Professional Documents

Culture Documents

NDT Testing

Uploaded by

mohanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NDT Testing

Uploaded by

mohanCopyright:

Available Formats

05/06/2015

About NDT

Home - A bout NDT

What is NDT?

The field of Nondestructive Testing (NDT) is a very

broad, interdisciplinary field that plays a critical role in

assuring that structural components and systems perform

their function in a reliable and cost effective fashion. NDT

technicians and engineers define and implement tests that

locate and characterize material conditions and flaws that

might otherwise cause planes to crash, reactors to fail,

trains to derail, pipelines to burst, and a variety of less

visible, but equally troubling events. These tests are

performed in a manner that does not affect the future

usefulness of the object or material. In other words, NDT allows parts and material to be

inspected and measured without damaging them. Because it allows inspection without

interfering with a product's final use, NDT provides an excellent balance between quality

control and cost-effectiveness. Generally speaking, NDT applies to industrial inspections.

The technologies that are used in NDT are similar to those used in the medical industry, but

nonliving objects are the subjects of the inspections.

NDT in use!

Rail Inspection

A ircraft Inspection

Liberty Bell Inspection

Bridge Inspection

Storage Tank Inspection

Wire Rope Inspection

Pipeline Inspection

What is NDE?

Nondestructive evaluation (NDE) is a term that is often used interchangeably with NDT.

However, technically, NDE is used to describe measurements that are more quantitative in

nature. For example, an NDE method would not only locate a defect, but it would also be

used to measure something about that defect such as its size, shape, and orientation. NDE

may be used to determine material properties, such as fracture toughness, formability, and

other physical characteristics.

Some NDT/NDE Technologies:

Many people are already familiar with some of the technologies that are used in NDT and

NDE from their uses in the medical industry. Most people have also had an X-ray taken and

many mothers have had ultrasound used by doctors to give their baby a checkup while still

in the womb. X-rays and ultrasound are only a few of the technologies used in the field of

NDT/NDE. The number of inspection methods seems to grow daily, but a quick summary

of the most commonly used methods is provided below.

Visual and Optical Testing (VT)

The most basic NDT method is visual examination. Visual examiners follow

procedures that range from simply looking at a part to see if surface

imperfections are visible, to using computer controlled camera systems to

automatically recognize and measure features of a component.

https://www.nde-ed.org/AboutNDT/aboutndt.htm

1/3

05/06/2015

About NDT

Radiography (RT)

RT involves using penetrating gamma- or X-radiation on materials and

products to look for defects or examine internal or hidden features. An X-ray

generator or radioactive isotope is used as the source of radiation. Radiation is

directed through a part and onto film or other detector. The resulting

shadowgraph shows the internal features and soundness of the part. Material

thickness and density changes are indicated as lighter or darker areas on the

film or detector. The darker areas in the radiograph below represent internal

voids in the component.

Magnetic Particle Testing (MT)

This NDT method is

accomplished by inducing a

magnetic field in a

ferromagnetic material and then

dusting the surface with iron

particles (either dry or

suspended in liquid). Surface

and near-surface flaws disrupt

the flow of the magnetic field within the part and force some of the field to leak

out at the surface. Iron particles are attracted and concentrated at sites of the

magnetic flux leakages. This produces a visible indication of defect on the

surface of the material. The images above demonstrate a component before

and after inspection using dry magnetic particles.

Ultrasonic Testing (UT)

In ultrasonic testing, high-frequency sound

waves are transmitted into a material to

detect imperfections or to locate changes in

material properties. The most commonly

used ultrasonic testing technique is pulse

echo, whereby sound is introduced into a

test object and reflections (echoes) from

internal imperfections or the part's

geometrical surfaces are returned to a

receiver. Below is an example of shear wave weld inspection. Notice the

indication extending to the upper limits of the screen. This indication is

produced by sound reflected from a defect within the weld.

Penetrant Testing (PT)

https://www.nde-ed.org/AboutNDT/aboutndt.htm

2/3

05/06/2015

About NDT

With this testing method, the test object is

coated with a solution that contains a

visible or fluorescent dye. Excess solution

is then removed from the surface of the

object but is left in surface breaking

defects. A developer is then applied to

draw the penetrant out of the defects. With

fluorescent dyes, ultraviolet light is used to

make the bleedout fluoresce brightly, thus

allowing imperfections to be readily seen. With visible dyes, a vivid color

contrast between the penetrant and developer makes the bleedout easy to see.

The red indications in the image represent a defect in this component.

Electromagnetic Testing (ET)

There are a number of electromagnetic

testing methods but the focus here will be

on eddy current testing. In eddy current

testing, electrical currents (eddy currents)

are generated in a conductive material by a

changing magnetic field. The strength of

these eddy currents can be measured.

Material defects cause interruptions in the

flow of the eddy currents which alert the

inspector to the presence of a defect or other change in the material. Eddy

currents are also affected by the electrical conductivity and magnetic

permeability of a material, which makes it possible to sort some materials

based on these properties. The technician in the image is inspecting an aircraft

wing for defects.

Leak Testing (LT)

Several techniques are used to detect and locate leaks in pressure containment

parts, pressure vessels, and structures. Leaks can be detected by using

electronic listening devices, pressure gauge measurements, liquid and gas

penetrant techniques, or simple soap-bubble tests.

Acoustic Emission Testing (AE)

When a solid material is stressed, imperfections within the material emit short

bursts of acoustic energy called "emissions." As in ultrasonic testing, acoustic

emissions can be detected by special receivers. Emission sources can be

evaluated through the study of their intensity and arrival time to collect

information (such as their location) about the sources of the energy.

-

https://www.nde-ed.org/AboutNDT/aboutndt.htm

3/3

05/06/2015

NDT - Liberty Bell

Home - A bout NDT

NDT Used to Evaluate

Potential Damage to the Liberty Bell

Contribution made by Steve James and Lou Truckley, The Boeing Company.

