Professional Documents

Culture Documents

A Paper4 Que

Uploaded by

zoom20Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Paper4 Que

Uploaded by

zoom20Copyright:

Available Formats

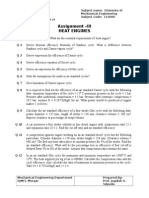

2nd NATIONAL CERTIFICATION EXAMINATION 2005

FOR

ENERGY AUDITORS

MODEL TEST SERIES A

Paper 4: Energy Performance Assessment for Equipment and Utility Systems

Duration:

Max. Marks: 100

HRS

General instructions:

oPlease check that this question paper contains 16 questions

oThe question paper is divided into three sections

oAll questions in all three sections are compulsory

oAll parts of a question should be answered at one place

oOpen Book Examination

Section I: Short Questions

Marks: 10 x 1 = 10

(i) Answer all Ten questions

(ii) Each question carries One mark

How boiler rated capacity is specified?

What are the components of surface heat loss in the furnaces and its dependent

factors affecting loss?

How Efficiency and Power Factor varies in motors with VSD Drives.

What are the three reasons for poor fan performance in the field?

How do you determine system resistance for a pump?

What are the measuring instruments required for a compressed air delivery test by

nozzle method ?

A refrigeration plant operating at 600 T is consuming 564 kW of compressor power.

Find out the kW/ton, COP and EER

What is Lamp Circuit Efficacy?

What is the capacity factor of wind turbine.

Paper 4/ Series A

Page 1 of 4

10 Name four type of wastage due to poorhouse keeping?

Section - II: Long Questions

Marks: 2 x 5 = 10

(i) Answer all Two questions

(ii) Each question carries Five marks

1 Compare the advantage of biogas generation over the direct burning of 25 kg

biomass?

2 What are the Factors Affecting Furnace Performance ?

Section - III: Numerical Questions

Marks: 4 x 20 = 80

(i) Answer all Four questions

(ii) Each question carries Twenty marks

1 A Boiler Efficiency trial was conducted in an Furnace Oil fired process boiler during

Energy Audit Study and the following data were collected.

Boiler Data :

Boiler Rated Capacity

Rated Boiler Efficiency

Actual steam generation pressure

Feed water Temperature

= 10 TPH (F&A 100oC)

= 84%

= 7 kg/cm2 (g) Saturated

= 45oC

Fuel Oil Data :

Furnace Oil Consumption

GCV of Oil

Specific gravity of oil

% Carbon

% Hydrogen

% Sulphur

% Oxygen

% Nitrogen

= 600 litre per hour

= 10200 Kcal/kg

= 0.92

= 84%

= 12%

= 3%

= Nil

= 1%

Flue Gas Data :

% O2 in Flue Gas

CO

Flue Gas Temperature

Specific Heat of Flue Gas

Moisture at Ambient air

= 5.5% by volume

= Nil

= 240oC

= 0.24

= 0.03 kg/kg of air

Paper 4/ Series A

Page 2 of 4

Ambient air temperature

= 40oC

Determine the boiler efficiency by indirect method by assuming 2% boiler surface

heat loss. Also find out the fuel oil saving in litre per hour, if efficiency of boiler was

improved to Rated efficiency.

2 A process plant requires 28 tonnes of steam per hour. The power requirement is 2250

kW. The plant operates for 8000 hours per annum.

Steam is generated at 2 bar in a coal fired boiler with an efficiency of 75% The feed

water temperature is 80OC. The calorific value of coal is 4000 kcal/kg. The cost of

coal is Rs.2000/tonne.

Power is drawn from the grid at Rs. 4/kWh. The contract demand is 3000 kVA and the

company is charged for 100 % of the contract demand at Rs. 300/kVA.

The company is planning for a back pressure cogeneration plant using the same coal

with the following parameters. The power and steam demand were fully met by the

cogeneration plant.

Boiler generation pressure

- 18 bar, 310OC

Boiler efficiency

- 81 %

A contract demand of 1000 kVA with the grid was kept for emergency purpose.

Investment required

- Rs. 20 crores

Generated power

= 2250 kW

Find out the IRR over a project life cycle of 6 years.

3 A centrifugal pump at base of cooling tower pumps 120 m3/hr at pressure 2.1 kg/cm2.

The cooling tower range was measured to be 4 oC. What is the power input at the

motor? (Efficiency of pump is 65% and motor efficiency is 82%).

Pump is throttled such that cooling tower range was 6oC. What is the new flow rate

under throttled conditions? (Pressure drop across the throttle valve is 0.5 kg/cm2).

