Professional Documents

Culture Documents

3041 Conveyor Drive - Burleson, Texas 76028 - Toll Free: 800-543-6558 - Phone: (817) 295-2240 - Fax: (817) 447-8528

Uploaded by

Juan Carlos ROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3041 Conveyor Drive - Burleson, Texas 76028 - Toll Free: 800-543-6558 - Phone: (817) 295-2240 - Fax: (817) 447-8528

Uploaded by

Juan Carlos RCopyright:

Available Formats

Email: sales@kwsmfg.com Web: www.kwsmfg.

com

3041 Conveyor Drive Burleson, Texas 76028 Toll Free: 800-543-6558 Phone: (817) 295-2240 Fax: (817) 447-8528

6

2

3

5

10

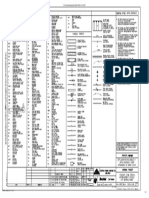

1. Screw Pumps

Eco-friendly solution for low

solids, high volume applications up

to 180,000 CFM.

Low maintenance, low energy

consumption and long service life.

KWS Environmental is a major U.S. based

manufacturer of wastewater process

equipment. We are unique in the scope of our

capabilities to meet the needs of customers in

KWS builds screw pumps up to

196 diameter holding the tight

manufacturing tolerances

necessary for an efficient design. Screw Pumps can also be rebuilt

to original equipment manufacturers tolerances.

this demanding industry.

Using our unsurpassed experience and

expertise, we work closely with the operators

and engineers to optimize the functionality and

reliability of our equipment KWS

Environmental, as a full service supplier,

provides engineered solutions, quality

manufacturing, commissioning assistance and

full maintenance/parts support after the sale

2. Screenings

Washers/

Compactors

Reduces the overall volume of

screenings up to 75%.

Reduces debris hauling costs.

Product is dryer and more

manageable with lower odor and

bacteria count.

on time and with sensitivity to budget.

KWS offers a compact, low cost

design with volumetric

capacities up to 120 ft3/hr. or may be custom

designed to fit your specific needs.

Email: sales@kwsmfg.com Web: www.kwsmfg.com

3041 Conveyor Drive Burleson, Texas 76028 Toll Free: 800-543-6558 Phone: (817) 295-2240 Fax: (817) 447-8528

6

3

5

10

3. Grit Washers/Classifiers

Washes and dewaters, greatly reducing the volatile organic and moisture content.

Separates excess water and reduces the putrescent nature.

KWS Grit Washers can be configured with single or multiple cyclones to process

and compact pumped grit slurry at a feed rate of 5 p.s.i. to 20 p.s.i. Concentrated

grit is discharged into the classifier for separation, washing and dewatering. KWS

fabricates with abrasion resistant materials including ceramics, stellite, tungsten

carbide and AR plates.

4. Shafted and Shaftless Screw Conveyors

Low cost, low maintenance solution for conveying difficult wastewater residuals.

KWS builds screw conveyors of stainless and carbon steel construction.

They may be designed to incorporate abrasion resistant linings of materials

such as ceramics and high-density plastics.

5. Storage Bins/Gates

Low cost solution to control the discharge of difficult solids.

Very low maintenance bin/gate or bin/gate with vibrating bin discharger.

Metered or non-metered.

KWS builds robust gates that can limit or eliminate troublesome leakage and

material build-up, common in wastewater processing. They are available in

open/close or infinitely controlled operation for product metering.

Email: sales@kwsmfg.com Web: www.kwsmfg.com

3041 Conveyor Drive Burleson, Texas 76028 Toll Free: 800-543-6558 Phone: (817) 295-2240 Fax: (817) 447-8528

6

2

3

5

10

6. Bin/Live Bottom Dischargers

Required for buffer capacity between continuous and non-continuous wastewater treatment

plant processes. (i.e. Dewatering and truck-loading.)

Provides storage and extraction of dewatered material.

KWS has unparalleled experience in supplying fully integrated truckloading systems.

KWS engineers develop equipment especially designed and manufactured for the

unique characteristics of wastewater plant residuals.

7. Shafted and Shaftless Vertical Screw Conveyors

Cost-effective, compact and low-maintenance.

