Professional Documents

Culture Documents

Us1955360 PDF

Uploaded by

RodrigoPomaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us1955360 PDF

Uploaded by

RodrigoPomaCopyright:

Available Formats

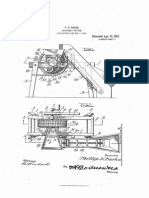

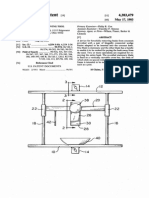

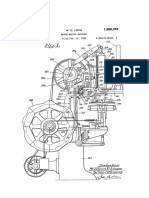

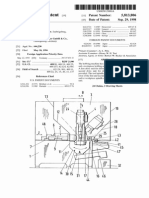

April 17, 1934.

J_ D, FERRY

1,955,360

VEGETABLE SLICER

Filed Nov. 20, 1931

4 Sheets-Sheet

J4

J0

gmntoz

@fosepii?i'arly

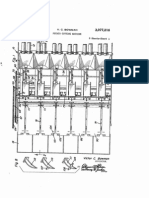

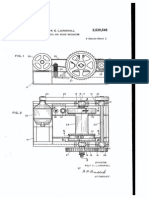

April 17, .1934.

J, D, FERRY

VEGETABLE SLICER

Filqd, Nov.> 20. v1931

1,955,360

4 Sheets-Sheet

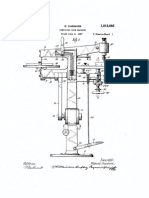

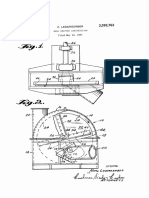

Apnl 17, 1934.

J. D. FERRY

1,955,360

VEGETABLE SLICER

Filed Nov. 20, 1931

74 .

E

Ill

342N

4 Sheets-Sheet 3

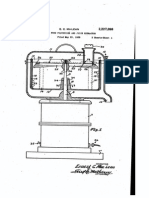

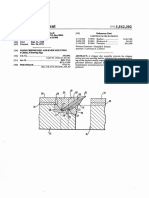

April 17, 1934.

_J.D.FERRY

VEGETABLE SLICER

Filed Nov. 20,

1931

1,955,360

4- Sheets-Sheet 4

Josepir?ierzy

1,955,360

Patented Apr. 17, 1934

1,955,380

VEGETABLE SLICEB

bnrg, Fa;

Application November 29, 3981, Serial No, 576,407

(or, ice-mien

' Eoseph D. Fern-y,

This invention relates to vegetable slicers, espe

to expose the rotor by which the potatoes are

cially adapted for use in the commercial prepara sliced,

Figure 2 is'a fragmentary side elevation of the

.tion of potato or Saratoga chips, although it will

be seen that the invention is adaptable toother improved slicer swung to an inoperative position

to afford direct and full access to the rotor, these

5 uses.

The vegetable slicer forming the subject of this rotor and a portion of the supporting and motion

application will be found to embody a rotor ar transmitting mechanism therefor being shown in

- ranged in operative relation to a vegetable feed

section,

Figure 3 is a fragmentary vertical sectional view

ing hopper and having one or more blades rigid

65

ly ?xed thereto, while the portions of the rotor through the improved vegetable slicer,

immediately in advance of the blades are rendered

. Figure 4: is a fragmentary bottom plan view

adjustable to provide for the simple and accurate of the improved vegetable slicer,

Figure 5 is a fragmentary group perspective of

regulation of the thickness of the vegetable slices,

this being in contrast to those vegetable slicers the rotor and the hopper,

Figure 6 is a vertical detailed sectional view m

in which the blades themselves are adjustable and

intersect the plane of the vegetable engaging sur through a portion of :the rotor and the adjacent

'

face of the rotor or other blade support, and are portion of the hopper,

Figure l is a detailed sectional-view illustrat

prone to lose their adjustment and which require

considerable skill as well as patience to provide ing the means bywhich the portions ot'the rotor

for extended use and the production of a slice immediately in advance of the cutting blades are 75

or chip that is of a uniform thickness throughout. depressed at angles to the plane of rotation of

The herein disclosed invention also embodies the rotor for presenting, the cutting edges of the

,

simple means by which ready access may be blades to the vegetable,

Figure 8 is a fragmentary plan view of the im

gained to the rotor for the purpose of providing

' for a change in the thickness oi the slices being proved vegetable slicer. '

produced or for the purpose of inspection or re

pair, it being noted thatlthe adjusting means for

Figure 9 is a perspective on a reduced scale of

a plain surfaced rotor.

80

In the drawings, the numeral 10 designates a

rate regulation of the thickness of the potato hopper having oppositely located radial arms 12

30 chips may be accomplished without the exercise detachably secured thereto and, provided with 85

means by which the hopper and the associated

_ of unusual skill.