Due to an unfortunate incident that occurred on April 6, 2001, Boeing employees

in Philadelphia were given the privilege of evaluating the Liberty Bell for damage

using NDT techniques. The Liberty Bell is over 200 years old, and is one of the

USA's most treasured symbols of liberty. In the early days of the American

colonies, the Liberty Bell was rung to call people together for special

announcements and events. The Liberty Bell rang out from the tower of

Independence Hall on July 8, 1776, summoning citizens to hear the first public

reading of the Declaration of Independence. The Bell has a very interesting

history which includes cracking on its test ring in 1752, being remelted and recast

only to have a poor tone, being remelted and recast for a third time in June of

1753. Sometime before 1846, the Bell developed a crack and on during its

ringing on George Washington's Birthday of that year, the crack grew to a length

that rendered the Liberty Bell unringable.

The Liberty Bell now rests in the Liberty Bell Pavilion on Independence Mall in

Philadelphia. Apparently during a regular tour, a man suddenly began to attack the Liberty Bell with a hammer. A park

service ranger had to tackle the man to end the assault. It was reported that there was minimal damage to the bell which

weighs over 2000 pounds. However, there was enough concern about damage for the National Park Service to call on

experts to perform an evaluation. Boeing was asked to help with the repair because of their expertise in metal structures

and nondestructive evaluation.

What kinds of nondestructive tests were conducted?

Boeing NDT specialists performed a series of nondestructive tests to

evaluate the possible damage to the Bell and also to document the overall

structural status of the Bell. These tests included:

Radiographs of the bell were taken that were compared to

radiographs taken more than 25 years ago.

Fluorescent penetrant inspection was performed on a small area of

the bell to check for possible cracks from the attack. (See picture)

Ultrasonic inspection was performed to attempt to locate any

internal flaws within the Bell.

An eddy current inspection was conducted to map the surface

cracks on the bell. The data obtained from this inspection was used as a baseline to compare and crack

propagation that may occur in the future.

Eddy current methods were used to measure the electrical conductivity of the Bell's bronze casing at a various

points to evaluate its uniformity. In the picture below, the white dots on the Bell indicate spots where conductivity

measurements were taken.

https://www.nde-ed.org/AboutNDT/SelectedApplications/Boeing-Liberty%20Bell/NDT-%20Liberty%20Bell.htm

1/2

05/06/2015

NDT - Liberty Bell

More information on the Liberty Bell can be found at the following sites

http://www.ushistory.org/libertybell/

http://www.libertybellmemorial.com/

https://www.nde-ed.org/AboutNDT/SelectedApplications/Boeing-Liberty%20Bell/NDT-%20Liberty%20Bell.htm

2/2

05/06/2015

Home - A bout NDT

Wire Rope Inspection

Wire Rope (Cable) Inspection

Most skiers and snowboarders rate ski resorts by their average powder base and

the overall quality of the slopes. Few likely give serious consideration to the safety of chair lifts

at their favorite mountains. It is likely, however, that many have looked up at that relatively small

cable that they are dangling from high in the air and hoped that someone had check to see that it

was in good working condition. Luckily, ski resort operators and governing authorities perform

regular inspections and maintenance of chair lifts to ensure passenger safety. One of the

components that gets close scrutiny is the cable.

Wire rope or cable is made by weaving many individual wires

together to produce a product that is both strong and flexible.

Wire rope is used in many safety critical applications in addition to chair lift and

gondola systems. Some of these applications include hoisting systems, such as cranes

and winches; guy wires used in tall antennas and towers; and mooring lines of oil

drilling platforms at sea. A cable failure in one of these applications could have very

serious consequences.

All wire rope eventually wears out making periodic inspections necessary throughout

the service life of the rope. Wire rope is prone to damage and wear due to abrasion,

fatigue, corrosion, and improper handling. NDT personnel look for localized flaws or

loss of metallic cross-sectional area using a variety of inspection methods. The least

sophisticated method is visual inspection. Inspector simply look for broken strands,

wear and corrosion on the surface of the cable. However, for a more thorough

evaluation, a number of instruments have been developed that allow inspectors to

assess the internal areas of the cable.

https://www.nde-ed.org/AboutNDT/SelectedApplications/WireRopeInspection/WireRopeInspection.htm

1/2

05/06/2015

Wire Rope Inspection

One of the more widely used of these instruments uses magnetism

to inspect the rope. The inspection instrument is placed around the

wire rope and moved along the rope or the rope is pulled through

the instrument. Strong permanent magnets or electromagnets are

used to create a strong magnetic field within the rope. The rope is

said to be magnetically saturated because it is caring all the magnet

flux that it possibly can. In areas where the rope is damaged, it can

not support as much of the magnet flux and some of it "leaks" out of

the rope. Sensors in the inspection head detect the magnetic flux

leakage caused by the internal or external defects in the rope.

Defects as small as 0.05 % of the rope's cross-sectional area can

often be detected.

https://www.nde-ed.org/AboutNDT/SelectedApplications/WireRopeInspection/WireRopeInspection.htm

2/2

05/06/2015

Home - A bout NDT

NDT in Aerospace

NONDESTRUCTIVE TESTING

IN THE AEROSPACE INDUSTRY

How essential is nondestructive testing (NDT) to airplanes?

In the aerospace industry, as with other transportation industries,

NDT can make the difference between life and death. Aircraft

components are inspected before they are assembled into the

aircraft and then they are periodically inspected throughout their

useful life. Aircraft parts are designed to be as light as possible

while still performing their intended function. This generally means

that components carry very high loads relative to their material

strength and small flaws can cause a component to fail. Since

aircraft are cycled (loaded and unloaded) as they fly, land, taxi,

and pressurize the cabin, many components are prone to fatigue

cracking after some length of time. If you are unfamiliar with the

term "fatigue cracking" think about what happens when you bend a

paper clip or piece of wire back and forth ...eventually it will break. Even parts that are loaded well below the level that

causes them to deform can develop fatigue cracks after being cycled for a long time. This is what happens in aircraft.

After they are used for a while, fatigue cracks start growing in some of their parts. Cracking can also occur due to other

things like a lightning strike. Aircraft have some protection against lightning strikes but occasionally they occur and can

results in cracks forming at the strike location like the one shown in the picture.

