Professional Documents

Culture Documents

EXP 7 Body

Uploaded by

Jeremias John KarloOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EXP 7 Body

Uploaded by

Jeremias John KarloCopyright:

Available Formats

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

EXPERIMENT 7

CALIBRATION OF WATER TANK AND WATER METER

OBJECTIVES:

To be able to compare the volume of the water by measurement and by weight.

To be able to exercise and enhance knowledge on measuring and computing

pressure including its relation with the other parameters such as height density

and gravitational acceleration guided by the equation P=.

To learn how to read the readings on the water meter.

THEORY/HYPOTHESIS:

Volume tank for liquids ranges in sizes from the large cylindrical steel tanks

holding several thousand gallons down to the calibrated cubic-foot bottles and the

chemists burettes and graduates. Many types of gages and devices are used to

indicate the liquid level, such as floats, linkages, gage-glass scales, and hook gages.

Physical tank calibration or wet calibrating involves the measuring of the actual

volumetric capacity of the vessel. This measurement must be precisely correlated to

depth so that a pressure/depth/volume table can be generated for the specific tank

geometry.

A weighted-water calibration is usually the most accurate, and this is done by

introducing water into the tank to be calibrated in carefully weighted amounts, observing

the water temperature. Critical to this procedure is the accuracy of the measuring

devices employed. A precision volume container or calibrator (calibration can) is

recommended. This volume measure should be certified and traceable to NIST

(formerly NBS) standards or through state bureau of weights and measures (USA).

The volume of most liquids, including water, is dynamic with temperature. Since

the objective of the calibration procedure is to determine a precise volume profile of the

tank, volume must be standardized to temperature; this requires a fairly accurate

temperature measurement of the water being used in the calibration process.

Temperature should be measured both at the beginning and at the end of the process.

Cool water (40-60F) is best used in calibration, never use hot water for a tank

calibration.

Measurements of fluid-flow quantities, both rates and velocities, are frequently

required in engineering. Many methods are available for such measurements, and the

engineer should know the advantages and limitations of several common methods. A

flow meter can also be used for tank calibrations. However, it should be noted that flow

meters are most accurate when flow rates remain relatively constant. In some

instances, a throttling valve should be employed to help maintain this constant flow rate.

Flow-measuring devices generally fall into one of two categories: quantity meters

and rate meters. The distinction between the two is based on the character of the

primary element, i.e., the element that interacts with the fluid. The secondary element

translates the interaction into numbers and indicates or records the values. Quantity

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

measurements, by mass or volume, are usually accomplished by counting successive

isolated portions, whereas rate measurements are inferred from the effects of flow rate

on pressure, force, heat transfer, flow area, etc. it is frequently possible to obtain the

rate of flow from a quantity meter by a suitable choice of the secondary element.

Orifices, nozzles, and venturis are by far the most common flowmeters for use in

closed conduits. The measured differential pressure results from a conversion between

static and velocity pressure, for the most part, and can be calculated by the steady-flow

energy equation.

For ease of analysis, the fluid properties, system geometry, and flow

characteristics are simplified by assumption and the actual deviations are accounted for

with correction factors. In particular, the fluid is assumed to be incompressible (constant

density); the flow area upstream from the metering element is assumed to be large

enough so that the velocity is negligible; the effect of elevation changes are assumed to

be negligible; and the flow is assumed to be steady, one-dimensional (uniform velocity

profiles, adiabatic, and to have no shaft work exchange with its surroundings.

Figure 1: Sample Set up

The following equations may be used in this experiment:

m

1.

Mass Density of water, w w

Vw

2.

Weight Density or Specific Weight of water, w

Ww

Vw

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

3.

Specific Volume of water, w

Vw

, (can also be determined from the steam table

mw

using the temperature.

LIST OF APPARATUS

1. Water tank / drum Used for

storing water and other related

liquid.

2. Platform Balance - a platform

balance is a form of equal-arm

balance in which two flat

platforms are attached to the top

side of the beam, one at each

end. The weight of an object is

found using the equilibrium of

forces.

3. Set of Counter Weights- A

counterweight is an equivalent

counterbalancing weight that

balances a load. Counterweights

are often used in traction lifts

(elevators), cranes and funfair

rides.

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

4. Water Meter- Used for measuring

the

volume

of

water

flowing

across a specific fluid flow path.

