Professional Documents

Culture Documents

Designing prestressed concrete bridge decks

Uploaded by

Prayas SubediOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Designing prestressed concrete bridge decks

Uploaded by

Prayas SubediCopyright:

Available Formats

Approach to designing prestressed concrete bridge decks

1. Define restraints.

1.

2.

3.

4.

5.

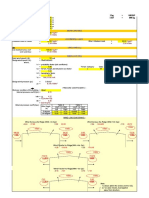

Consider obstruction being crossed span arrangement

Develop span arrangement with end spans 65~80% of main span length

Keep piers out of water if possible

If crossing roads, keep sufficient clearance to edge of carriageway

Judge convenient positions for abutments

e.g.:

30m

40m

35m

river

Approach to designing prestressed concrete bridge decks

2. Develop deck section.

1.

Consider user requirement

1.

Width of footpath?

2.

Width of roads?

3.

Parapets / safety barriers?

4.

Etc

2.

Span/depth usually about 20

(maximum 30, but this can work the structure hard and cause problems

during design)

5m

2.0m

span/20?

3. Next decide on section dimensions...

5m

Top slab,

Typically 200mm

2.0m

span/20?

Bottom Slab

150~200mm

30m cover

12mm dia bar

Webs

Prestressing duct

Minimum thickness = 30+12+12+?+12+12+30

= 108+ ?

= say 150mm min

may increase near pier if compression is too large

30m cover

20mm dia bar

12mm dia bar

Minimum thickness = 30+20+12+?+100+?+20+12+30

= 204+?+? Say = 250mm min (300mm probably better?)

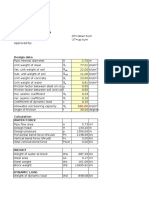

4. Next calculate section properties...

5m

2.0m

Area

I value

Depth to N-A

Ztop

Zbottom

5. Next calculate Bending Moments and Stresses in

top/bottom fibres of deck

Use frame analysis software

Hogging over pier

Sagging in mid-span

river

Dead Load

Superimposed Dead Load

Live Load (max. & Min.)

6. Make initial assumption for secondary moments:

Secondary moments in bridges is always sagging

Make initial guess based on span length

if span of 30m secondary moment probably around 5000kNm sagging

if span of 60m secondary moment probably around 20,000 kNm sagging

This is initial estimate only for initial derivation of prestress. Once prestress arrangement

chosen, the secondary moments need to be calculated and the following cycle repeated, until

actual secondary moment = assumed secondary moment

river

Sagging

5000 Kn-m???

7. Scheme up initial tendon layout

a) estimate the number of strands/tendons required at the piers and the mid-span

points (following procedure on next slide)

b) Choose prestress tendon layout to match number of strands/tendons needed

c) Prestress layout usually dependent on construction method

i) if balanced cantilever construction then cantilever and continuity tendons

ii) If build insitu, full length then full length tendons

iii) If cast span-by-span then staged prestressing to match construction

sequence

iv) etc

30m

40m

35m

5m

Tendons in top at piers

Tendons in bottom at mid-span

8. Estimate strands/tendons at each section

a) summaries Stresses (top and bottom)

b) estimate prestress from formulae below such that prestress compression > tension

from applied loads + secondary moments

c) Prestress force, P, will be the required prestress after long-term losses (assume

prestress at 60% UTS for this exercise)

E.g Top fibre stress range:

Tension

Compression

river

Dead Load

Superimposed Dead Load

Live Load

Secondary Moments

First estimate of prestress:

stress = P/A

+/-

M/z

M = Pe

P = stress / (1/A +/- e/z )

From P estimate number of cables/strands needed

9. After estimating number of strands / tendons & tendon

layout then input prestress into frame analysis as series of

equivalent loads and derive primary and secondary moments

Recheck this against secondary moments assumed earlier.

Repeat steps 7 & 8 with new secondary moments and assess

effect on the stress combinations.

If necessary, adjust number of strands/tendons so that

prestress compression > tension from applied loads

Repeat process until final stresses OK.

