievable.

3. Introducing the improvements

The big question then is why, given the scope for significant gains by low-cost modifications, fuel-inefficient

pump lift irrigation persists. There are a number of explanations. The first is that the development of lift irrigation has by and large taken place in a technological

vacuum. Unlike crop husbandry, water management and

well and pump technology choice has never been the subject of systematic agricultural extension, and technology

choices have been made by imitation rather than by informed decisions.

A second explanation for the low fuel-efficiencies is the

fragmented nature of the relevant service industry. At

farmer level a farmer will typically go to different persons

for installing wells and selecting a pumpset, a practice

that does not encourage optimum fits. At the level of

pumpset suppliers, the pumps and engines/ motors are

manufactured by different enterprises, and subsequently

assembled at local workshops, without taking into account

whether the combination of pump and engine is optimal.

Finally, the pumpset manufacturing sector is fragmented

in India and dominated by a large number of mediumsized producers. None of these has the resources to invest

in substantial R&D. Besides, due to the fragmented nature

of the sector (different manufacturers for pumps and engines, assembly by suppliers, sales by local dealers, all

independent from one another) feedback from the ultimate

customers does not reach the manufacturers. Moreover,

even manufacturers who are aware of the possibilities of

fuel savings are hesitant, because none of them dominates

the market. Most of them generally prefer to produce a

product that is indistinguishable from that of the competitors, rather than actively investing in a new type of pump.

A third explanation concerns the well technology and the

Energy for Sustainable Development

Table 2. Combined fuel efficiency improvement in North Bengal

Improvement

Fuel

savings

Remarks

Pumpset modifications

50%

Well technology improvements

30%

Conveyance improvements

15%

Total fuel saving

70%

Comparing 100m of

102 mm polyethylene

tube with established

earthen field channel

with 25% seepage loss

and corrected for

increased friction head.

use of conveyance systems. Here, what is common in one

area is not known in another. One reason seems to be that

the well development sector is artisanal. In each area a

limited number of well-drillers operate, who are sole service providers, accustomed to a certain technology. Among

farmers there is little awareness of well technology

choices. Moreover, water is an essential and critical input

in the irrigation of the dominant rabi (winter) crops in

North Bengal, i.e., vegetables and potatoes, but total water

requirements are not very high. In comparison with fertilizer or pesticides, therefore, water is a far less costly

input. Though investments in better wells, pumpsets and

conveyance systems can be recouped within one irrigation

season, fuel-saving does not have the topmost place on

the farmers agenda.

Clearly, under these circumstances there is no such

thing as a self-correction in private sector service delivery.

It serves as a reminder of the limitations of technology

improvement through the private sector. How then to promote fuel efficiency improvements in private groundwater

irrigation? One avenue that is being tried in the North

Bengal Terai Development Project consists of training of

farmers, mechanics, tubewell-drillers and dealers. This

has a positive result with one out of six farmers adopting

the pumpset modifications after demonstration and several

village mechanics and tubewell-drillers taking an active

interest in developing the pumpset modifications and well

rehabilitation as an additional line of business. The overall

impact of such a local training program is however limited, whereas the training resources required are substantial. What is more important is to convert the entire

tubewell service delivery sector. This is being done

through the dissemination of the improvements, but, more

important, through persuading some of the big tubewell

buyers in the public sector to adopt the changes and thus

set a new standard.

It could be useful if some kind of technological institute

developed appropriate standards for specific fuel consumption expressed in l/m4 (litres of fuel per unit volume

of water per unit total head). This would define in a practical way the combined performance of a diesel engine

and pump. Standards could furthermore be developed for

well filter resistance as a percentage of the dynamic water

level so as to define the well quality.

Acknowledgements

This note is essentially based on field studies implemented by a number of persons, who

l

Volume III No. 5

January 1997

49

Letters

are gratefully acknowledged: P.K. Biswas, Amer Dey, Aris van Herwijnen, Dhananjay Ray,

David van Raalten and P.K. Sen.