5. Steel Tape/Meter Stick- A meter

stick is a large ruler used for

measuring size or distance using

the metric scale.

PROCEDURE

Volume Measurement

1. Measure the tare weight of the steel drum as well as its diameter and height.

2. Get the initial reading of the water meter connected from the water supply line.

3. For trial 1, fill up the drum at a certain level and get the final reading of the

water meter.

4. Measure the height of water inside the drum and get the weight using the

platform balance.

5. Calculate the volume by measurement and volume by weight and compare

them with that of the water meter reading.

6. For trial 2, repeat the procedure no. 2 and add water to the drum up to the

desired second level.

7. Obtain the final reading of the water meter.

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

8. For the rest of the trials, repeat the above procedures as indicated in the data

sheet.

SET-UP OF APPARATUS

A. Determination of Volume by Water Meter

The volume of water was set to 36L by recording the initial reading on the meter.

The flow of water was stopped when the difference between the final and initial reading

is already 36.

B. Determination of Volume by Weight

The weight of the tank was first recorded. The volume of water was computed by

dividing its mass by its density.

C. Determination of Volume by Measurement

The diameter of the tank and height of the water at a reference point were

recorded. The volume of the water in the tank was computed using these dimensions.

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

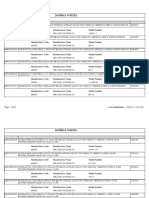

FINAL DATA SHEET

By Meter

By Weight

By Measurement

TRIAL

I.R

F.R

Volume(L)

I.R

F.R

Volume(L)

% Difference

I.R

F.R

Volume(L)

% Difference

525

561

36

17.2

52.8

33.1

8.06

0.13

32.6

9.44

561

597

36

52.8

86.6

33.8

6.11

0.13

0.265

33.84

597

633

36

86.6

119.8

33.2

7.78

0.265

0.4

33.85

5.97

633

669

36

119.8

156.6

36.8

2.22

0.4

0.535

33.84

669

705

36

156.6

191.4

34.8

3.33

0.535

0.675

35.11

2.47

Tare Weight = __17.2 kg___

Tank Calibration:

1 inch = 6.37 L

1 cm = 2.52 L

1 inch = 6.37 kg

1 cm = 2.52 kg

Diameter of Drum = __0.565 m__

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

SAMPLE COMPUTATION:

BY METER (TRIAL 1):

=

= 561 525

=

BY WEIGHT (TRIAL 1):

Volume

=

= 52.8 17.2 = 33.1

=

33.1

1

= .

Percent Difference

=

36 33.1

100% =

100 % = . %

36

BY MEASUREMENT (TRIAL 1):

Volume

=

(0.565)2

2

1000

(0.13 ) (

) = .

= =

4

4

3

Percent Difference

=

36 32.6

100% =

100 % = . %

36

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

CALIBRATION

1 inch

2.54

1000kg

2

) = .

= = = (0.565)2 (1 ) ( 100 ) (

4

4

1

m3

BUT: 1 kg water = 1 L water

6.37 kg = .

1 cm

= =

1

1000kg

)(

) = . = .

= (0.565)2 (1 ) (

4

4

100

m3

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

TEST DATA ANALYSIS

37

36

36

36

36

36

35.8

35.11

34.8

35

34

33

36

33.8

33.84

33.85

33.84

Actual (L)

By Weight (L)

33.2

33.1

By Measurement (L)

32.6

32

31

30

Trial 1

Trial 2

Trial 3

Trial 4

Trial 5

The chart above shows the results for the measurement of the volume of water

added on the water tank per trial. The blue line shows the actual reading of the water

meter (which is 36L per trial). The orange line shows the measured volume using the

change in weight of the water drum and the gray line portrays the result using the

change in height. According to the data, all of the data found in each trial has a lower

result as compared to the actual value. This can be due to the error that the group didnt

consider the water left on the hose when the water is being poured to the tank. Also,

another possibility is that the meter itself can be inaccurate. This can be proven by the

fact that the data gathered for both measurement by weight and height are almost the

same per trial.

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

The figure above shows the computed calibration for the given water tank in the

institute. This implies that per 1 inch change in height of water level, the tank gains 6.37

L and per 1 cm increase in water level, there is an increase of 2.52 L of water in the

tank. For water, 1L = 1 kg, therefore, the calibration is the same.

