Professional Documents

Culture Documents

Pump Room Method Statement

Uploaded by

SiroCivilCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pump Room Method Statement

Uploaded by

SiroCivilCopyright:

Available Formats

JOB METHOD STATEMENT

PROJECT TITLE : KARIANGAU CFSPP 2 X 15 MW

CONTRACT NO:

LOCATION / FACILITY : WATER PUMP ROOM

DATE :

NAME OF CLIENT : PT KARIANGAU POWER

NAME OF SUBCONTRACTOR (S) : PT DUTA JASA KONSTRUKSI

JOB / ACTIVITIY :

S.

No

ACTIVITY

PREPARATION

FOR

INSTALLATION

EQUIPMENTS /

TOOLS

REQUIRED

SAFETY

PRECAUTIONS

WORK

SEQUENCE

PROCEDURE

1. Cleaning location area project

2. Preparation equipment scaffolding, jack hammer and stampping

3. Preparation material wooden, plywood, and rebar

1.

2.

3.

4.

5.

6.

7.

1.

2.

3.

4.

5.

1.

2.

3.

4.

REMARKS

DETAIL WORK

SECOND

Scaffolding

Body harness

Helmet

Ear plug

Safety shoes

Welding visor and face shield

Concrete vibrator

Perform safety talk before doing the work

Using of body harnes for working

Use a welding visor if required in the welding work

Use of safety shoes to avoid because of the nails and slippery

conditions

To work the chipping of the concrete piles have to use ear plugs

Chipping of concrete pile

leveling and compacting the soil before lean concrete

Instalation of rebar and form work column and beam concrete work

be done before casting

Casting work using a hanging bucket on a crane 50 T

DETAILED WORK SEQUENCE

PT AE MATERIAL HANDLING SYSTEMS

Ref: AE-JMS-001

Page 1 of 5

JOB METHOD STATEMENT

PROJECT TITLE : KARIANGAU CFSPP 2 X 15 MW

LOCATION / FACILITY : WATER PUMP ROOM

CONTRACT NO:

DATE :

NAME OF CLIENT : PT KARIANGAU POWER

NAME OF SUBCONTRACTOR (S) : PT DUTA JASA KONSTRUKSI

JOB / ACTIVITIY :

SHIPMENT

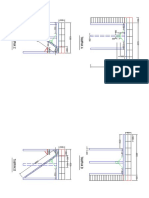

1. Concrete Slab Work :

Work was carried out after completion of work the concrete slab and

then proceed with the installation of rebar before work casting.

Implementation should use a vibrator to avoid a honey comb on the

concrete slab

2. Concrete Wall Work :

The first work is done prior to installation of scaffolding and working

steel rebar form work wall.

Second step after the completion of the working is the installation of

scafolding that serves as a peri formwork beam support of the wall

Assembly of steel rebar beams carried on top of the column, so do

safety by using a body harness in doing the steel rebar working on

the turbine installation to prevent falls from height at the location of

the wall

Implementation of the wall molding using a hanging concrete bucket

to a crane of capacity 50 ton.

3. Concrete Top Slab Work :

Demolish of formwork done before the pump room wall installation

work scaffolding.

Installation of scaffolding to work on the support of timber formwork

concrete top slab.

Implementation of the wall molding using a hanging concrete bucket

to a crane of capacity 50 ton.

PT AE MATERIAL HANDLING SYSTEMS

Ref: AE-JMS-001

Page 2 of 5

JOB METHOD STATEMENT

PROJECT TITLE : KARIANGAU CFSPP 2 X 15 MW

LOCATION / FACILITY : WATER PUMP ROOM

CONTRACT NO:

DATE :

NAME OF CLIENT : PT KARIANGAU POWER

NAME OF SUBCONTRACTOR (S) : PT DUTA JASA KONSTRUKSI

JOB / ACTIVITIY :