If instead of throttling, the existing impeller is replaced with a new impeller at a cost

of Rs.25000/- find the operating point and differential savings vis--vis throttling case

considering 8760 operating hours and unit cost of Rs.4/- (assume pump efficiency of

63% and motor efficiency of 82%)

4 In an air conditioning system, the air flow rate is 80,000 m3/hr at a density of 1.2

kg/m3.. The inlet and outlet enthalpies of air at Air Handling Unit is 105 kJ/kg and 79

kJ/kg. The COP of the system is 3.82. It is proposed to replace it with a vapour

absorption system at a cost of Rs. 50 lacs with an annual maintenance cost of Rs.4

lacs.. The steam consumption will be 4.5 kg/hr/TR. The steam is to be generated by a

coal fired boiler with an evaporation ratio of 4.5. The energy electrical energy cost is

Rs.4 per kWh and the system operates for 8000 hrs per annum. The cost of coal is

Paper 4/ Series A

Page 3 of 4

Rs.2000/tonne. Find out the payback period for the investment.

Paper 4/ Series A

Page 4 of 4

You might also like

- Paper 4A SolutionDocument10 pagesPaper 4A SolutionSHAMSIK2002No ratings yet

- ICE RevisionDocument4 pagesICE RevisionjehadyamNo ratings yet

- BeeDocument20 pagesBeeAnudeep ChittluriNo ratings yet

- ME 416 (ME 4) Internal Combustion Engine Practice ProblemsDocument3 pagesME 416 (ME 4) Internal Combustion Engine Practice ProblemsMark MagdaleNo ratings yet

- Paper 4 - Set A Key 14 National Certification Examination FOR Energy Auditors - August, 2013Document14 pagesPaper 4 - Set A Key 14 National Certification Examination FOR Energy Auditors - August, 2013Muthiah Chidambaram MuthiahNo ratings yet

- Paper-4 SetB Key Final 8may2009Document10 pagesPaper-4 SetB Key Final 8may2009chkk.ramakumarNo ratings yet

- Me8493 Te Rejinpaul Iq Am19 PDFDocument2 pagesMe8493 Te Rejinpaul Iq Am19 PDFAngelinNo ratings yet

- Shantanu DasDocument10 pagesShantanu DasarunkdevassyNo ratings yet

- Paper-4 SetA Key Final 8may2009Document10 pagesPaper-4 SetA Key Final 8may2009SHAMSIK2002No ratings yet

- ICE All ExercisesDocument10 pagesICE All ExercisesB Ninh100% (1)

- SQ - 4.1 - Boiler (Table Format)Document11 pagesSQ - 4.1 - Boiler (Table Format)Gajanan JagtapNo ratings yet

- YgDocument2 pagesYgVincent Martinez0% (1)

- PROJECT. (Final) ME3CDocument1 pagePROJECT. (Final) ME3CJoesun LizardoNo ratings yet

- Home Exercises - AllDocument6 pagesHome Exercises - AllRajithaSomathilakeNo ratings yet

- Unit I: Gas Power CyclesDocument78 pagesUnit I: Gas Power CyclesBalaji DsNo ratings yet

- Assignment 1 MEPPEDocument5 pagesAssignment 1 MEPPEFrancis Paulo CruzNo ratings yet

- Ejercicios Motores.Document10 pagesEjercicios Motores.Daniel ArmasNo ratings yet

- Power Plant Numerical ProblemsDocument3 pagesPower Plant Numerical ProblemsRishav niroulaNo ratings yet

- Thermal and Nuclear Power Plant Assignment QuestionsDocument3 pagesThermal and Nuclear Power Plant Assignment QuestionsAshok KumarNo ratings yet

- At AssignmentDocument3 pagesAt AssignmentYogesh PatilNo ratings yet

- ME FinalDocument81 pagesME FinalAnkit DahiyaNo ratings yet

- Gas Turbine Tutorial Part 1: Brayton Cycle AnalysisDocument4 pagesGas Turbine Tutorial Part 1: Brayton Cycle AnalysisGulain MayomboNo ratings yet

- ME6404 Thermal EngineeringDocument21 pagesME6404 Thermal EngineeringAnonymous mRBbdopMKfNo ratings yet

- Me 482 Energy Conservation and ManagementDocument15 pagesMe 482 Energy Conservation and ManagementTHIAGARAJAN ANo ratings yet

- Duration: 2 Hrs. Max. Marks: 100Document4 pagesDuration: 2 Hrs. Max. Marks: 100AshutoshBhattNo ratings yet

- Thermodynamics Assignment 2 QuestionsDocument2 pagesThermodynamics Assignment 2 QuestionshampaskacaNo ratings yet

- 144 BDocument14 pages144 BJoshi DhvanitNo ratings yet

- Thermal Engineering QP AuDocument14 pagesThermal Engineering QP AusaisenthNo ratings yet

- Final Practice-ProblemsDocument4 pagesFinal Practice-ProblemsMhd Donde Al HajNo ratings yet