10

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

DISCUSSION

The experiment is all about calibration of water tanks through measurement of volume

of tanks. This experiment employed the use of various methods in volume

measurement. These methods include measurement of volume by the use of water

meter, measurement of volume by weighing water sample and measurement of volume

of the container. Moreover, we compared and contrast the validity and accuracy of the

yield results of each method.

Initially, we measured the basic dimensions of the tank. We measure the

diameter and then the height of the tank. We place the tank at the platform balance and

filled the tank with sufficient amount of water.

(LEFT) Measuring the

diameter. (RIGHT) Measure

the height of the tank.

In the measurement of volume by the use of water meter, we observed the

following, the water meter continuously register reading as the water flows. The

difference in the reading between the final and initial registered reading is the volume of

the tank water. This method is the most accurate method of measuring the volume of

tanks since the water is directly routed to a device which directly measures the volume

of water passing. Knowledge of how to read the water meter is important. The last red

digits indicate volumes in liters while the first black digits represent the measurement in

cubic meters. When the reading is in between the two numbers, choose the number that

already passed the indicator. As what our professor have said, the encoder of the water

companies that visit our homes every month only reads the values that passed already

the indicator.

11

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

In the measurement of volume by weight, I realized that the result of the readings

is inconsistent since the platform balance deviates in reading as the load applied is

increased. The level of the platform balance should also be observed because the

weight of the tank may not be leveled and not on the center that causes the percent

difference. As we have learned in the previous experiment, the analog or the

conventional platform balance is not very accurate but we use this because it can carry

and measure heavier load than the digital platform balance. Moreover, the calculations

are also inconsistent since the temperature factor was not applied in the experiment.

This inconsideration accounted for a slight difference from the conventional reading.

Remember, the density of water changes with temperature. In the calculations I used 1

kg/L.

In the volume measurement by dimension, we noted

the

following

observations.

The

accuracy

of

the

measurement is the basis for acceptable results. The height

reading is taken by measuring the distance from the bottom

of the drum to the surface of the water. I realized that the

procedure that we did causes an error on the data that we

have gathered. This is because when we submerge the

meter stick I the water, it occupies space in the water which

adds another volume to the water and causes the water to

rise. There is already an error that acquired.

Submerging the meter stick

in the water gave a

difference in the values.

Tank Calibration is the process of accurately determining the capacity or partial

capacities of a tank and expressing this capacity as a volume for a given linear

increment or height of liquid. In other words tank calibration also means measuring

storage tanks, horizontal bullets, spherical tanks, vats, casks, barges, ship tanks and

liquid bulk containers. These measurements provide the necessary dimensions for

calculation of calibration charts.

12

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

At its simplest, a calibration of any vessel requires knowledge of the nominal

dimensions of the vessel from which the volume may be calculated. For a water tank

this may be enough and you probably will not need to call in a specialist tank calibrator.

At the other end of the scale, if you are selling a product on the basis of tank

levels, a tank can be measured precisely and calculations can be made to take into

account factors such as hydrostatic expansion of the tank during filling and thermal

expansion of the tank shell in service.

A flow meter can also be used for tank calibrations. However, it should be noted

that flow meters are most accurate when flow rates remain relatively constant. In some

instances, a throttling valve should be employed to help maintain this constant flow rate.

Generally, water should only be metered out of the tank. This avoids any

problems that can occur with fluctuations in supply pressure during tank filling. The

changing differential between water supply pressure and backpressure due to

increasing depth will cause the effective flow rate to vary. This relationship is difficult to

predict if water supply pressure fluctuates during the procedure.

A throttle valve (if used) would be used to gently restrict the flow of water out of

the tank when beginning the process. As depth in the tank decreased, the valve could

be slowly opened more fully to maintain relatively constant flow. (Because the

hydrostatic pressure pushing water out of the tank is reduced as depth decreases, the

throttle valve helps to equalize the flow rate.)

It will still be helpful to utilize some type of volumetric standard even when

metering is employed. It can be used to prove the meters functional accuracy. A

calibrator or volume standard is especially

recommended for measuring the final draw-offs

from the tank or for a fill-back procedure.