Another problem that aircraft have is that they are under the constant attack of corrosion. When an aircraft lands and the

door is opened, the inside of the plane often fills with warm moist air. When the plane takes flight, and reaches altitude,

https://www.nde-ed.org/AboutNDT/SelectedApplications/AircraftInspection/Aircraft%20Inspection.htm

1/2

05/06/2015

NDT in Aerospace

the skin of the aircraft becomes very cold due to the temperature of the outside air. This cause the moisture held by the

air inside the cabin to condense on the inside of the aircraft skin. The water will collect at low areas and serve as the

electrolyte needed for corrosion to occur.

The good news is that aircraft are designed to withstand a certain amount of damage from cracking and

corrosion without cause for concern, and NDT inspectors are trained to find the damage before it becomes a

major problem. The rigorous process used to design aircraft either allow for a certain amount of damage to occur

before a part fails, or in many cases, a part can fail completely and performance of the aircraft will not be affected. The

job of the NDT inspector is to find the damage while it is within acceptable limits.

What kind of NDT techniques are used to ensure the safety of the airplane?

Over 80 percent of the inspections done to an aircraft are visual inspections. At regular intervals inspectors look at

various component of the aircraft for signs of damage. During heavy maintenance work, much of the interior of the

aircraft is stripped out so inspectors can look for damage on the inside surface of the fuselage. However, not all areas of

the aircraft can be accessed for visual inspection and not all damage can be detected by visual means. This is were NDT

plays a critical role in thoroughly inspecting airplanes.

NDT methods allow inspectors to inspect areas of the plane that would otherwise

be uninspectable without disassembling structure to gain access to the internal areas.

NDT methods also allow inspectors to detect damage that is too small to be

detected by visual means. Eddy current and ultrasonic inspection methods are used

extensively to locate tiny cracks that would otherwise be undetectable. These

techniques are also used to measure the thickness of the aircraft skin from the

outside and detect metal thinning from corrosion on the inside surface of the skin. Xray techniques are used to find defects buried deep within the structure and to locate

areas were water has penetrated into certain structure. Obviously, this task requires

trained professionals who are capable of performing a variety of different NDT

techniques to get a complete and accurate status of the airplane.

There is no question that the success of the airplane industry is dependent on NDT.

Without NDT, the cost of maintaining and flying in airplanes would increase

dramatically, while the safety of flying would decrease. When people step into an

airplane they trust that it will get them to their destination with as little turbulence as

possible. NDT plays a vital role in keeping air travel one of the safest modes of

transportation.

https://www.nde-ed.org/AboutNDT/SelectedApplications/AircraftInspection/Aircraft%20Inspection.htm

2/2

05/06/2015

Pipeline Inspection

Home - A bout NDT

Pipeline Inspection

In the United States, millions of miles of pipeline carrying everything

from water to crude oil. The pipe is vulnerable to attack by internal and external

corrosion, cracking, third party damage and manufacturing flaws. If a pipeline

carrying water springs a leak bursts, it can be a problem but it usually doesn't harm

the environment. However, if a petroleum or chemical pipeline leaks, it can be a

environmental disaster. More information on recent US pipeline accidents can be

found at the, National Transportation Safety Board's Internet site. In an attempt to

keep pipelines operating safely, periodic inspections are performed to find flaws

and damage before they become cause for concern.

When a pipeline is built, inspection personnel may use visual, X-ray, magnetic

particle, ultrasonic and other inspection methods to evaluate the welds and

ensure that they are of high quality. The image to the left show two NDT

technicians setting up equipment to perform an X-ray inspection of a pipe weld.

These inspections are performed as the pipeline is being constructed so gaining

access the inspection area is not problem. In some areas like Alaska, sections of

pipeline are left above ground like shown above, but in most areas they get

buried. Once the pipe is buried, it is undesirable to dig it up for any reason.

So, how do you inspect a buried pipeline?

Have you ever felt the ground move under your feet? If you're standing in New York City, it

may be the subway train passing by. However, if you're standing in the middle of a field in

Kansas it may be a pig passing under your feet. Huh??? Engineers have developed devices,

called pigs, that are sent through the buried pipe to perform inspections and clean the pipe. If

you're standing near a pipeline, vibrations can be felt as these pigs move through the pipeline.

The pigs are about the same diameter of the pipe so they range in size from small to huge. The

pigs are carried through the pipe by the flow of the liquid or gas and can travel and perform

inspections over very large distances. They may be put into the pipe line on one end and taken

out at the other. The pigs carry a small computer to collect, store and transmit the data for

analysis. In 1997, a pig set a world record when it completed a continuous inspection of the

Trans Alaska crude oil pipeline, covering a distance of 1,055 km in one run. Click here to read

more about this record setting inspection.

https://www.nde-ed.org/AboutNDT/SelectedApplications/PipelineInspection/PipelineInspection.htm

1/2

05/06/2015

Pipeline Inspection

Pigs use several nondestructive testing methods to perform the

inspections. Most pigs use a magnetic flux leakage method but

some also use ultrasound to perform the inspections. The pig shown

to the left and below uses magnetic flux leakage. A strong magnetic

field is established in the pipe wall using either magnets or by

injecting electrical current into the steel. Damaged areas of the pipe

can not support as much magnetic flux as undamaged areas so

magnetic flux leaks out of the pipe wall at the damaged areas. An

array of sensor around the circumference of the pig detects the

magnetic flux leakage and notes the area of damage. Pigs that use

ultrasound, have an array of transducers that emits a high frequency

sound pulse perpendicular to the pipe wall and receives echo

signals from the inner surface and the outer surface of the pipe. The

tool measures the time interval between the arrival of a reflected

echos from inner surface and outer surface to calculate the wall

thickness.

On some pipelines it is easier to use remote visual inspection equipment to assess the condition of the pipe. Robotic

crawlers of all shapes and sizes have been developed to navigate the pipe. The video signal is typically fed to a truck

where an operator reviews the images and controls the robot.

https://www.nde-ed.org/AboutNDT/SelectedApplications/PipelineInspection/PipelineInspection.htm

2/2

05/06/2015

Rail Inspection

Home - A bout NDT

Contributions

made by

Sperry Rail Service

Rail Inspection

One of the major problems that railroads have

faced since the earliest days is the prevention of

service failures in track. As is the case with all

modes of high-speed travel, failures of an essential

component can have serious consequences. The

North American railroads have been inspecting

their most costly infrastructure asset, the rail, since

the late 1920's. With increased traffic at higher

speed, and with heavier axle loads in the 1990's,

rail inspection is more important today than it has

ever been. Although the focus of the inspection

seems like a fairly well-defined piece of steel, the

testing variables present are significant and make

the inspection process challenging.