PT AE MATERIAL HANDLING SYSTEMS

Ref: AE-JMS-001

Page 3 of 5

JOB METHOD STATEMENT

PROJECT TITLE : KARIANGAU CFSPP 2 X 15 MW

LOCATION / FACILITY : WATER PUMP ROOM

CONTRACT NO:

DATE :

NAME OF CLIENT : PT KARIANGAU POWER

NAME OF SUBCONTRACTOR (S) : PT DUTA JASA KONSTRUKSI

JOB / ACTIVITIY :

PT AE MATERIAL HANDLING SYSTEMS

Ref: AE-JMS-001

Page 4 of 5

JOB METHOD STATEMENT

PROJECT TITLE : KARIANGAU CFSPP 2 X 15 MW

CONTRACT NO:

LOCATION / FACILITY : WATER PUMP ROOM

DATE :

NAME OF CLIENT : PT KARIANGAU POWER

NAME OF SUBCONTRACTOR (S) : PT DUTA JASA KONSTRUKSI

JOB / ACTIVITIY :

Prepared By: PT AE MHS

Reviewed By : PT AE MHS

Approved By :

Signature

Signature

Signature

Name

Name

Name

Date

Date

Date

Reviewed By :

Signature

Name

Date

Reviewed By :

Signature

Name

Date

Reviewed By :

Signature

Name

Date

PT AE MATERIAL HANDLING SYSTEMS

Ref: AE-JMS-001

Page 5 of 5

You might also like

- Method Statement - Crack Control Joint For CCB RC WallDocument7 pagesMethod Statement - Crack Control Joint For CCB RC WallReza RosenoNo ratings yet

- Method Statement For Excavation & BackfillingDocument5 pagesMethod Statement For Excavation & BackfillingPaul LadjarNo ratings yet

- Method Statement (PAIP 400)Document4 pagesMethod Statement (PAIP 400)Shafiq MustapaNo ratings yet

- Method Statement ClearingDocument5 pagesMethod Statement Clearingqoci5koNo ratings yet

- Earth Work Method StatementDocument5 pagesEarth Work Method StatementToyEn MEgat100% (1)

- Method Statement For Concrete Works (Rev.01)Document12 pagesMethod Statement For Concrete Works (Rev.01)EmadHassan0% (1)

- Caisson Method Statement For Pipe JackingDocument2 pagesCaisson Method Statement For Pipe JackingTeddy TP100% (1)

- Method Statement For Stone WorksDocument10 pagesMethod Statement For Stone WorksvisanuNo ratings yet

- Construction of Dormitory & Housing compounds in NorochcholaiDocument33 pagesConstruction of Dormitory & Housing compounds in Norochcholaisaranga100% (1)

- Road and Pedestrian Work Method StatementDocument4 pagesRoad and Pedestrian Work Method StatementND100% (1)

- Ground Improvement Method StatementDocument7 pagesGround Improvement Method StatementMAYMODERN STEELNo ratings yet

- Method Statement For Roadway EmbankmentDocument6 pagesMethod Statement For Roadway EmbankmentFlavio Jose MuhaleNo ratings yet

- EXCAVATION METHOD STATEMENT FOR HIGHLANDS HIGHWAY REHABILITATIONDocument9 pagesEXCAVATION METHOD STATEMENT FOR HIGHLANDS HIGHWAY REHABILITATION施智捷100% (1)

- Method of Statement For R.C Piling WorkDocument10 pagesMethod of Statement For R.C Piling WorkMacgjoyner SaLauNo ratings yet

- 17 Kerb MethodologyDocument2 pages17 Kerb MethodologyAnish Panchal100% (2)

- Method of Statement For Core Drilling WorksDocument7 pagesMethod of Statement For Core Drilling WorksUgurNo ratings yet

- Method Statement: Emergency Contact DetailsDocument9 pagesMethod Statement: Emergency Contact DetailsShazwaniNo ratings yet

- MS FOR INSTALLATION OF TOWER CRANE BETOX-200 Rev 1Document5 pagesMS FOR INSTALLATION OF TOWER CRANE BETOX-200 Rev 1sattiNo ratings yet

