Professional Documents

Culture Documents

Garrett Manual

Uploaded by

dromakiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Garrett Manual

Uploaded by

dromakiCopyright:

Available Formats

GARRETT TURBOCHARGER INSTALLATION

INSTRUCTIONS

Before installing a replacement turbocharger it is important to find the

reason for the damage to the previous turbo.

If in doubt, contact your Garrett Distributor for advice.

IMPORTANT NOTES:

1. Failure to follow these instructions can lead to turbocharger damage and

may void warranty.

2. Changing the calibration of a wastegated turbo may damage the

turbo/engine and voids warranty.

3. Correct gaskets must be used - they must not overlap holes.

n Gasket covering part of oil hole - reduces oil supply to turbo or if gasket

material breaks away, may totally stop oil flow. o Gasket clear of oil hole.

Liquid gasket or sealants are not recommended, particularly for the oil

inlet/outlet. Excess material may break away, reducing or stopping oil flow.

4. Refer to engine/vehicle manufacturers literature for correct oil type and

quantity. Also, for correct torques and installation details.

5. Prevent dirt/debris from entering any part of the turbo during installation.

6. Before fitting the turbocharger, check that the part number is the correct one

for the engine - fitting the incorrect turbo to an engine may damage the

turbo/engine and will void the warranty.

INSTALLING THE TURBO

All air hoses connected to the turbo must be totally clean and undamaged.

Air filter and housing must be totally clean and free from debris.

Clean engine breather system and check function.

Remove old gasket material from the exhaust manifold and pipe. Faces

must be undamaged.

REMOVE PLASTIC OR FOAM BLANKING PLUGS FROM THE

TURBO BEFORE FITTING.

Fill the oil inlet hole of the turbocharger with new engine oil and spin the

compressor wheel by hand a few times - it should spin freely. Note: it is

normal to feel some up and down movement on the wheels.

Fit turbocharger onto manifold or engine block (as applicable) using the

correct new gasket or joint ring, then reconnect the exhaust pipe. Tighten all

nuts/bolts.

Oil feed and drain lines must be totally clean and undamaged - oil flow

MUST be unrestricted. Check that any flexible hose liners have not collapsed

internally. Check that oil feed line is not too close to source of heat. p Oil

level OK, but drain line damaged - causes oil leaks from turbo.

Fit oil drain line. Refill the oil inlet hole with new clean engine oil and

reconnect the oil feed line.

Fit air hoses and tighten.

Use new air, oil and fuel filters, refill engine with new engine oil.

If possible, prevent the engine from firing and crank the engine for 10 - 15

seconds to prime oil feed. Start the engine and idle for 3 to 4 minutes before

increasing speed. Check for oil and gas/air leaks.

Stop engine and re-check engine oil level Note: oil level should NOT be

above the point where oil returns from the turbo to the engine.

q Oil level too high - blocks oil drain from turbo - causes oil leaks from

turbo.

r Oil level correct to specification.

Check crankcase pressure. High pressure may be caused by piston bypass or

blocked breather system.

s High crankcase pressure can stop oil from draining - causes oil leaks from

turbo.

You might also like

- Mazda 32318 I 16 VBPDocument49 pagesMazda 32318 I 16 VBPJon Luc Pulido Julian0% (2)

- 5HP18 PDFDocument39 pages5HP18 PDFCesar SantibañezNo ratings yet

- DTC P1120/19 Accel. Position Sensor Circuit (Open/Short)Document7 pagesDTC P1120/19 Accel. Position Sensor Circuit (Open/Short)Jehuty88No ratings yet

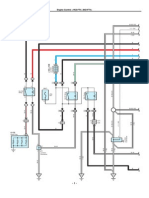

- WWW - Nasicoelec.ir: Electrical Wiring DiagramDocument60 pagesWWW - Nasicoelec.ir: Electrical Wiring DiagramMuhammad Fauzi100% (2)