Rail is manufactured in different weights; there are

different rail conditions (wear, corrosion etc)

present; there are a significant number of potential

defects possible; and the task has to be performed

with some speed to reliably inspect the thousands

of miles of track stretching across the land. Sperry

Rail Service, one of the country's leading inspector

of railroad tracks, has been using specialized test

equipment mounted on self-propelled rail cars for

over seventy years to protect the safety of

passengers and freight. This information provides a

brief look at rail inspection.

The history of railroading is rooted in the production of the first metal rails near the city of Sheffield,

England in 1776. The rail improved the transportation of materials in industries such as mining. In 1803

the first railroad intended for public use was opened for operation between the London docks and

Croyden. This first railway, the Surrey Iron Railway, offered a smoother ride than a wagon, but offered

no real advantage in speed since draft animals were used for locomotion. However, the first steam

locomotive was soon to arrive on the scene. In 1804, a steam locomotive pulled a train of cars

carrying several tons of ore for the iron works at Merthyr Tydfil in South Wales. The first American

locomotive, the Best Friend of Charleston, was placed in operation on the South Carolina Railroad in

1831.

https://www.nde-ed.org/AboutNDT/SelectedApplications/RailInspection/RailInspection.htm

1/5

05/06/2015

Rail Inspection

The rails have evolved from cast iron plates to specially alloyed steels, which are rolled to a standard

shape and specially heat-treated to obtain the desired properties. The figures above show the

progression of rail development. Present day steel rails are vastly superior to their predecessors in both

strength and wear qualities, however defects still develop. The heavy loads and high speed of today's

trains can cause rails to fail in service unless regular inspections are performed.

Rail inspections were initially performed solely by visual means. Of

course, visual inspections will only detect external defects and sometimes

the subtle signs of large internal problems. The need for a better inspection

method became a high priority because of a derailment at Manchester,

NY in 1911, in which 29 people were killed and 60 seriously injured. In

the U.S. Bureau of Safety's (now the National Transportation Safety

Board) investigation of the accident, a broken rail was determined to be

the cause of the derailment. The bureau established that the rail failure was

caused by a defect that was entirely internal and probably could not have been detected by visual

means. The defect was called a transverse fissure (example shown on the left). The railroads began

investigating the prevalence of this defect and found transverse fissures were widespread.

In 1915, the Bureau of Standards began research to determine if magnetic testing could be used to

detect transverse fissures. The inspection technique involved passing a magnetizing solenoid along the

rail to establish a flux in the rail. Flux leakage caused by a defect was detected with search coils. The

technique was successful in the laboratory but was unable to differentiate between defects and nonrelevant rail features in the field.

https://www.nde-ed.org/AboutNDT/SelectedApplications/RailInspection/RailInspection.htm

2/5

05/06/2015

Rail Inspection

In 1923, Dr. Elmer Sperry, started to develop and

build a rail inspection car with the capability of

detecting transverse fissures in railroad rails. In 1927

Sperry built an inspection car (shown on the right)

under contract with the American Railway

Association. The small flatbed in front of the cab

contained the inspection equipment. The operator and

recording devices were housed in the cab.

In 1928, a Sperry built inspection car, SRS 102, was

testing rail on the Wabash Railway in Montpelier, Ohio. The inspection technique Sperry used

established a strong magnetic field in the rail by passing a large amount of low voltage current through

it. A pair of search coils, fixed at a constant distance from the rail, detected any changes in the

magnetic field around the rail. This magnetic induction flux leakage technique became the foundation of

early rail inspection.

This drawing on the left shows the basic operation

of rail inspection using the induction method.

Brushes are used to contact the rail and "inject"

electrical current. The current creates a strong

magnetic field in the rail. Where there is a defect in

the rail, the steel material will not support magnetic

flux and some of the flux is forced out of the part.

The sensing coil detects a change in the magnetic

field and the defect indication is recorded on the

strip chart. Computers are now being used to

record and evaluate the date.

Unfortunately, transverse fissures are not the only types of defects found in rail. Other manufacturing

and service-related defects that can occur include inclusions, seams, shelling, and corrosion. Fatigue

cracks can initiate from these defects, as well as normal features of the rail such as bolt-holes. If these

defects go undetected, they can lead to rail head and web separations. Many of these defects are not

detectable with the flux leakage method because the flaws run parallel to the magnet flux lines or the

flaws are too far away from the sensing coils to detect. The induction technique inspects mainly the

railhead.

To complement the flux leakage method, and detect additional flaw types, ultrasonic inspection has

become common. High-frequency sound is transmitted into the metal rail and reflections from rail joints

and surface conditions, as well as internal defects, are displayed on a screen or cause movement of a

pen on a recording tape. Both normal- and angle-beam techniques are used, as are both pulse-echo

and pitch-catch techniques. The different transducer arrangements offer different inspection

capabilities. Manual contact testing is done to evaluate small sections of rail but the ultrasonic

inspection has been automated to allow inspection of large amounts of rail, like the electromagnetic

technique previously discussed. The first all-ultrasonic inspection car was introduced in 1959. This car

was developed specifically to meet the needs of the New York City Transit Authority (NYCTA).

Fluid filled wheels or sleds are often used to couple the transducers to the rail. Sperry Rail Services

has, over the years, developed and made use of Roller Search Units (RSU's) comprising a

combination of different transducer angles to achieve the best inspection possible. A schematic of an

RSU is shown below.

https://www.nde-ed.org/AboutNDT/SelectedApplications/RailInspection/RailInspection.htm

3/5

05/06/2015

Rail Inspection

At Sperry, there are two primary inspection units. The

Sperry Rail Detector Car, referred to as the "big" car, uses

both ultrasonic and electromagnetic technologies to identify

defects. The inspection equipment on a Sperry test car is

carried in a carriage slung between the axles.