- Surface GI Conduit Installation Method StatementDocument4 pagesSurface GI Conduit Installation Method StatementJaneNo ratings yet

- P610 Beinn Eagagach Hydroelectric Scheme Construction MethodDocument14 pagesP610 Beinn Eagagach Hydroelectric Scheme Construction MethoddjgiumixNo ratings yet

- Method Statement - DEMOLITION BUILDING - FENCINGDocument7 pagesMethod Statement - DEMOLITION BUILDING - FENCINGprisma integratedNo ratings yet

- Construction of new gantry sign at KM 399.9 North South HighwayDocument15 pagesConstruction of new gantry sign at KM 399.9 North South HighwayAmirul AkmalNo ratings yet

- Method Statement FOR Acoustic Ceiling TilesDocument12 pagesMethod Statement FOR Acoustic Ceiling Tilesraks07010% (1)

- Method StatementDocument12 pagesMethod Statementfelix sowah-laryeaNo ratings yet

- Method Statement For Trial LoadingDocument5 pagesMethod Statement For Trial LoadingPunithan PunithanNo ratings yet

- Method Statement For Cmu Block WorkDocument8 pagesMethod Statement For Cmu Block WorkAnwar MohiuddinNo ratings yet

- Excavation and Pile Cutting Method StatementDocument7 pagesExcavation and Pile Cutting Method StatementMohammad Arif RasheedNo ratings yet

- Excavation Method StatementDocument6 pagesExcavation Method StatementWaleed SalihNo ratings yet

- Installation of Plumbing and Sanitary System at Bunut SubstationDocument4 pagesInstallation of Plumbing and Sanitary System at Bunut SubstationKAKANo ratings yet

- Chain-link Fence Construction MethodologyDocument8 pagesChain-link Fence Construction MethodologyIrene Ionie Rarangol - TengcoNo ratings yet

- Method Statement For The Installation of MCC RoofDocument1 pageMethod Statement For The Installation of MCC RoofAmb Patrick OghateNo ratings yet

- Method Statement For Trial Pit ExcavationDocument4 pagesMethod Statement For Trial Pit ExcavationCwazy MarooyNo ratings yet

- 1701-Drainage Method StatementDocument3 pages1701-Drainage Method StatementMisz_10_ScorpioNo ratings yet

- Method Statement For Excavating Additional 3m Deep Trial Pits (2013!08!13)Document16 pagesMethod Statement For Excavating Additional 3m Deep Trial Pits (2013!08!13)Gary Lo0% (2)

- Method Statement Water StorageDocument2 pagesMethod Statement Water StorageAzmi Fauzi100% (5)

- Construction Method for Pump Station - معدلDocument36 pagesConstruction Method for Pump Station - معدلM.ZEKEBA100% (1)

- Method Statement for Excavation WorksDocument12 pagesMethod Statement for Excavation WorksBasem DoniaNo ratings yet

- MS-G-003 - General Method Statement For Horizontal PumpDocument19 pagesMS-G-003 - General Method Statement For Horizontal PumpNGUYEN VINHNo ratings yet

- MOS DrainageDocument16 pagesMOS DrainageMohammad Hadoumi Saldan100% (1)

- Methodology of Earth WorksDocument8 pagesMethodology of Earth WorksMartinNo ratings yet

- Multiplex Vertical Structures Method StatementDocument7 pagesMultiplex Vertical Structures Method StatementAdel SaqqaNo ratings yet

- Method Statement For Earthwork Cutting and FillingDocument8 pagesMethod Statement For Earthwork Cutting and FillingABDO ALLIANo ratings yet

- Method Statement For Roof FinishingDocument6 pagesMethod Statement For Roof FinishingEmadHassanNo ratings yet

- QCS 2010 Section 3 Part 3 Pits and TrenchesDocument4 pagesQCS 2010 Section 3 Part 3 Pits and Trenchesbryanpastor106No ratings yet