- 4 3 CogenerationDocument10 pages4 3 CogenerationJayvin RossNo ratings yet

- Fallsem2013-14 Cp0084 Asgn03 Assignment3Document2 pagesFallsem2013-14 Cp0084 Asgn03 Assignment3Agnibh PrakashNo ratings yet

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocument12 pagesEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshNo ratings yet

- SY - Thermal Engineering - JAN 2019Document3 pagesSY - Thermal Engineering - JAN 2019Paras kapoorNo ratings yet

- Paper 4SetA 24nov2009 KeyDocument8 pagesPaper 4SetA 24nov2009 KeySHAMSIK2002No ratings yet

- Mce320 Tutorial KitDocument20 pagesMce320 Tutorial KitxentrixxNo ratings yet

- Heat engines assignment solutionsDocument6 pagesHeat engines assignment solutionsSaniya Jumani0% (1)

- Chapter 8 Van NessDocument76 pagesChapter 8 Van NessConrad MonterolaNo ratings yet

- Air Standard Cycles and Engine SystemsDocument5 pagesAir Standard Cycles and Engine SystemsGerlan Madrid MingoNo ratings yet

- Ormat Technologies Inc. - Ormat Energy Converters Proven Power From Cement Plant Waste Heat - 2013-05-09Document7 pagesOrmat Technologies Inc. - Ormat Energy Converters Proven Power From Cement Plant Waste Heat - 2013-05-09Kiran VeerubhotlaNo ratings yet

- Universiti Teknologi Mara Final Examination: Confidential EM/APR 2007/KJM451Document10 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/APR 2007/KJM451Diraf AlipNo ratings yet

- Local Media1133470422700059155Document6 pagesLocal Media1133470422700059155Billy JhunNo ratings yet

- Sheet 1Document3 pagesSheet 1saad ElsheikhNo ratings yet

- Tutorial AssignmentDocument5 pagesTutorial AssignmentAnup ChauhanNo ratings yet

- 4.9 HVAC SystemDocument5 pages4.9 HVAC Systembsunanda01No ratings yet

- Me8595 Iq R17Document2 pagesMe8595 Iq R17Narayanan SubramanianNo ratings yet

- Final Exam ENGI 2800 - Engineering Thermodynamics IDocument2 pagesFinal Exam ENGI 2800 - Engineering Thermodynamics Iياسر سعيد عبادي البحريNo ratings yet

- Mechanical Engineering Department Refrigeration & Air Conditioning (ME 434) Sheet 1Document3 pagesMechanical Engineering Department Refrigeration & Air Conditioning (ME 434) Sheet 1Ahmed SabryNo ratings yet

- Cog en Era Ti OnDocument12 pagesCog en Era Ti OnMayank DubeyNo ratings yet

- National Certification Examination 2008 FOR Energy AuditorsDocument10 pagesNational Certification Examination 2008 FOR Energy AuditorsMukesh KumarNo ratings yet

- Tutorials 1-4Document6 pagesTutorials 1-4KrishnaNo ratings yet

- Nhom 10 - Chuong 4Document10 pagesNhom 10 - Chuong 4Alfie StacyNo ratings yet

- HVACDocument17 pagesHVACashwini_kumar1984No ratings yet

- Solutions Gas Turbines Q1-8Document18 pagesSolutions Gas Turbines Q1-8Tom TambeNo ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Analysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantFrom EverandAnalysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantNo ratings yet

- TATA McGRAW Spotting ErrrorsDocument37 pagesTATA McGRAW Spotting ErrrorsBiswajit BeheraNo ratings yet

- National Income AccountingDocument5 pagesNational Income Accountingzoom20No ratings yet

- Correct Your Grammar-100 RulesDocument17 pagesCorrect Your Grammar-100 Rulessushil4056No ratings yet

- A Paper3 SolDocument15 pagesA Paper3 Solzoom20No ratings yet

- Ecology Part1Document7 pagesEcology Part1zoom20No ratings yet

- English Grammar SecretsDocument66 pagesEnglish Grammar SecretsMbatutes94% (33)

- 1008071281160783correct Errors in The Use of PrepositionsDocument2 pages1008071281160783correct Errors in The Use of PrepositionsRajeev RanjanNo ratings yet

- A Paper2 QueDocument8 pagesA Paper2 Quezoom20No ratings yet

- Atlas World Map For PracticeDocument1 pageAtlas World Map For PracticeRahul KatrawatNo ratings yet

- 2015 Appointments (Jan-August) by AffairsCloudDocument10 pages2015 Appointments (Jan-August) by AffairsCloudzoom20No ratings yet

- MODI Schemes & Tours 2014 - 15 - Hand Notes by AffairsCloudDocument12 pagesMODI Schemes & Tours 2014 - 15 - Hand Notes by AffairsCloudShriram AryanNo ratings yet