Shah, T., (no date). Water Markets in North Bihar: Synthesis of Six Village Studies in Muzaffarpur District, The Policy School Foundation Studies, Anand.

References

Tyagi, B.N., 1995. Requirements for Electric Power for Agriculture in Uttar Pradesh, Centre

for Advanced Development Research, Lucknow.

Chakraborty, K.K., Bom, G.J., and van Raalten, D., 1997. Improved fuel efficiency of diesel

pumpsets in India, to appear in Journal of the Institution of Engineers.

Van Herwijnen, A., and Ray, D., 1997. The Modification of the Shallow Tubewell: the Improvement and Cleaning of the Well, North Bengal Terai Development Project, Jalpaiguri.

Patel, S.M., 1988. Low cost and quick yielding measures for energy consumption in agricultural pumps, Pacific and Asian Journal of Energy, Vol. 2, No. 1, pp. 3-11.

Van Raalten, D., 1996. Crop Water Requirements and Irrigation Efficiencies in North Bengal,

North Bengal Terai Development Project, Jalpaiguri.

Reinemann, D.J., and Saqib, S., 1991. Tubewell audit and retrofit for improved energy

efficiency, TIDE, Vol. 1, No. 4.

Van Raalten, D., 1997. Report on conveyance techniques, North Bengal Terai Development

Project, Jalpaiguri.

Indoor thermal comfort: the

Pakistan study

tures that people find comfortable in different climatic

zones and seasons. During 1995-96, following doubts

about the general applicability of results from so small a

sample, a second survey (transverse) was undertaken using 846 subjects at monthly intervals over a whole year.

The results of the survey confirmed the previous findings.

The aim of the research was to produce guidelines for

providing comfortable indoor temperatures for buildings

in Pakistan. The objective of the surveys was to determine

the temperature found most comfortable (or the temperature found comfortable by the largest number of people)

in each climatic zone in each season and to:

l relate this to outdoor climate;

l suggest a method of setting indoor air temperature

standards for Pakistan;

l make recommendations for future work in the area in

Pakistan; and

l set a methodology for international work in this field.

The surveys showed that there was a definite relationship

between indoor comfort and outdoor conditions. This paper describes two thermal comfort surveys (longitudinal

and transverse) conducted in Pakistan. The variation of

comfort and discomfort with indoor temperatures and that

of comfort temperatures with indoor and outdoor temperatures are analysed.

J. Fergus Nicol and Iftikhar A. Raja

School of Architecture, Oxford Brookes University, Oxford OX3 OBP, United Kingdom

1. Introduction

The existing indoor design temperatures in Pakistan are

based on ASHRAE standards. These are 26C in the cooling seasons and 21C in the heating seasons irrespective

of where in Pakistan the building is to be built [ENERCON, 1990]. The evidence suggests that many air-conditioning systems are designed to provide a constant 22C.

Analysis of field studies of thermal comfort has shown

that indoor comfort temperatures vary with the mean temperature outdoors [Humphreys 1978, 1978a; Auliciem and

deDear, 1986].

Limited energy resources in Pakistan demand the promotion of greater saving in energy and efficient use of

energy. The National Energy Conservation Centre (ENERCON) of Pakistan is responsible for helping to frame

legislation for the government with a view to minimising

energy consumption. In the field of buildings it has produced a Building Energy Code for Pakistan [ENERCON,

1990]. In buildings, an increasingly important fraction of

the energy is used by air-conditioning systems. However,

the energy cost of air-conditioning is affected by indoor

air temperature standards. Realising these facts, ENERCON commissioned the School of Architecture, Oxford

Brookes University, to advise on the setting of appropriate

indoor temperatures in the different climatic regions of

Pakistan. The operational thermal comfort standards are

based on non-flexible ASHRAE standards [ASHRAE,

1981]. On the other hand, the country, having a highly

variable climate from region to region at macro-scale and

within a region at micro-scale, needs variable indoor temperature standards that take into account the outdoor climate.

