Professional Documents

Culture Documents

EEMF Troubleshooting On Electrical Machines

Uploaded by

Abrar SmektwoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EEMF Troubleshooting On Electrical Machines

Uploaded by

Abrar SmektwoCopyright:

Available Formats

Troubleshooting

on

electrical machines

EEM/F

Student workbook

SH5002-3P

2nd edition

Author: Ralf Linnertz

Lucas-Nlle Lehr- und Messgerte GmbH

Siemensstrae 2 D-50170 Kerpen

Troubleshooting on electrical machines

Table of contents

Equipment

Basic experiment without fault simulator

Fault switch 2 actuated

Fault switch 5 actuated

Fault switch 11 actuated

Fault switches 1 and 4 actuated

Fault switches 3 and 6 actuated

Fault switches 4 and 5 actuated

Fault switches 5 and 8 actuated

All fault switches actuated

1

3

9

15

21

27

33

39

45

51

..............................................................................................................................................

..........................................................................................

........................................................................................................................

......................................................................................................................

....................................................................................................................

.......................................................................................................

.......................................................................................................

.......................................................................................................

.......................................................................................................

.................................................................................................................

EEM/F TABLE OF CONTENTS

Troubleshooting on electrical machines

EEM/F TABLE OF CONTENTS

Troubleshooting on electrical machines

Equipment

SE2662-9D

LM8501

SE2662-3G, SE2672-3G

SE2663-1k, SE2673-1k

SE2662-5G, SE2672-5G

SE2663-1H, SE2673-1H

EEM/F EQUIPMENT

Device

Fault simulator

Metriso C insulation tester

Three-phase motor with squirrel-cage rotor,

0.3 kW/1 kW

Quantity

1

1

1

Troubleshooting on electrical machines

EEM/F EQUIPMENT

Troubleshooting on electrical machines

Basic experiment without fault simulation

Experiment objectives

Exercises:

Measurement of winding resistance in a three-phase induction motor with squirrelcage rotor

Measurement of insulation resistance in a three-phase induction motor with squirrelcage rotor

Identification of winding and/or insulation faults

EEM/F/1 BASIC EXPERIMENT WITHOUT FAULT SIMULATION

Troubleshooting on electrical machines

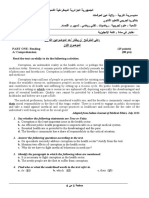

Circuit

U1

V1

W1

W2

U2

V2

Terminal panel

Screen terminal

Housing (frame)

Stator coil U

Stator coil W

Stator coil V

M

3~

Sample measurements

Winding-to-winding insulation resistance

measurement

Winding resistance measurement

U1

V1

W1

W2

U2

V2

Winding-to-housing insulation

resistance measurement

EEM/F/1 BASIC EXPERIMENT WITHOUT FAULT SIMULATION

Troubleshooting on electrical machines

Equipment/components

Three-phase induction motor with squirrel-cage rotor

Multimeter (or ohmmeter, if available)

Insulation tester

Note:

The winding resistances (coil U, coil V, coil W) of a three-phase induction motor must be

identical in order to generate a symmetrical rotating field in the stator. However, even if the

winding resistances are identical, it is still possible for insulation faults to occur (winding-towinding or winding-to-frame).

A winding-to-winding insulation fault can result in a short circuit (triggering the circuit breaker)

or overcurrent which is then shut off by the motor protection relay or a general motor

protection mechanism (NTC, PTC).

A winding-to-frame insulation fault can pose a contact hazard since a potential difference

arises between the housing or frame and earth.

In this case, it is important to install a dependable protective mechanism which disconnects

the motor from the mains when hazardous contact voltages (> 50 V) occur.

The measured winding resistances should be approximately equal to the following values:

270 (0.1 kW), 100 (0.3 kW), 20 (1 kW).

The insulation resistances must be at least 1 k/V according to VDE specifications. This

means that no insulation fault should be present as long as the winding-to-winding resistance

is at least 400k and the resistance between windings and the grounded frame or housing

is at least 230k.

EEM/F/1 BASIC EXPERIMENT WITHOUT FAULT SIMULATION

Troubleshooting on electrical machines

Measurement procedure

Select a suitable measuring instrument, measure the winding resistance for each of the coils

U, V, W and enter the values in the table provided.

Winding resistance can be measured with a universal multimeter (or an ohmmeter).

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

Coil U (U1-U2)

Coil V (V1-V2)

Coil W (W1-W2)

Select a suitable measuring instrument, measure the winding-to-winding insulation

resistance values and enter the values in the table provided.

Winding-to-winding insulation resistance can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1 V1

U1 W1

V1 W1

U2 V2

U2 W2

V2- W2

EEM/F/1 BASIC EXPERIMENT WITHOUT FAULT SIMULATION

Troubleshooting on electrical machines

Select a suitable measuring instrument, measure the insulation resistance values between

windings and the frame or housing

and enter the values in the table provided for this

purpose.

The resistance between windings and frame

can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1

V1

W1

U2

V2

W2-

EEM/F/1 BASIC EXPERIMENT WITHOUT FAULT SIMULATION

Troubleshooting on electrical machines

Fill in all the measurements on the following diagram of the motor.

What can be said about the motor windings and insulation?

EEM/F/1 BASIC EXPERIMENT WITHOUT FAULT SIMULATION

Troubleshooting on electrical machines

Fault switch 2 actuated

Experiment objectives

Exercises:

Measurement of winding resistance in a three-phase induction motor with squirrelcage rotor

Measurement of insulation resistance in a three-phase induction motor with squirrelcage rotor

Identification of winding and/or insulation faults

Open the fault simulator and actuate fault switch 2 without simulating any other faults.

Close the fault simulator again.

