Professional Documents

Culture Documents

Design Methodology of Garlic Peeling Machine

Uploaded by

IJSTECopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Methodology of Garlic Peeling Machine

Uploaded by

IJSTECopyright:

Available Formats

IJSTE - International Journal of Science Technology & Engineering | Volume 02 | Issue 02 | August 2015

ISSN (online): 2349-784X

Design Methodology of Garlic Peeling Machine

Dhananjay G. Dange

Department of Mechanical Engineering

K.D.K.C.E. Nagpur, India

Dr. S. K. Choudhary

Professor

Department of Mechanical Engineering

K.D.K.C.E. Nagpur, India

A. P. Ninawe

Assistant Professor

Department of Mechanical Engineering

K.D.K.C.E Nagpur, India

Abstract

This paper presents the design calculation of garlic peeling machine. Assumptions and references are taken for designing the

garlic peeling machine. The design calculation of garlic peeling machine is done. For designing the garlic peeling machine, it is

calculate required design parameters such as speed of crank, strokes of garlic pot, design of worm and worm wheel and design of

connecting rod.

Keywords: Design of V-Belt, Design of Pulley, Design of Connecting Rod, Design of Worm and Worm Gear

________________________________________________________________________________________________________

I. INTRODUCTION

Capacity of machine or mass of peeling garlic, MPG = 2 Kg

Mass of garlic pot with cage, MGP = 3 Kg

Stroke length, h = 152 mm = 0.152 m

Taking obliquity ratio, n = 6 = Lc/r

Where, Lc is length of connecting rod

r is length of crank

We know that stroke is double of crank length i.e. Stroke, h = 2r

Therefore crank length, r = h/2 = 152/2 = 76 mm = 0.076 m

Then, length of connecting rod, Lc

Lc = 6r = 676 = 456 mm = 0.456 m

Total weight, WT = Mass of peeling garlic + Mass of garlic pot

WT = (2 + 3) 9.8 = 49 N

Force required to break the garlic bulb varies between

FBreak = 4.88 N to 6.1 N

Force required to peel the garlic clove varies between

FPeeling = 1.83 N to 3.05 N

Force required to crush the garlic clove varies between

FCrush = 7.32 N to 8.54 N

Fig. 1: Slider Crank Mechanism (Force)

In the machine, first impact force will be breaking the garlic bulb and then it will peel the garlic clove.

Stress developed due to impact load, Impact

All rights reserved by www.ijste.org

83

Design Methodology of Garlic Peeling Machine

(IJSTE/ Volume 2 / Issue 2 / 013)

Impact = [F/A] [1 (1 + (2hAE/FL))0.5]

Where, F, is a gradual force, N

A, is area of garlic clove, m2

h, is height of impact, m

E, is youngs modulus of garlic, N/m2

L, is length of garlic clove, m

Therefore,

F = 6.1 N,

h = 0.15 m,

L = 3 cm = 0.03 m, d = 15 mm = 0.015 m,

A = 1.767 x 10-4 m2, E = 1.62 x 105 N/m2

Impact = 204469.95 N/m2

Therefore, FImpact

FImpact = Impact A

FImpact = 36.13 N

Total force, FT

FT = Total weight + Impact force

FT = 49 + 36.13

FT = 85.13 N

Kinetic energy, KE

KE = Total force x Stroke

KE = 12.94 Nm

Also Kinetic energy KE = 0.5 MT VGP2

Where, MT = Total mass in Kg

MT = MPG + MGP

MT = 5 Kg

And

VGP = Velocity of garlic pot in m/s

.. 12.94 = 0.55VGP2

.. VGP = 2.275 m/s

i.e. Linear velocity of garlic pot, VGP = 2.275 m/s

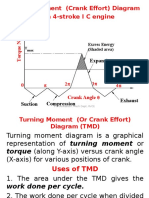

Now considering slider crank mechanism at 90 o

Fig. 2: Slider Crank Mechanism (Velocity)

From figure, when crank at 90o and 270o, the point B having maximum linear velocity VMax . When point A at IDC or ODC

then point B will be at TDC or BDC respectively and also having zero linear velocity i.e. V zero . Also at this position, the crank

velocity and slider velocity will be same i.e. point A and point B having same velocity at 90 o. So we can take,

Velocity of slider = Velocity of crank

VGP = Vcrank = 2.275 m/s

Now using relation Vcrank = r crank

Where, Vcrank is linear velocity of crank, m/s

r is length of crank, m

crank is angular velocity of crank, rad/s

.. crank = 29.93 rad/s

Also, crank = 2N/60

.. N = Ncrank = 285.8 RPM

All rights reserved by www.ijste.org

84

Design Methodology of Garlic Peeling Machine

(IJSTE/ Volume 2 / Issue 2 / 013)

II. SPECIFICATION OF ELECTRIC MOTOR

The specifications of electric motor available in market are as follows.