By way of further brief reference to the rotor mechanism to be described may be connected to

and the accessibility of the same, it is pointed a support 14 such as a potato making machine.

out that the rotor is held inplaoe by the employ More speci?cally, the hopper might advantage

ment of a single set screw or similarly simple ras ously be located immediately above a chip wash 90

tening device allowing a plain surfaced rotor ing tank vforming a part of a potato making ma

to be easily and quickly removed and a corru chine, but since this forms no part of the herein

gated rotor substituted or vice versa, the corru disclosed invention, no detailed illustration there

the rotor are arranged and located so thatv accu

gated rotor being intended for use in the making

of appears.

As best shown in Figures 1 and 8 the radial

Another aim of the invention is .to provide a arms 12 are provided with trunnions l6 rotatably

vegetable slicer of the character speci?ed, which extended through the cars 18 of brackets 20 to

is of highly simpli?ed construction, ef?cient in provide a means by which the hopper and asso

ciated mechanism may be conveniently swung

use and relatively cheap to manufacture.

Other objects and advantages will be appar from the upright position shown in Figure l to 100

45

out during the course of the following descripy the horizontal position shown in Figure 2 and

vice versa. The brackets 20 are shown to be se-=

tion,

m the accompanying drawings, forming a part cured to the upper portion of the support is

of this application and in which like numerals are of whatever nature the latter happens to be and

r 5g employed to designate like parts throughout the the brackets are provided with semi-circular seats 195

22 for pins 24, the latter being somewhat similar

Figure l is a side elevation of the improved in structure to the trunnions 1d and being one

vegetable slicer mountedon a portion of a potato tended in spaced parallel relation thereto. Gleam

chip making machine, a portion of the potato 1y, with-(the trunnlons 16 extended through the '

40

of corrugated potato chips.

same,

55 chip making machine being shown broken away ears, 1'8 and the stopv pins 24 resting on the seats HQ

1,955,360

22 the hopper and associated mechanism is held

in the desired position for use.

On the other hand, with the hopper and asso

ciated parts swung to the position shown in Fig

or less segmental sections preferably formed in

a single piece with the hub of the rotor. One

radial edge portion of each of the segmental

sections is shown to be abruptly depressed or

ure 2, ready access is gained to the rotor for stepped to form supporting seats for blades 60. 80

any one of a number of purposes, all of which Each of the blades is securely and positively

will appear as the description proceeds.

held in place by fastening devices and has the

The hopper 10 is in the form of an annular body upper surface and the cutting edge thereof ?ush

surrounding a centrally located hub 30 and hav

10 ing connection with the hub through the inter

vention of a pair of oppositely located vanes or

pressure plates 32. The pressure plates have the

inner and outer edges thereof welded or other

wise secured to the hub and the body of the

15 hopper. It is shown in Figures 5 and 6 that the

pressure plates or vanes 32 dip or descend in the

direction of travel of the rotor located below and

at the same time, the vanes are sloped downward.

with the vegetable contacting surface of the rotor.

By stepping the rotor to form the blade seats, 85

the blades are securely backed "and the thrust

on the blade fastening devices is thus reduced.

The other radial edge portion of each seg

mental section of the rotor is also stepped or

slightly depressed as indicated at 63 to form

90

seats for approach plates 64, the approach plates

being of circumferential dimensions to ?t be

tween the segmental sections of the rotor with

toward the outer edges thereof. In other words, slight spaces between the approach plates and

20 the pressure plates or vanes 32 are inclined cir

the blades.

Screw bolts or the like provide a

cumferentially and radially and cooperate with convenient 'means\ for securing the approach

the rotor below in the formation of gradually re plates 64 to the relatively ?xed portion of the

stricted pockets opening at the rear ends thereof rotor.

for the reception of potatoes or other vegetables

It will be seen that each arcuate approach

25 to be sliced and diminishing in height toward plate 64 is anchored at what might be said to 100

what might be said to be'the forward ends thereof. be the leading end or edge thereof and is free

The downward inclination of the pressure plates from positive connection at the inner and outer

or vanes 32 toward the outer edges thereof is tov edges thereof with the body of the rotor so that

resist centrifugal force incident to the turning the trailing edge or rear end thereof is free for

30 of the rotor below with the result that while the adjustment with respect to the adjacent blade.

105

potatoes are being sliced the same are held

The material forming the arcuate plates 64

against shifting. The pressure plates or vanes has an inherent ?exibility su?icient to allow of

are of ogee formation.

the adjustment of the plates to bring about the

The rotor is designated by the numeral 40 and production of potato slices of the desired thick

35 as shown in Figure 5 is in the form of a disc keyed ness.