For bridges with internal tendons, the number of tendons and

tendon layouts are always governed by the SLS stress check

For bridges with external tendons, the ULS moments sometime

govern the required prestress layouts and quantities. In this

case, check the ULS first and scheme up on this basis.

10. Finishing off the longitudinal design

Consider actual losses in prestress (from BS5400) - derive initial prestress required

Check this against earlier assumptions of 60%UTS after long term, and if necessary

adjust prestress layout/forces until stresses are OK

Check stress levels along deck at each critical stage in structures life and if

necessary adjust prestress layout/forces until stresses are OK

Check Ultimate Moment Capacity

Check Ultimate Shear and provide reinforcement to suit

11. Also need to consider:

Temperature stresses

Differential settlement

If complex deck arrangement :

Shear lag

Distortion and torsional warping

12. Finishing off the longitudinal design

Consider details:

Anchorage of tendons

Horizontal profile of tendons

Tendon profile at anchors

Cover to tendons / anchors

Grouting tube location

13. Do not forget the transverse design!

Also bearings?

Drainage?

Expansion joints?

You might also like

- Concrete Rules of ThumbDocument8 pagesConcrete Rules of Thumbdeekchik121No ratings yet

- Pcd-Basic, C-Line-Load Balancing MethodsDocument29 pagesPcd-Basic, C-Line-Load Balancing Methodsfrancis baldonadoNo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Seismic Analysis of Water TankDocument4 pagesSeismic Analysis of Water TankhungNo ratings yet

- Steel Corbel Design Based On AISC-ASD 9th, Appendix F Design CriteriaDocument3 pagesSteel Corbel Design Based On AISC-ASD 9th, Appendix F Design CriteriaPrayas SubediNo ratings yet

- Final PDFDocument69 pagesFinal PDFKenneth CabarNo ratings yet

- Basic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandBasic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 4 out of 5 stars4/5 (4)

- Slab With OpeningDocument16 pagesSlab With OpeningTomislav Šimag100% (1)

- Understanding Loft Conversions SampleDocument18 pagesUnderstanding Loft Conversions SampleElZahraa SaidNo ratings yet

- Paving Design GuideDocument56 pagesPaving Design GuideSHERIF ABBAS100% (1)

- Post Tension BIJAN AALAMIDocument14 pagesPost Tension BIJAN AALAMIKhaled Abdelbaki50% (6)

- Selection Criteria For Lines Subject To Comprehensive Stress AnalysisDocument10 pagesSelection Criteria For Lines Subject To Comprehensive Stress AnalysisNithin Zs100% (1)

- Station KeepingDocument67 pagesStation KeepingSagar MhatreNo ratings yet

- Pipe Stress Analysis Using CAESAR IIDocument42 pagesPipe Stress Analysis Using CAESAR IIpca97100% (1)

- Type of Soil Support Zone, Z Importance Factor, IDocument7 pagesType of Soil Support Zone, Z Importance Factor, IPrayas SubediNo ratings yet

- How Do You Carry Out Estimation? Ans: 1. Input From BidDocument21 pagesHow Do You Carry Out Estimation? Ans: 1. Input From BidSunil ShaNo ratings yet

- Batching Plant Installation Schedule With Comment Rev 24september2017Document1 pageBatching Plant Installation Schedule With Comment Rev 24september2017crys suryo prayogo100% (1)

- Stress QuizDocument8 pagesStress QuizNagarjuna SeellaNo ratings yet

- PRESTRESSED GIRDER STRESSINGDocument16 pagesPRESTRESSED GIRDER STRESSINGd_ko_alam2169100% (3)

- Jib Crane Design SellDocument13 pagesJib Crane Design Selljafary100% (3)

- Design and Analysis of Corbels Using NSCP 2010 ProvisionsDocument27 pagesDesign and Analysis of Corbels Using NSCP 2010 ProvisionsChris Paulo100% (2)

- Eurocode 7 workshop design examplesDocument12 pagesEurocode 7 workshop design examplesmilan_popovic_2100% (3)

- Methodology For Stressing of PSC Girders (C)Document2 pagesMethodology For Stressing of PSC Girders (C)HegdeVenugopalNo ratings yet