Alternative to cake pumps as a means of addressing difficult plant routing.

KWS shaftless vertical screw conveyors are engineered to provide solutions to your unique plant layout.

8. Cylindrical Silos/Sliding Frame Dischargers

Cost-effective and space efficient alternative to typical rectangular bins.

Sliding frame system allows the use of a flat floor on the bin.

Acts as a combination bridge-breaker and a means of directing solids to an extraction screw conveyor and/or gate.

KWS is one of only a very few companies with the applications knowledge and specialized manufacturing

capabilities required to design and manufacture this system for wastewater solids. We understand the

unique issues to be dealt with in designing and building equipment compatible with many types of

storage vessels. We build silo extraction screws, live bottom screw assemblies based on shafted,

shaftless, ribbon, paddle or a combination of designs to optimize performance on a specific application.

Email: sales@kwsmfg.com Web: www.kwsmfg.com

3041 Conveyor Drive Burleson, Texas 76028 Toll Free: 800-543-6558 Phone: (817) 295-2240 Fax: (817) 447-8528

6

2

3

5

10

9. Lime Stabilization Systems

KWS understands EPA 503 regulations regarding stabilization of dewatered solids and builds complete stabilization

systems from admixture delivery screw conveyors to product storage.

10. Mixers

Offers efficient mixing of wastewater solids and admixtures.

Provides recirculation to coater stream in a drying or stabilization process.

KWS designs and builds paddle, ribbon, and plough style mixers and will

select the right equipment for your application. Ensured through the use of

a pilot plant, KWS can simulate the application and analyze the projected

full-scale results.

Email: sales@kwsmfg.com Web: www.kwsmfg.com

3041 Conveyor Drive Burleson, Texas 76028 Toll Free: 800-543-6558 Phone: (817) 295-2240 Fax: (817) 447-8528

You might also like

- WellDocument12 pagesWellmuklis anggaraNo ratings yet

- Humes PDFDocument6 pagesHumes PDFBrian BlankenshipNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- SCC Screw Lift 289B LDocument12 pagesSCC Screw Lift 289B LJuan Carlos RNo ratings yet

- Sigma Marine Coatings Manual - Part87Document2 pagesSigma Marine Coatings Manual - Part87Tommy2020No ratings yet

- Applied HydrogeologyDocument10 pagesApplied HydrogeologyJuliana Quinderé Carneiro0% (1)

- MCQ MasterDocument11 pagesMCQ MasterMonzieAir67% (9)

- Leftover Aluminum WireDocument2 pagesLeftover Aluminum WiremamazookeeprNo ratings yet

- Acids and Alkalis Practice Test 1Document3 pagesAcids and Alkalis Practice Test 1Harry Baggaley100% (1)

- AWS D1.1 Short Code Tests #3Document4 pagesAWS D1.1 Short Code Tests #3Malcolm DiamondNo ratings yet

- ACP SuperCorDocument16 pagesACP SuperCorHaryo WidodoNo ratings yet

- Attenuation Sprinkler and StorageDocument6 pagesAttenuation Sprinkler and StorageIman Rizki SimatupangNo ratings yet

- Umbilical Broshure - Low ResDocument12 pagesUmbilical Broshure - Low ResFlorincrihanNo ratings yet

- Box Culverts HumesDocument12 pagesBox Culverts HumesawwalnafiNo ratings yet

- RFA-TECH Technical Solutions Brochure 2012 LRDocument32 pagesRFA-TECH Technical Solutions Brochure 2012 LRsplaw9484No ratings yet

- Slipform BrochureDocument8 pagesSlipform BrochureRen SalazarNo ratings yet

- Drain Center Pipe Support GuideDocument16 pagesDrain Center Pipe Support GuideminhthanhmosNo ratings yet

- Flexpipe Makes Solutions: The Installation SolutionDocument2 pagesFlexpipe Makes Solutions: The Installation Solutionraulosvaldo_1No ratings yet

- Well StreamDocument6 pagesWell StreamErick de la CruzNo ratings yet

- Box Culvert BrochureDocument4 pagesBox Culvert Brochurepramoedya04No ratings yet