EEM/F/2 FAULT SWITCH 2 ACTUATED

Troubleshooting on electrical machines

Circuit

U1

V1

W1

Terminal panel

W2

U2

V2

Screen terminal

Housing (frame)

Stator coil "U"

Stator coil "W"

Stator coil "V"

M

3~

Sample measurements

Winding resistance

10

Winding-to-winding insulation resistance

measurement

U1

V1

W1

W2

U2

V2

Winding-to-frame

insulation resistance

measurement

EEM/F/2 FAULT SWITCH 2 ACTUATED

Troubleshooting on electrical machines

Equipment/components

Three-phase induction motor with squirrel-cage rotor

Multimeter (or ohmmeter, if available)

Insulation tester

Note:

The winding resistances (coil U, coil V, coil W) of a three-phase induction motor must be

identical in order to generate a symmetrical rotating field in the stator. However, even if the

winding resistances are identical, it is still possible for insulation faults to occur (winding-towinding or winding-to-frame).

A winding-to-winding insulation fault can result in a short circuit (triggering the circuit breaker)

or overcurrent which is then shut off by the motor protection relay or a general motor

protection mechanism (NTC, PTC).

A winding-to-frame insulation fault can pose a contact hazard since a potential difference

arises between the housing or frame and earth.

In this case, it is important to install a dependable protective mechanism which disconnects

the motor from the mains when hazardous contact voltages (> 50 V) occur.

The measured winding resistances should be approximately equal to the following values:

270 (0.1 kW), 100 (0.3 kW), 20 (1 kW).

The insulation resistances must be at least 1 k/V according to VDE specifications. This

means that no insulation fault should be present as long as the winding-to-winding resistance

is at least 400k and the resistance between windings and the grounded frame or housing

is at least 230k.

EEM/F/2 FAULT SWITCH 2 ACTUATED

11

Troubleshooting on electrical machines

Measurement procedure

Select a suitable measuring instrument, measure the winding resistance for each of the coils

U, V, W and enter the values in the table provided.

Winding resistance can be measured with a

___________________________________________________..

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

Coil U (U1-U2)

Coil V (V1-V2)

Coil W (W1-W2)

Select a suitable measuring instrument, measure the winding-to-winding insulation

resistance values and enter the values in the table provided.

Winding-to-winding insulation resistance can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1 V1

U1 W1

V1 W1

U2 V2

U2 W2

V2- W2

12

EEM/F/2 FAULT SWITCH 2 ACTUATED

Troubleshooting on electrical machines

Select a suitable measuring instrument, measure the insulation resistance values between

windings and the frame or housing

and enter the values in the table provided for this

purpose.

The resistance between windings and frame

can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1

V1

W1

U2

V2

W2-

EEM/F/2 FAULT SWITCH 2 ACTUATED

13

Troubleshooting on electrical machines

Fill in all the measurements on the following diagram of the motor.

What can be said about the motor windings and insulation?

14

EEM/F/2 FAULT SWITCH 2 ACTUATED

Troubleshooting on electrical machines

Fault switch 5 actuated

Experiment objectives

Exercises:

Measurement of winding resistance in a three-phase induction motor with squirrelcage rotor

Measurement of insulation resistance in a three-phase induction motor with squirrelcage rotor

Identification of winding and/or insulation faults

Open the fault simulator and actuate fault switch 5 without simulating any other faults.

Close the fault simulator again.

EEM/F/3 FAULT SWITCH 5 ACTUATED

15

Troubleshooting on electrical machines

Circuit

U1

V1

W1

W2

U2

V2

Terminal panel

Screen terminal

Housing (frame)

Stator coil "U"

Stator coil "W"

Stator coil "V"

M

3~

Sample measurements

Winding-to-winding insulation

resistance measurement

Winding resistance measurement

16

U1

V1

W1

W2

U2

V2

Winding-to-frame insulation

resistance measurement

EEM/F/3 FAULT SWITCH 5 ACTUATED

Troubleshooting on electrical machines

Equipment/components

Three-phase induction motor with squirrel-cage rotor

Multimeter (or ohmmeter, if available)

Insulation tester

Note:

The winding resistances (coil U, coil V, coil W) of a three-phase induction motor must be

identical in order to generate a symmetrical rotating field in the stator. However, even if the

winding resistances are identical, it is still possible for insulation faults to occur (winding-towinding or winding-to-frame).

A winding-to-winding insulation fault can result in a short circuit (triggering the circuit breaker)

or overcurrent which is then shut off by the motor protection relay or a general motor

protection mechanism (NTC, PTC).

A winding-to-frame insulation fault can pose a contact hazard since a potential difference

arises between the housing or frame and earth.

In this case, it is important to install a dependable protective mechanism which disconnects

the motor from the mains when hazardous contact voltages (> 50 V) occur.

The measured winding resistances should be approximately equal to the following values:

270 (0.1 kW), 100 (0.3 kW), 20 (1 kW).

The insulation resistances must be at least 1 k/V according to VDE specifications. This

means that no insulation fault should be present as long as the winding-to-winding resistance

is at least 400k and the resistance between windings and the grounded frame or housing

is at least 230k.

EEM/F/3 FAULT SWITCH 5 ACTUATED

17

Troubleshooting on electrical machines

Measurement procedure

Select a suitable measuring instrument, measure the winding resistance for each of the coils

U, V, W and enter the values in the table provided.

Winding resistance can be measured with a

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

Coil U (U1-U2)

Coil V (V1-V2)

Coil W (W1-W2)

Select a suitable measuring instrument, measure the winding-to-winding insulation

resistance values and enter the values in the table provided.

Winding-to-winding insulation resistance can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1 V1

U1 W1

V1 W1

U2 V2

U2 W2

V2- W2

18

EEM/F/3 FAULT SWITCH 5 ACTUATED

Troubleshooting on electrical machines

Select a suitable measuring instrument, measure the insulation resistance values between

windings and the frame or housing and enter the values in the table provided for this

purpose.

The resistance between windings and frame

can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1

V1

W1

U2

V2

W2-

EEM/F/3 FAULT SWITCH 5 ACTUATED

19

Troubleshooting on electrical machines

Fill in all the measurements on the following diagram of the motor.

What can be said about the motor windings and insulation?

20

EEM/F/3 FAULT SWITCH 5 ACTUATED

Troubleshooting on electrical machines

Fault switch 11 actuated

Experiment objectives

Exercises:

Measurement of winding resistance in a three-phase induction motor with squirrelcage rotor

Measurement of insulation resistance in a three-phase induction motor with squirrelcage rotor

Identification of winding and/or insulation faults

Open the fault simulator and actuate fault switch 11 without simulating any other

faults.