To work out appropriate new indoor temperature standards for Pakistan, the two surveys were undertaken by a

team from Oxford Brookes University in co-operation

with ENERCON of Pakistan. The first survey was longitudinal, undertaken during 1993-94 in five cities of Pakistan, using 25 subjects for a week in two seasons. The

results showed that there were big variations in tempera50

Energy for Sustainable Development

2. Climatic regions

Pakistan is a country of diverse climate. On the basis of

different schemes a number of climatic regions have been

identified. For example, Khan [1991] divided the country

into 8 zones, Shamshad [1988] presented 11 zones and

Raja [1996] 16 zones. However, on the basis of homogeneity of climatic elements of interest, temperature and precipitation, the country may be divided into 5 major

climatic regions.

The climatic division of the country is given in Table

1 and the boundaries of different regions are marked in

Figure 1. Each region has its own cultural and architectural traditions, reflecting its own particular climate. The

mean monthly average temperatures for a representative

city in each region are given in Table 2.

3. Thermal comfort survey

The aim of the survey was to establish the indoor temperature that the inhabitants of each climatic region of

Pakistan find most comfortable. There are five major climatic regions. One city in each climatic zone was chosen.

These are indicated in Figure 1. The target group for del

Volume III No. 5

January 1997

You might also like

- Basic Control Systems EngineeringDocument457 pagesBasic Control Systems EngineeringBinh Le Khac82% (17)

- Design of Drip Irrigation SystemDocument7 pagesDesign of Drip Irrigation Systemroop singhNo ratings yet

- Manual de Despiece Honda Beat 100Document84 pagesManual de Despiece Honda Beat 100jorgeeu8833% (3)

- TAS360VoIP ExDocument56 pagesTAS360VoIP ExOscar Damián Gómez HernándezNo ratings yet

- Gem WK6/WK8 Service ManualDocument18 pagesGem WK6/WK8 Service Manualalex_seidiu100% (5)

- TMJDocument38 pagesTMJAnonymous 6kAmeZzINo ratings yet

- Adsorption Processes For Water Treatment and Purification PDFDocument266 pagesAdsorption Processes For Water Treatment and Purification PDFVictor Rezende Moreira100% (1)

- Improved Fuel Efficiency of Diesel Irrigation Pumpsets in IndiaDocument9 pagesImproved Fuel Efficiency of Diesel Irrigation Pumpsets in IndiaKashif AdeemNo ratings yet

- All Code Jurisdictions Have Maximum Allowable Turnover Times For FiltrationDocument13 pagesAll Code Jurisdictions Have Maximum Allowable Turnover Times For FiltrationCamilo RochaNo ratings yet

- Development and Operational Experience With Topless Wood Gasifier Running A 3.75 KW Diesel Engine PumpsetDocument10 pagesDevelopment and Operational Experience With Topless Wood Gasifier Running A 3.75 KW Diesel Engine PumpsetMag FhearadhaighNo ratings yet

- Improvement of Philrice-Designed Ricehull Gasifier Engine-Pump System For Rainfed Lowland IrrigationDocument11 pagesImprovement of Philrice-Designed Ricehull Gasifier Engine-Pump System For Rainfed Lowland IrrigationRenato AguilarNo ratings yet

- Energy Saving Schemes at IFFCO - Kalol UnitDocument5 pagesEnergy Saving Schemes at IFFCO - Kalol Unitlokeshmishra123No ratings yet

- Treadle PumpsDocument6 pagesTreadle PumpsKawchhar AhammedNo ratings yet

- The End of It Is The Beginning-Nagesh-IndiaDocument22 pagesThe End of It Is The Beginning-Nagesh-IndiatallkumarNo ratings yet

- Determination of Basic Domestic Water Requirements Per CapitaDocument6 pagesDetermination of Basic Domestic Water Requirements Per CapitaengrmarNo ratings yet