- Pipe Stress Manual CalcDocument62 pagesPipe Stress Manual CalcEsapermana Riyan100% (2)

- Comarison Between Aci 440 and Fib 14 Design GuidelinesDocument10 pagesComarison Between Aci 440 and Fib 14 Design GuidelinesShuvo ShahaNo ratings yet

- Prestress Beam PDFDocument12 pagesPrestress Beam PDFramapraveengNo ratings yet

- Wind Load CalculationsDocument1 pageWind Load CalculationsPrayas SubediNo ratings yet

- Rock AnchorDocument49 pagesRock Anchorrajeshri.1664100% (10)

- RDSO Steel Bridges Technical PaperDocument314 pagesRDSO Steel Bridges Technical PaperTarun Kant Goyal100% (7)

- Expansion Loop DesignDocument61 pagesExpansion Loop DesignTauqueerAhmadNo ratings yet

- Methodology For Stressing of PSC GirdersDocument8 pagesMethodology For Stressing of PSC GirdersHegdeVenugopal100% (1)

- Rock AnchorDocument49 pagesRock Anchorpandian100% (1)

- Methodology For Stressing of PSC Girders (C)Document2 pagesMethodology For Stressing of PSC Girders (C)VB665No ratings yet

- PrestressingDocument44 pagesPrestressingPravin100% (1)

- Concretesteelcon01eddy BWDocument460 pagesConcretesteelcon01eddy BWREMACHE LEILANo ratings yet

- AASHTO PC Girder Post Tensioning MethodologyDocument16 pagesAASHTO PC Girder Post Tensioning MethodologyKiryaki FrancisNo ratings yet

- Strap footing design analysisDocument16 pagesStrap footing design analysisWaqar Ahmed75% (4)

- Astm C 393Document4 pagesAstm C 393Arash Aghagol0% (1)

- Approved Welding Procedures-Rebar Indirect Butt Joint With Splice AngleDocument8 pagesApproved Welding Procedures-Rebar Indirect Butt Joint With Splice Anglecipele12No ratings yet

- Prestressed Concrete - 1 IntroductionDocument21 pagesPrestressed Concrete - 1 Introduction4493464No ratings yet

- Circular PrestressingDocument18 pagesCircular Prestressingbemd_ali69900% (1)

- BCT573 IBS PSC Design CourseDocument17 pagesBCT573 IBS PSC Design Coursesharifah atiqahNo ratings yet

- A Critical Appraisal of The Design Construction AnDocument13 pagesA Critical Appraisal of The Design Construction Anelilta koyasNo ratings yet

- Methodology For PSC GirdersDocument5 pagesMethodology For PSC GirdersvnilNo ratings yet

- Zinq - AnalysisDocument116 pagesZinq - AnalysisAimiNo ratings yet

- Gravity Dam StabilityDocument14 pagesGravity Dam StabilityHarilal Kishan67% (3)

- MARCH 2020 AMENDMENTS TO MCHW VOLUME 1 SPECIFICATIONDocument7 pagesMARCH 2020 AMENDMENTS TO MCHW VOLUME 1 SPECIFICATIONalejandraoy9No ratings yet

- Reservoir Engineering in Modern Oilfields: Vertical, Deviated, Horizontal and Multilateral Well SystemsFrom EverandReservoir Engineering in Modern Oilfields: Vertical, Deviated, Horizontal and Multilateral Well SystemsNo ratings yet

- Beam Design ThumbruleDocument5 pagesBeam Design ThumbrulehipreyashNo ratings yet

- Engr. Warel Demaisip - Workshop No 1Document4 pagesEngr. Warel Demaisip - Workshop No 1rhonNo ratings yet

- Prestressed Concrete Structures - Design PDFDocument20 pagesPrestressed Concrete Structures - Design PDFyanickdouce1206No ratings yet

- Plate Girder Design and Failure Mode Check ProcedureDocument17 pagesPlate Girder Design and Failure Mode Check ProcedureSandeep SinghNo ratings yet

- Design of Steel StructuresDocument40 pagesDesign of Steel StructuresTan Kai XianNo ratings yet