- Draft MOS For Cable LayingDocument8 pagesDraft MOS For Cable LayingHtun SoeNo ratings yet

- Method Statement Steel Structure 1 4 Meg PDFDocument26 pagesMethod Statement Steel Structure 1 4 Meg PDFemeka2012No ratings yet

- Roof Truss InstallationDocument8 pagesRoof Truss InstallationSai Shankar LakshminarayananNo ratings yet

- Method Statement For Office Container and Equipment Mobilization RGDocument12 pagesMethod Statement For Office Container and Equipment Mobilization RGFurqan Afzal100% (1)

- Fencing Method StatementDocument6 pagesFencing Method StatementMuhammad Zaimmuddin0% (1)

- Method Statement For Installation SS PipesDocument14 pagesMethod Statement For Installation SS PipesJayakrishnan RadhakrishnanNo ratings yet

- Concreting MethodologyDocument2 pagesConcreting Methodologyervnglen08No ratings yet

- Method of Statement - Drainage WorksDocument6 pagesMethod of Statement - Drainage Worksainamin77No ratings yet

- Method Statement For Water Rec WorksDocument3 pagesMethod Statement For Water Rec WorksKAKA100% (1)

- Method Statement of WorksDocument24 pagesMethod Statement of WorksTuan Le100% (1)

- 065 Method Statement For Construction of Access BridgeDocument12 pages065 Method Statement For Construction of Access BridgeaflalNo ratings yet

- Method Statement FOR Embedded Conduits, Boxes and Fittings InstallationDocument6 pagesMethod Statement FOR Embedded Conduits, Boxes and Fittings InstallationWalidNo ratings yet

- Turbine Method StatementDocument5 pagesTurbine Method StatementSiroCivil0% (1)

- PML-D-C-50121-1 - Method of Satement Procedure For Seal Pit Work - Update Nov. 11 2014Document37 pagesPML-D-C-50121-1 - Method of Satement Procedure For Seal Pit Work - Update Nov. 11 2014Abdullah Mukhul Jihad100% (1)

- CT2 AssignmentDocument16 pagesCT2 AssignmentCHI YAN KONGNo ratings yet

- Lifting Sequence Boiler Steel StructureDocument18 pagesLifting Sequence Boiler Steel StructureXwerty BoxNo ratings yet

- Batching Plant Drawing Model 2Document1 pageBatching Plant Drawing Model 2SiroCivilNo ratings yet

- Batching Plant Drawing Model 2Document1 pageBatching Plant Drawing Model 2SiroCivilNo ratings yet

- Batching Plant Drawing Model 1Document1 pageBatching Plant Drawing Model 1SiroCivilNo ratings yet

- Pipe Rack Foundation DocumentsDocument3 pagesPipe Rack Foundation DocumentsSiroCivilNo ratings yet

- Turbine Method StatementDocument5 pagesTurbine Method StatementSiroCivil0% (1)

- Mix Design 1 m3 Adukan Beton: Semen: 200 KG Pasir/Aggregat Halus: 1036.8 KG Aggregate Kasar: 1537.92 KG Air: 96 KGDocument1 pageMix Design 1 m3 Adukan Beton: Semen: 200 KG Pasir/Aggregat Halus: 1036.8 KG Aggregate Kasar: 1537.92 KG Air: 96 KGSiroCivilNo ratings yet

- Revenue and Support CenterDocument3 pagesRevenue and Support CenterEphraim Boadu0% (1)

- SAP SD Certification Exam Syllabus - ERPPrepDocument4 pagesSAP SD Certification Exam Syllabus - ERPPrepfiestamix0% (1)

- Rancang Bangun Set Eksperimen Gerak Harmonis Sederhana: Jurnal Aplikasi Fisika Nomor 3 Oktober 2017Document8 pagesRancang Bangun Set Eksperimen Gerak Harmonis Sederhana: Jurnal Aplikasi Fisika Nomor 3 Oktober 2017fapriliaNo ratings yet