- Gujarat Report of Development of Ambuja CementDocument14 pagesGujarat Report of Development of Ambuja Cementvkry007No ratings yet

- Experimental Fluid Mechanics: A Report OnDocument9 pagesExperimental Fluid Mechanics: A Report OnGanesh V IyerNo ratings yet

- Pedal Water PumpDocument51 pagesPedal Water PumpAlmubeenNo ratings yet

- Design Considerations When Rod Pumping Gas WellsDocument12 pagesDesign Considerations When Rod Pumping Gas Wellssurakhi2011No ratings yet

- Pumping System DesignDocument4 pagesPumping System DesignGanesh AyerNo ratings yet

- New Developments in Hydraulic Ram PumpingDocument6 pagesNew Developments in Hydraulic Ram PumpingAirPop24No ratings yet

- Treadle Pumps Treadle Pumps Treadle Pumps Treadle PumpsDocument6 pagesTreadle Pumps Treadle Pumps Treadle Pumps Treadle PumpsSuraj BhatNo ratings yet

- Development and Evaluation of A Fixed Dome Plug Flow Anaerobic DigesterDocument11 pagesDevelopment and Evaluation of A Fixed Dome Plug Flow Anaerobic DigesterAryadharma PrasetyoNo ratings yet

- DynaPump Field Evaluation SWPSCDocument14 pagesDynaPump Field Evaluation SWPSCpoint blankNo ratings yet

- ARPNpaperDocument13 pagesARPNpaperIan B. YtomNo ratings yet

- Evolving Design Chiller PlantDocument7 pagesEvolving Design Chiller PlantMohsin KhanNo ratings yet

- Indonesia Energy Survey, NIFESDocument36 pagesIndonesia Energy Survey, NIFESMoly69xNo ratings yet

- Dewatering Bore Pumps - Reducing Costs and Emissions by Maximising Pumping Efficiency Over TimeDocument4 pagesDewatering Bore Pumps - Reducing Costs and Emissions by Maximising Pumping Efficiency Over TimeMaiza HussinNo ratings yet

- LUF617 - DW - 8Hx11 - F Gas WellDocument10 pagesLUF617 - DW - 8Hx11 - F Gas WellJosé TimanáNo ratings yet

- Mek 2Document44 pagesMek 2Gaurav ShuklaNo ratings yet

- PumpDocument7 pagesPumpYohanis DabesaNo ratings yet

- Chapter Five Jet Pumping System (JP)Document33 pagesChapter Five Jet Pumping System (JP)mghareebNo ratings yet

- Water System Sizing LectureDocument11 pagesWater System Sizing LectureBliven GarciaNo ratings yet

- Greater Kegalle Water Treatment PlantDocument9 pagesGreater Kegalle Water Treatment PlantRanjithNo ratings yet

- Guidelines For Effic in Pumping Ver2 Rev 12.07Document11 pagesGuidelines For Effic in Pumping Ver2 Rev 12.07Gonuguntla Kondala RaoNo ratings yet

- Pumps Turbine Submersible PumpDocument11 pagesPumps Turbine Submersible Pumpahsanul haqueNo ratings yet

- Pumped Outlets For Subsurface Drainage: Technical, Planning and DesignDocument3 pagesPumped Outlets For Subsurface Drainage: Technical, Planning and DesignAli HydarNo ratings yet

- DynaPump Field EvaluationDocument14 pagesDynaPump Field EvaluationNiurkarisNo ratings yet

- Pump Clinic 33Document8 pagesPump Clinic 33fnahas_bhNo ratings yet

- Pumps As Turbines For Low Cost Micro HydroDocument8 pagesPumps As Turbines For Low Cost Micro Hydrojinker360% (1)

- 3 CsDocument14 pages3 CsRavindra PawarNo ratings yet

- 6 Prime Movers of Energy: 6.1. PUMPSDocument40 pages6 Prime Movers of Energy: 6.1. PUMPSIan AsNo ratings yet