- P2146Document30 pagesP2146Engine Tuning UPNo ratings yet

- Sienna SparkPlug RemovalDocument17 pagesSienna SparkPlug Removalazeemm1No ratings yet

- Engine ControlDocument15 pagesEngine ControlMichael Porter100% (4)

- 2005 Diesel Ref Manual PDFDocument68 pages2005 Diesel Ref Manual PDFWilmer P MendozaNo ratings yet

- Fuel Injection SystemDocument26 pagesFuel Injection Systemjayant pathakNo ratings yet

- IDS User ManualDocument49 pagesIDS User ManualMihai BecleaNo ratings yet

- 1kd FTV PDFDocument2 pages1kd FTV PDFDayro Jose Geney OrtizNo ratings yet

- Nissan TD Diesel Engine Workshop Manual Td23 Td25 Td27 Td27tDocument5 pagesNissan TD Diesel Engine Workshop Manual Td23 Td25 Td27 Td27tJuan Diego Vergel Rangel0% (1)

- Kia Picanto PDFDocument3 pagesKia Picanto PDFManuales De Maquinaria Jersoncat100% (1)

- Automatic Transaxle Manual PDFDocument429 pagesAutomatic Transaxle Manual PDFJeff UptagrafftNo ratings yet

- 6D110 SeriesDocument301 pages6D110 SeriesEduardo Sanchez67% (3)

- Common Rail Injector Tester CR-C +S60H Multifunction Test MachineDocument3 pagesCommon Rail Injector Tester CR-C +S60H Multifunction Test MachineAlen HuangNo ratings yet

- 2GR FE CoolingDocument36 pages2GR FE CoolingLuks FernandezNo ratings yet

- 2022 TRA Base BEMM Publishable 25-07-2022Document135 pages2022 TRA Base BEMM Publishable 25-07-2022Jack Norhy100% (1)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- NV and Vanos DME PinoutsDocument4 pagesNV and Vanos DME Pinoutsrobertobaggio2009No ratings yet

- T1 Cam Trigger Instructions 1Document10 pagesT1 Cam Trigger Instructions 1Initial_BG100% (1)

- Headgasket Case History PDFDocument3 pagesHeadgasket Case History PDFdromakiNo ratings yet

- Engine - ID4 2.2L Diesel - : Item SpecificationDocument104 pagesEngine - ID4 2.2L Diesel - : Item SpecificationRichard Andrianjaka LuckyNo ratings yet

- Toyota OBD CodesDocument2 pagesToyota OBD Codesnanorutamilan100% (1)

- GDI DENSO InjectorsDocument19 pagesGDI DENSO InjectorsPāvels SmilgaNo ratings yet

- 1C Engine Fuel System Rz4eDocument119 pages1C Engine Fuel System Rz4eYuber CuevasNo ratings yet

- Carnival 2,5L KV6 Spark Plugs - Manual ExtractDocument11 pagesCarnival 2,5L KV6 Spark Plugs - Manual ExtractLuiz Nogueira100% (2)

- Basic Equipment Wiring AGY EngineDocument20 pagesBasic Equipment Wiring AGY EnginemasterbfishNo ratings yet

- Repair Autocom CDP VCIDocument5 pagesRepair Autocom CDP VCIMed Ali cNo ratings yet

- 2008 Honda CR-V: Engine AssemblyDocument7 pages2008 Honda CR-V: Engine Assemblyfrancisco Alba100% (1)

- Australian Motorcycle News - November 23, 2023 AUDocument116 pagesAustralian Motorcycle News - November 23, 2023 AUOscar ValladaresNo ratings yet

- Bolt Tightening e PDFDocument15 pagesBolt Tightening e PDFdromaki0% (1)

- Bosch Mono MotronicDocument7 pagesBosch Mono MotronicvictorjoseteixeiraNo ratings yet

- Renault Torque ValuesDocument14 pagesRenault Torque ValuesMihai ChitzanuNo ratings yet