Water

measuring

metering

water

use.

is

the

In

many

process

of

developed

countries water meters are used to measure the

13

Water meter in residential houses

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

volume of water used by residential and commercial building that are supplied with

water by a public water supply system. Water meters can also be used at the water

source, well, or throughout a water system to determine flow through that portion of the

system. In most of the world water meters measure flow in Cubic meters (m3) or litters

but in the USA and some other countries water meters are calibrated in cubic feet (ft.3),

or US gallons on a mechanical or electronic register. Some electronic meter registers

can display rate-of-flow in addition to total usage. There are several types of water

meters in common use. Selection is based on different flow measurement methods, the

type of end user, the required flow rates, and accuracy requirements.

3 Types of Water Meters Explained

Among the types of water meters are those that differ in the method used to

measure water volume, and the flow control and measurement devices in the water

meter itself. Learn more about the 4 most common types of water meters below.

Type 1 - Displacement Water Meters

Displacement water meters measure how much water occupies a given space

over a preset time. The water flow displaces the measuring device according to the

volume of water in either gallons or cubic feet that passes through the meter. A piston or

a mutating disk controls the movement of a magnet that activates the water volume

register.

Type 2 - Positive Displacement Meters

Positive displacement meters or PD meters are the most common water meters

for homes and small businesses. They can measure small volumes of water at low flow

rates to a high degree of accuracy. The water pipes in displacement water meters range

from as small as 5/8 inch up to 2 inches in diameter. A displacement meter is made of

brass, high-impact plastic and stainless steel. The measurement register consists of a

clear plastic bubble over the odometer-type or LCD display gauge. For measurements

of less than 1/10 of a gallon, a sweep hand is also used on the measurement register.

14

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

These meters can also be installed in separate units of a condominium or apartment to

track individual water usage.

Type 3 - Velocity Meters

The speed at which the water moves is measured by velocity water meters. The

velocity through the meter's specific volume is measured and converted to units of

volume, either gallons or cubic feet. These meters can be calibrated to adjust the

accuracy of their measurement.

Types of Velocity-Based Water Meters

1. Single and Multiple-Jet Water Meters

Single and multiple-jet water meters use velocity to measure water volume. The

water flow turns an impeller which rotates at a known speed compared to the water

speed. These meters have internal strainer grids to prevent the jets from clogging with

particles in the water. They are used for low-volume applications as the impellers

cannot withstand high flow rates.

2. Turbine Water Meters

Turbine meters are used for water pipe diameters up to 12 inches across. They

are used for high-volume commercial sites such as factories and large office

complexes, and as control meters for sections of a town or city. Fire hydrant water

meters are also of this type.

3. Compound Water Meters

In circumstances where water flow can vary from high velocity to low, a

compound meter can accurately measure water usage. These have two measuring

components and a valve to control the flow rate to each. The turbine meter handles high

flow rates and a multi-jet meter gauges the lowest flow. The utility reader adds the totals

indicated on both meters to determine total water usage.

4. Electromagnetic and Ultrasonic Meters

15

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

A pair of electromagnets can measure water flow in or out of the system in a

"mag meter", based on fluid induction principles. Ultrasonic meters send sound waves

through water to measure its speed, and derive a water volume reading. These are

used in large-volume applications and for fluids other than water.

16

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

QUESTIONS AND ANSWERS:

1. What is the significance of the term inferential as applied to flowmeters?

Inferential in flowmeters is associated with the flow of fluid such as a drop

in static pressure at a restriction in a pipe, or the rotation of an impeller or rotor,

rather than measurement of the actual mass flow. Inferential flowmeters do not

measure volume, velocity or mass, but rather measure flow by inferring its value

from other measured parameters. Examples of flowmeter technologies that

measure inferentially include differential pressure (orifices, venturi, nozzles),

target and variable area flowmeters

2. Certain flowmeters are known as variable head meters. Explain clearly what is

meant by the designation variable head.

The variable head meters work on the principle that a variation of the flow

rate through a constriction with a constant cross-sectional area causes a

pressure drop suffered by the fluid as it flows through the constriction. The

pressure drop is related to the flow rate, and hence variations of the pressure

drop can be used to measure variations in the flow rate. The most common

examples of variable head meters used in industry are the venturi meter and the

orifice meter.