- 2017 - Skotak A - Designing of Pump Turbine For Non Restricted Range of Operation - Hydrovision 2017, DenverDocument13 pages2017 - Skotak A - Designing of Pump Turbine For Non Restricted Range of Operation - Hydrovision 2017, DenvernamitaNo ratings yet

- Microcontroller Based Drip Irrigation System: Chitrachedu Dada KalandarDocument4 pagesMicrocontroller Based Drip Irrigation System: Chitrachedu Dada KalandarrithinNo ratings yet

- Windmill InfoDocument12 pagesWindmill InfotdecebalusNo ratings yet

- Dalmia Cement AriyalurDocument31 pagesDalmia Cement AriyalurMohammed Shafi AhmedNo ratings yet

- Domestic Hot Water RecirculationDocument2 pagesDomestic Hot Water RecirculationSam Wing HongNo ratings yet

- Design of Sucker Rod PumpDocument13 pagesDesign of Sucker Rod Pumppramod_prasad_3No ratings yet

- Seawater Desalination by Reverse Osmosis (Case Study) : De!HllnationDocument7 pagesSeawater Desalination by Reverse Osmosis (Case Study) : De!HllnationAnil JoshiNo ratings yet

- Ram Pump PDFDocument9 pagesRam Pump PDFoliververonamanuelNo ratings yet

- Mekanika Fluida - 2020-2021 Gasal - TUGAS - 1B - Fluid DynamicsDocument7 pagesMekanika Fluida - 2020-2021 Gasal - TUGAS - 1B - Fluid DynamicsAnnisa FauziaNo ratings yet

- SPE 165669 PCP Sand Handling TechnologiesDocument15 pagesSPE 165669 PCP Sand Handling TechnologiesJosé TimanáNo ratings yet

- CEA Water RequirementDocument52 pagesCEA Water RequirementtozirconNo ratings yet

- Design of Vacuum Systems For Crude Oil Vacuum Tower DistillationDocument5 pagesDesign of Vacuum Systems For Crude Oil Vacuum Tower DistillationnasirmuzaffarNo ratings yet

- T S - 3 Efficiency Improvement in Auxiliary EquipementDocument59 pagesT S - 3 Efficiency Improvement in Auxiliary Equipementmoorthymtps_54120305No ratings yet

- Hydrogen Generator Booster PDFDocument61 pagesHydrogen Generator Booster PDFbabu100% (2)

- Case Study On STPDocument5 pagesCase Study On STPraviswm180No ratings yet

- Underground Gas Storage Facilities: Design and ImplementationFrom EverandUnderground Gas Storage Facilities: Design and ImplementationNo ratings yet

- Good Stoves Facilitation: How to Innovate and Change the WorldFrom EverandGood Stoves Facilitation: How to Innovate and Change the WorldNo ratings yet

- JQ2015 Chiu LoDocument15 pagesJQ2015 Chiu LofawadazeemqaisraniNo ratings yet

- Jççéääáåöi Páãìä Íáçåi Åç Méêñçêã Ååé Å Äóëáë ÇÑ Eóäêáç Mçïéê Póëíéã Ñçê Jçäáäé Jéçáå Ä 'Äáåáå David Arap Cheruiyot CherusDocument98 pagesJççéääáåöi Páãìä Íáçåi Åç Méêñçêã Ååé Å Äóëáë ÇÑ Eóäêáç Mçïéê Póëíéã Ñçê Jçäáäé Jéçáå Ä 'Äáåáå David Arap Cheruiyot CherusfawadazeemqaisraniNo ratings yet

- Renewable Energy TechnologiesDocument74 pagesRenewable Energy TechnologiesfawadazeemqaisraniNo ratings yet

- Alternative Energy - An Overview - v3Document44 pagesAlternative Energy - An Overview - v3Kenny SiludNo ratings yet

- Power Transmission, Distribution and UtilizationDocument12 pagesPower Transmission, Distribution and UtilizationfawadazeemqaisraniNo ratings yet