Close the fault simulator again.

EEM/F/4 FAULT SWITCH 11 ACTUATED

21

Troubleshooting on electrical machines

Circuit

U1

V1

W1

W2

U2

V2

Terminal panel

Screen terminal

Housing (frame)

Stator coil "U"

Stator coil "W"

Stator coil "V"

M

3~

Sample measurements

Winding-to-winding insulation

resistance measurement

Winding resistance measurement

22

U1

V1

W1

W2

U2

V2

Winding-to-frame insulation

resistance measurement

EEM/F/4 FAULT SWITCH 11 ACTUATED

Troubleshooting on electrical machines

Equipment/components

Three-phase induction motor with squirrel-cage rotor

Multimeter (or ohmmeter, if available)

Insulation tester

Note:

The winding resistances (coil U, coil V, coil W) of a three-phase induction motor must be

identical in order to generate a symmetrical rotating field in the stator. However, even if the

winding resistances are identical, it is still possible for insulation faults to occur (winding-towinding or winding-to-frame).

A winding-to-winding insulation fault can result in a short circuit (triggering the circuit breaker)

or overcurrent which is then shut off by the motor protection relay or a general motor

protection mechanism (NTC, PTC).

A winding-to-frame insulation fault can pose a contact hazard since a potential difference

arises between the housing or frame and earth.

In this case, it is important to install a dependable protective mechanism which disconnects

the motor from the mains when hazardous contact voltages (> 50 V) occur.

The measured winding resistances should be approximately equal to the following values:

270 (0.1 kW), 100 (0.3 kW), 20 (1 kW).

The insulation resistances must be at least 1 k/V according to VDE specifications. This

means that no insulation fault should be present as long as the winding-to-winding resistance

is at least 400k and the resistance between windings and the grounded frame or housing

is at least 230k.

EEM/F/4 FAULT SWITCH 11 ACTUATED

23

Troubleshooting on electrical machines

Measurement procedure

Select a suitable measuring instrument, measure the winding resistance for each of the coils

U, V, W and enter the values in the table provided.

Winding resistance can be measured with a

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

Coil U (U1-U2)

Coil V (V1-V2)

Coil W (W1-W2)

Select a suitable measuring instrument, measure the winding-to-winding insulation

resistance values and enter the values in the table provided.

Winding-to-winding insulation resistance can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1 V1

U1 W1

V1 W1

U2 V2

U2 W2

V2- W2

24

EEM/F/4 FAULT SWITCH 11 ACTUATED

Troubleshooting on electrical machines

Select a suitable measuring instrument, measure the insulation resistance values between

windings and the frame or housing

and enter the values in the table provided for this

purpose.

The resistance between windings and frame

can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1

V1

W1

U2

V2

W2-

EEM/F/4 FAULT SWITCH 11 ACTUATED

25

Troubleshooting on electrical machines

Fill in all the measurements on the following diagram of the motor.

What can be said about the motor windings and insulation?

26

EEM/F/4 FAULT SWITCH 11 ACTUATED

Troubleshooting on electrical machines

Fault switches 1 and 4 actuated

Experiment objectives

Exercises:

Measurement of winding resistance in a three-phase induction motor with squirrelcage rotor

Measurement of insulation resistance in a three-phase induction motor with squirrelcage rotor

Identification of winding and/or insulation faults

Open the fault simulator and actuate fault switches 1 and 4 without simulating any

other faults.

Close the fault simulator again.

EEM/F/5 FAULT SWITCHES 1 AND 4 ACTUATED

27

Troubleshooting on electrical machines

Circuit

U1

V1

W1

W2

U2

V2

Terminal panel

Screen terminal

Housing (frame)

Stator coil "U"

Stator coil "W"

Stator coil "V"

M

3~

Sample measurements

Winding-to-winding insulation

resistance measurement

Winding resistance measurement

28

U1

V1

W1

W2

U2

V2

Winding-to-frame insulation

resistance measurement

EEM/F/5 FAULT SWITCHES 1 AND 4 ACTUATED

Troubleshooting on electrical machines

Equipment/components

Three-phase induction motor with squirrel-cage rotor

Multimeter (or ohmmeter, if available)

Insulation tester

Note:

The winding resistances (coil U, coil V, coil W) of a three-phase induction motor must be

identical in order to generate a symmetrical rotating field in the stator. However, even if the

winding resistances are identical, it is still possible for insulation faults to occur (winding-towinding or winding-to-frame).

A winding-to-winding insulation fault can result in a short circuit (triggering the circuit breaker)

or overcurrent which is then shut off by the motor protection relay or a general motor

protection mechanism (NTC, PTC).

A winding-to-frame insulation fault can pose a contact hazard since a potential difference

arises between the housing or frame and earth.

In this case, it is important to install a dependable protective mechanism which disconnects

the motor from the mains when hazardous contact voltages (> 50 V) occur.

The measured winding resistances should be approximately equal to the following values:

270 (0.1 kW), 100 (0.3 kW), 20 (1 kW).

The insulation resistances must be at least 1 k/V according to VDE specifications. This

means that no insulation fault should be present as long as the winding-to-winding resistance

is at least 400k and the resistance between windings and the grounded frame or housing

is at least 230k.

EEM/F/5 FAULT SWITCHES 1 AND 4 ACTUATED

29

Troubleshooting on electrical machines

Measurement procedure

Select a suitable measuring instrument, measure the winding resistance for each of the coils

U, V, W and enter the values in the table provided.

Winding resistance can be measured with a

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

Coil U (U1-U2)

Coil V (V1-V2)

Coil W (W1-W2)

Select a suitable measuring instrument, measure the winding-to-winding insulation

resistance values and enter the values in the table provided.

Winding-to-winding insulation resistance can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1 V1

U1 W1

V1 W1

U2 V2

U2 W2

V2- W2

30

EEM/F/5 FAULT SWITCHES 1 AND 4 ACTUATED

Troubleshooting on electrical machines

Select a suitable measuring instrument, measure the insulation resistance values between

windings and the frame or housing

and enter the values in the table provided for this

purpose.