AC electric motor

Power 1 HP

Rotation 1440 RPM

III. DESIGN OF V-BELT AND PULLEY

A. Design of V-Belt:

From Table XV 9 (DDB)

Design power, Pd = PR x kl

Where, PR is Rated power = 0.746 KW

kl is load factor

from table XV 2 (DDB)

load factor, kl = 1.15

.. Design power, Pd = 0.858 KW

Selection of belt on the basis of design power i.e. P d = 0.858 KW from design data book.

Form table XV 8 (DDB)

Belt designation is A

Normal width, w = 13 mm

Normal thickness, t = 8 mm

Recommended minimum pulley diameter, D = 75 mm

Taking velocity ratio VR = 2.7

Now by using the velocity ratio

VR = N2/N1 = D1/D2

D1 = VR x D2 = 2.7x75

D1 = 202.5 mm 203 mm

Peripheral velocity, VP

VP = D1N1/60

VP = 15.30 m/s

Centre distance between two pulleys, C

From Table XV 10 (DDB)

C = D1+D2 where, D1 Bigger pulley diameter

C = 203+75 D2 Smaller pulley diameter

C = 278 mm = 0.278 m

Fig. 3: Details of V Belt and Pulley

All rights reserved by www.ijste.org

85

Design Methodology of Garlic Peeling Machine

(IJSTE/ Volume 2 / Issue 2 / 013)

Length of V Belt, L

L = (/2) x (D1+D2) + 2C +{[( D1-D2)2 ]/ 4C}

L = 1050.44 mm = 1.05 m

From table XV 1 (DDB)

= (D1-D2)/C

Where, angle of lap or contact

1 angle of lap or contact on larger pulley

2 angle of lap or contact on smaller pulley

1 = + (D1-D2)/C

1 = 3.6 rad

2 = - (D1-D2)/C

2 = 2.68 rad

From table XV 11 (DDB)

For D2 = 75 mm

Angle = 34o

Power rating per belt, Watt

From table XV 9 (DDB)

(Power/Belt) = (FW - FC){[e(/sin(/2)) 1]/[e(/sin(/2))]}VP

Where,

FW = Working load, N

FW = w2

FW = 169 N

FC = Centrifugal Tension, N

FC = kc (VP/5)2

kc = Centrifugal Tension factor

From Table XV 8 (DDB)

kc = 2.52

FC = 23.6 N

= Arc of contact on smaller pulley, rad

= 2.68 rad

= Co-efficient of friction

From Table XV 10 (DDB)

= 0.3

= Cone angle = 34o

.. (Power/Belt) = 2082.4 W = 2.08 KW

Number of strand, n

Number of strand = Design power, P d /Power per belt

Number of strand = 0.858 /2.08

Number of strand = 0.4125

Taking number of strand is 1

Bending load, Fb , N

From Table XV 9 (DDB)

Fb = kb / D Where, kb Bending stress factor and

D Pulley diameter in mm

From table XV 8 (DDB)

Kb = 17.6 x 103

For larger pulley, D1

Bending load, Fb = 86.7 N

For Smaller pulley, D2

Bending load, Fb = 234.67 N

Taking maximum bending force, Fbmax

.. Fbmax = 234.67 N

Belt tension ratio

For V Belt, belt tension ratio

(T1/T2) = e(/sin(/2))

Where, = 0.3

= 2.68

= 34o

.. T1/T2 = 15.64

Also, From Table XV 1 (DDB)

All rights reserved by www.ijste.org

86

Design Methodology of Garlic Peeling Machine

(IJSTE/ Volume 2 / Issue 2 / 013)

Belt Tension, T1, T2, N

(T1-T2) = Pd/VP

where, Pd = Design Power = 858 W

.. (T1-T2) = 56.08 N VP = Peripheral Velocity = 15.30 m/s But, T 1/T2 = 15.64

.. T1 = 15.64 T2

(15.64 T2-T2) = 56.08 N

.. T2 = 3.83 N

and

.. T1 = 59.91 N

From Table XV 1 (DDB)

Initial Tension, Ti , N

2(Ti)0.5 = (T1)0.5 + (T2)0.5

.. Ti = 23.51 N

From Table XV 9 (DDB)

Maximum total force, F1 = Ti + FC + Fbmax

.. F1 = 281.78 N

B. Smaller Pulley:

From table XV 7 (DDB)

Material of pulley cast iron

Type of construction

Diameter below 150 mm Web construction

Diameter above 150 mm Arm construction

Fig. 4: Details of Pulley

So, smaller pulley having 75 mm diameter, therefore construction will be web construction.