The Hi-Rail

trucks

currently use

only

ultrasonics

because the electromagnet equipment is too large for this

vehicle. The detector car will test rail between 6.5 and

13 miles per hour. However, higher speed units are in

development.

The data from the inspection equipment is fed to the operator

inside the car. A picture of the operator station is shown on

the right. Federal Railroad Administration (FRA) rules require

that any indication considered suspect by the test equipment

on the test car are hand verified immediately. This leads to a

stop-start test mode. When the operator sees something on

the tape indicating a problem, he uses a buzzer signal system

to tell the driver up front to stop. The car then backs up to the

point of examination where the operator gets out to hand test

the rail with an ultrasonic test set mounted on the rear of the car. If a defect is confirmed, it is marked

and a railroad work crew following the Sperry car will change the rail. If they can't get to it right away,

the section of track is assigned a slow order (slower speed) until the crew can repair it. The amount of

https://www.nde-ed.org/AboutNDT/SelectedApplications/RailInspection/RailInspection.htm

4/5

05/06/2015

Rail Inspection

rail being tested can be increased by the use of chase cars following the testing vehicles. The chase

cars will receive a radioed signal of the test being done by the lead truck and will stop to do the

necessary hand testing. This elimination of the need to back up to hand test, allows the testing vehicle

to move forward, continuously testing, with the results being sent and recorded for examination by the

chase car.

https://www.nde-ed.org/AboutNDT/SelectedApplications/RailInspection/RailInspection.htm

5/5

OS Process Order

Order Pfx./No. : SC - 1516000551

Order Date

Supplier

SS045

Payment Term T005

Price Term

CNF

Line

1

Item

13.05.2015 OSP Order No.

SKR INDUSTRIES

Order Type

#45 DAYS FROM DATE OF RECEIPT ShipVia

COST AND FREIGHT

Status

Rev.

E153287Z

Supplier :SS045-SKR INDUSTRIES

Description

Order Qty.

0 METAL SEAT END 15 CF3M 73 FB FS

CL.150RF

Drawing No : MG-73-15-883M-TB

Process

S.No.

Process

1 EFINS

SC - 1516000551

Standard

10009

BY ROAD

Approved

Description

END FINISHING

12.000

Rate

Ext. Rate

1,032.88

Total :

Lot / Serial Details

SNO

Lot No.

1

Line

2

Item

Rev.

B153271Z

Process

S.No.

Process

1 12OP

2 4OP

3 DRTP

OSP3020 Run By :RAVI

Serial No.

12,394.56

12,394.56

Quantity

12.000

Description

Order Qty.

0 METAL SEAT BODY 15 CF3M 73 FB FS

CL 150RF

Drawing No : MG-73-15-212M-TB

Description

FIRST ,SECOND OPERATION

FOURTH OPERATION

DRILLING AND TAPPING

Lot / Serial Details

SNO

Lot No.

1

Required Prod. Ord. No.

Date

13.05.2015 1516003966

Serial No.

1

12.000

Rate

Required Prod. Ord. No.

Date

13.05.2015 1516003965

Ext. Rate

410.00

4,920.00

160.00

130.00

1,920.00

1,560.00

Total :

8,400.00

Quantity

12.000

Page 1 of 2

Run On : 05-JUN-15 03:05 PM

OS Process Order

Order Pfx./No. : SC - 1516000551

Line

3

Item

Rev.

B303271Z

Description

Description

FIRST ,SECOND OPERATION

FOURTH OPERATION

DRILLING AND TAPPING

Lot / Serial Details

SNO

Lot No.

1

Item

Order Qty.

0 METAL SEAT BODY 30 CF3M 73 FB FS

CL 150RF

Drawing No : MG-73-30-212M-TD

Process

S.No.

Process

1 12OP

2 4OP

3 DRTP

Line

Supplier :SS045-SKR INDUSTRIES

Rev.

E303287Z

Process

S.No.

Process

1 EFINS

2.000

Rate

Ext. Rate

0.10

0.20

0.10

0.10

0.20

0.20

Total :

0.60

Serial No.

Quantity

2.000

Description

Order Qty.

0 METAL SEAT END 30 CF3M 73 FB FS

CL.150RF

Drawing No : MG-73-30-883M-TC

2.000

Description

END FINISHING

Lot / Serial Details

SNO

Lot No.

1

Required Prod. Ord. No.

Date

13.05.2015 1516003967

Rate

Required Prod. Ord. No.

Date

13.05.2015 1516003968

Ext. Rate

0.10

0.20

Total :

0.20

Serial No.

Quantity

2.000

Total (Process) :

20,795.36

Tax Amount :

0.00

Total Amount :

20,795.36

For VAAS AUTOMATION PRIVATE LIMITED

Authorised Signatory

Prepared By

OSP3020 Run By :RAVI

Page 2 of 2

Run On : 05-JUN-15 03:05 PM

05/06/2015

Storage Tank Inspection

Home - A bout NDT

Storage Tank Inspection

Above Ground Tanks

Large chemical and petroleum product storage tanks can be found at chemical processing plants,

refineries, and industrial locations. They are huge metal structures 150 feet in diameter and 50-60

feet tall and can easily hold more than two million gallons of gas or other hazardous liquids. Most

tanks are made of steel plate that is welded together to form the structure. The material and the

welds are inspected for manufacturing defects when constructed but must also be periodically

inspected throughout their service life for signs of damage. The carbon steel is prone to attack by

corrosion and in some circumstances cracks can form over time. NDT personnel use visual, X-ray,

ultrasonic and other inspection methods to search for flaws and service-induced damage.

Inspections and thickness measurements of the tank walls can be made manually with the

inspector in a man lift or hanging down from the top. However a much safer way to make an

inspection is to use a crawling robot. These robots have magnetic wheels that allow them to

cling to the tank walls. Using remote controls, an operator guides them into positions and

makes the necessary measurements. They work great on the side walls, however, getting to a

tank floor is a different story since it is not accessible from the outside. The floor is

particularly prone to thinning due to corrosion attack and tank owners must find the weak

spots in the floors before they breach the tank's integrity. This often involves the costly

process of draining the contents, removing the layer of sludge from the bottom and cleaning

the tanks so inspection personnel may enter it.