- Brigham Joffs Electric Vehicle Conversion DesignDocument25 pagesBrigham Joffs Electric Vehicle Conversion DesignSadegh Simorgh100% (4)

- BMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesFrom EverandBMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesNo ratings yet

- Nissan Seccion MT Standar Fs5w71c, Fs5r30a, Fs5w71c, Fs5r30aDocument64 pagesNissan Seccion MT Standar Fs5w71c, Fs5r30a, Fs5w71c, Fs5r30aAlex BassocoNo ratings yet

- VP44 Install PDFDocument6 pagesVP44 Install PDFAlberto AbarcaNo ratings yet

- w58 RebuildDocument49 pagesw58 RebuildtfphoenixNo ratings yet

- Adj Camshaft Timing N42Document6 pagesAdj Camshaft Timing N42Kloos Eduard-AndreasNo ratings yet

- Overhauling OF Diesel Engines: Internship Presentation OnDocument22 pagesOverhauling OF Diesel Engines: Internship Presentation OnGanesh harikantraNo ratings yet

- Repair Guides - Specifications - Torque SpecificationsDocument5 pagesRepair Guides - Specifications - Torque SpecificationsFelix Martinez PlataNo ratings yet

- Mazda 323 b3 Engine Manual Download of Mazda 323 b6 Engine Manual WorkshopDocument3 pagesMazda 323 b3 Engine Manual Download of Mazda 323 b6 Engine Manual WorkshopJuan David Mira PinedaNo ratings yet

- The Ignition Timing Specs For 2.3L M102 EngineDocument1 pageThe Ignition Timing Specs For 2.3L M102 Enginebengal100% (1)

- Terracan BodyDocument137 pagesTerracan BodyIvan Alexandru50% (2)

- Cam Belt (M40)Document11 pagesCam Belt (M40)Metin OmerNo ratings yet

- Volta 1.2 Instructions PDFDocument10 pagesVolta 1.2 Instructions PDFMick BurnsNo ratings yet

- Motor 2.0 Diesel Journey 2009Document177 pagesMotor 2.0 Diesel Journey 2009Injeletro Diesel100% (1)

- Diesel Sales Presentation For Diesel Partner (DP) - 30062016Document39 pagesDiesel Sales Presentation For Diesel Partner (DP) - 30062016kallatisNo ratings yet

- WWW Academia Edu 32095591 TOYOTA Manual de Taller Manual de Reparaciones y Mantenimiento Toyota Hilux 1KD 2KDDocument452 pagesWWW Academia Edu 32095591 TOYOTA Manual de Taller Manual de Reparaciones y Mantenimiento Toyota Hilux 1KD 2KDLuis Torrez Flores100% (1)

- Naza Ria Rover KV6 Engine Cam Marking ManualDocument7 pagesNaza Ria Rover KV6 Engine Cam Marking ManualLee Ming Fee100% (1)

- Charging For Toyota Land CruiserDocument16 pagesCharging For Toyota Land CruiserAbu AliNo ratings yet

- Mitsubishi FTODocument14 pagesMitsubishi FTOJhonatan JalluranaNo ratings yet

- All Passenger Car Dealers/TascsDocument9 pagesAll Passenger Car Dealers/TascssouravNo ratings yet

- 2AZ-FE FuelDocument43 pages2AZ-FE FuelAdedeji OluwatobilobaNo ratings yet

- Toyota 1kd-ftv Pares de AprieteDocument1 pageToyota 1kd-ftv Pares de AprieteTAMIRU TESFAYENo ratings yet

- Engine Oil Nissan N16 ManualDocument2 pagesEngine Oil Nissan N16 Manualsabir siddiqui50% (2)

- SM 35Document236 pagesSM 35BUKURU Juma100% (2)

- Peugeot 405Document8 pagesPeugeot 405robertoNo ratings yet

- Cav Injector Repair ManualDocument5 pagesCav Injector Repair ManualDouglas Sobral50% (2)