The resistance between windings and frame

can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1

V1

W1

U2

V2

W2-

EEM/F/5 FAULT SWITCHES 1 AND 4 ACTUATED

31

Troubleshooting on electrical machines

Fill in all the measurements on the following diagram of the motor.

What can be said about the motor windings and insulation?

32

EEM/F/5 FAULT SWITCHES 1 AND 4 ACTUATED

Troubleshooting on electrical machines

Fault switches 3 and 6 actuated

Experiment objectives

Exercises:

Measurement of winding resistance in a three-phase induction motor with squirrelcage rotor

Measurement of insulation resistance in a three-phase induction motor with squirrelcage rotor

Identification of winding and/or insulation faults

Open the fault simulator and actuate fault switches 3 and 6 without simulating any

other faults.

Close the fault simulator again.

EEM/F/6 FAULT SWITCHES 3 AND 6 ACTUATED

33

Troubleshooting on electrical machines

Circuit

U1

V1

W1

W2

U2

V2

Terminal panel

Screen terminal

Housing (frame)

Stator coil "U"

Stator coil "W"

Stator coil "V"

M

3~

Sample measurements

Winding-to-winding insulation

resistance measurement

Winding resistance measurement

34

U1

V1

W1

W2

U2

V2

Winding-to-frame insulation

resistance measurement

EEM/F/6 FAULT SWITCHES 3 AND 6 ACTUATED

Troubleshooting on electrical machines

Equipment/components

Three-phase induction motor with squirrel-cage rotor

Multimeter (or ohmmeter, if available)

Insulation tester

Note:

The winding resistances (coil U, coil V, coil W) of a three-phase induction motor must be

identical in order to generate a symmetrical rotating field in the stator. However, even if the

winding resistances are identical, it is still possible for insulation faults to occur (winding-towinding or winding-to-frame).

A winding-to-winding insulation fault can result in a short circuit (triggering the circuit breaker)

or overcurrent which is then shut off by the motor protection relay or a general motor

protection mechanism (NTC, PTC).

A winding-to-frame insulation fault can pose a contact hazard since a potential difference

arises between the housing or frame and earth.

In this case, it is important to install a dependable protective mechanism which disconnects

the motor from the mains when hazardous contact voltages (> 50 V) occur.

The measured winding resistances should be approximately equal to the following values:

270 (0.1 kW), 100 (0.3 kW), 20 (1 kW).

The insulation resistances must be at least 1 k/V according to VDE specifications. This

means that no insulation fault should be present as long as the winding-to-winding resistance

is at least 400k and the resistance between windings and the grounded frame or housing

is at least 230k.

EEM/F/6 FAULT SWITCHES 3 AND 6 ACTUATED

35

Troubleshooting on electrical machines

Measurement procedure

Select a suitable measuring instrument, measure the winding resistance for each of the coils

U, V, W and enter the values in the table provided.

Winding resistance can be measured with a

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

Coil U (U1-U2)

Coil V (V1-V2)

Coil W (W1-W2)

Select a suitable measuring instrument, measure the winding-to-winding insulation

resistance values and enter the values in the table provided.

Winding-to-winding insulation resistance can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1 V1

U1 W1

V1 W1

U2 V2

U2 W2

V2- W2

36

EEM/F/6 FAULT SWITCHES 3 AND 6 ACTUATED

Troubleshooting on electrical machines

Select a suitable measuring instrument, measure the insulation resistance values between

windings and the frame or housing

and enter the values in the table provided for this

purpose.

The resistance between windings and frame

can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1

V1

W1

U2

V2

W2-

EEM/F/6 FAULT SWITCHES 3 AND 6 ACTUATED

37

Troubleshooting on electrical machines

Fill in all the measurements on the following diagram of the motor.

What can be said about the motor windings and insulation?

38

EEM/F/6 FAULT SWITCHES 3 AND 6 ACTUATED

Troubleshooting on electrical machines

Fault switches 4 and 5 actuated

Experiment objectives

Exercises:

Measurement of winding resistance in a three-phase induction motor with squirrelcage rotor

Measurement of insulation resistance in a three-phase induction motor with squirrelcage rotor

Identification of winding and/or insulation faults

Open the fault simulator and actuate fault switches 4 and 5 without simulating any

other faults.

Close the fault simulator again.

EEM/F/7 FAULT SWITCHES 4 AND 5 ACTUATED

39

Troubleshooting on electrical machines

Circuit

U1

V1

W1

W2

U2

V2

Terminal panel

Screen terminal

Housing (frame)

Stator coil "U"

Stator coil "W"

Stator coil "V"

M

3~

Sample measurements

Winding-to-winding insulation

resistance measurement

Winding resistance measurement

40

U1

V1

W1

W2

U2

V2

Winding-to-frame insulation

resistance measurement

EEM/F/7 FAULT SWITCHES 4 AND 5 ACTUATED

Troubleshooting on electrical machines

Equipment/components

Three-phase induction motor with squirrel-cage rotor

Multimeter (or ohmmeter, if available)

Insulation tester

Note:

The winding resistances (coil U, coil V, coil W) of a three-phase induction motor must be

identical in order to generate a symmetrical rotating field in the stator. However, even if the

winding resistances are identical, it is still possible for insulation faults to occur (winding-towinding or winding-to-frame).

A winding-to-winding insulation fault can result in a short circuit (triggering the circuit breaker)

or overcurrent which is then shut off by the motor protection relay or a general motor

protection mechanism (NTC, PTC).

A winding-to-frame insulation fault can pose a contact hazard since a potential difference

arises between the housing or frame and earth.

In this case, it is important to install a dependable protective mechanism which disconnects

the motor from the mains when hazardous contact voltages (> 50 V) occur.

The measured winding resistances should be approximately equal to the following values:

270 (0.1 kW), 100 (0.3 kW), 20 (1 kW).

The insulation resistances must be at least 1 k/V according to VDE specifications. This

means that no insulation fault should be present as long as the winding-to-winding resistance

is at least 400k and the resistance between windings and the grounded frame or housing

is at least 230k.

EEM/F/7 FAULT SWITCHES 4 AND 5 ACTUATED

41

Troubleshooting on electrical machines

Measurement procedure

Select a suitable measuring instrument, measure the winding resistance for each of the coils

U, V, W and enter the values in the table provided.