However, researchers at the Department of

Energy's Idaho National Engineering and

Environmental Laboratory and Solex

Robotics in Idaho Falls, Idaho, have

developed a new robot to enter filled tanks

and make the inspections. His name is

Maverick and he is designed to go where no

person can or would want to go. He's a

remote-controlled, submersible robot who

will immerse himself in gasoline and other hazardous liquids to do his job. He looks like

a suitcase on steroids and is packed with an array of cameras, sonar and ultrasonic

devices. The inspectors lower him with a pulley to the bottom of as full a tank as

possible. A 500-foot umbilical cord connects him to the command trailer outside the

tank. Maverick has bright red spotlights that provide light for his infrared eyes, and he constantly pings out his position to

external sonar beacons as he searches the floor for flaws with his ultrasonic array. In the command trailer, separate

computers control Maverick's position, his cameras and the ultrasonic inspection system for the tank floor. Maverick's

automated ultrasonic array takes millions of measurements and makes a 3-D map of the inspected tank floor.

For more information on the Maverick robot see this story on the INEEL web site.

https://www.nde-ed.org/AboutNDT/SelectedApplications/TankInspection/TankInspection.htm

1/2

05/06/2015

Storage Tank Inspection

Buried Tanks

Not all tanks are built above ground. A very special

inspection situation involves the tanks used to store

nuclear waste. Weapons, space, medical, and other

research and production programs in the United States

have generated millions of gallons of radioactive waste.

This waste has been stored in approximately 280

underground tanks, which are located primarily at five

Department of Energy sites in the US. These tanks were

built from the 1940's to the 1980's and have capacities

ranging from 13,000 to over 1,000,000 gallons. Many of

these tanks have exceeded their original design life, and

as the tanks age concerns about their leaks continue to

increase.

What makes these inspections especially difficult is that

the tanks are buried underground to help shield the

radiation. Since the waste is particularly hazardous,

special precautions must be taken to limit exposure to

personnel to the radiation and chemical hazards. This

extraordinary situation has resulted in many innovative

technologies being developed to inspect the tanks. Visual

examinations of the tanks are conducted using remote

video cameras. These cameras are mounted on robotic

arms that are lowered into the tanks. The images to the

right show what is know as the light-duty utility arm fitted

with the video inspection system inside a tank and being

deployed down into a tank from above. Some of the

tanks are manufactured with two shells and there is a small space between the walls of the shells. The robotic crawlers

can be lowered down into this space and used to perform ultrasonic inspections of welds and to make thickness

measurements of the tank walls.

https://www.nde-ed.org/AboutNDT/SelectedApplications/TankInspection/TankInspection.htm

2/2

You might also like

- Metalscan Inspection Services Presents: Nondestructive EvaluationDocument15 pagesMetalscan Inspection Services Presents: Nondestructive Evaluationnaganathan100% (2)

- 4-5-6. Non Destructive TestingDocument59 pages4-5-6. Non Destructive TestingTEZ ANALYSIS AND STORIES100% (1)

- By P. Chetan Phani (06010417) Deep Gandhi (06010419) Hemant Kumar Bhaskar (06010421)Document36 pagesBy P. Chetan Phani (06010417) Deep Gandhi (06010419) Hemant Kumar Bhaskar (06010421)Anonymous ouZFaSBRNo ratings yet

- Importance of Quality Assurance in TheDocument6 pagesImportance of Quality Assurance in TheniroNo ratings yet

- Eddy Current Testing/Array For Aviation: Razibul IslamDocument58 pagesEddy Current Testing/Array For Aviation: Razibul IslamRazibul islamNo ratings yet

- TSC - Technical Info, ACFM and Tank Floor Weld InspectionDocument2 pagesTSC - Technical Info, ACFM and Tank Floor Weld InspectionhcmcrlhoNo ratings yet

- Shrikant B. Moje CVDocument6 pagesShrikant B. Moje CVPaul PhiliphsNo ratings yet

- Magnetic Particle InspectionDocument10 pagesMagnetic Particle InspectionZhafri Suhaimi100% (1)

- Liquid Penetrant Test Procedure: Document No.: SP-1.5 Rev. 1.2Document12 pagesLiquid Penetrant Test Procedure: Document No.: SP-1.5 Rev. 1.2Anas PratamaNo ratings yet

- Pec Basics v9 PDFDocument8 pagesPec Basics v9 PDFWayneNo ratings yet

- MPI Procedure For BCEII-FinalDocument10 pagesMPI Procedure For BCEII-FinalBCE DeNo ratings yet

- Durham E-Theses: Investigation Into The Use of Zero Angle Ultrasonic Probe Array For Defect Detection and LocationDocument191 pagesDurham E-Theses: Investigation Into The Use of Zero Angle Ultrasonic Probe Array For Defect Detection and LocationRakesh SrivastavaNo ratings yet

- EMAT Inspection ServicesDocument2 pagesEMAT Inspection ServicesCepi Sindang KamulanNo ratings yet

- Req Trial Audit WW 2009 PDFDocument1 pageReq Trial Audit WW 2009 PDFZedNo ratings yet

- List NDT Techniques Commonly Used For Inspecting and ComponentsDocument12 pagesList NDT Techniques Commonly Used For Inspecting and ComponentscollinsNo ratings yet

- Liquid Penetrant ProcedureDocument5 pagesLiquid Penetrant Procedurenur hudaNo ratings yet

- Scope of WorksDocument3 pagesScope of WorksGovindraj KrishnanNo ratings yet

- Non-Destructive Testing 03Document111 pagesNon-Destructive Testing 03Muhammad AbidinNo ratings yet

- Procedure For LiftingDocument7 pagesProcedure For LiftingAbideen RaheemNo ratings yet

- NDTDocument3 pagesNDTSUJITH G100% (2)

- Cswipdiv7952 2Document43 pagesCswipdiv7952 2Rex ElvinNo ratings yet

- ATTAR Hands On Intro To NDTDocument3 pagesATTAR Hands On Intro To NDTRony Prayitno Simeon0% (1)

