Professional Documents

Culture Documents

Low Alloy Steels Part2

Uploaded by

fedaquiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Low Alloy Steels Part2

Uploaded by

fedaquiCopyright:

Available Formats

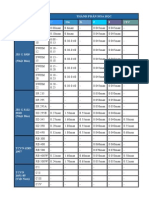

Part 2

Low alloy steels

Stooss

specification

DIN

material

no.

Short

specification

according

to DIN

EN

specification

GB

USA

Type

Chemical analysis in weight per cent

Si

Mn

min.

max.

0.20

0.25

0.30

0.50

0.80

min.

max.

0.30

0.34

0.15

0.40

min.

max.

0.28

0.34

min.

max.

Upper and lower range

Ni

Mo

Al

1.70

0.010 0.015 2.00

0.90

1.20

0.60

0.80

0.05

0.025

0.50

0.80

1.80

0.015 0.007 2.20

1.80

2.20

0.30

0.50

0.15

0.40

0.40

0.70

2.30

0.009 0.007 2.70

0.30

0.37

0.15

0.35

0.40

0.60

1.50

0.025 0.025 1.80

0.90

1.10

0.15

0.25

min.

max.

0.50

0.60

0.10

0.40

0.65

0.95

1.00

0.030 0.030 1.20

1.50

1.80

0.45

0.55

UNS

Cr

Nb

Other

Low alloy tempering steels

23 CrNiMo 7 4 7

23 CrNiMo 7 4 7

ASTM A471

1.6749

SEW 555 / Turbine and generator construction / Hub and cover disks

30 CrNiMo 8

1.6580HH

30 CrNiMo 8 HH 30 CrNiMo 8

823M30

DIN 17201 / SEW 550 / EN 10083-1 / Machine and equipment construction

31 CrMoV 9

1.8519

31 CrMoV 9

DIN 17211 / Nitride steel / crankshafts, valve spindles

34 CrAlNi 7

34 CrAlNi 7

1.8550

DIN 17211 / Nitride steel / piston rods, spindles

56 NiCrMoV 7

56 NiCrMoV 7

35CrMo8

1.2714

DIN 17350 / Tool steel / tools for hot work / forging dies

40 NiCrMo 6

40 NiCrMo 6

818M40

1.6565

Tool steel / dies for briquetting and compacting equipment

SNC M8

min.

max.

0.36

0.44

0.15

0.35

0.50

0.70

1.00

0.025 0.025 1.40

1.40

1.70

0.20

0.30

15 Mo 3

1.5415

15 Mo 3

16Mo3

243B

K11820

15D3

STBA 12

DIN 17243 / EN 10028 / High temperature steel / application temperature up to max. 500c. / power station construction / flanges

min.

max.

0.12

0.20

0.15

0.35

0.50

0.70

0.035 0.030 0.25

0.30

0.25

0.35

22 Mo 4

1.5419

22 Mo 4

G20Mo5

245

SAE 4422

SCPH 11

DIN 17245 / EN 10213-2 / High temperature steel / application temperature up to max. 500c. / power station construction / flanges

min.

max.

0.18

0.25

0.20

0.40

0.40

0.70

0.015 0.018 0.30

20 CrMoNiV 4 7

1.6979

20 CrMoNiV 4 7

SEW 555 / Turbine construction and generator devices

min.

max.

0.17

0.25

0.30

0.30

0.50

1.20

0.015 0.018 1.40

0.50

0.60

0.80

1.00

13 CrMo 4 4

13 CrMo 4 4

13CrMo4-5

620

K11562

15CD4-05

STBA 20

1.7335

DIN 17243 / EN 10028-2 / High temperature steel / application temperature up to max. 530c. / power station construction

min.

max.

0.10

0.18

0.10

0.35

0.40

0.70

0.80

0.025 0.015 1.10

0.30

0.45

0.60

0.030

10 CrMo 9 10

1.7380

10 CrMo 9 10

10CrMo9-10

622

K21390

12CD9-10

STBA 24

DIN 17243 / EN 10028 / SEW 595 / High temperature steel / application temperature up to max. 500c. / power station construction

min.

max.