Winding resistance can be measured with a

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

Coil U (U1-U2)

Coil V (V1-V2)

Coil W (W1-W2)

Select a suitable measuring instrument, measure the winding-to-winding insulation

resistance values and enter the values in the table provided.

Winding-to-winding insulation resistance can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1 V1

U1 W1

V1 W1

U2 V2

U2 W2

V2- W2

42

EEM/F/7 FAULT SWITCHES 4 AND 5 ACTUATED

Troubleshooting on electrical machines

Select a suitable measuring instrument, measure the insulation resistance values between

windings and the frame or housing

and enter the values in the table provided for this

purpose.

The resistance between windings and frame

can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1

V1

W1

U2

V2

W2-

EEM/F/7 FAULT SWITCHES 4 AND 5 ACTUATED

43

Troubleshooting on electrical machines

Fill in all the measurements on the following diagram of the motor.

What can be said about the motor windings and insulation?

44

EEM/F/7 FAULT SWITCHES 4 AND 5 ACTUATED

Troubleshooting on electrical machines

Fault switches 5 and 8 actuated

Experiment objectives

Exercises:

Measurement of winding resistance in a three-phase induction motor with squirrelcage rotor

Measurement of insulation resistance in a three-phase induction motor with squirrelcage rotor

Identification of winding and/or insulation faults

Open the fault simulator and actuate fault switches 5 and 8 without simulating any

other faults.

Close the fault simulator again.

EEM/F/8 FAULT SWITCHES 5 AND 8 ACTUATED

45

Troubleshooting on electrical machines

Circuit

U1

V1

W1

W2

U2

V2

Terminal panel

Screen terminal

Housing (frame)

Stator coil "U"

Stator coil "W"

Stator coil "V"

M

3~

Sample measurements

Winding-to-winding insulation

resistance measurement

Winding resistance measurement

46

U1

V1

W1

W2

U2

V2

Winding-to-frame insulation

resistance measurement

EEM/F/8 FAULT SWITCHES 5 AND 8 ACTUATED

Troubleshooting on electrical machines

Equipment/components

Three-phase induction motor with squirrel-cage rotor

Multimeter (or ohmmeter, if available)

Insulation tester

Note:

The winding resistances (coil U, coil V, coil W) of a three-phase induction motor must be

identical in order to generate a symmetrical rotating field in the stator. However, even if the

winding resistances are identical, it is still possible for insulation faults to occur (winding-towinding or winding-to-frame).

A winding-to-winding insulation fault can result in a short circuit (triggering the circuit breaker)

or overcurrent which is then shut off by the motor protection relay or a general motor

protection mechanism (NTC, PTC).

A winding-to-frame insulation fault can pose a contact hazard since a potential difference

arises between the housing or frame and earth.

In this case, it is important to install a dependable protective mechanism which disconnects

the motor from the mains when hazardous contact voltages (> 50 V) occur.

The measured winding resistances should be approximately equal to the following values:

270 (0.1 kW), 100 (0.3 kW), 20 (1 kW).

The insulation resistances must be at least 1 k/V according to VDE specifications. This

means that no insulation fault should be present as long as the winding-to-winding resistance

is at least 400k and the resistance between windings and the grounded frame or housing

is at least 230k.

EEM/F/8 FAULT SWITCHES 5 AND 8 ACTUATED

47

Troubleshooting on electrical machines

Measurement procedure

Select a suitable measuring instrument, measure the winding resistance for each of the coils

U, V, W and enter the values in the table provided.

Winding resistance can be measured with a

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

Coil U (U1-U2)

Coil V (V1-V2)

Coil W (W1-W2)

Select a suitable measuring instrument, measure the winding-to-winding insulation

resistance values and enter the values in the table provided.

Winding-to-winding insulation resistance can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1 V1

U1 W1

V1 W1

U2 V2

U2 W2

V2- W2

48

EEM/F/8 FAULT SWITCHES 5 AND 8 ACTUATED

Troubleshooting on electrical machines

Select a suitable measuring instrument, measure the insulation resistance values between

windings and the frame or housing

and enter the values in the table provided for this

purpose.

The resistance between windings and frame

can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1

V1

W1

U2

V2

W2-

EEM/F/8 FAULT SWITCHES 5 AND 8 ACTUATED

49

Troubleshooting on electrical machines

Fill in all the measurements on the following diagram of the motor.

What can be said about the motor windings and insulation?

50

EEM/F/8 FAULT SWITCHES 5 AND 8 ACTUATED

Troubleshooting on electrical machines

All fault switches actuated

Experiment objectives

Exercises:

Measurement of winding resistance in a three-phase induction motor with squirrelcage rotor

Measurement of insulation resistance in a three-phase induction motor with squirrelcage rotor

Identification of winding and/or insulation faults

Open the fault simulator and actuate all fault switches.

Close the fault simulator again.

EEM/F/9 ALL FAULT SWITCHES ACTUATED

51

Troubleshooting on electrical machines

Circuit

U1

V1

W1

W2

U2

V2

Terminal panel

Screen terminal

Housing (frame)

Stator coil "U"

Stator coil "W"

Stator coil "V"

M

3~

Sample measurements

Winding-to-winding insulation

resistance measurement

Winding resistance measurement

52

U1

V1

W1

W2

U2

V2

Winding-to-frame insulation

resistance measurement

EEM/F/9 ALL FAULT SWITCHES ACTUATED

Troubleshooting on electrical machines

Equipment/components

Three-phase induction motor with squirrel-cage rotor

Multimeter (or ohmmeter, if available)

Insulation tester

Note:

The winding resistances (coil U, coil V, coil W) of a three-phase induction motor must be

identical to generate a symmetric rotary field in the stator. However, even if the winding

resistances are identical, it is still possible for insulation faults to occur (winding-to-winding or

winding-to-frame).

A winding-to-winding insulation fault can result in a short circuit (triggering the circuit breaker)

or overcurrent which is then shut off by the motor protection relay or a general motor

protection mechanism (NTC, PTC).

A winding-to-frame insulation fault can pose a contact hazard since a potential difference

arises between the housing or frame and earth.