- D-p5-Bv-pd-007 - Ect, Issue 01, Rev 00 - Eddy Current TestingDocument18 pagesD-p5-Bv-pd-007 - Ect, Issue 01, Rev 00 - Eddy Current TestingThinh NguyenNo ratings yet

- Basic Knowledge Required For Entry: Wavemaker G3 Level 1 Training CourseDocument24 pagesBasic Knowledge Required For Entry: Wavemaker G3 Level 1 Training CourseJose OcañaNo ratings yet

- Magnetic Particle Inspection - Use and Implementation of ASTM-E-1444Document17 pagesMagnetic Particle Inspection - Use and Implementation of ASTM-E-1444jaga67No ratings yet

- Dye Penetrant InspectionDocument2 pagesDye Penetrant InspectionsuparnaNo ratings yet

- 3) Geometric Unsharpness (Radiographic)Document11 pages3) Geometric Unsharpness (Radiographic)Alirza AliyevNo ratings yet

- 546 - MT-B3-103-01-1503 Rev 4Document13 pages546 - MT-B3-103-01-1503 Rev 4GIOVANNINo ratings yet

- INS - Pulsed Eddy Current (PEC)Document2 pagesINS - Pulsed Eddy Current (PEC)benergy84No ratings yet

- NDT LEVEL II UT Technician Resume CV Format CV Sample Model Example BioData Template Cover Letter PDFDocument3 pagesNDT LEVEL II UT Technician Resume CV Format CV Sample Model Example BioData Template Cover Letter PDFJeevanandam ShanmugaNo ratings yet

- Eddy Current TheoryDocument5 pagesEddy Current TheorypondpakkaNo ratings yet

- Magnetic Particle InspectionDocument11 pagesMagnetic Particle InspectionLuis Guevara0% (1)

- JSA For DPTDocument3 pagesJSA For DPTMohammed Minhaj100% (1)

- Liquid Penetrating TestingDocument99 pagesLiquid Penetrating Testingfaraz090611100% (1)

- SWP CHECKLISTS - Welding Cutting and HeatingDocument3 pagesSWP CHECKLISTS - Welding Cutting and HeatingSrinivas Dumpala HSE100% (1)

- An Introduction To Long-Range Screening Using Guided WavesDocument8 pagesAn Introduction To Long-Range Screening Using Guided WavesVikas TiwariNo ratings yet

- Non-Destructive Testing: Prof. Tarapada RoyDocument12 pagesNon-Destructive Testing: Prof. Tarapada RoySIVARAM PRASADNo ratings yet

- ACFM Applications1Document12 pagesACFM Applications1naoufel1706No ratings yet

- (WTC) Repair Welding in Power PlantsDocument23 pages(WTC) Repair Welding in Power PlantsSarah FrazierNo ratings yet

- 3 4 U Master DocumentDocument21 pages3 4 U Master DocumentandriaerospaceNo ratings yet

- Welcome: Jubail Industrial College Non Destructive Testing (NDT) Training CenterDocument37 pagesWelcome: Jubail Industrial College Non Destructive Testing (NDT) Training CenterAhmed shabanNo ratings yet

- Jspl-Introduction of NDTDocument75 pagesJspl-Introduction of NDTvsnaiduqc100% (1)

- DR Writing Style For Engineers Australia - An Example: Example of Career Episode ReportDocument2 pagesDR Writing Style For Engineers Australia - An Example: Example of Career Episode ReportkamalgaihreNo ratings yet

- NDTDocument29 pagesNDTIhsan Durani67% (3)

- Ur w35 PDFDocument5 pagesUr w35 PDFBala MuruganNo ratings yet

- Shahin Internship Report On Non-Destructive Testing in Saj Engineering and Trading CompanyDocument127 pagesShahin Internship Report On Non-Destructive Testing in Saj Engineering and Trading CompanyShahin Manjurul AlamNo ratings yet

- Method Statement For Near Field Test: DCSM Project 2019Document5 pagesMethod Statement For Near Field Test: DCSM Project 2019Thinh NguyenNo ratings yet

- Corrosion Mapping Solutions EddyfiDocument4 pagesCorrosion Mapping Solutions EddyfiTHIRU.SNo ratings yet

- Eddy Current in BriefDocument23 pagesEddy Current in BriefRamakrishnan AmbiSubbiahNo ratings yet

- Curso Leak DetectionDocument21 pagesCurso Leak DetectionDurgamadhaba Mishra100% (1)

- NDT Unit 1to5Document373 pagesNDT Unit 1to5UdamanNo ratings yet

- Liquid Penetrant TestingDocument11 pagesLiquid Penetrant Testingaamirapi100% (1)

- Magnetic Particle InspectionDocument9 pagesMagnetic Particle Inspectionmuthub4uNo ratings yet

- Ust ProcedureDocument18 pagesUst ProcedureVikiseptNo ratings yet

- Risk Assessment for Human Metal Exposures: Mode of Action and Kinetic ApproachesFrom EverandRisk Assessment for Human Metal Exposures: Mode of Action and Kinetic ApproachesNo ratings yet

- Intro For NDT and NDEDocument3 pagesIntro For NDT and NDEkonainglincho001No ratings yet

- NDT DataDocument3 pagesNDT Dataduayogesh07No ratings yet

- Nondestructive Testing: Take This Link To Learn About The Background of NDT and NDEDocument4 pagesNondestructive Testing: Take This Link To Learn About The Background of NDT and NDEAdrian DavidNo ratings yet

- Pmi Report 16.09.2015 To 17Document68 pagesPmi Report 16.09.2015 To 17mohanNo ratings yet

- Material Specification: WWW - Auer-Kunststofftechnik - de Info@auer-Kunststofftechnik - deDocument1 pageMaterial Specification: WWW - Auer-Kunststofftechnik - de Info@auer-Kunststofftechnik - demohanNo ratings yet