110

in any suitable manner to the motion transmit

Referring now'to the particular means by

ting shaft 42 which passes through the hub 30. which the approach plates ,64 may be adjusted

Figure 2 illustrates that the shaft 42 is held in a with respect to the associated blades, attention

central position in the hub 30 through the mediumv is invited to Figures 3, 4, 5, 6 and 7 in which

40 of bearings of any appropriate character and the it is shown that the hub of the rotor is pro

upper portion of the shaft and the adjacent end vided with oppositely directed nearly radial arms

of a second shaft 46 are provided with interlock 70 underlying the trailing edges of the arcuate

ing motion transmitting gears 47.

plates 64 and having spaced internally threaded

, In Figure 3 it is illustrated that the nut 45

bosses 72 through which sleeve nuts or adjust

45 which is threaded on the upper portion of the ing elements '74 are threaded. As shown in Fig- ;,

shaft 42 has pressure relation with the gear 4'7 ure 7, the bores of the several sleeve nuts 74

mounted on the shaft 42 so that by advancing are smooth for the free passage of cap screws

the nut, wear is taken up on the bearings 44. 76, the forward portions of which are threaded

In explaining this it is pointedout that advance into bosses '78 on the undersides of the approach

50 ment of the nut 45 will have the effect of rais~ plates 64. The rear portions of the cap screws '

ing or drawing up the cone of the lower bearing are diametrically enlarged to form heads for en

and depressing the cone of the upper bearing so gagement with the rear ends of the sleeve nuts

that neatness'of both bearings may be main 74. By this arrangement, backing up of the

tained, all by the adjustment of a single nut. Also, sleeve nuts '74 will depress the trailing edges of

55 the nut 45 acts as a means to hold one of the the approach plates 64 with respect to the asso- ;

gears 47 on the shaft 42.

i

_

ciated blades. This, of course, affects an in

Referring now to Figure 3, it will be seen that crease in the thickness of the slices produced.

what might be said to be the drive shaft 46 is After adjustment of the sleeve nuts 74, the cap

extended through and is supported by bearings screws are advanced sui?ciently to act as locking

48 and 49, the bearing 48 being carried by the devices holding the~bosses 78 in ?rm pressure 17',

gear housing 50 while the bearing 49 is mounted contact with the forward ends of the sleeves.

on the upper end of a standard 52 on one of the

radial arms 12. The drive shaft 46 has connec

tlon with a suitable source of power.

65

In carrying out the invention, the gear hous

ing 50 may be provided with an opening 54 nor

mally closed by a plug and providing a means

by which a lubricant of a suitable consistency

may be introduced into the housing and into

thehub 30. A felt washer 56 provides a simple

means by which the lubricant introduced into

the gear housing 28 and the hub 30 is held against

escape.

'

, Referring now to Figure 5, it will be seen that

Inthis connection, it is noted that the cap screws

76 are not bottomed in the sockets in the bosses

78. On the contrary there is sufiicient space

between the threaded ends of the cap screws "

76 and the inner ends of the sockets in the bosses

to allow the cap screws to be advanced to bring

about the desired pressure contact between the

opposed surfaces of @he bosses 78 and the sleeve

nuts 74.

1-15

'

Qfcourse, the range of adjustment of the trail

ing edges of the several approach plates 64 is

slight, possibly not more than a matter of a

the rotor embodies two oppositely located more few thousandths of an inch, because under ordi 150

1,956,360

nary operating conditions a greater range of to the undersideslpf the body of the rotor to

adjustment is not required.

' strengthen and reinforce the same, it-being un

Figures 5 and 7-i1lustrate that the adjusting derstood, of course, that the hub of the rotor and

units for the approach'plates engage the trail the oppositely located segments thereof forming

ing edges of the approach plates at radially the body of the rotor are, along with the rein

spaced points and preferably adjacent to the. forcing ribs preferably cast in a single piece.

inner and outer edges thereof so that the ap

To prepare the improved slicer for use, the

proach plates may be uniformly adjusted from same is swung back to the inoperative position

the inner to the'outer edges thereof. That is shown in Figure 2, to expose the rotor and the

to say; the arrangementlof the adjusting "units blades thereof so that the approach plates 64

with respect to the approach plates provides for may be adjusted for the production of chips of

the ?xing of gaps of uniform width throughout uniform thickness. After the adjustment of the

between the blades and the approach plates.

members 74 and 76 to incline the approach plates

In further adverting to the adjustment unit, 64 in the manner previously explained, the slicer

15 it is pointed out that the same provides for im is swung to the position shown in Figure 1 and

parting to the approach or gauge plates 64 slight when the potatoes have been introduced into

circumferential helical twists. This makes pose the hopper, the rotor and more particularly, the

sible uniformity, in the matter of space between blades thereof will cut the potatoes into slices of

the approach plates and theassociated blades. uniform thickness. Of course, therotor is start

20 That is to say, there is made possible a uniform ed before the introduction of potatoes into the

space throughout between a particular blade and hopper. Incidentally, the hopper body 10 may

the associated approach plate from the inner to be provided with a suitable extension 96* increas

the outer d of such blade. By reason of this ing the capacity of the hopper and it will be seen

construction, vegetableslices of a uniform thick that one side. of the extension is provided with

25 ness are produced. The slices have the same an inclined inlet portion for the introduction of

thickness throughout and by reason of this a par potatoes into the hopper.