3. What is meant by the primary element of certain types of flowmeters?

A primary element is the element of a flow meter that serves to indicate

the quantity or velocity of flow. For example, in the case of an orifice flow meter,

the differential pressure across the orifice plate is the primary flow element. A

turbine meter is equipped with a magnetic pickup that senses the proximity of the

turbine blades as the fluid motion causes the turbine to spin; this pickup is the

primary flow element for a turbine meter. Diaphragm meters and other positive

displacement meters are equipped with a crank shaft, the rotation of which acts

as the primary flow element

4. What is meant by the term discharge coefficient of a flowmeter?

17

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

The discharge coefficient is the ratio of the mass flow rate at the discharge

end of the nozzle to that of an ideal nozzle which expands an identical working

fluid from the same initial conditions to the same exit pressures.

5. What is meant by the term vena contracta?

It is the area of the contraction of the flow of the water when it is

discharged from an orifice.

6. Give the classification of flow meters.

Flowmeters are classified into many types:

a. Positive Displacement or Vollumetric Flowmeter - measures the volume of the

passing fluid directly by impellers, vanes and gears.

b. Differential pressure Flowmeter inferentially measures the volume of a

passing fluid by analyzing the pressures and forces acting over the devices.

c. Variable area flow meter measures the pressure of the fluid by constriction of

the flow area of the fluid.

d. Target or Momentum Flowmeter measures the internal forces of the fluid

particles by pacing a target plate where fluid forces will act.

h. Ultrasonic Flowmeter uses the effect of motion of a sound source and its

effect on the frequency of the sound to determine the fluid properties.

h. Thermal Flowmeter - thermal mass flowmeter operates independent of

density, pressure, and viscosity. It obtains thermal reception of the fluid through

receptors.

i. Mass Flow Meter - measure the mass flow rate directly.

7. All volumetric flowmeters that are subjected to high head pressure should be

protected by what type of valve?

18

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

Check valves are one of the best suitable valves that can be used to

protect volumetric flowmeters. A check valve or one-way valve is a mechanical

device, a valve, which normally allows fluid (liquid or gas) to flow through it in

only one direction.

8. Why is it necessary to blow steam after each run when the liquid metered is hot?

Yes. In order to prevent thermal deformation on the meter (which will

cause error in reading the flow of hot liquid), blowing of steam is required. This

ensures that the meter is cool and its components are not thermally stressed.

9. Why is a draw-off connection needed in the piping manifold when installing

volumetric flow meters?

In order to prevent unnecessary wastage of water and interruption of

water supply during the installation of a flowmeter, a draw-off connection is used.

It is simply an alternate route to where flowing water can pass.

10. What is the difference between an orifice and a nozzle?

An orifice is simply a bore or a hole on a fluid reservoir where fluids can

flow out. It is commonly situated below the water level. Meanwhile a nozzle is an

extension with an orifice on its mouth, to where the fluids can flow out. It can be

situated below the fluid level, or above the fluid level (which will require a pump

to operate).

19

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

CONCLUSION

For this experiment, the group was given 3 objectives, namely: to compare the

volume of the water by measurement and by weight; to be able to exercise and

enhance knowledge on measuring and computing pressure including its relation with

the other parameters such as height density and gravitational acceleration guided by

the equation P= and to learn how to read the readings on the water meter.

During the course of the activity, the group used to test in order to measure the

volume of water flowing into the tank. It was observed that the results for both

measurement and weight are almost coherent with one another, proving the validity of

the results. Also, the group compared the readings of the water meter with the data

gathered through the tests. According to the data, the reading on the water meter is

much higher compared to what the group has recorded for the first part. Possible

sources of error for this are the inaccuracy on the tests and the flaw of the water meter

itself.

To know the calibration for the water tank, the group made use of the concept

that pressure is dependent on the height of the fluid and gravitational acceleration or P

= . It was noticed, that when considering water, 1 kg = 1L.

20

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

RECOMMENDATION

Since the main source of error for this experiment is the inaccuracy of the

students while conducting the test, it is recommended that the procedure to be carefully

instructed by the facilitator.