0.10

0.14

0.15

0.30

0.40

0.60

2.00

0.015 0.010 2.50

0.90

1.10

0.010

0.040

Cu max. 0.25 N max. 0.012

3520

1.3520

100 CrMn 6

100CrMn6

DIN 17230 / Roller bearing steel / WD to 50 mm

min.

max.

0.90

1.00

0.55

0.70

1.05

1.20

1.45

0.025 0.008 1.65

0.30

0.080

0.005

0.050

Ti max. 0.003 Cu max. 0.25

O max. 0.0015

3539

1.3539

100 CrMnMo 8

DIN 17230 / Roller bearing steel / WD > 50 mm

min.

max.

0.90

1.00

0.40

0.60

0.80

1.10

1.80

0.025 0.008 2.05

0.30

0.50

0.60

0.015

0.050

Ti max. 0.003 Cu max. 0.25

O max. 0.0015

3536

1.3536

100 CrMo 7 3

100CrMnMo7

DIN 17230 / Roller bearing steel / WD > 50 mm

min.

max.

0.90

1.00

0.20

0.40

0.60

0.80

1.65

0.025 0.008 1.95

0.30

0.20

0.35

0.015

0.050

Ti max. 0.003 Cu max. 0.25

O max. 0.0015

100 Cr 6

1.3505

100 Cr 6

100Cr6

DIN 17230 / Roller bearing steel / WD up to 30 mm

min.

max.

0.98

1.05

0.20

0.30

0.25

0.45

1.40

0.025 0.025 1.60

0.30

100 Cr 6 M1

1.3505

100 Cr 6

Modified Analysis

DIN 17230 / Roller bearing steel / WD up to 30 mm

min.

max.

0.90

1.00

0.20

0.35

0.30

0.45

1.45

0.025 0.008 1.65

0.25

65 Cr 3

1.7017

65 Cr 3

Alloy construction steel / rail vehicle construction / wheel tyres

min.

max.

0.63

0.68

0.25

0.40

0.55

0.70

0.30

0.035 0.035 0.50

AISI 4130

(1.7218)

25 CrMo 4

25CrMo4

ASTM A29 / General machine construction

AISI 4130

min.

max.

0.28

0.33

0.20

0.30

0.40

0.60

0.80

0.015 0.015 1.10

0.20

0.25

0.15

0.25

AISI 4130 M1

Modified Analysis

ASTM A29 / General machine construction

AISI 4130

min.

max.

0.28

0.33

0.20

0.30

0.40

0.60

0.80

0.010 0.010 1.10

0.25

0.15

0.25

AISI 4130 M2

Modified Analysis

ASTM A29 / Ni-alloy / General machine construction

AISI 4130

min.

max.

0.29

0.32

0.20

0.30

0.50

0.60

0.95

0.012 0.010 1.10

0.60

0.70

0.20

0.25

AISI 4135

(1.7220)

34 CrMo 4

34CrMo4

ASTM A29 / General machine construction

708A30

AISI 4135

min.

max.

0.33

0.37

0.15

0.30

0.70

0.90

0.90

0.020 0.015 1.10

0.25

0.15

0.25

AISI 4140

(1.7225)

42 CrMo 4

42CrMo4

ASTM A 29 / General machine construction

708M40

min.

max.

0.39

0.43

0.15

0.30

0.75

0.90

0.90

0.020 0.015 1.10

0.25

0.15

0.25

0.30

AISI 4140 M1

Modified Analysis

ASTM A 29 / General machine construction

min.

max.

0.39

0.43

0.20

0.30

0.80

1.10

0.90

0.025 0.025 1.10

0.15

0.25

0.03

AISI 4340

(1.6565)

40 NiCrMo 6

ASTM A182 Tool steel

818M40

min.

max.

0.38

0.43

0.15

0.30

0.60

0.80

0.70

0.025 0.010 0.90

0.20

0.30

0.05

A 182 F12

(1.7335)

13 CrMo 44

13CrMo4-5

ASTM A 182 / Parts for valves / pipe flanges

620 - 440

ASTM A182F12

K11564

15CD4.05

STBa 20

min.

max.