From Table XV 11 (DDB)

Groove section A

lp 11 mm

b 3.3 mm

h 8.7 mm

e 150.3 mm

f 9 To 12 10.5 mm

DP 75 mm

34o

Width of pulley, w

w = (n-1) e + 2f where, n number of belt = 1

.. w = 21 mm

C. Shaft Design for Smaller Pulley:

From Table XI 1 (DDB)

Design torque, Td

Td = (60PK1)/2N Nm

Where, P = Rated power = 746 W

All rights reserved by www.ijste.org

87

Design Methodology of Garlic Peeling Machine

(IJSTE/ Volume 2 / Issue 2 / 013)

Kl = Load factor

From table XI 5 (DDB)

Kl = 1.75

N = Rotation = 3888 RPM

.. Td = 3.21 Nm

Taking solid shaft

From table XI 1 (DDB)

Maximum stress, Max

Max = (16/D3)[(KbM)2 + (KtTd)2]0.5

Where, Max < 0.30 Syt or

Max < 0.18 Sut

From table II 7

For shaft selecting material SAE 1030

Sut = 527 MPa

Syt = 296 MPa

From table I 20 (A) (DDB)

Taking factor of safety = 2

.. FOS = Sut / Working Stress or

FOS = Syt / Working Stress

.. Max < 0.30 Working stress or

Max < 0.30 Syt / 2 = 44.4 N/mm2 or

Max < 0.18 Sut / 2 = 47.43 N/mm2

Taking minimum stress i.e.

Max = 44.4 N/mm2

Weight of smaller pulley

Mass of pulley = Density Volume

M = AL

For cast iron, = 7800 Kg/m3

A = Area of pulley = (/4)D S2 DS = 75 mm = 0.075 m and L = w = 21 mm = 0.021 m

.. A = 4.4210-3 m2

.. M = 0.7236 Kg

.. Weight of smaller pulley, WSmall

WSmall = Mg

WSmall = 7.1 N

Now considering the smaller pulley is mounted on the drive shaft at 75 mm away from fix end and shaft is cantilever type. On

the pulley the self acted in downward direction and tension forces acted in horizontal direction.

D. Vertical Plane:

Fig. 5: Force Diagram in Vertical Plane

From Table I 2 (DDB)

MV = Wb Where, W = 7.1 N and b = 75 mm

.. MV = 532.5 Nmm = 0.5325 Nm

All rights reserved by www.ijste.org

88

Design Methodology of Garlic Peeling Machine

(IJSTE/ Volume 2 / Issue 2 / 013)

E. Horizontal Plane:

Fig. 6: Force Diagram in Horizontal Plane

From Table I 2 (DDB)

MH = Wb Where, W = 63.74 N and b = 75 mm

.. MH = 4780.5 Nmm = 4.78 Nm

So, Resultant Bending Moment, MR

MR = (MV2+MH2)0.5

MR = 4.81 Nm

Then equivalent torque, Te

Te = [(kbM)2+(ktTd)2]0.5

From Table XI 3 (DDB)

For rotating shaft, suddenly applied load (Heavy shock)

Kb 2.0 to 3.0 and Kt 1.5 to 3.0

..Te = 17.35 Nm

Te = Max (/16) D3

D = 0.01258 m = 12.58 mm

Also,

Equivalent moment, Me

Me = {(kbM)+[(kbM)2+(ktT)2]0.5}/2

Me = 15.89 Nm

Me = t (/32) D3 where, t = Sut / FOS = 263.5106 N/m2

D = 0.0085 m = 8.5 mm

So, taking maximum diameter of driven shaft i.e. D = 12.58 mm

From table XI 4 (DDB)

Selecting Shaft diameter, D = 14 mm

.. Shaft diameter of smaller pulley, D S = 14 mm

From table XV 7 (DDB)

Hub proportions

Diameter of hub, Dh = 1.5Ds+25

Diameter of hub, Dh = 46 mm

Length of hub, Lh = 1.5Ds

Length of hub, Lh = 21 mm

F. Larger Pulley:

By using the smaller pulley diameter and velocity ratio, we already have larger pulley diameter.

DLarger = 203 mm

From table XV 7 (DDB)

Material of pulley Cast Iron

Type of Construction Diameter above 150 mm Arm construction

Number of arms 4

Number of set 1

Hub proportions

Diameter of hub, Dh = 1.5Ds+25

Diameter of hub, Dh = 55 mm

All rights reserved by www.ijste.org

89

Design Methodology of Garlic Peeling Machine

(IJSTE/ Volume 2 / Issue 2 / 013)

Length of hub, Lh = 1.5Ds

Length of hub, Lh = 30 mm

IV. DESIGN OF WORM AND WORM GEAR

In reduction gear box, there is worm and worm wheel is used.

Available rotation at the worm, NW = 3888 RPM

Required speed of crank, Ncrank = 285.8 RPM i.e.

Rotation of worm gear, NG = 285.8 RPM

So, reduction ratio, VR = NW/NG = 13.6

.. Approximate efficiency of worm gear drive,

= 1-0.005VR

= 93.2 %

Available rated power, PR = 0.746 KW

Calculated design power, Pd = 0.858 KW

From table XVI 16 (DME)

Selecting number of teeth on worm, tw = 2 for VR between 12 36

Number of teeth on gear, tg = VR tw = 27.2 29

Lead angle = 6o per worm tooth = 62 = 12o

For compact design = tan 1 (Ng/Nw)1/3

= 22.73o

Pressure angle, n

For lead angle = 20o to 25o, pressure angle n = 22.5o

Let the module of gear be m mm.