It is tobe understood that the form of inven

ticular slice will be fried or cooked. uniformly

throughout with the same degree of crispness, tion, herewith shown and described is to be taken

80

85

90

.

95

100

from edge to edge as distinguished from a slice merely as a preferred example of the same and

30 of varying thickness, crisp at one edge portion that such minor changes in arrangement and 105

and unnecessarily thick at the diametrically op

construction of parts may be made as will remain

within the spirit of the invention and the scope

Referring now to Figures 4 and 7, it will be of what is claimed.

seen that the rear portions of the adjusting

Having thus described my invention, what is

posite edge portion.

35 sleeves 74 have annular dials 80 fixed thereon and

110

1. In a vegetable slicer, a movable element hav

gers 82 in indicating the position of the several. ing a blade, a ?exible plate carriedby the niov

sleeve nuts. This'provides for the co-extensive able element in advance of said blade, an arm in

adjustment of the several sleeve nuts 'with the operative relation to said ?exible plate, a sleeve 1'

40 result that the adjustment of the rotor may be nut carried by said am and having means to en

made without the exercise of unusualskill and gage said vplate, and a cap screw extended freely

with facility. In carrying out the invention, the throughsaid sleeve nut and having threaded en

markers 82 may be positioned between the indi gagement with, said plate, said cap screw being

cating discs 80 in which case the same are 0p provided with a diametricalenlargement engag

45 positely pointed or there may be a separatemark ing a portion of said sleeve nut to lock the flexible 120

er for each dial, all of which is shown in Figure plate in an adjusted position.

4, In fact, any pointing means such as simple

2_. In a machine for slicing potatoes, a body and.

marks on the arms 70 may be employed for co a central hub, a plurality, of tilted arcuate pres

operation with the indicating discs, this being a - sure plates between. the hub and. thebody and 50 matter that is entirely optional and within the"v being of ogee formation, and a cutter rotatably 125

skill of those acquainted with this art.

mounted beneath said pressure plates and co

As previously stated, the rotor 40 is keyed on operating therewith in the formation of potato

the lower portion of the shaft 42 and in addi receiving pockets, said pressure plates being in

tion is held in place by a single set screw 86 so clined downwardly transversely from the inner to

that the rotor may be conveniently detached as the outer edges thereof.

E30

claimed is:

graduated for cooperation with markers or fin

115.

a unit.

This makes it possible to substitute a

3. In a machine of the character described, a

plain surfaced. rotor 93yas shown in Figure 9, for body and a hub within the body, and a plurality

the annularly corrugated one, shown in theother of segmental pressure plates between the body

?gures, it being apparent that the presence of the and the hub and being inclined downwardly

corrugations bring about the production of cor transversely from the inner to the outer edges 135

rugated potato chips.

thereof, said pressure plates also'being bowed

. '

When a corrugated rotor is employed, the downward in 'the direction of the circumference _

blades. and the approach plates thereof are also of the same to present convex surfaces to the po

corrugated and the pressure'exerted on the po tatoes beneath the same.

tatoes by the pressure plates 32 "will cause the

4. In a potato slicing apparatus, an annular 140

lower portions of the potatoes to take the- form body, a hub within the annular body, and a pres

of'the surface of the rotor so that upon being sure plate con?ned between the hub and the

engaged by the blades corrugated chips will body, a disk beneath said plate and cooperating

therewith and said body and the hub in the for

result.

As shown in Figures 1 and 3, an annular apron mation of an arcuate pocket adapted for the re 145

88 is suspended from the lower portion of the ception of potatoes, the space between the pres

sure plate and the disk-being diminished radially

ing outward by centrifugal force. Also, in Fig and uniformly in the direction of vthe annular

,ures l and 3, it is illustrated that suitable rein body thereby

the height of the pocket

hopper 10 to prevent the potato chips from ?y

forcing ribs 90 extend from the hub of the rotor from the inner to the outer radial side thereof.