- EnMS Manual For LAs FINALDocument67 pagesEnMS Manual For LAs FINALvino280286No ratings yet

- BS/BSC (B.tech Hons) Engineering Technology New Curriculum 2015-2016Document179 pagesBS/BSC (B.tech Hons) Engineering Technology New Curriculum 2015-2016EngrEjazURRehmanNo ratings yet

- Schiffer StabilityAndPowerSharingDocument43 pagesSchiffer StabilityAndPowerSharingfawadazeemqaisraniNo ratings yet

- Chapter 24 PDFDocument38 pagesChapter 24 PDFRayyan SalmanNo ratings yet

- Ref 11effect of Environmental Parameters On The Water Solubility of The Polycyclic Aromatic Hydrocarbons and Derivatives Using Taguchi Experimental Design MethodologyDocument4 pagesRef 11effect of Environmental Parameters On The Water Solubility of The Polycyclic Aromatic Hydrocarbons and Derivatives Using Taguchi Experimental Design MethodologyfawadazeemqaisraniNo ratings yet

- APEN Multiapartament Microgrid 2015-LibreDocument13 pagesAPEN Multiapartament Microgrid 2015-LibrefawadazeemqaisraniNo ratings yet

- Design and Economy of Renewable Energy Sources To SupplyDocument4 pagesDesign and Economy of Renewable Energy Sources To SupplyfawadazeemqaisraniNo ratings yet

- 1 J 2017Document13 pages1 J 2017fawadazeemqaisraniNo ratings yet

- Micro-Grid Simulation During Grid-Connected and Islanded Modes of OperationDocument6 pagesMicro-Grid Simulation During Grid-Connected and Islanded Modes of OperationNguyễn Đức NguyệnNo ratings yet

- Analysis of Power Converters Control Techniques in Grid-Tie andDocument142 pagesAnalysis of Power Converters Control Techniques in Grid-Tie andfawadazeemqaisraniNo ratings yet

- Analysis of Power Converters Control Techniques in Grid-Tie andDocument142 pagesAnalysis of Power Converters Control Techniques in Grid-Tie andfawadazeemqaisraniNo ratings yet

- 1 s2.0 S1364032113006370 MainDocument16 pages1 s2.0 S1364032113006370 MainKarthik KumarNo ratings yet

- Financial and Operating Performance of Privatized Firms A Case Study of Pakistan PDFDocument27 pagesFinancial and Operating Performance of Privatized Firms A Case Study of Pakistan PDFfawadazeemqaisraniNo ratings yet

- So Sanh CSI Voi VSIDocument8 pagesSo Sanh CSI Voi VSIRen Hong GiangNo ratings yet

- Electric Vehicles PaperDocument9 pagesElectric Vehicles PaperfawadazeemqaisraniNo ratings yet

- Paper Related To BiofuelsDocument19 pagesPaper Related To BiofuelsfawadazeemqaisraniNo ratings yet

- Flat Plate Solar SystemDocument4 pagesFlat Plate Solar SystemRD1_LNVNo ratings yet

- Electric Vehicles PaperDocument9 pagesElectric Vehicles PaperfawadazeemqaisraniNo ratings yet

- Frequenz Online Brochure en Final 2Document51 pagesFrequenz Online Brochure en Final 2lisusedNo ratings yet

- Evaluation of Heat Loss Coefficients in SolarDocument5 pagesEvaluation of Heat Loss Coefficients in SolarEdson ViniciusNo ratings yet

- Energy Conversion and Management: Eklas Hossain, Ersan Kabalci, Ramazan Bayindir, Ronald PerezDocument22 pagesEnergy Conversion and Management: Eklas Hossain, Ersan Kabalci, Ramazan Bayindir, Ronald PerezfawadazeemqaisraniNo ratings yet

- Journal of Power SourcesDocument10 pagesJournal of Power SourcesfawadazeemqaisraniNo ratings yet