.. Dg = tg m = 29m and

VP = (Dg/1000)(Ng/60)

VP = 0.43m, m/sec

From table XVI 15 (DME)

Tooth load, Ft = Pd/VP = 1995.35/m, N

Beam strength by Lewis equation, FB = SO CV b Y m

Where SO Basic strength

From table XVI 10 (DME)

Material of construction

Worm SAE 3120 steel

Gear Ph bronze SAE 65, SO = 84

CV = 0.75 (trial value)

b Face width = 2.38m = 7.47m

Y = 0.314+0.0151(n 14.5)

Y = 0.435

So, FB = 376.27 m2

Now equating FB to Ft

376.27 m2 = 1995.35/m

.. m = 1.744

From table XVI 7 (DME)

Selecting a recommended module, m = 4 mm

Therefore,

Dg = tg m = 116 mm

VP = 0.43m = 1.72 m/sec

b = 2.38 m + 6.25 = 36.16 mm

Ft = 1995.35/m = 1995.35/4 = 498.84 N

FB = SO CV b Y m

CV = 6 / (6+VP) = 0.777

FB = 4106.56 N

.. FB Ft So design is O.K.

To check for wear

Fd = Ft / CV = 642.01 N

From table XVI 15 (DME)

Limiting wear strength, FW = Dg b K2

From table XVI 17 (DME)

All rights reserved by www.ijste.org

90

Design Methodology of Garlic Peeling Machine

(IJSTE/ Volume 2 / Issue 2 / 013)

K2 = 0.70 MPa

FW = 2936.19 N

.. FW Fd So design is O.K.

From Table XVI 19 (DME)

A. Worm:

Normal pressure angle n = 14.5o

Pitch Dia. of worm bored for shaft DW = (2.4 m) + 27.5 =

DW = 57.66 mm

Face Length LW = (4.5+0.02t) m = 57.05 mm

Depth of tooth h = 0.686 m = 8.62 mm

Fig. 7: Details of Worm

Addendum a = 0.318 m = 3.996 mm

Hub diameter dh = (1.66 m) + 25 = 45.86 mm

Minimum bore of shaft dw = m + 16 = 28.56 mm

B. Gear:

Fig. 8: Details of Worm Gear

All rights reserved by www.ijste.org

91

Design Methodology of Garlic Peeling Machine

(IJSTE/ Volume 2 / Issue 2 / 013)

Normal pressure angle n = 14.5o

Outside diameter Do = Dg + 1.0315 m = 128.96 mm

Throat diameter Dr = Dg + 1.0636 m = 129.36 mm

Face width b = 2.38 m + 6.25 = 36.16 mm

Radius of gear face r = 0.882 m + 13.75 = 24.83 mm

Radius of gear rim rb = 2.2 m + 13.75 = 41.39 mm

Radius of edge rr = 0.25 m = 3.14 mm

Hub diameter db = 1.875 m = 23.56 mm

V. DESIGN OF CONNECTING ROD

From table II 6 (DDB)

Material for connecting rod is SAE 1040

From table II 7 (DDB)

For SAE 1040 Sut = 632 MPa

Syt = 350 MPa

Total force generated at the end of connecting rod, FT = 85.13 N

Length of connecting rod, LC = 0.456 m = 456 mm

Length of crank, r = 0.076 m = 76 mm

Obliquity ratio, LC/r = n = 6

Stroke, h = 0.152 m = 152 mm

Design of connecting rod will be done under the critical load, F cr

.. Critical Load, Fcr = (SyAc) / (1+a2)

Where, Fcr Critical Load, N

Sy Yield strength of material, N/mm2

Ac Cross sectional area of connecting rod, mm2

a Factor depending on material and end fixity. For steel and iron part it is assumed as

a = 1/7500

Slenderness ratio = Lc/K

where, Lc Length of connecting rod, mm

K Radius of gyration, mm

For safety operation, the critical load should be at least 5 to 6 times of the actual load on the connecting rod. Taking cross

section of connecting rod is rectangular type.

For rectangular section, from table I 1

I = bt3/12

Z = bt2/6

K = 0.289 t

AC = bt and Taking b = 2t

.. I = (2tt3)/ 12 = t4/6

.. K = 0.289 t

Taking factor of safety is 12

So, critical force = FOS Total Force

Fcr = FOS FT

Fcr = 1021.56 N

Slenderness ratio, = LC/K

= 456/0.289t

= 1577.85/t

Substituting all values in equation of critical force i.e.