0.10

0.15

0.10

0.60

0.30

0.80

0.80

0.015 0.010 1.25

AISI 8620

(1.6523)

20 NiCrMo 22

20NiCrMo2-2

ASTM A29 / General machine construction

805M20

AISI 8620

G86200

20NCD2

SNC M21

min.

max.

0.18

0.23

0.20

0.35

0.70

0.95

0.010 0.40

0.025 0.025 0.65

0.40

0.75

0.15

0.25

AISI 8630

(6545)

30 NiCrMo 22

30NiCrMo2 KD

ASTM A29 / General machine construction

AISI 8630

G86300

30NCD2

min.

max.

0.28

0.33

0.15

0.35

0.70

0.90

0.40

0.035 0.040 0.60

0.40

0.70

0.15

0.25

AISI 8630 M1

Modified Analysis

ASTM A29 / General machine construction

AISI 8630

min.

max.

0.28

0.33

0.15

0.35

0.75

0.90

0.85

0.015 0.010 1.00

0.80

0.90

0.35

0.45

ASTM A355

K32800

30CND8

SNC M1

K52440

AISI 4340

K19195

100CM6

100CrMnMo8

ASTM A485

2S.135

100CrMo7-3

SAE 52100

100C6

25CD4

34CD4

AISI 4140

42CD4

SUJ 2

SCCr M1

SCCr M3

SCCr M4

AISI 4140

AISI 4340

G43400

SNC M8

The chemical analysis conform to STOOSS purchasing specifications. The comparative national designations may differ

from the STOOSS analysis and are purely for information purposes.

0.15

0.25

Cu max. 0.20

Sn max. 0.025 Cu max. 0.20

0.10

0.20

Sn max. 0.010 Cu max. 0.20

0.80

1.10

0.07

0.12

0.008

0.020

Cu +10Sn max. 0.50

0.050

0.30

0.50

0.25

0.35

0.020

Cu max. 0.30

0.010 Cu

0.050 0.25

0.080

As max. 0.04 Sn max. 0.03 Ti max. 0.003

O max. 0.0015 Sb max. 0.005 Pb max. 0.002

N max. 0.0070

1.65

2.00

0.05

Cu max. 0.35

Cu max. 0.35

0.05

0.020

0.040 0.01

As max. 0.025 Sn max. 0.025 N max. 0.010 B max. 0.0005

Sb max. 0.002 Pb max. 0.0015 Cu max. 0.20

Cu max. 0.35

Cu max. 0.35

0.020

0.040 0.01

As max. 0.025 Sn max. 0.025 N max. 0.010 B max. 0.0005

Sb max. 0.002 Pb max. 0.0015 Cu max. 0.20

0.44

0.65

0.010

0.006 0.020 0.006

Cu max. 0.20 Ti max. 0.007

Details on material application are for description purposes only. They are provided to the best of our knowledge,

but without any guarantee. Special agreements in writing are always required.

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Steel Grade Indian StandardsDocument5 pagesSteel Grade Indian StandardsPriyanathan ThayalanNo ratings yet

- Cross Reference Ro SteelsDocument17 pagesCross Reference Ro SteelsJosé SilvérioNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- ASM Cross Reference For NonferrousDocument17 pagesASM Cross Reference For Nonferrousfedaqui100% (2)

- History of Refrigeration - From Ice Boxes to Modern SystemsDocument34 pagesHistory of Refrigeration - From Ice Boxes to Modern SystemsNSS GBPECNo ratings yet

- DIN 17102 Welded Steel GradesDocument10 pagesDIN 17102 Welded Steel Gradesjulio_rocha_1No ratings yet

- Prevention, Fishing and Casing Repair - Jim Short - Part 2Document249 pagesPrevention, Fishing and Casing Repair - Jim Short - Part 2MitsúMilagrosToroSayasNo ratings yet

- Material Properties and Chemical CompositionDocument20 pagesMaterial Properties and Chemical CompositionMani Maran89% (9)