- 2015 Appointments (Jan-August) by AffairsCloudDocument10 pages2015 Appointments (Jan-August) by AffairsCloudzoom20No ratings yet

- Mechanical Gate Paper ADocument16 pagesMechanical Gate Paper AAbhilash G NairNo ratings yet

- Indian and World Geography PDFDocument42 pagesIndian and World Geography PDFsaket1989No ratings yet

- A complete guide for competitive examsDocument51 pagesA complete guide for competitive examsViz PrezNo ratings yet

- An Overview of Turbulent Flows PDFDocument20 pagesAn Overview of Turbulent Flows PDFmervedNo ratings yet

- Topic:-Structuree of Atom Made By: - Nikunj Agarwal 1XDDocument16 pagesTopic:-Structuree of Atom Made By: - Nikunj Agarwal 1XDUday GuptaNo ratings yet

- 2021 Report TotalEnergies Energy LandscapeDocument126 pages2021 Report TotalEnergies Energy LandscapeRana Muhammad Ayyaz RasulNo ratings yet

- CH-HW-PH-115 MWAC BARAS SOLAR POWER PLANT CHANNEL LINING SOLUTION-Rev2-Jun22-ENDocument2 pagesCH-HW-PH-115 MWAC BARAS SOLAR POWER PLANT CHANNEL LINING SOLUTION-Rev2-Jun22-ENAmihan SantosNo ratings yet

- Solar Powered Cathodic ProtectionDocument2 pagesSolar Powered Cathodic ProtectionncharalaNo ratings yet

- Solar RadiationtransDocument51 pagesSolar RadiationtransmrizqynugrahaNo ratings yet

- Experiment 8 - Report - Specific HeatDocument3 pagesExperiment 8 - Report - Specific HeatRami HammoudNo ratings yet

- Seminario 1Document5 pagesSeminario 1Javier FrancoNo ratings yet

- AbstractDocument5 pagesAbstractTarak A PositiveNo ratings yet

- Ce6401 PDFDocument143 pagesCe6401 PDFPrithiv D CruzzNo ratings yet

- Bird Extended AIChE CEEDocument8 pagesBird Extended AIChE CEEJairo Silva CoreaNo ratings yet

- Pollution in Lebanon Grade 6Document2 pagesPollution in Lebanon Grade 6Amir Mershad100% (1)

- The Impact of Chemical Fertilizers On Our Environment and EcosystemDocument19 pagesThe Impact of Chemical Fertilizers On Our Environment and EcosystemDiana DainaNo ratings yet

- Panduan Geologi Struktur TGL FT UGMDocument37 pagesPanduan Geologi Struktur TGL FT UGMKhansamutiayNo ratings yet

- SoilThermalResistivity PDFDocument29 pagesSoilThermalResistivity PDFgnklol3No ratings yet

- Physics 2.2 Mechanics 2-181 To 2-190Document8 pagesPhysics 2.2 Mechanics 2-181 To 2-190siddiqueNo ratings yet

- TOEFL Readings 28Document4 pagesTOEFL Readings 28Seni Dan OlahragaNo ratings yet

- HW3 Molecular Polymorphism SolutionDocument2 pagesHW3 Molecular Polymorphism SolutionMiriam KaufmanNo ratings yet

- Lis 773 Layton Collection Development ProposalDocument14 pagesLis 773 Layton Collection Development Proposalapi-599263295No ratings yet

- GasesDocument90 pagesGasesthatoNo ratings yet

- General Physics 1 - Course OutlineDocument2 pagesGeneral Physics 1 - Course OutlineFeliph Angelo Sinfuego CalunodNo ratings yet

- Project Proposal CS661Document6 pagesProject Proposal CS661SusovanNo ratings yet

- Geography Hon.Document18 pagesGeography Hon.Bijay Krishna DasNo ratings yet

- Gas Analyzer - SKCDocument38 pagesGas Analyzer - SKCajayNo ratings yet

- The Planets of The Solar System With All Their DescriptionsDocument1 pageThe Planets of The Solar System With All Their DescriptionsMiranda SosaNo ratings yet

- Lecture 1 1489485680Document52 pagesLecture 1 1489485680Dato TevzadzeNo ratings yet

- Statements of the Second Law ExplainedDocument45 pagesStatements of the Second Law ExplainedSindhu KemburuNo ratings yet

- Notes On CeramicsDocument11 pagesNotes On Ceramicsleebrown21082003No ratings yet

- Bernoullis TheoremDocument3 pagesBernoullis TheoremM Thiru ChitrambalamNo ratings yet

- Environmental Impact of Cement ProductionDocument2 pagesEnvironmental Impact of Cement ProductionRahul SainiNo ratings yet