Fcr = (SytAc) / (1+a2)

1021.56 = (3502t2) / (1+ (1/7500)( 1577.85/t)2)

700t4 1021.56t2 339106.84 = 0

Putting t2 = T

.. 700T2 1021.56T 339106.84 = 0

.. T = 22.75 = t2

.. t = 4.77 mm 5 mm and

.. B = 10 mm

All rights reserved by www.ijste.org

92

Design Methodology of Garlic Peeling Machine

(IJSTE/ Volume 2 / Issue 2 / 013)

VI. CONCLUSION

The designs of various parts and parameters are taken into consideration and above values obtained successfully. These values

are implemented of fabrication of same machine which is working successfully.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

Design Data Book, Prof. B. D. Shiwalkar, Denett Publication, 2015 Edition.

Design of Machine Elements, Prof. B. D. Shiwalkar, Denett Publication, Third Edition.

A Text Book of Mechanical System Design, Farazdak Haideri, Third Edition, Chapter 2, Page No. 149 241.

Mechanics of Materials I, Third Edition, E. J. Hearn, University of Warwick, United Kingdom, Chapter 1, Page No. 1-8.

Mechanical Vibrations, Thammaiah Gowda, Jagadeesha T, D. V. Girish, Tata Mcgraw Hill Education Private Limited, Page No. 44, Topic Spring

Element.

Strength of Materials, S. Ramamrutham, R. Narayanan, Dhanpat Rai Publication Company, Page No. 116-118.

All rights reserved by www.ijste.org

93

You might also like

- Design Consideration of Corn Sheller MachineDocument6 pagesDesign Consideration of Corn Sheller MachineIJIRST100% (2)

- Career Episode 3Document7 pagesCareer Episode 3Nishar Alam Khan 19MCD0042No ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- Design Calculation of Pulley & Belt DriveDocument7 pagesDesign Calculation of Pulley & Belt Drivesiva1071988No ratings yet

- Turning Moment Diagram & FlywheelDocument88 pagesTurning Moment Diagram & FlywheelAvinash Jayashankar100% (5)

- Estrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignDocument12 pagesEstrella, Tria A. BSME 5-1 ME 511a Machine Design 1 Exercise #1: Nature of Mechanical DesignHannahNo ratings yet

- Mathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsFrom EverandMathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsRoderick MelnikNo ratings yet

- INTRODUCTIONDocument24 pagesINTRODUCTIONnaveeen chackoNo ratings yet

- Design Calculation of Pulley & Belt DriveDocument8 pagesDesign Calculation of Pulley & Belt Drivesiva107198887% (31)

- Addis Ababa University FinalDocument9 pagesAddis Ababa University Finaldagem100% (1)

- Velocity in the pipe = 2m/s Using the formula Diameter of penstock (Dm) = ( (4 ×Q m3/s) / (π ×Vm/s) ) = ( (4 ×0.15) / (π ×2) ) = 0.31mDocument4 pagesVelocity in the pipe = 2m/s Using the formula Diameter of penstock (Dm) = ( (4 ×Q m3/s) / (π ×Vm/s) ) = ( (4 ×0.15) / (π ×2) ) = 0.31mSujan JoshiNo ratings yet

- Design and Analysis of A Sprocket-Hub AssemblyDocument7 pagesDesign and Analysis of A Sprocket-Hub AssemblyJackson PhinniNo ratings yet

- Stresses in Cylinder WallDocument9 pagesStresses in Cylinder WallAarzoo ShahNo ratings yet

- Design of Multi-Axis Welding Positioner WithDocument7 pagesDesign of Multi-Axis Welding Positioner Withsuraj dhulannavarNo ratings yet

- MINAS BLinfomationDocument7 pagesMINAS BLinfomationmashudi_fikriNo ratings yet

- Hydro Electric Project-Basic Layout For Francis, As Per Is, USBR and Other StandardsDocument15 pagesHydro Electric Project-Basic Layout For Francis, As Per Is, USBR and Other Standardsबिपन गुलेरियाNo ratings yet

- Design and Fabrication of An Electrically Powered Rotary Slicer For Raw Plantain Chips ProductionDocument7 pagesDesign and Fabrication of An Electrically Powered Rotary Slicer For Raw Plantain Chips ProductionAJER JOURNALNo ratings yet

- Power Transmission: Components Used To Transmit Power: Gears, Belt, Clutch and BrakesDocument17 pagesPower Transmission: Components Used To Transmit Power: Gears, Belt, Clutch and Brakesrip111176No ratings yet

- Exercises Belt Drives 3Document14 pagesExercises Belt Drives 3ZIZIPHO MNTUMNINo ratings yet

- Minggu 4, Perc Mesin, Tegangan KombinasiDocument4 pagesMinggu 4, Perc Mesin, Tegangan KombinasiUwais AlqurniyNo ratings yet

- MECH68Document8 pagesMECH68GogyNo ratings yet

- Calculation Coconut Dehusking and Decorticating MachineDocument10 pagesCalculation Coconut Dehusking and Decorticating MachineJakeNo ratings yet

- Turning Moment Diagram & FlywheelDocument88 pagesTurning Moment Diagram & FlywheelAshishAgarwal100% (1)

- Can CrusherDocument11 pagesCan CrusherElakkiya KarthicNo ratings yet

- Designing, Planning and Analysis of VillaDocument34 pagesDesigning, Planning and Analysis of VillaMohamed FarweezNo ratings yet