- Wealth Management A Comparison of Switzerland, Singapore, and Hong KongDocument9 pagesWealth Management A Comparison of Switzerland, Singapore, and Hong Kongdavoud rezaeiNo ratings yet

- 5G Automation Network Slicing SB1Document3 pages5G Automation Network Slicing SB1Sebastian WawrzyniakNo ratings yet

- 02.3 Crop Establishment - Mechanized TransplantingDocument70 pages02.3 Crop Establishment - Mechanized TransplantingRexie GuillermoNo ratings yet

- Specpro A01 MidtermsDocument5 pagesSpecpro A01 MidtermsEmmanuel YrreverreNo ratings yet

- Circuit HealthDocument46 pagesCircuit HealthprakharNo ratings yet

- Children Where Is It-Kids Word MatchDocument4 pagesChildren Where Is It-Kids Word MatchAnish Chintalgattu (804AniChin)No ratings yet

- RPG Cables Company Profile and Technical CatalogueDocument32 pagesRPG Cables Company Profile and Technical CatalogueKvj SrinivasaraoNo ratings yet

- IBM's Evolution in Invention, Patenting and CommercializationDocument6 pagesIBM's Evolution in Invention, Patenting and CommercializationmokeNo ratings yet

- Pending Requirement Letter - UL201919178230Document1 pagePending Requirement Letter - UL201919178230nadiaNo ratings yet

- MPC Thermostats enDocument37 pagesMPC Thermostats enfuty_889107No ratings yet

- Inbounderz India Digital Marketing Agency ProfileDocument23 pagesInbounderz India Digital Marketing Agency Profilesubham swabhimanNo ratings yet

- Sotero 5quiz! InventoryDocument2 pagesSotero 5quiz! Inventorybernadette soteroNo ratings yet

- DocumentDocument5 pagesDocumentQuý PtitNo ratings yet

- 1 s2.0 S1319016421000414 MainDocument8 pages1 s2.0 S1319016421000414 MainMohamedikbal MerzouguiNo ratings yet

- Pirenne, Henri. (1925) - "City Origins" and Cities and European Civilization"Document8 pagesPirenne, Henri. (1925) - "City Origins" and Cities and European Civilization"Elif ArpaNo ratings yet

- Bukti Grand Inna Daira Palembang 2Document2 pagesBukti Grand Inna Daira Palembang 2Richa Fera YulianaNo ratings yet

- Fire Fighting and Use of Fire ExtinguisherDocument23 pagesFire Fighting and Use of Fire ExtinguisherAvinash ShindeNo ratings yet

- Chatroom Using Python Project ReportDocument3 pagesChatroom Using Python Project ReportAyush Kagane100% (2)

- Interior Design: An Introduction to False CeilingsDocument9 pagesInterior Design: An Introduction to False CeilingsNilesh ThanviNo ratings yet

- Propagation Models: Okumura-Hata & Walfisch-Ikegami MethodsDocument6 pagesPropagation Models: Okumura-Hata & Walfisch-Ikegami MethodsPunit SharmaNo ratings yet

- Pragati ITDocument3 pagesPragati ITSagar Prakash PatilNo ratings yet

- Miniprof: Technical ReferenceDocument33 pagesMiniprof: Technical ReferenceYacoub CheikhNo ratings yet

- 5s Housekeeping Observations Checklist: Sort Distinguished Between What Is Needed and What Is Not NeededDocument2 pages5s Housekeeping Observations Checklist: Sort Distinguished Between What Is Needed and What Is Not Neededsaeed ahmedNo ratings yet

- Define WorkDocument26 pagesDefine Workcarlos juarezNo ratings yet

- PKL Welding Qualification ProcedureDocument8 pagesPKL Welding Qualification ProcedureDeri Agung WicaksonoNo ratings yet

- Effect of Different Wax PatternDocument9 pagesEffect of Different Wax PatternMd Ibrahim KhalilNo ratings yet