21

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

REFERENCE

http://www.doityourself.com/stry/3-types-of-water-meters-explained#b

http://www.engineeringtoolbox.com/flow-meters-d_493.html

http://en.wikipedia.org/wiki/Water_metering

https://srac.tamu.edu/index.cfm/event/getFactSheet/whichfactsheet/4/

22

EXP 7: CALIBRATION OF WATER TANK AND WATER METER

PRELIMINARY DATA SHEET

23

You might also like

- Melab1 Exp3Document11 pagesMelab1 Exp3privateziel100% (1)

- Performance Test of A Hydraulic Turbine Mid Term 2Document8 pagesPerformance Test of A Hydraulic Turbine Mid Term 2jethro ganeloNo ratings yet

- Drop and Hardness Tests of GreasesDocument15 pagesDrop and Hardness Tests of GreasesGuirigay MarbenJohnNo ratings yet

- Assignment 2Document5 pagesAssignment 2Noraishah Syahirah Azhar100% (1)

- Compiled Lab ReportDocument25 pagesCompiled Lab ReportSaAhRaNo ratings yet

- Steam Power Plant PDFDocument21 pagesSteam Power Plant PDFJan Rangel Sabado De VeraNo ratings yet

- Online Lab - Me Lab1 Expt 2 Area MeasurementDocument5 pagesOnline Lab - Me Lab1 Expt 2 Area MeasurementDessa GuditoNo ratings yet

- Keys Coupling With SampleDocument9 pagesKeys Coupling With SampleGen ReyesNo ratings yet

- Experiment No. 5 - Measurement of SpeedDocument8 pagesExperiment No. 5 - Measurement of SpeedNiño Gerard JabagatNo ratings yet

- Heat Loss in Bare & Lagged Pipes PresentationDocument15 pagesHeat Loss in Bare & Lagged Pipes PresentationKristian Vince R Pallar100% (1)

- Circuits1 1 Laboratory Meters and Power SupplyDocument2 pagesCircuits1 1 Laboratory Meters and Power SupplyJad DimabuyuNo ratings yet

- Refrigeration-Systems Part 1Document11 pagesRefrigeration-Systems Part 1Sean GuanzonNo ratings yet

- SET A With Answer Key Quiz 2 Fluid Machineries (Prof. Enh. 2)Document4 pagesSET A With Answer Key Quiz 2 Fluid Machineries (Prof. Enh. 2)Famela Gad100% (1)

- 3 Diesel PerformanceDocument10 pages3 Diesel PerformanceyanyanNo ratings yet

- ME Con-1 Mock-1Document15 pagesME Con-1 Mock-1vidya chakitwarNo ratings yet

- Tutorial 1& 2 - SolDocument10 pagesTutorial 1& 2 - SolAli ZaghloulNo ratings yet

- Basic Process Control System Module (Revised)Document8 pagesBasic Process Control System Module (Revised)Christy Jane SanchezNo ratings yet

- HW 1 2Q1314 QuestionaireDocument1 pageHW 1 2Q1314 QuestionairejenninajubanNo ratings yet

- Hydroelectric Powerplant: ContentsDocument36 pagesHydroelectric Powerplant: ContentsSecret SecretNo ratings yet

- Fans and Blowers Practice ProblemsDocument2 pagesFans and Blowers Practice ProblemsFour AyesNo ratings yet

- Chapter 1Document8 pagesChapter 1Von A. Damirez0% (1)

- Design Procedure For Flat BeltDocument2 pagesDesign Procedure For Flat BeltKutty AravindNo ratings yet

- Me152l - Experiment 5 - AmahmudDocument23 pagesMe152l - Experiment 5 - AmahmudAli Requiso MahmudNo ratings yet

- AIR CONDITIONING AND VENTILATION SYSTEM Prelim ExamDocument1 pageAIR CONDITIONING AND VENTILATION SYSTEM Prelim ExamJames Patrick TorresNo ratings yet

- Module 5 Activity No. 4Document1 pageModule 5 Activity No. 4dracarysNo ratings yet

- Performance and Efficiency Test of A Refrigeration Plant Test ProcedurDocument4 pagesPerformance and Efficiency Test of A Refrigeration Plant Test ProcedurEJ TolentinoNo ratings yet

- Assignment No. 1 in PpeDocument3 pagesAssignment No. 1 in PpeJenny Mae PomedaNo ratings yet

- Chapter 1 SpecificationDocument4 pagesChapter 1 SpecificationBasil BautistaNo ratings yet

- Introduction To PumpsDocument33 pagesIntroduction To PumpsArgie CayabyabNo ratings yet

- Online Lab - Me Lab1 Expt 2 Area MeasurementDocument8 pagesOnline Lab - Me Lab1 Expt 2 Area MeasurementDessa GuditoNo ratings yet