- 15-5 PHDocument2 pages15-5 PHfedaquiNo ratings yet

- 13-8 MoDocument2 pages13-8 MofedaquiNo ratings yet

- Columbus Stainless Pocket GuideDocument29 pagesColumbus Stainless Pocket Guidebruteforce2000No ratings yet

- ASTM Materials - CHINA MaterialsDocument29 pagesASTM Materials - CHINA MaterialsHema HemaNo ratings yet

- Catalogo de Ejes CromsteelDocument20 pagesCatalogo de Ejes CromsteelJhonFerneyBohorquezSaldarriagaNo ratings yet

- Cilindro Servo KONGSBERGDocument47 pagesCilindro Servo KONGSBERGAnonymous UjSbzQ100% (1)

- Indian Standard Steel SectionsDocument9 pagesIndian Standard Steel SectionsAmitava SilNo ratings yet

- Cold Drawn Seamless Steel Tubes For Mechanical ApplicationsDocument8 pagesCold Drawn Seamless Steel Tubes For Mechanical ApplicationsAndres FlorezNo ratings yet

- Sae 5115Document1 pageSae 5115Tatumi SobueNo ratings yet

- ASTM A 269 Standar Spec. For Seamless and Welded Autenitic SS TubingDocument6 pagesASTM A 269 Standar Spec. For Seamless and Welded Autenitic SS TubingJose TorresNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- 4340M or 300MDocument2 pages4340M or 300MfedaquiNo ratings yet

- Steel GradesDocument12 pagesSteel GradesDidar Singh Thethi100% (1)

- Hot Rolled and Structural Steel Grades (40Document4 pagesHot Rolled and Structural Steel Grades (40sudeponnaniNo ratings yet

- Ss 400Document4 pagesSs 400A Rahim A Bakar100% (1)

- Dunaferr Cold Rolled Product catalogueDocument12 pagesDunaferr Cold Rolled Product catalogueMihály PálffyNo ratings yet

- Unalloyed Steels e 0219Document1 pageUnalloyed Steels e 0219iuliaNo ratings yet

- Specifications For PlatesDocument4 pagesSpecifications For PlatesRv VaghasiaNo ratings yet

- WS410Document7 pagesWS410Martin OusephNo ratings yet

- Chemical CompositionDocument13 pagesChemical Compositionssharma3474No ratings yet

- Low Alloy Steels Part2 PDFDocument1 pageLow Alloy Steels Part2 PDFnedunchiNo ratings yet

- Mechanical PropertiesDocument4 pagesMechanical PropertiesSh KittanehNo ratings yet

- Leaded Tin Bronze C54400Document3 pagesLeaded Tin Bronze C54400nfcastingsNo ratings yet

- CDA110 Specifaction SheetDocument5 pagesCDA110 Specifaction SheetGendakensNo ratings yet

- Tabel Besi IspatindoDocument6 pagesTabel Besi Ispatindotonni.s36No ratings yet

- SensoMatic Cataloge 2009Document8 pagesSensoMatic Cataloge 2009pradipiitgNo ratings yet

- Jis G4051Document7 pagesJis G4051tnchsgNo ratings yet

- Clad Steel Plate: Cat - No.C1E-009-02Document23 pagesClad Steel Plate: Cat - No.C1E-009-02Marimari MinteaNo ratings yet

- Vergleichstabelle Von Verschiedenen Stahlsorten Nach Werkstoff-NummernDocument6 pagesVergleichstabelle Von Verschiedenen Stahlsorten Nach Werkstoff-NummerndarkquinkNo ratings yet

- Tieu Chuan Ky Thuat Thep PominaDocument3 pagesTieu Chuan Ky Thuat Thep PominaColombus ChristopherNo ratings yet

- SPECIFICATIONSDocument9 pagesSPECIFICATIONSRicardo VelozNo ratings yet

- SPECIFICATIONS FOR STRUCTURAL STEEL AND SHEET PILEDocument9 pagesSPECIFICATIONS FOR STRUCTURAL STEEL AND SHEET PILEAbdul Syukur ZNo ratings yet