150

1,955,360

5. In a vegetable slicer, a movable element hav

ing a blade, a ?exible plate carried by the mov

and means for imparting a slight circumferential

twist to the approach plate to space the trailing

able element and having one edge thereof adja- end of the approach plate uniformly throughout

cent to said blade, a support in operative relation from the blade.

to said ?exible plate, a sleeve nut carried by said

9. In a vegetable slicer, a rotor having a blade 80

support and having means to engage said plate, rigidly secured thereto, said rotor being provided

and a screw extended through said sleeve nut and immediately in advance of the blade with a ?exi

having threaded engagement with said plate, said ble arcuate circumferentially extending approach

screw being provided with means engaging a por plate rigidly secured to the rotor and being free

10 tion of said sleevenuu to lock the ?exible plate in at'the inner and outer peripheral edges thereof, 85

an adjusted position in pressure relation to said and means for imparting a slight circumferential

sleeve nut.

helical twist to the approach plate to uniformly

6. In a vegetable slicer, a rotor having a blade = space the trailing end of the plate from the inner

?xed thereto, said rotor being provided imme

15 diately in advance of the blade with a ?exible

to the outer end of the blade and embodying ra

dially spaced separate adjusting devices having ~ 90

arcuate approach plate secured rigidly at the operative connection with the trailing portion

leading edge thereof to the rotor and being free of said arcuate approach plate at radially spaced

at the inner and outer edges thereof, separate points, each of said adjusting devices being in

abutment elements adjacent the trailing edge of dependently adjustable for twisting the approach

plate circumferentially, there being abutment ele 95

20 the approach plate at spaced points for engage

ment by spaced portions of the approach plate, ments associated with said adjusting devices for

and locking devices securing the trailing edge pressure engagement by the trailing edge portion

portion of the approach plate in pressure engage of said arcuate approach plate.

ment with the abutment elements, said spaced

25 abutment elements being independently and se

10. In a vegetable slicer, a rotor having a blade

rigidly secured thereto, said rotor being provided 100

lectively adjustable to establish a'uniform space immediately in advance of the blade with a ?exi

throughout between the blade and the approach ble arcuate circumferentially extending approach

plate.

,

plate rigidly secured to the rotor and being free

7. In a vegetable slicer, a rotor having a blade at the inner and outer peripheral edges thereof,

rigidly secured thereto, said rotor being provided and means for imparting a slight circumferential 105

immediately in advance of the blade with a ?exi helical twist to the approach plate to uniformly

ble arcuate circumferentialy extending approach space the trailing end of the plate from the inner

plate rigidly secured to the rotor and being free at to the outer end of the blade and embodying ra

the inner and outer peripheral edges thereof, and dially spaced separate adjusting devices having

means for imparting a slight circumferential hel operative connection with the trailing portion of 110

ical twist to the approach plate to uniformly said arcuate approach plate at radially spaced

space the trailing end of the plate from the inner points, each of said adjusting devices being inde

to the outer endof the blade and , embodying pendently adjustable for twisting the approach

radially spaced separate adjusting devices having pl'ate circumferentially, there being abutment ele

40 operative connection with the trailing portion of ments associated with said adjusting devices for 115

said arcuate approach plate at radially spaced pressure engagement by the trailing edge portion

points, each of said adjusting devices being inde of said arcuate approach plate, an arm underly

pendently adjustable for twisting the approach ing said approach plate and supporting said abut

plate circumferentially.

ment elements, and cooperating members carried

454

8. In a vegetable slicer, a rotor having a blade by said arms and said abutment elements to indi 120

rigidly secured thereto, said rotor being provided cate the relative positions of the abutment ele

in advance of the blade with a ?exible arcuate ments.

circumferentially extending approach plate free

JOSEPH D. FERRY.

at the inner and outer peripheral edges thereof,

125

5.5

.130

60

135

140

145

150

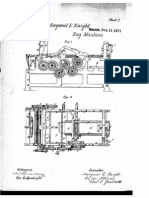

You might also like

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Us1223254 PDFDocument7 pagesUs1223254 PDFRodrigoPomaNo ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiNo ratings yet

- Aug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1Document4 pagesAug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1raseks1No ratings yet

- Cheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetDocument7 pagesCheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetmephitNo ratings yet

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Document3 pagesM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonNo ratings yet

- 19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Document5 pages19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Azri LunduNo ratings yet

- LL-LLL'LL-FLL: 31, 1940. E. C. MmleanDocument7 pagesLL-LLL'LL-FLL: 31, 1940. E. C. MmleanKrozeNo ratings yet

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Document13 pages(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNo ratings yet

- Us2765819 PDFDocument8 pagesUs2765819 PDFAzri LunduNo ratings yet

- "A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Document7 pages"A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Guillermo Avila RiveraNo ratings yet