- DEFINITIONS (Machine Shop-Design)Document19 pagesDEFINITIONS (Machine Shop-Design)Marcial Jr. MilitanteNo ratings yet

- Nu Day 3Document2 pagesNu Day 3Jan Tiangco100% (1)

- Steam Jet Refrigeration: AnswerDocument4 pagesSteam Jet Refrigeration: AnswerKent NabzNo ratings yet

- Fans and BlowersDocument2 pagesFans and BlowersNeil RubsNo ratings yet

- POWER PlantDocument26 pagesPOWER PlantChincel G. ANINo ratings yet

- PPE TerminologiesDocument3 pagesPPE TerminologiesJamiel CatapangNo ratings yet

- ME Lab 1 Exp 3 Measurement of Power, Speed and Time PDFDocument10 pagesME Lab 1 Exp 3 Measurement of Power, Speed and Time PDFJAMAL HALIBAYNo ratings yet

- MAGATDocument1 pageMAGATReden LopezNo ratings yet

- Terms ReviewerDocument47 pagesTerms ReviewerAarfebre100% (1)

- Review Questions : G(S) C(S)Document7 pagesReview Questions : G(S) C(S)Angel CallejebrioNo ratings yet

- Section 16Document97 pagesSection 16Carolina FerrerNo ratings yet

- Sheldon - S File 3Document7 pagesSheldon - S File 3Prince Leonard R. VergaraNo ratings yet

- Performance Test of A Non-Positive Displacement PumpDocument7 pagesPerformance Test of A Non-Positive Displacement PumpBOSS BabyNo ratings yet

- Quiz#3 PDFDocument1 pageQuiz#3 PDFJohn MameNo ratings yet

- Cooling Tower Lab ReportDocument20 pagesCooling Tower Lab Reportgodfrey100% (1)

- Board of Mechanical Engineering: Hon. Jesus M. Redelosa, PME, PEE, FPSME, FSPAC, FpameeDocument1 pageBoard of Mechanical Engineering: Hon. Jesus M. Redelosa, PME, PEE, FPSME, FSPAC, FpameeBienNo ratings yet

- Ipe Plate 2 Fluid MachineriesDocument93 pagesIpe Plate 2 Fluid Machineriesjanuel borelaNo ratings yet

- PSME CodeDocument163 pagesPSME Coderaymart caluag100% (1)

- Combustion of CoalDocument12 pagesCombustion of CoalAlteaAl100% (1)

- A. B. 0.99 M /KG 0.79 M /KG 0.89 M /KG 0.69m /KGDocument143 pagesA. B. 0.99 M /KG 0.79 M /KG 0.89 M /KG 0.69m /KGRyan Togonon100% (1)

- Lab 2 ThermalDocument18 pagesLab 2 ThermalMuhamad Arif100% (1)

- Theoretical CyclesDocument49 pagesTheoretical CyclesMariaEzzaSyUyNo ratings yet

- Air Changes Per HourDocument4 pagesAir Changes Per HourDIPAK S100% (1)

- ME Lab 2 Module No. 5 PDFDocument24 pagesME Lab 2 Module No. 5 PDFIsmaeli KielNo ratings yet

- MachineDocument15 pagesMachinemaria katherine pantojaNo ratings yet

- Power Plant Design With Renewable EnergyDocument14 pagesPower Plant Design With Renewable EnergyJohn Steven LlorcaNo ratings yet

- Dynamometer and Power MeasurementDocument44 pagesDynamometer and Power MeasurementAndrei NobleNo ratings yet

- Section 16 PDFDocument97 pagesSection 16 PDFherrerafaridNo ratings yet

- EXP7 WATER TANK-minDocument15 pagesEXP7 WATER TANK-mingoblinsbrideNo ratings yet

- Laboratory Exercise No 5Document3 pagesLaboratory Exercise No 5John Kennedy BalletaNo ratings yet

- Obliged To LoveDocument13 pagesObliged To LoveJeremias John KarloNo ratings yet

- Engineering Solutions To ControlDocument5 pagesEngineering Solutions To ControlJeremias John KarloNo ratings yet

- Jeremias, IAQ Round 1Document6 pagesJeremias, IAQ Round 1Jeremias John KarloNo ratings yet