- WS412Document7 pagesWS412Martin OusephNo ratings yet

- Aisi 200 SeriesDocument19 pagesAisi 200 Seriessgupta_192494No ratings yet

- Qualitat Cargols I FemellesDocument34 pagesQualitat Cargols I FemelleshecdomNo ratings yet

- Steel Bars, Carbon, Hot-Wrought, Special Quality: Standard Specification ForDocument6 pagesSteel Bars, Carbon, Hot-Wrought, Special Quality: Standard Specification ForIngrid Tatiana RojasNo ratings yet

- 42crmo4 - HardnessDocument8 pages42crmo4 - HardnessavijayakumarsamyNo ratings yet

- DIN 17175-79 Seamless Steel Tubes Chemical CompositionsDocument0 pagesDIN 17175-79 Seamless Steel Tubes Chemical CompositionsAhmed SaadNo ratings yet

- Flowmeter SelectionDocument4 pagesFlowmeter SelectionsrshahNo ratings yet

- Square Rectangular Hollow SectionDocument76 pagesSquare Rectangular Hollow Sectionbusiness.developmentNo ratings yet

- Technical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40Document5 pagesTechnical Data of Black and Hot Dip Galvanized Steel Pipes Conforming To Astm A 53 Grade A & B Sch-40mechmohsin4745No ratings yet

- Material PropertiesDocument4 pagesMaterial Propertiesbratkp100% (1)

- Home About Us Products Display News Contact ProductsDocument8 pagesHome About Us Products Display News Contact ProductsBosz InNo ratings yet

- ESAB Plasma Cutting DataDocument11 pagesESAB Plasma Cutting DataVignesh PrabhuvelpariNo ratings yet

- Standards R M Salem - UserguideDocument49 pagesStandards R M Salem - Userguidearunas1081No ratings yet

- En10028 2Document12 pagesEn10028 2Patilea DanielaNo ratings yet

- Tool Steel Grade and Property GuideDocument2 pagesTool Steel Grade and Property GuideDuy NguyenNo ratings yet

- 1 8159-51CrV4Document2 pages1 8159-51CrV4black_absynthNo ratings yet

- "Over 35 Years of Manufacturing Excellence": IPS - Iron Pipe Size Sewer PipeDocument1 page"Over 35 Years of Manufacturing Excellence": IPS - Iron Pipe Size Sewer PipeAnonymous eq5zSUNo ratings yet

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- Stainless Steel & Heat Resistant Steel Electrodes: (Vacuum Pack)Document1 pageStainless Steel & Heat Resistant Steel Electrodes: (Vacuum Pack)Waqas WaqasNo ratings yet

- SPECIAL STEELS PRODUCT CODE :: PKG/RO/41Document9 pagesSPECIAL STEELS PRODUCT CODE :: PKG/RO/41Pranav TripathiNo ratings yet

- New 4130 Alloy SteelDocument3 pagesNew 4130 Alloy SteelfsijestNo ratings yet

- Werkstoffe E PDFDocument12 pagesWerkstoffe E PDFirajfarji2481No ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Workbench Under Stair Storage PlansDocument20 pagesWorkbench Under Stair Storage PlansKeleen WrightNo ratings yet

- Photomicrographs of Iron and Steel, ReedDocument288 pagesPhotomicrographs of Iron and Steel, Reedfedaqui100% (1)

- Alloy20 PennSDainlessProductsDocument2 pagesAlloy20 PennSDainlessProductsfedaquiNo ratings yet

- Nickel Maraging Steel PropertiesDocument30 pagesNickel Maraging Steel PropertiesRobert NatasorpNo ratings yet

- 4340Document2 pages4340fedaquiNo ratings yet

- 17 4Document2 pages17 4fedaquiNo ratings yet

- ASCII TableDocument7 pagesASCII TableSheriff SammyNo ratings yet

- Module 4 Introduction To Electrical Conductors Wiring Techniques and Schematic Reading Part1Document10 pagesModule 4 Introduction To Electrical Conductors Wiring Techniques and Schematic Reading Part1Jan Renn ArleNo ratings yet