- Coco Inven PDFDocument4 pagesCoco Inven PDFsushil-funNo ratings yet

- H. J. Smith: Potato Cutting Machine 28 Filed 00Document3 pagesH. J. Smith: Potato Cutting Machine 28 Filed 00RodrigoPomaNo ratings yet

- Jurnal Bubut FixsafasfasfDocument6 pagesJurnal Bubut FixsafasfasfAdiBimaSanjaya100% (1)

- Anti-Aircraft Fire Control Device (1937)Document10 pagesAnti-Aircraft Fire Control Device (1937)CAP History LibraryNo ratings yet

- US2128620 - Bending MachineDocument5 pagesUS2128620 - Bending MachinedevheadbotNo ratings yet

- No. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed GearingDocument4 pagesNo. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed Gearingbelchior alvaroNo ratings yet

- Patented May 27, 1919.: S. H. GarstDocument4 pagesPatented May 27, 1919.: S. H. GarstKrozeNo ratings yet

- April 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932Document8 pagesApril 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932jojaberiNo ratings yet

- United States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986Document3 pagesUnited States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986wahaha06No ratings yet

- Milliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaDocument4 pagesMilliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaOscar Lora SiñaniNo ratings yet

- US2099314Document3 pagesUS2099314Jhonnatan E Avendaño Florez100% (1)

- Vasos de PapelDocument18 pagesVasos de Papelpafredo007No ratings yet

- L'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545Document12 pagesL'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545lfilippiniNo ratings yet

- Byfwf p41 ': March 7, 1961 O. Danyluke 2,973,909Document5 pagesByfwf p41 ': March 7, 1961 O. Danyluke 2,973,909KrozeNo ratings yet

- European Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorDocument16 pagesEuropean Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorSelvaraji MuthuNo ratings yet

- 1895 - Us570025Document5 pages1895 - Us570025Enrico Bruce GioloNo ratings yet

- Unidad IV Intercambiadores de CalorDocument4 pagesUnidad IV Intercambiadores de CalorRafael CórdobaNo ratings yet

- Berthier Us1366863Document9 pagesBerthier Us1366863cll1968No ratings yet

- No. 679,020. Patented July 23, 1901.: (G) '... H."G SG 70Document3 pagesNo. 679,020. Patented July 23, 1901.: (G) '... H."G SG 70AlecsandrNo ratings yet

- United States Patent (191: Lown (45) Nov. 11, 1980Document4 pagesUnited States Patent (191: Lown (45) Nov. 11, 1980HamedJamshidiNo ratings yet

- @341 A É'Wqkammm: Filed July 28-, 1944Document3 pages@341 A É'Wqkammm: Filed July 28-, 1944devheadbotNo ratings yet

- Title - Wood Chipper ConstructionDocument4 pagesTitle - Wood Chipper Constructionمحمد عبدالدايمNo ratings yet

- July 4, 1950 E. L. Masters 2,53,810: Filed April 10, 1946 2 Sheets-SheetDocument5 pagesJuly 4, 1950 E. L. Masters 2,53,810: Filed April 10, 1946 2 Sheets-SheetVijayakumar G VNo ratings yet

- Title - Wood Chipper Disc and Knife MountingDocument5 pagesTitle - Wood Chipper Disc and Knife Mountingمحمد عبدالدايمNo ratings yet

- Us955823 PDFDocument3 pagesUs955823 PDFSashikant SharmaNo ratings yet

- 1,138,232. Patented May 4, 1915,: 0, J, McgannDocument3 pages1,138,232. Patented May 4, 1915,: 0, J, McgannVyacheslavNo ratings yet

- Sept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Document16 pagesSept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Jin SongNo ratings yet

- United States Patent (191: Swearingen (11) 4,287,758Document7 pagesUnited States Patent (191: Swearingen (11) 4,287,758NicandroGonzalesNo ratings yet

- Another Corn Dog Machine PatentDocument14 pagesAnother Corn Dog Machine PatentMinnesota Public RadioNo ratings yet

- Nov. 22, 1932. W. D. Lpps. 1888,353Document12 pagesNov. 22, 1932. W. D. Lpps. 1888,353AGUAVIVANJNo ratings yet

- Data Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateDocument3 pagesData Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateJaymar ManualNo ratings yet

- MMM-@U: H. M. SpragueDocument4 pagesMMM-@U: H. M. SpraguedjsfNo ratings yet

- June 23, 1925.: F . I: ZacherDocument3 pagesJune 23, 1925.: F . I: ZachershamsNo ratings yet

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Document7 pagesSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNo ratings yet

- W, B. Kidder. : Tree Climbing MotorDocument4 pagesW, B. Kidder. : Tree Climbing Motormonem2014No ratings yet