- Transom Analysis ComparisonDocument38 pagesTransom Analysis ComparisonRifky NetriadyNo ratings yet

- 107 ConcreteDocument44 pages107 Concretenoadspls2029No ratings yet

- AssignmentDocument2 pagesAssignmentMamuye Busier YesufNo ratings yet

- Methodology of Post-Tensioning Work - Online CivilDocument3 pagesMethodology of Post-Tensioning Work - Online CivilDyeri FloresNo ratings yet

- Optimization of Prestressed Concrete Bridge DecksDocument7 pagesOptimization of Prestressed Concrete Bridge DecksParth TrivediNo ratings yet

- Refresher Exam 01Document6 pagesRefresher Exam 01Andrea MagtutoNo ratings yet

- CV301 Lab 4 Flexural Strength of Concrete 09-08-20Document5 pagesCV301 Lab 4 Flexural Strength of Concrete 09-08-20Muhammad Ali HafeezNo ratings yet

- SM Lab ManualsDocument27 pagesSM Lab ManualspraveenampilliNo ratings yet

- Prestressed Concrete Design PrinciplesDocument7 pagesPrestressed Concrete Design Principlesassis alihNo ratings yet

- Single Reinforce BeamDocument4 pagesSingle Reinforce BeamAngelica TejedoNo ratings yet

- 3 (D) Workability of Concrete - Flow Table TestDocument11 pages3 (D) Workability of Concrete - Flow Table TestFrank JohnNo ratings yet

- Answer Key 3 - Prestressed Concrete DesignDocument2 pagesAnswer Key 3 - Prestressed Concrete DesignAndro RebuyasNo ratings yet

- Determination of Strain in A Steel Bar PDFDocument8 pagesDetermination of Strain in A Steel Bar PDFEarl AradoNo ratings yet

- Construction Stage Analysis using FCM WizardDocument63 pagesConstruction Stage Analysis using FCM Wizardthanzawtun1981No ratings yet

- 1.design For Shear For Prestressed ConcreteDocument34 pages1.design For Shear For Prestressed ConcretealexNo ratings yet

- TE 1997 and 2003 Course Oct 2009Document492 pagesTE 1997 and 2003 Course Oct 2009Ajay Solate0% (1)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Spring Constant Calculation1Document3 pagesSpring Constant Calculation1DipeshNo ratings yet

- Tunnel Lenth 3500 M Tunnel Diameter Inside Area (m2) Wetted Perimeter (M)Document26 pagesTunnel Lenth 3500 M Tunnel Diameter Inside Area (m2) Wetted Perimeter (M)Prayas SubediNo ratings yet

- Diff BWT Is 800 101Document96 pagesDiff BWT Is 800 101tops123No ratings yet

- SW NewDocument1 pageSW NewPrayas SubediNo ratings yet

- Cantilever wall design parameters optimizationDocument9 pagesCantilever wall design parameters optimizationPrayas SubediNo ratings yet

- Typ RW FinishedDocument18 pagesTyp RW FinishedPrayas SubediNo ratings yet

- Stability Sheet For Various RWDocument14 pagesStability Sheet For Various RWPrayas SubediNo ratings yet

- Stability-Bulk Head Gate NewDocument1 pageStability-Bulk Head Gate NewPrayas SubediNo ratings yet

- Typ RW FinishedDocument18 pagesTyp RW FinishedPrayas SubediNo ratings yet

- T-Beam Design-BMPDocument1 pageT-Beam Design-BMPPrayas SubediNo ratings yet

- T-Beam Design-BMPDocument1 pageT-Beam Design-BMPPrayas SubediNo ratings yet

- Ses Coeff - UthpDocument4 pagesSes Coeff - UthpPrayas SubediNo ratings yet

- Chapter 6 SEISMIC DESIGN - SP-17 - 09-07Document28 pagesChapter 6 SEISMIC DESIGN - SP-17 - 09-07Prayas SubediNo ratings yet