In this case, it is important to install a dependable protective mechanism which disconnects

the motor from the mains when hazardous contact voltages (> 50 V) occur.

The measured winding resistances should be approximately equal to the following values:

270 (0.1 kW), 100 (0.3 kW), 20 (1 kW).

The insulation resistances must be at least 1 k/V according to VDE specifications. This

means that no insulation fault should be present as long as the winding-to-winding resistance

is at least 400k and the resistance between windings and the grounded frame or housing

is at least 230k.

EEM/F/9 ALL FAULT SWITCHES ACTUATED

53

Troubleshooting on electrical machines

Measurement procedure

Select a suitable measuring instrument, measure the winding resistance for each of the coils

U, V, W and enter the values in the table provided.

Winding resistance can be measured with a

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

Coil U (U1-U2)

Coil V (V1-V2)

Coil W (W1-W2)

Select a suitable measuring instrument, measure the winding-to-winding insulation

resistance values and enter the values in the table provided.

Winding-to-winding insulation resistance can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1 V1

U1 W1

V1 W1

U2 V2

U2 W2

V2- W2

54

EEM/F/9 ALL FAULT SWITCHES ACTUATED

Troubleshooting on electrical machines

Select a suitable measuring instrument, measure the insulation resistance values between

windings and the frame or housing

and enter the values in the table provided for this

purpose.

The resistance between windings and frame

can be measured with an

___________________________________________________.

Resistance

Measurement

0.1 kW

0.3 kW

1 kW

U1

V1

W1

U2

V2

W2-

EEM/F/9 ALL FAULT SWITCHES ACTUATED

55

Troubleshooting on electrical machines

Fill in all the measurements on the following diagram of the motor.

What can be said about the motor windings and insulation?

56

EEM/F/9 ALL FAULT SWITCHES ACTUATED

Troubleshooting on electrical machines

Working together with you and for you:

Your personal experience and observations can contribute to improvements to this product

and the elimination of any errors. Your comments will be of considerable importance to us in

future revisions of our manuals.

We wish to thank you for your interest and your

cooperation.

Reg.: Manual

Notes:

Date:

Copyright 2007 LUCAS-NLLE GmbH. All rights reserved.

This manual is protected by copyright. All rights pertaining thereto are reserved. Any reproduction of

this document as a file or in written form be it photocopy, microfilm or any other method or conversion

into a machine-compatible language, in particular for data processing systems, without the expressed

written approval of the LUCAS-NLLE GmbH is strictly forbidden.

The one specific exception to the above is the reproduction of worksheets for students to be used

entirely within the organisation that has purchased this resource and solely for the purposes of

education. Such worksheets may be reproduced in any numbers as long as no alterations to the

content are made.

If changes have been performed in a manner which was not strictly authorised by the LUCAS-NLLE

GmbH, any product liability or warranty claims pertaining thereto are null and void.

LUCAS-NLLE Lehr- und Megerte GmbH

Address: Siemensstrae 2 D-50170 Kerpen (Sindorf)

Postal address: Postfach 11 40 D-50140 Kerpen

Tel.: 02273 / 567-0 Fax: 02273 / 567-30 E-mail: vertrieb@lucas-nuelle.com

FEEDBACK

16

Lucas-Nlle Lehr- und Megerte GmbH

Siemensstrae 2 D-50170 Kerpen-Sindorf

Telefon +49 2273 567-0 Fax +49 2273 567-30

www.lucas-nuelle.de

You might also like

- DeforestionlDocument3 pagesDeforestionlعبد الحميدNo ratings yet

- The Second Term Examination of English: A/ Comprehension: 1Document3 pagesThe Second Term Examination of English: A/ Comprehension: 1oumamaNo ratings yet

- English Project N1 Making A Job Application Booklet 2 AsDocument6 pagesEnglish Project N1 Making A Job Application Booklet 2 Askhkh100% (1)

- Dzexams 4am Anglais 422777Document5 pagesDzexams 4am Anglais 422777cheriefNo ratings yet

- Bank of Exams 2 AsDocument39 pagesBank of Exams 2 AsaissaNo ratings yet

- Level: 2 Year (M.Eco) TIMING: 1 Hour.: Read The Text Carefully Then Do The ActivitiesDocument3 pagesLevel: 2 Year (M.Eco) TIMING: 1 Hour.: Read The Text Carefully Then Do The ActivitiesLarbi Nadia100% (2)

- DZ Exams Bac Anglais 2017Document6 pagesDZ Exams Bac Anglais 2017nishanth abirNo ratings yet

- Level: 2ASLLE 2019/2020 English Exam (First Term) Time/ 2 Hours Name: SurnameDocument3 pagesLevel: 2ASLLE 2019/2020 English Exam (First Term) Time/ 2 Hours Name: Surnameamel smailiNo ratings yet

- 1AS 3rd Term Exam of EnglishDocument2 pages1AS 3rd Term Exam of English,arcis0% (1)

- Dzexams 2as Anglais As - d2 20181 375420Document4 pagesDzexams 2as Anglais As - d2 20181 375420Aniss MadridiNo ratings yet

- First Term Test: Part One: A/-Reading / Interpreting: (7pts)Document2 pagesFirst Term Test: Part One: A/-Reading / Interpreting: (7pts)sabrina's worldNo ratings yet

- 3 Sujets Science 1 Et 2Document4 pages3 Sujets Science 1 Et 2RihabSallamNo ratings yet

- 4AM 2trim EnglishDocument23 pages4AM 2trim EnglishabouishakjazairiNo ratings yet

- First Test of English: Ibrahim Secondary SchoolDocument2 pagesFirst Test of English: Ibrahim Secondary SchoolBatoul BatoulNo ratings yet

- The Algerian Democratic Republic High School: Khalifa Ben Mahmoud First English ExamDocument3 pagesThe Algerian Democratic Republic High School: Khalifa Ben Mahmoud First English Examdidia100% (2)

- The Second English Exam: Task OneDocument1 pageThe Second English Exam: Task OnekaderNo ratings yet

- BAC Exam Sample 3rd Year F.LDocument3 pagesBAC Exam Sample 3rd Year F.LAZZOUZ OMARNo ratings yet