- Application Bulletin - Paints and CoatingsDocument2 pagesApplication Bulletin - Paints and CoatingsjoseNo ratings yet

- V410065 en US FactSheet Main 01Document1 pageV410065 en US FactSheet Main 01Janeth MendozaNo ratings yet

- Signet 2714-2717 Twist-Lock pH/ORP Electrodes: FeaturesDocument4 pagesSignet 2714-2717 Twist-Lock pH/ORP Electrodes: FeaturesHuuDuydluNo ratings yet

- Tetraamin Copper (II) Sulphate SynthesisDocument9 pagesTetraamin Copper (II) Sulphate SynthesisIntan SaviraNo ratings yet

- Is 694Document30 pagesIs 694nm_rangaNo ratings yet

- Teledyne DirectoryDocument5 pagesTeledyne DirectorySww WisdomNo ratings yet

- Electronic Thermostat Circuit Using TransistorsDocument2 pagesElectronic Thermostat Circuit Using Transistorstim schroderNo ratings yet

- Sodium Chlorate Civilizations EndDocument3 pagesSodium Chlorate Civilizations EndlunicyNo ratings yet

- JIS-Z-8901 (Polvos de Quarzo) PDFDocument38 pagesJIS-Z-8901 (Polvos de Quarzo) PDFAlondra CVNo ratings yet

- As 5056-2006 Metallic Coatings - Powder Metal (And Composites) Applied by Mechanical Means at Ambient TemperaDocument7 pagesAs 5056-2006 Metallic Coatings - Powder Metal (And Composites) Applied by Mechanical Means at Ambient TemperaSAI Global - APACNo ratings yet

- Recommendations For Assessment Eurocodes For Bridges: Chris R HendyDocument12 pagesRecommendations For Assessment Eurocodes For Bridges: Chris R Hendymicael_89100% (1)

- Cambridge International General Certifi Cate of Secondary EducationDocument16 pagesCambridge International General Certifi Cate of Secondary EducationBrianChanNo ratings yet

- Able Ucts: (Wiring Channels)Document4 pagesAble Ucts: (Wiring Channels)VIJAY KUMAR SAJJANo ratings yet

- Konnerup (2012) Design of Steel-Concrete Composite Structures For A High-Rise BuildingDocument185 pagesKonnerup (2012) Design of Steel-Concrete Composite Structures For A High-Rise Buildingint8No ratings yet

- As-Welded Wrought Austenitic Stainless Steel Fittings For General Corrosive Service at Low and Moderate TemperaturesDocument4 pagesAs-Welded Wrought Austenitic Stainless Steel Fittings For General Corrosive Service at Low and Moderate Temperaturesrgi178No ratings yet

- Harvel - Linha de Produtos em Vinis PVC e CPVCDocument126 pagesHarvel - Linha de Produtos em Vinis PVC e CPVCdanilobossuNo ratings yet

- Cement Practice QuestionsDocument2 pagesCement Practice QuestionsSureshKonamNo ratings yet

- Katalog 2011 enDocument278 pagesKatalog 2011 ener_wenNo ratings yet

- Ml7420a8088 e Honeywell Valve ActuatorDocument4 pagesMl7420a8088 e Honeywell Valve ActuatorstranfirNo ratings yet

- Austempered Ductile Iron Castings: Standard Specification ForDocument9 pagesAustempered Ductile Iron Castings: Standard Specification ForRaja Hone0% (1)

- Tabela de Corrosão Little GiantDocument12 pagesTabela de Corrosão Little GiantAlex Sandro FerreiraNo ratings yet

- MST-ME331-Prospect of Cutting Tool ManufacturingDocument7 pagesMST-ME331-Prospect of Cutting Tool ManufacturingAmin Al ShuvoNo ratings yet

- Theory-Manual Eng 2011 PDFDocument119 pagesTheory-Manual Eng 2011 PDFErisvaldo de LimaNo ratings yet

- Toshiba 1550 Service ManualDocument192 pagesToshiba 1550 Service ManualБорис БорянNo ratings yet

- Daily Progress ReportDocument2 pagesDaily Progress ReportmkpqNo ratings yet