- ICE LectureDocument44 pagesICE LectureTravis BullockNo ratings yet

- HelloDocument38 pagesHelloJeremias John KarloNo ratings yet

- PVT Relations Formula: 1. Isometric (V)Document1 pagePVT Relations Formula: 1. Isometric (V)Jeremias John KarloNo ratings yet

- ModuleDocument7 pagesModuleJeremias John KarloNo ratings yet

- Design of Grit Channels Controlled by Parshall FlumesDocument16 pagesDesign of Grit Channels Controlled by Parshall FlumesGarethNo ratings yet

- BarnoulliDocument8 pagesBarnoulliameenNo ratings yet

- Experiment 1 Online 1Document1 pageExperiment 1 Online 1Clarence BautistaNo ratings yet

- 5 - Flow Through Packed BedsDocument2 pages5 - Flow Through Packed BedsAstra BeckettNo ratings yet

- Hydraulics 1Document82 pagesHydraulics 1Vincent Louie Escover Foronda75% (16)

- Module 2 - Fluid MachineryDocument5 pagesModule 2 - Fluid MachineryMark Renbel ParanNo ratings yet

- Relative PermeabilityDocument116 pagesRelative PermeabilityYinzhang100% (2)

- Friction FactorDocument10 pagesFriction FactorsandeepNo ratings yet

- Answer All Questions: Assist. Prof. Hussein AliwiDocument2 pagesAnswer All Questions: Assist. Prof. Hussein Aliwihitham al-miedamahNo ratings yet

- Astm 2161Document26 pagesAstm 2161tony juarezNo ratings yet

- Tecnología en Spray y Control de PolvoDocument20 pagesTecnología en Spray y Control de PolvoAmbyLopezNo ratings yet

- Minor Losses Lab ReportDocument11 pagesMinor Losses Lab ReportAbenezer TasewNo ratings yet

- Numerical Calculation of Centrifugal Fan NoiseDocument11 pagesNumerical Calculation of Centrifugal Fan NoiseAnuj shuklaNo ratings yet

- Open Channel Flow SessionalDocument24 pagesOpen Channel Flow SessionalMd saydul islamNo ratings yet

- Chapter 2Document38 pagesChapter 2Muhammad ImranNo ratings yet

- SolveDocument11 pagesSolveShamanAcolyteNo ratings yet

- Oloa 4994CDocument2 pagesOloa 4994Csafindit50% (2)

- FluidsDocument1 pageFluidsnico aspraNo ratings yet

- Master Flo Choke Control Valve Sizing - Version 7.1.0.0046I CV Sizing Calculation - Surface ValvesDocument2 pagesMaster Flo Choke Control Valve Sizing - Version 7.1.0.0046I CV Sizing Calculation - Surface ValvesFabian Solano100% (1)

- Heat Transfer in Forced ConvectionDocument3 pagesHeat Transfer in Forced Convectionangela yuNo ratings yet

- Master - Three Phase Horizontal Separator Rev 0Document6 pagesMaster - Three Phase Horizontal Separator Rev 0Naeem HussainNo ratings yet

- Unit - I OPEN CHANNEL FLOW (Uniform & Non-Uniform Flow) : Hydraulics & Hydraulic MachineryDocument7 pagesUnit - I OPEN CHANNEL FLOW (Uniform & Non-Uniform Flow) : Hydraulics & Hydraulic MachinerySri E.Maheswar Reddy Assistant ProfessorNo ratings yet

- AEE 342 Aerodynamics II: Dr. Mohamed Salem ElmnefiDocument12 pagesAEE 342 Aerodynamics II: Dr. Mohamed Salem ElmnefiDilara Kevser ÇAKMAKNo ratings yet

- Mechanics of Coastal Sediment TransportDocument393 pagesMechanics of Coastal Sediment TransportKrakozyabra100% (7)

- Basic Equation in Fluid MechanicsDocument9 pagesBasic Equation in Fluid Mechanicsapi-286406608No ratings yet

- Lubricant Viscosities - Fluids Recommendations (M0087328)Document6 pagesLubricant Viscosities - Fluids Recommendations (M0087328)mauricio100% (1)

- ReportDocument53 pagesReportYip DavidNo ratings yet

- Lubricating Grease - Colombia - Nov 2016Document40 pagesLubricating Grease - Colombia - Nov 2016SERGIO PAVANo ratings yet

- Chemical EngineeringDocument3 pagesChemical EngineeringMeshiel BonaosNo ratings yet