- 1AS 1st Term Exam - Docx SCDocument2 pages1AS 1st Term Exam - Docx SC,arcis100% (1)

- 2nd Test of The Second Term 2nd Year FL Stream.Document2 pages2nd Test of The Second Term 2nd Year FL Stream.Brahim BelitNo ratings yet

- Ramadan Planner - A4 Size PDFDocument2 pagesRamadan Planner - A4 Size PDFmerveNo ratings yet

- Dzexams 1as Anglais t1 20160 14550Document2 pagesDzexams 1as Anglais t1 20160 14550Nouh NahnouhNo ratings yet

- 3 Serie 10 Exosol Aiebk Unite1Document8 pages3 Serie 10 Exosol Aiebk Unite1BECHAR WALIDNo ratings yet

- Dzexams 2as Anglais 325738Document3 pagesDzexams 2as Anglais 325738ملاذ الحب خوخةNo ratings yet

- The First Term Test 2 ASDocument2 pagesThe First Term Test 2 ASWassim Touitou100% (2)

- Project of Make Peace Groupe HinaDocument12 pagesProject of Make Peace Groupe HinaLarbi NadiaNo ratings yet

- Ahmed Zabana Secondary School - Zahana English Class 2 Year Foreign Languages Mr. Nouairi OmarDocument24 pagesAhmed Zabana Secondary School - Zahana English Class 2 Year Foreign Languages Mr. Nouairi OmarNouha Mezloug100% (1)

- DZ Exams Bac Anglais 2019Document6 pagesDZ Exams Bac Anglais 2019nishanth abirNo ratings yet

- Comments: Write A Letter To Your Friend Telling Him/her About Your Daily LifeDocument2 pagesComments: Write A Letter To Your Friend Telling Him/her About Your Daily Lifeartshot bdNo ratings yet

- 2as - Exam1 - Martin Luther KingDocument2 pages2as - Exam1 - Martin Luther Kingfouzia43fouzia43100% (1)

- Second Exam MS3 2022Document6 pagesSecond Exam MS3 2022Karima SemaiNo ratings yet

- Exam 2asDocument3 pagesExam 2asMîss SihamNo ratings yet

- No Man Is An Island (Tests & Exams)Document50 pagesNo Man Is An Island (Tests & Exams)Lylia MezNo ratings yet

- Counterfeiting Benefits Consumers Is A Mistaken Claim.: TopicDocument3 pagesCounterfeiting Benefits Consumers Is A Mistaken Claim.: TopicsamouNo ratings yet

- School: School Year: 2019 - 2020 Second Term Test Class: 4M1/ NameDocument2 pagesSchool: School Year: 2019 - 2020 Second Term Test Class: 4M1/ NameRaiane IouaflekhNo ratings yet

- 3as Autre Anglais Livre ProfDocument93 pages3as Autre Anglais Livre Profbendjillali youcef75% (16)

- مواضيع وحلول الإنجليزية أشبال الأمة 2020Document6 pagesمواضيع وحلول الإنجليزية أشبال الأمة 2020dila sailNo ratings yet

- 2as Test Unit Make Peace Nobel Peace Prize Tests 131908Document6 pages2as Test Unit Make Peace Nobel Peace Prize Tests 131908maian saja100% (1)

- 2nd Year Foreign LanguagesDocument3 pages2nd Year Foreign LanguagesDouNia DoNo ratings yet

- Lesson of Equality InequalityDocument3 pagesLesson of Equality InequalitySamira BedadNo ratings yet

- Eureka!: Profile of An InventionDocument13 pagesEureka!: Profile of An Inventiondaloulasud30100% (1)

- Second Term English Exam Read The Text Carefully Then Do The ActivitiesDocument3 pagesSecond Term English Exam Read The Text Carefully Then Do The ActivitiesSouheila BerrehailNo ratings yet

- Figurative Language ExamplesDocument6 pagesFigurative Language Examplesapi-239323495No ratings yet

- Make Peace Test 2021Document2 pagesMake Peace Test 2021Djihed100% (2)

- Adapted From InternetDocument34 pagesAdapted From InternetMé RiamNo ratings yet

- 1st Year Test 1Document4 pages1st Year Test 1nour edhohaNo ratings yet

- Diversity TestDocument2 pagesDiversity TestMourtadha bougheraraNo ratings yet

- Examen Blanc 3ASS Anglais 1er SujetDocument3 pagesExamen Blanc 3ASS Anglais 1er Sujetsalima190No ratings yet

- Dzexams 3as Anglais t1 20171 1Document6 pagesDzexams 3as Anglais t1 20171 1salima190100% (4)

- Dzexams 1as Anglais t1 20160 347603Document2 pagesDzexams 1as Anglais t1 20160 347603Nouh Nahnouh100% (2)

- Rachid Rida Achouri Level: 2 Y/ LPH Second Term Test Time: 45 MDocument3 pagesRachid Rida Achouri Level: 2 Y/ LPH Second Term Test Time: 45 Msara wilson100% (1)

- 2AM EXAMrattrapageDocument2 pages2AM EXAMrattrapageAyat FzNo ratings yet

- Unit Two. Make PeaceDocument26 pagesUnit Two. Make Peacekltm azz100% (1)

- درس الدوال اللوغاريتمية علوم رياضيةDocument6 pagesدرس الدوال اللوغاريتمية علوم رياضيةghostinoNo ratings yet

- 1AS Tests Unit OneDocument24 pages1AS Tests Unit OneWissemNo ratings yet

- Peace in English 2asDocument18 pagesPeace in English 2asMohamed YacineNo ratings yet

- Dzexams-1am-Anglais-E1-20180-756174 (11 Files Merged)Document33 pagesDzexams-1am-Anglais-E1-20180-756174 (11 Files Merged)Asma SumaNo ratings yet

- English 4am 2trim11Document2 pagesEnglish 4am 2trim11abouishakjazairiNo ratings yet

- Class: 3 LPH First Term English Test Part One: Reading: A/ Comprehension (07 PTS)Document8 pagesClass: 3 LPH First Term English Test Part One: Reading: A/ Comprehension (07 PTS)DjihedNo ratings yet