- Bucket Elevators, Bucket Conveyors and MoreDocument22 pagesBucket Elevators, Bucket Conveyors and MoreDilnesa EjiguNo ratings yet

- Box Culvert Brochure Web VersionDocument8 pagesBox Culvert Brochure Web Versionsiva_civil4051No ratings yet

- ESCO CastlipDocument8 pagesESCO CastlipRiady SulindroNo ratings yet

- Good Practices RecoommendedDocument2 pagesGood Practices RecoommendedyopatmetNo ratings yet

- SteelFab Company Profile 2021Document26 pagesSteelFab Company Profile 2021CrestNo ratings yet

- ScrewFast Brochure Aug 2014Document6 pagesScrewFast Brochure Aug 2014dinup71No ratings yet

- Weir Oil Gas BrochureDocument33 pagesWeir Oil Gas BrochureRatnakar Patil100% (1)

- Steel DetailingDocument32 pagesSteel Detailingveeba100% (1)

- Food & Beverage Processing: Bio-Fuels Corn Wet Milling Ethanol Malting Starch SugarDocument12 pagesFood & Beverage Processing: Bio-Fuels Corn Wet Milling Ethanol Malting Starch SugarHenry VergaraNo ratings yet

- Waterex ThickenersDocument2 pagesWaterex ThickenerssaravananNo ratings yet

- 05 Box CulvertsDocument9 pages05 Box CulvertsAllan James Anticamara FernandezNo ratings yet

- Essential Technical Data On Steel Reinforcement: InforcingDocument68 pagesEssential Technical Data On Steel Reinforcement: InforcingNil DGNo ratings yet

- Analysis and Design of Hammer Head Bridge Pier Using Strut and Tie MethodDocument20 pagesAnalysis and Design of Hammer Head Bridge Pier Using Strut and Tie Methodဒုကၡ သစၥာNo ratings yet

- Large Pellet Mills PagedDocument12 pagesLarge Pellet Mills PagedNguyên Võ TriệuNo ratings yet

- Permastore BrochureDocument12 pagesPermastore BrochureagungkiworejoNo ratings yet

- Bespoke Fabrication Systems for Unique Site SolutionsDocument13 pagesBespoke Fabrication Systems for Unique Site Solutionswish uNo ratings yet

- Beany Block: Kerb Drainage at Its Most EfficientDocument2 pagesBeany Block: Kerb Drainage at Its Most EfficientMihaela TodiricaNo ratings yet

- Denseveyor Brochure1Document4 pagesDenseveyor Brochure1rumabiswas853100% (1)

- Drag Chain Con Bototm Wear Liner MaterialDocument4 pagesDrag Chain Con Bototm Wear Liner MaterialSandeep GuptaNo ratings yet

- Coplastix Brochure 2006Document4 pagesCoplastix Brochure 2006bmpNo ratings yet

- Box Culverts HumesDocument12 pagesBox Culverts Humespete0980No ratings yet

- Contech Bridge BrochureDocument12 pagesContech Bridge BrochureCONTECHCPINo ratings yet

- DeepConeThickeners BrochureDocument4 pagesDeepConeThickeners BrochureustavNo ratings yet

- Engineered Sealing, Cutting and Punching SolutionsDocument30 pagesEngineered Sealing, Cutting and Punching SolutionsJuan Manuel Sanchez BalderaNo ratings yet

- DMW PowerDocument4 pagesDMW PowerHari Krishna.MNo ratings yet

- Drain CoilDocument12 pagesDrain CoilBerlinNo ratings yet

- Weighbridges Min 1Document12 pagesWeighbridges Min 1KhalidNo ratings yet

- SLB Xcelis PsDocument2 pagesSLB Xcelis Pseduardo navarroNo ratings yet

- CALVERTDuctos Barra Fase No Segregada NSPBInglesDocument16 pagesCALVERTDuctos Barra Fase No Segregada NSPBInglesmartinpellsNo ratings yet

- CRP Subsea Tether Clamp v1.1Document2 pagesCRP Subsea Tether Clamp v1.1michaelsullivan1973No ratings yet

- Concrete Manure TanksDocument4 pagesConcrete Manure Tanksshivas34regalNo ratings yet