- Frequenz Online Brochure en Final 2Document51 pagesFrequenz Online Brochure en Final 2lisusedNo ratings yet

- Infant of A Diabetic MotherDocument17 pagesInfant of A Diabetic MotherLovina Falendini AndriNo ratings yet

- Bilingual-Paper WDocument4 pagesBilingual-Paper WzNo ratings yet

- Peethas ListDocument1 pagePeethas ListChetan PrajapatiNo ratings yet

- 1Document3 pages1Pradeep PunterNo ratings yet

- ASD Fan CalculatorsDocument14 pagesASD Fan CalculatorslubricacionNo ratings yet

- Draf Model LC 2024 Non TransferableDocument3 pagesDraf Model LC 2024 Non TransferablepresidenciaNo ratings yet

- Us 5596162Document9 pagesUs 5596162Stanley PinesNo ratings yet

- Wheatley Hp600 Quintuplex Plunger PumpDocument2 pagesWheatley Hp600 Quintuplex Plunger Pumpmetasoniko2014No ratings yet

- Therelek - Heat Treatment ServicesDocument8 pagesTherelek - Heat Treatment ServicesTherelek EngineersNo ratings yet

- CEBUANO ERNESTO CODINA (Astonaut Hardware Designer)Document1 pageCEBUANO ERNESTO CODINA (Astonaut Hardware Designer)Dessirea FurigayNo ratings yet

- Measuring Salinity in Crude Oils Evaluation of MetDocument9 pagesMeasuring Salinity in Crude Oils Evaluation of Metarmando fuentesNo ratings yet

- Buku Murid Bahasa Inggris - Student's Book My Next Word For Elementary School Unit 10 - Fase BDocument8 pagesBuku Murid Bahasa Inggris - Student's Book My Next Word For Elementary School Unit 10 - Fase BKeni KenizaNo ratings yet

- Methodology of Static Pile Load TestDocument33 pagesMethodology of Static Pile Load Testraju_420034520100% (1)

- Easy Guide For Fujitsu T901 LaptopDocument141 pagesEasy Guide For Fujitsu T901 LaptopElaineNo ratings yet

- COR5500U Series: Digital and CRT Readout OscilloscopeDocument7 pagesCOR5500U Series: Digital and CRT Readout OscilloscopeFlavio FalcãoNo ratings yet

- IMDB - ColaboratoryDocument10 pagesIMDB - Colaboratory4416 LikhithaNo ratings yet

- Pre Post Tests For HPPDocument3 pagesPre Post Tests For HPPapi-434982019No ratings yet

- Masterseal 530: Surface Applied Capillary Waterproofing For Concrete and MortarDocument2 pagesMasterseal 530: Surface Applied Capillary Waterproofing For Concrete and MortarHoang An ViNo ratings yet

- Sperm Cell: Specialised CellsDocument2 pagesSperm Cell: Specialised CellsRhynnieNo ratings yet

- Manual African Airstrip Adventures EnglDocument46 pagesManual African Airstrip Adventures EnglDele Jnr EriboNo ratings yet

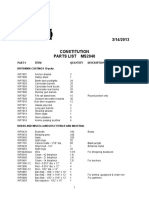

- MS2040 Constitution Parts ListDocument6 pagesMS2040 Constitution Parts ListTemptationNo ratings yet

- Part 7 Mean Field TheoryDocument40 pagesPart 7 Mean Field TheoryOmegaUserNo ratings yet

- Author Name Title Paper/Submission ID Submission Date Total Pages Document TypeDocument32 pagesAuthor Name Title Paper/Submission ID Submission Date Total Pages Document TypeArka ChakrabortyNo ratings yet

- VisakhapatnamDocument27 pagesVisakhapatnamCherukupalli Gopala KrishnaNo ratings yet

- Federal Bylaw 12 Air Pollution 2006 English Translation v2 OCRDocument63 pagesFederal Bylaw 12 Air Pollution 2006 English Translation v2 OCRIsmail SultanNo ratings yet