- Session 2Document4 pagesSession 2vijayakumar100% (1)

- Mechanical ShaftsDocument52 pagesMechanical ShaftsErnesto Elljr Landisan Locaben Jr.75% (16)

- Board Solved Problems & FormulasDocument6 pagesBoard Solved Problems & FormulasJC YabisNo ratings yet

- Central Tool Room and Training Center Bhubaneswar: ROLL NO.-149Document17 pagesCentral Tool Room and Training Center Bhubaneswar: ROLL NO.-149Suryanshu Sundar ChopdarNo ratings yet

- Unit II Chapter 9: Vibration Control: UE15ME352: Mechanical Vibrations Question Bank: Partial SolutionsDocument11 pagesUnit II Chapter 9: Vibration Control: UE15ME352: Mechanical Vibrations Question Bank: Partial SolutionsNABIL HUSSAINNo ratings yet

- Muthu Cad 2Document8 pagesMuthu Cad 2Sagarias AlbusNo ratings yet

- Design of Gear: The Standard Values and Equations Taken From Text Book of Machine Design byDocument4 pagesDesign of Gear: The Standard Values and Equations Taken From Text Book of Machine Design byLemi Chala BeyeneNo ratings yet

- 1.1 Specifications of Maruti Swift Engine: Click Here To See The Old (Before Incorporating Changes) KnolDocument24 pages1.1 Specifications of Maruti Swift Engine: Click Here To See The Old (Before Incorporating Changes) KnolPrashant ShahNo ratings yet

- Power Calculation Power Calculation:: Note Book For Marine EngineersDocument4 pagesPower Calculation Power Calculation:: Note Book For Marine EngineersMohammad AliNo ratings yet

- 77-9 Design of CranesDocument10 pages77-9 Design of Cranesrip111176No ratings yet

- Shear Check To Eurocode 2Document4 pagesShear Check To Eurocode 2smkumar121No ratings yet

- XongDocument4 pagesXongVu Duc Hoang LongNo ratings yet

- Plate Girder DesignDocument8 pagesPlate Girder Designkalpanaadhi100% (1)

- HES3350 Machine Design, Assignment 2: Gear Specification With Consideration of Bending Fatigue and Surface Durability (Semester 1, 2012)Document21 pagesHES3350 Machine Design, Assignment 2: Gear Specification With Consideration of Bending Fatigue and Surface Durability (Semester 1, 2012)StephenPYBongNo ratings yet

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocument26 pagesWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraNo ratings yet

- Boiler CalculationDocument67 pagesBoiler Calculationkeerthi dayarathnaNo ratings yet

- Strap FootingDocument6 pagesStrap Footingrukesh104No ratings yet

- Design of A Hovercraft Model: Under The Guidance of Dr. K. PadmanabanDocument34 pagesDesign of A Hovercraft Model: Under The Guidance of Dr. K. PadmanabanramyasweetyNo ratings yet

- Engine Propeller Matching: Kelompok 1 Rega Ardian Syah Angga Wahyu P Pandika DarmawanDocument15 pagesEngine Propeller Matching: Kelompok 1 Rega Ardian Syah Angga Wahyu P Pandika DarmawanyuniardimzNo ratings yet

- Determine Material Property (PSG Data Book Page No 1.9 & 1.5)Document28 pagesDetermine Material Property (PSG Data Book Page No 1.9 & 1.5)Sagarias Albus100% (1)

- PDF SF BMD and Spindle DesignDocument65 pagesPDF SF BMD and Spindle DesignPRAVEEN ENo ratings yet

- Yarn CalculationsDocument28 pagesYarn CalculationsM Ali92% (13)

- An Serv 002 PDFDocument20 pagesAn Serv 002 PDFMario TapiaNo ratings yet

- Steel Design To Eurocode 3 - University of Sheffield Structural Engineering MastersDocument13 pagesSteel Design To Eurocode 3 - University of Sheffield Structural Engineering Mastersfatabass100% (13)

- AbaqusDocument9 pagesAbaqusAlfredo Soliz GamboaNo ratings yet

- Lecture 2 Sample Problems WordDocument9 pagesLecture 2 Sample Problems Wordjake luis matthewNo ratings yet

- Centrifugal Fan Design MethodologiesDocument10 pagesCentrifugal Fan Design MethodologiesMausam100% (2)

- Guided By: DR P.V. Washimkar Presented By:-: Roshan Sao (Group Niraj Shah Saurabh Yadav Omkumar KushwahaDocument19 pagesGuided By: DR P.V. Washimkar Presented By:-: Roshan Sao (Group Niraj Shah Saurabh Yadav Omkumar KushwahaRoshanNo ratings yet

- Track Monorail Guide Way BeamDocument47 pagesTrack Monorail Guide Way BeamBasyaruddin89No ratings yet