- 19 Walkersele Radial Lip Seals Issue 43 1Document48 pages19 Walkersele Radial Lip Seals Issue 43 1wholenumberNo ratings yet

- AmphiMaster BrochureDocument6 pagesAmphiMaster BrochuresonakmalelaNo ratings yet

- Hayman Industries Utility Poles 178785 PDFDocument8 pagesHayman Industries Utility Poles 178785 PDFvcockscribdNo ratings yet

- Mechanical Ash Handling Systems: MetsoDocument4 pagesMechanical Ash Handling Systems: Metsormm99rmm99No ratings yet

- Tubular Drag ConveyorsDocument8 pagesTubular Drag ConveyorsLuiz CostaNo ratings yet

- 6 Page BROCHURE HCC PDFDocument9 pages6 Page BROCHURE HCC PDFManu MohanNo ratings yet

- Manhole Chamber Catalogue 2022 LatestDocument20 pagesManhole Chamber Catalogue 2022 LatestSusanta PanigrahyNo ratings yet

- Wedge Wire ScreensDocument6 pagesWedge Wire Screenscumpio425428No ratings yet

- SuperCor 2008Document16 pagesSuperCor 2008PD AWSSIESPNo ratings yet

- Alternative Construction SystemDocument21 pagesAlternative Construction SystemTom Ate100% (1)

- Brochure HCCDocument13 pagesBrochure HCCManu MohanNo ratings yet

- Flowtite Product Guide 2010Document28 pagesFlowtite Product Guide 2010Anonymous 87xpkIJ6CFNo ratings yet

- KAT0400-0001-E Product Overview Conveyor SystemsDocument16 pagesKAT0400-0001-E Product Overview Conveyor Systemspithaloka100% (1)

- Sluice Gates - Slide Gates - PenstocksDocument28 pagesSluice Gates - Slide Gates - Penstocksnazar750100% (2)

- ExEE Rentals Solids Control & Waste Management BrochureDocument24 pagesExEE Rentals Solids Control & Waste Management BrochureAndrew GoadNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Civil Drawing 24097-0000-C-101r2.75FDocument1 pageCivil Drawing 24097-0000-C-101r2.75FJuan Carlos RNo ratings yet

- Cañete ModelDocument1 pageCañete ModelJuan Carlos RNo ratings yet

- Conf 39Document1 pageConf 39Juan Carlos RNo ratings yet

- Modular Plastic Screw Conveyors: MartinDocument4 pagesModular Plastic Screw Conveyors: MartinJuan Carlos RNo ratings yet

- IndexDocument47 pagesIndexJuan Carlos RNo ratings yet

- Cangilon RoncuziDocument6 pagesCangilon RoncuziJuan Carlos RNo ratings yet

- Techo Puerto 1Document1 pageTecho Puerto 1Juan Carlos RNo ratings yet

- Elevator BucketsDocument11 pagesElevator BucketsJuan Carlos RNo ratings yet

- Drive TrainDocument90 pagesDrive TrainJuan Carlos RNo ratings yet

- Backup Alarm and Pressure Test Options for Model 417-4176Document8 pagesBackup Alarm and Pressure Test Options for Model 417-4176Juan Carlos RNo ratings yet

- Power UnitDocument28 pagesPower UnitJuan Carlos RNo ratings yet

- Bulk Material Handling Equipment from KWSDocument4 pagesBulk Material Handling Equipment from KWSJuan Carlos RNo ratings yet

- Screw Conveyor ManualDocument14 pagesScrew Conveyor ManualDavid100% (1)

- Install and Operate Bucket Elevator ManualDocument12 pagesInstall and Operate Bucket Elevator ManualKoevoet1No ratings yet

- Install and Operate Bucket Elevator ManualDocument12 pagesInstall and Operate Bucket Elevator ManualKoevoet1No ratings yet

- Gentle Handling for Your ProductDocument7 pagesGentle Handling for Your ProductJuan Carlos RNo ratings yet

- Cylindrical Roller Bearing CatalogDocument108 pagesCylindrical Roller Bearing Catalogsandu53100% (1)