- WEIRS Design1Document46 pagesWEIRS Design1June CruzNo ratings yet

- Feasibility Study-MoroccoDocument215 pagesFeasibility Study-MoroccoPrayas SubediNo ratings yet

- Spacing of ReinforcementDocument4 pagesSpacing of ReinforcementPrayas SubediNo ratings yet

- Stresses in Support PipeDocument20 pagesStresses in Support PipePrayas SubediNo ratings yet

- Autodesk Land Desktop 2007Document4 pagesAutodesk Land Desktop 2007Prayas SubediNo ratings yet

- Lecture Notes 12Document26 pagesLecture Notes 12tnvishNo ratings yet

- ABDocument4 pagesABPrayas Subedi100% (1)

- General Principles EQRDDocument5 pagesGeneral Principles EQRDPrayas SubediNo ratings yet

- Appendix D - Existing Conditions Bridge Assessment Report ADocument44 pagesAppendix D - Existing Conditions Bridge Assessment Report APrayas SubediNo ratings yet

- Dynamic Tests of Large Reinforcing Bar SplicesDocument185 pagesDynamic Tests of Large Reinforcing Bar SplicesPrayas SubediNo ratings yet

- 12.design Problems in Lap Welded Joints of Reinforcing Steel BarsDocument7 pages12.design Problems in Lap Welded Joints of Reinforcing Steel BarsHalil DemirNo ratings yet

- Office of The Project Manager Daily Activity & Labour ReportDocument6 pagesOffice of The Project Manager Daily Activity & Labour ReportBhupender SinghNo ratings yet

- Structural Notes for General Building ConstructionDocument1 pageStructural Notes for General Building ConstructionErika Faye CalzetaNo ratings yet

- Final Sor Katchchh 2021-22 (16.02.22)Document376 pagesFinal Sor Katchchh 2021-22 (16.02.22)Mahek GoraniNo ratings yet

- Chapter - (C) NewDocument32 pagesChapter - (C) NewMeza DhayanNo ratings yet

- Hume Pipe Culvert EstimateDocument6 pagesHume Pipe Culvert EstimateChandu NaniNo ratings yet

- Reference Panel Guidance NotesDocument22 pagesReference Panel Guidance Notesanele_amisNo ratings yet

- Concept Big Me She SengDocument204 pagesConcept Big Me She SengmulviNo ratings yet

- Applicability of API p-y Curves for Offshore Foundation AnalysisDocument28 pagesApplicability of API p-y Curves for Offshore Foundation AnalysisnsaifulNo ratings yet

- V4s44A Cement Specification StandardsDocument18 pagesV4s44A Cement Specification StandardsDilnesa EjiguNo ratings yet

- Behavior of Reinforced Concrete Beam and Composite Column JointDocument9 pagesBehavior of Reinforced Concrete Beam and Composite Column JointSaiteja PanyamNo ratings yet

- Truss and AccessoriesDocument31 pagesTruss and AccessoriesEugene ArnoldNo ratings yet

- Plan Diseño de Mezcla de CCR: Proyecto: Suministro de Agua ConstruccionDocument28 pagesPlan Diseño de Mezcla de CCR: Proyecto: Suministro de Agua ConstruccionAndre FarfanNo ratings yet

- Structure and Light Main PDFDocument14 pagesStructure and Light Main PDFŘeðiét ĂłemñehNo ratings yet

- Water Proofing BoqDocument4 pagesWater Proofing Boqravi1214No ratings yet

- Nondestructive Testing for Bridge EvaluationDocument11 pagesNondestructive Testing for Bridge EvaluationMichael MatshonaNo ratings yet

- Statically Indeterminate Beams Differential EquationsDocument10 pagesStatically Indeterminate Beams Differential EquationsRafael Sánchez CrespoNo ratings yet

- Brick Masonry Material Properties GuideDocument10 pagesBrick Masonry Material Properties GuideRoy H Mayo JrNo ratings yet

- 22FI0002 Construction Schedule, S-Curve, Manpower & Eqpt Sched - R1Document29 pages22FI0002 Construction Schedule, S-Curve, Manpower & Eqpt Sched - R1Dennis SagaoNo ratings yet