- Belt Drives and Chain DrivesDocument39 pagesBelt Drives and Chain DrivesSeparatorNo ratings yet

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocument29 pagesMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- Design and Analysis of Magneto Repulsive Wind TurbineDocument7 pagesDesign and Analysis of Magneto Repulsive Wind TurbineIJSTENo ratings yet

- Automatic Generation Control in Three-Area Power System Operation by Using "Particle Swarm Optimization Technique"Document8 pagesAutomatic Generation Control in Three-Area Power System Operation by Using "Particle Swarm Optimization Technique"IJSTENo ratings yet

- RFID Based Toll Gate AccessDocument5 pagesRFID Based Toll Gate AccessIJSTENo ratings yet

- Partial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderDocument7 pagesPartial Replacement of Fine Aggregate With Iron Ore Tailings and Glass PowderIJSTENo ratings yet

- Multipurpose Scheme of Workshop Exhaust System For Ventilation and Electrical Power GenerationDocument9 pagesMultipurpose Scheme of Workshop Exhaust System For Ventilation and Electrical Power GenerationIJSTENo ratings yet

- FPGA Implementation of High Speed Floating Point Mutliplier Using Log Based DesignDocument4 pagesFPGA Implementation of High Speed Floating Point Mutliplier Using Log Based DesignIJSTENo ratings yet

- Optimization of Overall Efficiency Using Facilities Planning in Ropp Cap Making IndustryDocument8 pagesOptimization of Overall Efficiency Using Facilities Planning in Ropp Cap Making IndustryIJSTENo ratings yet

- Optimization of Treatability by FACCO For Treatment of Chemical Industry EffluentDocument9 pagesOptimization of Treatability by FACCO For Treatment of Chemical Industry EffluentIJSTENo ratings yet

- A Mixture of Experts Model For ExtubationDocument4 pagesA Mixture of Experts Model For ExtubationIJSTENo ratings yet

- A Cloud Based Healthcare Services For Remote PlacesDocument4 pagesA Cloud Based Healthcare Services For Remote PlacesIJSTENo ratings yet

- Effect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsDocument9 pagesEffect of RIB Orientation in Isogrid Structures: Aerospace ApplicationsIJSTENo ratings yet

- A Comprehensive Survey of Techniques/Methods For Content Based Image Retrieval SystemDocument6 pagesA Comprehensive Survey of Techniques/Methods For Content Based Image Retrieval SystemIJSTENo ratings yet

- Development of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityDocument6 pagesDevelopment of Relationship Between Saturation Flow and Capacity of Mid Block Section of Urban Road - A Case Study of Ahmedabad CityIJSTENo ratings yet

- Enriching Gum Disease Prediction Using Machine LearningDocument6 pagesEnriching Gum Disease Prediction Using Machine LearningIJSTENo ratings yet

- App-Based Water Tanker Booking, Monitoring & Controlling SystemDocument6 pagesApp-Based Water Tanker Booking, Monitoring & Controlling SystemIJSTENo ratings yet

- The Bicycle As A Mode Choice - A Gendered ApproachDocument4 pagesThe Bicycle As A Mode Choice - A Gendered ApproachIJSTENo ratings yet

- A Radar Target Generator For Airborne TargetsDocument8 pagesA Radar Target Generator For Airborne TargetsIJSTENo ratings yet

- An Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabDocument5 pagesAn Implementation and Design A Customized Advanced Image Editor Using Image Processing in MatlabIJSTENo ratings yet

- Interstage Construction Techniques For Mass Gain: An OverviewDocument5 pagesInterstage Construction Techniques For Mass Gain: An OverviewIJSTENo ratings yet

- Optimum Placement of DG Units Using CPF MethodDocument6 pagesOptimum Placement of DG Units Using CPF MethodIJSTENo ratings yet

- Comparative Study and Analysis of PCC Beam and Reinforced Concrete Beam Using GeogridDocument7 pagesComparative Study and Analysis of PCC Beam and Reinforced Concrete Beam Using GeogridIJSTENo ratings yet

- Onerider The Bike TaxiDocument3 pagesOnerider The Bike TaxiIJSTENo ratings yet

- Wireless Information Process and Power Transfer in Single-User OFDM SystemDocument6 pagesWireless Information Process and Power Transfer in Single-User OFDM SystemIJSTENo ratings yet

- Technology Advancement For Abled PersonDocument9 pagesTechnology Advancement For Abled PersonIJSTENo ratings yet

- Duplicate Detection Using AlgorithmsDocument3 pagesDuplicate Detection Using AlgorithmsIJSTENo ratings yet

- Optimizing Turning Process For EN43 by Taguchi Method Under Various Machining ParametersDocument4 pagesOptimizing Turning Process For EN43 by Taguchi Method Under Various Machining ParametersIJSTENo ratings yet

- Using The Touch-Screen Images For Password-Based Authentication of IlliteratesDocument6 pagesUsing The Touch-Screen Images For Password-Based Authentication of IlliteratesIJSTENo ratings yet