- Illlllllllllilllllllllilllllllllli: United States Patent (191Document3 pagesIlllllllllllilllllllllilllllllllli: United States Patent (191dgfsduuwioNo ratings yet

- Us1434007 PDFDocument5 pagesUs1434007 PDFsebastian escobarNo ratings yet

- Us 8210068us 8210068us 8210068us 8210068Document9 pagesUs 8210068us 8210068us 8210068us 8210068JameszouqunNo ratings yet

- Dec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Document8 pagesDec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Rezicky ImamNo ratings yet

- Us 4407085Document5 pagesUs 4407085rte678No ratings yet

- Us2467764 PDFDocument10 pagesUs2467764 PDFRodrigoPomaNo ratings yet

- Bottle Filler and Capper Unit: June 24, 1930. G. E. Strandt 1,766,962Document8 pagesBottle Filler and Capper Unit: June 24, 1930. G. E. Strandt 1,766,962Luis Enrique Barreto GarciaNo ratings yet

- 3/ Z7 VZMZM/ZZ : V. Holek 2,216,412Document3 pages3/ Z7 VZMZM/ZZ : V. Holek 2,216,412wererNo ratings yet

- BYY "So: June 7, 1966 M, A Brown 3,254,776Document7 pagesBYY "So: June 7, 1966 M, A Brown 3,254,776Yu YangNo ratings yet

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocument6 pagesDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNo ratings yet

- United States Patent (19) (11) 4,298,078Document9 pagesUnited States Patent (19) (11) 4,298,078lfilippiniNo ratings yet

- LM 7805 RegulatorDocument12 pagesLM 7805 RegulatorFadel BairuniNo ratings yet

- 1 ChuquisacaDocument6 pages1 ChuquisacaRodrigoPomaNo ratings yet

- Large Batch Hard Candy and LollipopsDocument2 pagesLarge Batch Hard Candy and LollipopsRodrigoPomaNo ratings yet

- Nov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedDocument7 pagesNov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedRodrigoPomaNo ratings yet

- Us 4106436Document10 pagesUs 4106436RodrigoPomaNo ratings yet

- Diagrama Bases 1Document1 pageDiagrama Bases 1RodrigoPomaNo ratings yet

- United States Patent: Dreve, Jr. (45) May 16, 1972Document6 pagesUnited States Patent: Dreve, Jr. (45) May 16, 1972RodrigoPomaNo ratings yet

- United States Patent (19) : Miiller (45) Date of PatentDocument8 pagesUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaNo ratings yet

- United States Patent: Dreve, Jr. (45) May 16, 1972Document6 pagesUnited States Patent: Dreve, Jr. (45) May 16, 1972RodrigoPomaNo ratings yet

- Us659197 PDFDocument3 pagesUs659197 PDFRodrigoPomaNo ratings yet

- Us 2296645Document4 pagesUs 2296645RodrigoPomaNo ratings yet

- Us2467764 PDFDocument10 pagesUs2467764 PDFRodrigoPomaNo ratings yet

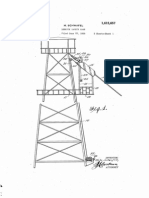

- M. Schwafel: Derrick Safety CageDocument4 pagesM. Schwafel: Derrick Safety CageRodrigoPomaNo ratings yet

- United States Patent - (191: Mayeux Et AlDocument4 pagesUnited States Patent - (191: Mayeux Et AlRodrigoPomaNo ratings yet

- June 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960Document6 pagesJune 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960RodrigoPomaNo ratings yet

- Us4589264 PDFDocument6 pagesUs4589264 PDFRodrigoPomaNo ratings yet

- United States Patent (19) : Grote Et A1Document9 pagesUnited States Patent (19) : Grote Et A1RodrigoPomaNo ratings yet

- MikroDocument5 pagesMikroAmir Si KetengNo ratings yet

- Us2678614 PDFDocument6 pagesUs2678614 PDFRodrigoPomaNo ratings yet

- Jan. 1, 1952 F, J, Uprighete 2,580,864: Ea 6-) "?? (0 JUPE/GHTDocument5 pagesJan. 1, 1952 F, J, Uprighete 2,580,864: Ea 6-) "?? (0 JUPE/GHTRodrigoPomaNo ratings yet

- Datasheet UA741CPDocument19 pagesDatasheet UA741CPlcruz_86No ratings yet

- A9 PDFDocument25 pagesA9 PDFRodrigoPomaNo ratings yet

- Us116842 PDFDocument6 pagesUs116842 PDFRodrigoPomaNo ratings yet

- Musical Intelligence: Let's Cut It Off! I Guess You Are Out of TuneDocument1 pageMusical Intelligence: Let's Cut It Off! I Guess You Are Out of TuneHenry GutierrezNo ratings yet