- Annexure - 1Document2 pagesAnnexure - 1mohanNo ratings yet

- v-60 BallDocument1 pagev-60 BallmohanNo ratings yet

- PVDF Material Properties Data Sheet: Kynar Hylar Mechanical Property ASTM Method Unit 1000 HD MP-10Document1 pagePVDF Material Properties Data Sheet: Kynar Hylar Mechanical Property ASTM Method Unit 1000 HD MP-10JorgeLuisRiveraNo ratings yet

- NDT TestingDocument20 pagesNDT TestingmohanNo ratings yet

- TickrtDocument2 pagesTickrtmohanNo ratings yet

- 2 12 73 Conformity & MTCDocument3 pages2 12 73 Conformity & MTCmohanNo ratings yet

- 7 ., A O D.Llmited: Os Process OrderDocument2 pages7 ., A O D.Llmited: Os Process OrdermohanNo ratings yet

- Vaas Automation Private Limited: Inspection Report Perungudi PlantDocument50 pagesVaas Automation Private Limited: Inspection Report Perungudi PlantmohanNo ratings yet

- Inspection RequestDocument4 pagesInspection RequestmohanNo ratings yet

- A Subsidiary of Bray InternationalDocument1 pageA Subsidiary of Bray InternationalmohanNo ratings yet

- A105 BarDocument1 pageA105 BarmohanNo ratings yet

- Astm A370 1977Document56 pagesAstm A370 1977mohanNo ratings yet

- Vaas Automation Private LimitedDocument1 pageVaas Automation Private LimitedmohanNo ratings yet

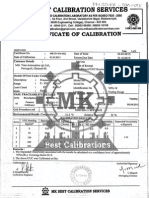

- Calibration CertificateDocument3 pagesCalibration CertificatemohanNo ratings yet

- A TM Banking!: Chilr.! tt"6Document2 pagesA TM Banking!: Chilr.! tt"6mohanNo ratings yet

- Serie 61P 62PDocument16 pagesSerie 61P 62PmohanNo ratings yet

- Inspection RequestDocument4 pagesInspection RequestmohanNo ratings yet

- Vaas Automation Private LimitedDocument1 pageVaas Automation Private LimitedmohanNo ratings yet

- Calibration CertificateDocument3 pagesCalibration CertificatemohanNo ratings yet

- Aberdeen Proving GroundDocument106 pagesAberdeen Proving GroundCAP History Library100% (1)

- Inventory Management in Iffco VDocument89 pagesInventory Management in Iffco VShrinivas NagarappaNo ratings yet

- LA Metro - 176Document2 pagesLA Metro - 176cartographica100% (1)

- Main PaperDocument66 pagesMain PaperAkash MajjiNo ratings yet

- Red Bus TicketDocument1 pageRed Bus TicketAjay Kumar100% (1)

- EdinburghDocument76 pagesEdinburghainog100% (1)

- SLEWING Shiploader Quinhuangdao DrehgeraDocument2 pagesSLEWING Shiploader Quinhuangdao DrehgeraMinh TríNo ratings yet

- BG Tunisia: Maintenance DepartmentDocument17 pagesBG Tunisia: Maintenance Departmentghazi kallelNo ratings yet

- Underpass Top Down PaperDocument17 pagesUnderpass Top Down PaperAlok MehtaNo ratings yet

- Air Driven Engine VehicleDocument7 pagesAir Driven Engine VehicleBharanidharan RajmohanNo ratings yet

- TBMDocument26 pagesTBMMamuye Busier YesufNo ratings yet

- Adding Charts To Your Dashboard AfterDocument231 pagesAdding Charts To Your Dashboard Afterhassan1989No ratings yet

- WWII 4th Armored DivisionDocument77 pagesWWII 4th Armored DivisionCAP History LibraryNo ratings yet

- Lockheed C-130 - Phase Style Aircraft Maintenance Platforms and Stands - Fall Arrest Solutions - Aircraft Fall Protection SystemsDocument4 pagesLockheed C-130 - Phase Style Aircraft Maintenance Platforms and Stands - Fall Arrest Solutions - Aircraft Fall Protection SystemsDaniel Neves PereiraNo ratings yet

- April 10, 2015 Strathmore TimesDocument28 pagesApril 10, 2015 Strathmore TimesStrathmore TimesNo ratings yet

- Delhi Master Plan-Lal Dora OpportunityDocument5 pagesDelhi Master Plan-Lal Dora OpportunityAnkit JainNo ratings yet

- Schematic - Preamp With Tone Control - 2023-09-23Document1 pageSchematic - Preamp With Tone Control - 2023-09-23Mario RazielNo ratings yet

- Unit-4 Material Handling SystemsDocument26 pagesUnit-4 Material Handling SystemsNarayana Perumal100% (1)

- 43u-0000-003-0 Fitting Towerhead (Montage-Pivot)Document13 pages43u-0000-003-0 Fitting Towerhead (Montage-Pivot)hanyNo ratings yet

- Study On The Effectiveness of The Newly Improvised Beep Machine (Philippines)Document21 pagesStudy On The Effectiveness of The Newly Improvised Beep Machine (Philippines)Hyacinth Gasmin20% (5)

- Conditions For Implementing Trolleybuses in Public Urban TransportDocument8 pagesConditions For Implementing Trolleybuses in Public Urban TransportSorin ScutarasuNo ratings yet

- CLI QB EnglishDocument91 pagesCLI QB EnglishBala RajuNo ratings yet

- LRN Level B2 January 2016 Exam Paper PDFDocument14 pagesLRN Level B2 January 2016 Exam Paper PDFpumpboygrNo ratings yet

- Omnibus Iiib Stock Market Game 1870sDocument3 pagesOmnibus Iiib Stock Market Game 1870sapi-235000986No ratings yet

- Si Ferry ScheduleDocument2 pagesSi Ferry ScheduleElsinrNo ratings yet

- BIG RED LONDON BUSES Upper - IntermediateDocument2 pagesBIG RED LONDON BUSES Upper - IntermediateperdidalmaNo ratings yet

- Glosario Ingles LogisticaDocument18 pagesGlosario Ingles LogisticaCarlos WcNo ratings yet

- Berlin in Your Pocket #38 April/May 2009Document39 pagesBerlin in Your Pocket #38 April/May 2009berlin_iypNo ratings yet