- 2nd Term Exam 2aphDocument3 pages2nd Term Exam 2aphking wail0% (1)

- 34OJWN3gb Installation and OperatingDocument16 pages34OJWN3gb Installation and OperatingluanagueNo ratings yet

- Modbus Signal Listing MCS100EDocument12 pagesModbus Signal Listing MCS100EAbrar SmektwoNo ratings yet

- Flowcom SystecDocument110 pagesFlowcom SystecAbrar SmektwoNo ratings yet

- Passive VoiceDocument3 pagesPassive VoiceAbrar SmektwoNo ratings yet

- 016 - Lewis Blackburn-Symmetrical Components For Power Systems Engineering-CRC Press (1993)Document241 pages016 - Lewis Blackburn-Symmetrical Components For Power Systems Engineering-CRC Press (1993)Abrar Smektwo100% (1)

- Dinamik ProgrammingDocument31 pagesDinamik ProgrammingAbrar SmektwoNo ratings yet

- Modul Escalator 1Document41 pagesModul Escalator 1Abrar SmektwoNo ratings yet

- Ulx2803, Ulx2804, Ulx2823, and Ulx2824: Discontinued ProductDocument10 pagesUlx2803, Ulx2804, Ulx2823, and Ulx2824: Discontinued ProductAbrar SmektwoNo ratings yet

- EEM 2 DC MachinesDocument106 pagesEEM 2 DC MachinesAbrar Smektwo50% (2)

- Pitman SolutionDocument190 pagesPitman SolutionBon Siranart50% (2)

- Case Study (Co2 Flooding)Document10 pagesCase Study (Co2 Flooding)Jessica KingNo ratings yet

- Inverse Curve Trip Time Calculation: Enter Values in White CellDocument3 pagesInverse Curve Trip Time Calculation: Enter Values in White CellVijay FxNo ratings yet

- Practical - 2: Preparation of The FixativeDocument14 pagesPractical - 2: Preparation of The FixativeIseth ISethNo ratings yet

- Setting Times of ConcreteDocument3 pagesSetting Times of ConcreteP DhanunjayaNo ratings yet

- Part 3-Chap 2 - Classification of Buildings Based On OccupanciesDocument60 pagesPart 3-Chap 2 - Classification of Buildings Based On Occupanciesfaruque65No ratings yet

- Frequency Converter English ManualDocument33 pagesFrequency Converter English Manualproduccion multipack100% (2)

- Boundary ScanDocument61 pagesBoundary ScanGéza HorváthNo ratings yet

- Burst Abdomen 3Document12 pagesBurst Abdomen 3Satvik BansalNo ratings yet

- Temposonics: Absolute, Non-Contact Position SensorsDocument23 pagesTemposonics: Absolute, Non-Contact Position Sensorssorangel_123No ratings yet

- Smith KJ Student Mathematics Handbook and Integral Table ForDocument328 pagesSmith KJ Student Mathematics Handbook and Integral Table ForStrahinja DonicNo ratings yet

- 5 160 1 PBDocument13 pages5 160 1 PBLotkomoaidone Harahu TukambaNo ratings yet

- 2019 - High Levels of Polypharmacy in RheumatoidDocument7 pages2019 - High Levels of Polypharmacy in RheumatoidGustavo ResendeNo ratings yet

- Company Profile Pt. KPT PDFDocument23 pagesCompany Profile Pt. KPT PDFfery buyaNo ratings yet

- Sperm Count EvaluationDocument3 pagesSperm Count EvaluationGarry Kin CamarilloNo ratings yet

- American Pile Driving Equipment Equipment CatalogDocument25 pagesAmerican Pile Driving Equipment Equipment CatalogW Morales100% (1)

- Bitsat Paper 5Document19 pagesBitsat Paper 5pranka5240100% (1)

- Outerstellar Self-Impose RulesDocument1 pageOuterstellar Self-Impose RulesIffu The war GodNo ratings yet

- May New 2011 NYBMA (Web)Document15 pagesMay New 2011 NYBMA (Web)Erik HooverNo ratings yet

- Proknow VersionDocument21 pagesProknow Versionapi-392523563No ratings yet

- CFD Analysis of Flow Through Compressor CascadeDocument10 pagesCFD Analysis of Flow Through Compressor CascadeKhalid KhalilNo ratings yet

- The Western and Eastern Concepts of SelfDocument3 pagesThe Western and Eastern Concepts of SelfTakumi Shawn Hinata100% (3)

- Air System Sizing Summary For NIVEL PB - Zona 1Document1 pageAir System Sizing Summary For NIVEL PB - Zona 1Roger PandoNo ratings yet

- Qa/Qc Mechanical Monthly Progress Report For June 2015: Area/System Description Status RemarksDocument1 pageQa/Qc Mechanical Monthly Progress Report For June 2015: Area/System Description Status RemarksRen SalazarNo ratings yet

- Magical ExercisesDocument5 pagesMagical ExercisesAnonymous ytxGqZNo ratings yet

- Pelton2014 Para-Equilibrium Phase DiagramsDocument7 pagesPelton2014 Para-Equilibrium Phase DiagramsAbraham Becerra AranedaNo ratings yet

- Bsi MD Ivdr Conformity Assessment Routes Booklet Uk enDocument15 pagesBsi MD Ivdr Conformity Assessment Routes Booklet Uk enGuillaumeNo ratings yet

- Diabetes in Pregnancy: Supervisor: DR Rathimalar By: DR Ashwini Arumugam & DR Laily MokhtarDocument21 pagesDiabetes in Pregnancy: Supervisor: DR Rathimalar By: DR Ashwini Arumugam & DR Laily MokhtarHarleyquinn96 DrNo ratings yet

- Ora Laboratory Manual: Section 1 Section 1Document36 pagesOra Laboratory Manual: Section 1 Section 1Ahmed IsmailNo ratings yet

- Feasibility Study On The Seaweed Kappaphycus Alvarezii Cultivation Site in Indari Waters ofDocument9 pagesFeasibility Study On The Seaweed Kappaphycus Alvarezii Cultivation Site in Indari Waters ofUsman MadubunNo ratings yet