- Research On Storage Privacy Via Black Box and Sanitizable SignatureDocument6 pagesResearch On Storage Privacy Via Black Box and Sanitizable SignatureIJSTENo ratings yet

- An Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemDocument5 pagesAn Implementation of Maximum Power Point Tracking Algorithms For Photovoltaic Systems Using Matlab and Arduino Based RTOS SystemIJSTENo ratings yet

- H1.001858 Strongpack Nigeria-Electrical Loads List For Layout Utilities-Rev-02Document1 pageH1.001858 Strongpack Nigeria-Electrical Loads List For Layout Utilities-Rev-02yseffoNo ratings yet

- Components of A Rainwater Harvesting SystemDocument38 pagesComponents of A Rainwater Harvesting SystembudiperNo ratings yet

- Practice Questions Human Nutrition Part 1Document4 pagesPractice Questions Human Nutrition Part 1PeiYi TanNo ratings yet

- Pipe TobaccoDocument6 pagesPipe TobaccoVictorIoncuNo ratings yet

- Unit5 TestDocument3 pagesUnit5 TestAndrea MészárosnéNo ratings yet

- How To Make Panna CottaDocument3 pagesHow To Make Panna CottaBintNo ratings yet

- MCQDocument5 pagesMCQJagdishVankar100% (1)

- Father of Different Fields of Science & Technology PDFDocument3 pagesFather of Different Fields of Science & Technology PDFJacob PrasannaNo ratings yet

- Musculoskeletal 20,000 Series CPT Questions With Answers-CpcDocument16 pagesMusculoskeletal 20,000 Series CPT Questions With Answers-Cpcanchalnigam25100% (7)

- Test Unit 2 Urbanisation L P 12Document9 pagesTest Unit 2 Urbanisation L P 12Xuân NguyenNo ratings yet

- ComFlor 80 Load Span Tables PDFDocument4 pagesComFlor 80 Load Span Tables PDFAkhil VNNo ratings yet

- Pediatric Medication Dosing GuildelinesDocument2 pagesPediatric Medication Dosing GuildelinesMuhammad ZeeshanNo ratings yet

- WAUZZZ8K0BA159120Document10 pagesWAUZZZ8K0BA159120Vedad VedaddNo ratings yet

- LFAMS Fee Structure OCT'2013Document7 pagesLFAMS Fee Structure OCT'2013Prince SharmaNo ratings yet

- Organic Facial Remedies Versus Inorganic Facial RemediesDocument13 pagesOrganic Facial Remedies Versus Inorganic Facial Remediesapi-271179911No ratings yet

- Physical Fitness TestDocument1 pagePhysical Fitness TestGiessen Fran RamosNo ratings yet

- OSCE Pediatric Dentistry Lecture-AnswersDocument40 pagesOSCE Pediatric Dentistry Lecture-AnswersR MNo ratings yet

- 2006 SM600Document2 pages2006 SM600Ioryogi KunNo ratings yet

- Tiling Checklist UpdatedDocument3 pagesTiling Checklist UpdatedSayed Taimoor shahNo ratings yet

- B 700 FDocument25 pagesB 700 FMohammed HdyliNo ratings yet

- Comparative Study of Financial Statements of Company, Oil and Gas.Document105 pagesComparative Study of Financial Statements of Company, Oil and Gas.Ray Brijesh AjayNo ratings yet

- Music Therapy: Treatment For Grade 11 Stem Students Who Suffer Stress From Basic CalculusDocument12 pagesMusic Therapy: Treatment For Grade 11 Stem Students Who Suffer Stress From Basic CalculusArvinel L. VileganoNo ratings yet

- Performantele MTADocument5 pagesPerformantele MTAana aNo ratings yet

- Steel Scrap Recycling Policy 06.11.2019 PDFDocument31 pagesSteel Scrap Recycling Policy 06.11.2019 PDFAnshul SableNo ratings yet

- 6L45, 6L50, 6L80, 6L90: Time Tested - Industry TrustedDocument1 page6L45, 6L50, 6L80, 6L90: Time Tested - Industry TrustedCelso BidinotiNo ratings yet

- Standard Into-Plane Fueling Service Levels and SafetyDocument8 pagesStandard Into-Plane Fueling Service Levels and SafetyPrekelNo ratings yet

- X FEDEX EIDocument13 pagesX FEDEX EINISREEN WAYANo ratings yet

- Geographical Perspective On Selected Issues and Problems #ToppersnotesDocument16 pagesGeographical Perspective On Selected Issues and Problems #ToppersnotesParidhi JainNo ratings yet

- BS 5422 2001 Method For Specifying Thermal Insulating Materials For Pipes, Tanks, Vessels, DuctDocument60 pagesBS 5422 2001 Method For Specifying Thermal Insulating Materials For Pipes, Tanks, Vessels, DuctRamiAl-fuqahaNo ratings yet

- Recipe Book: Yule Logs 2020Document28 pagesRecipe Book: Yule Logs 2020Cwt Chan100% (1)