- CSC Catalog ColorDocument16 pagesCSC Catalog ColorMauricio Mpinto100% (1)

- SP 360 CmanualDocument35 pagesSP 360 CmanualencontreelrepuestoNo ratings yet

- R311 Catalyst 06.2004 msds3434Document6 pagesR311 Catalyst 06.2004 msds3434rawaronteksNo ratings yet

- Zener BZX83CDocument2 pagesZener BZX83CPelotaDeTrapoNo ratings yet

- Spherical Bearings Loader Slot Bearings Rod End Bearings Sleeve BearingsDocument43 pagesSpherical Bearings Loader Slot Bearings Rod End Bearings Sleeve BearingsMar SolNo ratings yet

- Formation of Delta Ferrite in 9 WT.% CR Steel Investigated by In-Situ X-Ray Diffraction Using Synchrotron RadiationDocument9 pagesFormation of Delta Ferrite in 9 WT.% CR Steel Investigated by In-Situ X-Ray Diffraction Using Synchrotron Radiationsmallik3No ratings yet

- Rates Worksheet HWDocument8 pagesRates Worksheet HWMr. CrustNo ratings yet

- Millman Halkias - Integrated ElectronicsDocument14 pagesMillman Halkias - Integrated ElectronicsSushruti Richaa KashyapNo ratings yet

- 200 ML of Water and 300 ML of Water Into Container B, C and D RespectivelyDocument3 pages200 ML of Water and 300 ML of Water Into Container B, C and D RespectivelyAlexandra ChiengNo ratings yet

- Steel-Concrete Composites Beams Considering Shear Slip EffectDocument23 pagesSteel-Concrete Composites Beams Considering Shear Slip EffectAnnisa Prita MelindaNo ratings yet

- Alloy Cuni 70-30Document2 pagesAlloy Cuni 70-30didiethardoyoNo ratings yet

- Determination of Vinyl Chloride Monomer in Food Contact Materials by Solid Phase Microextraction Coupled With Gas Chromatography/Mass SpectrometryDocument6 pagesDetermination of Vinyl Chloride Monomer in Food Contact Materials by Solid Phase Microextraction Coupled With Gas Chromatography/Mass SpectrometryPhuongthuy127No ratings yet

- GtryeDocument66 pagesGtryePholNo ratings yet

- Lowara LSN Low Res LDocument12 pagesLowara LSN Low Res LDodi SuhendraNo ratings yet

- Compatibility of Materials With Liquid Oxygen (Impact Sensitivity Threshold and Pass-Fail Techniques)Document12 pagesCompatibility of Materials With Liquid Oxygen (Impact Sensitivity Threshold and Pass-Fail Techniques)Ahmed AlzubaidiNo ratings yet

- Cetco Hydraul EzDocument4 pagesCetco Hydraul Ezjaredf@jfelectric.comNo ratings yet

- B001 Arihant PDFDocument12 pagesB001 Arihant PDFmathclubNo ratings yet

- Predictive Wear Modelling of Lubricated Piston Rings in A Diesel EngineDocument14 pagesPredictive Wear Modelling of Lubricated Piston Rings in A Diesel EngineJoel E ValenciaNo ratings yet

- Chapter 1 (Semicon) FLOYDDocument2 pagesChapter 1 (Semicon) FLOYDanon_337840562No ratings yet

- Cooling System of TransformerDocument6 pagesCooling System of TransformerFaiza RafliNo ratings yet

- Chapter-2-LEVEL MEASUREMENTDocument26 pagesChapter-2-LEVEL MEASUREMENTMohammed YusufNo ratings yet

- Chapter 8 - Synthesis of Nanomaterials - 2009 Ashby - Nanomaterials Nanotechnology An Introduction PDFDocument17 pagesChapter 8 - Synthesis of Nanomaterials - 2009 Ashby - Nanomaterials Nanotechnology An Introduction PDFkaoru9010-1No ratings yet

- Lec34 Soil P and KDocument24 pagesLec34 Soil P and KDIBINo ratings yet

- Inorganic 3Document7 pagesInorganic 3Ephraim PeasahNo ratings yet

- Types of PumpsDocument68 pagesTypes of PumpsVicky JeganNo ratings yet