- MXTVXVW PDFDocument3 pagesMXTVXVW PDFRodrigoPomaNo ratings yet

- Cba The GPSDocument7 pagesCba The GPSRodrigoPomaNo ratings yet

- H. J. Smith: Potato Cutting Machine 28 Filed 00Document3 pagesH. J. Smith: Potato Cutting Machine 28 Filed 00RodrigoPomaNo ratings yet

- Auto Components 2018Document168 pagesAuto Components 2018Ankush GuptaNo ratings yet

- Bearing Load CalculationDocument8 pagesBearing Load Calculationmac_devNo ratings yet

- Wartsila RTA96C Engine Technology ReviewDocument24 pagesWartsila RTA96C Engine Technology ReviewVolodymyr SavchukNo ratings yet

- Methodology For Sag Mill InstallationDocument5 pagesMethodology For Sag Mill InstallationFranco Angelo RegenciaNo ratings yet

- Fundamentals of Engineering Tribology With Applications / Harish Hirani. - Delhi, Cop. 2016Document5 pagesFundamentals of Engineering Tribology With Applications / Harish Hirani. - Delhi, Cop. 2016Dr Junaid Hassan MasoodiNo ratings yet

- Hydraulic Breaker PDFDocument69 pagesHydraulic Breaker PDFRofie Tritho100% (1)

- Mobil Glygoyle™ 11, 22, and 30 Mobil Glygoyle™ 11, 22, and 30 Mobil Glygoyle™ 11, 22, and 30 Mobil Glygoyle™ 11, 22, and 30Document4 pagesMobil Glygoyle™ 11, 22, and 30 Mobil Glygoyle™ 11, 22, and 30 Mobil Glygoyle™ 11, 22, and 30 Mobil Glygoyle™ 11, 22, and 30EduleofNo ratings yet

- Design of A Small Scale Hulling Machine For Improved Wet Processed CoffeeDocument7 pagesDesign of A Small Scale Hulling Machine For Improved Wet Processed Coffeeblank stringNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument20 pagesNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNo ratings yet

- LNGPumps Technologies R0Document14 pagesLNGPumps Technologies R0yavor karaivanovNo ratings yet

- Motores GMDocument50 pagesMotores GMWilson Bueno100% (1)

- Case IhDocument4 pagesCase Ihchrideer100% (1)

- Model 3196 ANSI B73.1M Process Pump: Engineered Performance For Increased Plant ReliabilityDocument74 pagesModel 3196 ANSI B73.1M Process Pump: Engineered Performance For Increased Plant Reliabilityscottt_84No ratings yet

- PGP 500 Series PGM 500 Series: Single or Multiple Aluminum Pumps & MotorsDocument24 pagesPGP 500 Series PGM 500 Series: Single or Multiple Aluminum Pumps & MotorspinkoskyNo ratings yet

- Cam Clutch OperationDocument92 pagesCam Clutch OperationLlewayne FesterNo ratings yet

- Professional IndustrialproductsDocument32 pagesProfessional IndustrialproductsEscurçó NegreNo ratings yet

- Pump Vibration-Case StudiesDocument10 pagesPump Vibration-Case StudiesGyogi MitsutaNo ratings yet

- Shelf Life For Timken Cylindrical Roller BearingDocument1 pageShelf Life For Timken Cylindrical Roller BearingBosNo ratings yet

- Paper Fan PumpsDocument8 pagesPaper Fan PumpsnazeerNo ratings yet

- 98 Exciter 135 SE EXS1200Document72 pages98 Exciter 135 SE EXS1200wilsonmoto15No ratings yet

- 8-Lubricating Oil SystemDocument20 pages8-Lubricating Oil SystemMehar Tariq GoheerNo ratings yet

- Hocl ReportDocument10 pagesHocl Reportdebashish babuNo ratings yet

- Torque Tension ControlDocument5 pagesTorque Tension ControlLéia FernandesNo ratings yet

- Wastewater Treatment Plants-Part 1: General Construction PrinciplesDocument16 pagesWastewater Treatment Plants-Part 1: General Construction Principlesdaprc100% (1)

- Dme KtuDocument9 pagesDme Ktuhyy5u6No ratings yet

- ROTEXDocument77 pagesROTEXmaac1987100% (1)

- 4 1443 & 1460-1466 & 1490-1505 Maintenance Manual 600i Rev E TUG (US)Document32 pages4 1443 & 1460-1466 & 1490-1505 Maintenance Manual 600i Rev E TUG (US)Jeeva RathinamNo ratings yet

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- 250P Series Core BarrelDocument4 pages250P Series Core BarrelJuan Miguel RobledoNo ratings yet

- Parts List: KewpumpDocument11 pagesParts List: KewpumpAriel Espinoza100% (1)