- 2M (256K 8/128K 16) BIT: Flash MemoryDocument49 pages2M (256K 8/128K 16) BIT: Flash MemoryEdson CostaNo ratings yet

- DSM Tuning Sheet v2.1Document15 pagesDSM Tuning Sheet v2.1Ultraman NexusNo ratings yet

- 2tz Fze 2Document22 pages2tz Fze 2che-ahmad-majdi-7191No ratings yet

- Verna WorkshopDocument1,230 pagesVerna WorkshopYasser NassarNo ratings yet

- Preparation 2zr-Fe Engine Mechanical SST PDFDocument3 pagesPreparation 2zr-Fe Engine Mechanical SST PDFAlbert BriceñoNo ratings yet

- Do's & Don'Ts For TurbochargersDocument7 pagesDo's & Don'Ts For Turbochargersvikrant GarudNo ratings yet

- Turbo Installation 91913Document5 pagesTurbo Installation 91913MoeinNo ratings yet

- Traction Control ArticleDocument8 pagesTraction Control ArticledromakiNo ratings yet

- Torsen T-3 DifferentialDocument4 pagesTorsen T-3 DifferentialdromakiNo ratings yet

- Torsen T-1 Technical SheetDocument2 pagesTorsen T-1 Technical SheetdromakiNo ratings yet

- T-2R (RaceMaster) PDFDocument3 pagesT-2R (RaceMaster) PDFdromakiNo ratings yet

- T-2R (RaceMaster) PDFDocument3 pagesT-2R (RaceMaster) PDFdromakiNo ratings yet

- Gleason's Impossible DifferentialDocument2 pagesGleason's Impossible Differentialdromaki100% (1)

- Torsen General Frequently Asked Questions PageDocument4 pagesTorsen General Frequently Asked Questions PagedromakiNo ratings yet

- Torsen Application ChartDocument1 pageTorsen Application ChartdromakiNo ratings yet

- OPTIMA (MG) 2010 G 2.7 DOHC Smart Key SystemDocument6 pagesOPTIMA (MG) 2010 G 2.7 DOHC Smart Key SystemdromakiNo ratings yet

- Detonation (Detonation Information)Document4 pagesDetonation (Detonation Information)dromakiNo ratings yet

- Thule Ocean 80 ManualDocument2 pagesThule Ocean 80 ManualSandu ButnaruNo ratings yet

- MAVERICK DISTRIBUTING JUNE 2016 BulletinDocument6 pagesMAVERICK DISTRIBUTING JUNE 2016 Bulletindforeman4509No ratings yet

- Module-Body Control C6/F: Connector DetailsDocument3 pagesModule-Body Control C6/F: Connector DetailsEnrique Arevalo LeyvaNo ratings yet

- Site Development Plan: Rizal Technological UniversityDocument1 pageSite Development Plan: Rizal Technological UniversityLigaya Delos SantosNo ratings yet

- B767 ChecklistDocument2 pagesB767 ChecklistWalter Hugo Friaes PintoNo ratings yet

- MOTORSDocument8 pagesMOTORSADESH TRIVEDINo ratings yet

- Document Number: Document TitleDocument7 pagesDocument Number: Document TitletalangocdayNo ratings yet

- Dave Stevenson: DetailsDocument2 pagesDave Stevenson: DetailsPhethego Caprivian MokgaloNo ratings yet

- History of ICEDocument14 pagesHistory of ICEAbdisalaam mohamudNo ratings yet

- Semi TopicsDocument3 pagesSemi TopicsHemad YousefiNo ratings yet

- New Ceramic Products: Visit Us Online atDocument5 pagesNew Ceramic Products: Visit Us Online atmiab1No ratings yet

- No Less Than Legendary: The All-New Toyota Land CruiserDocument2 pagesNo Less Than Legendary: The All-New Toyota Land CruiserRj Balboa LeriasNo ratings yet

- 2021 Odyssey AccessoriesDocument1 page2021 Odyssey AccessoriesKevin YoungNo ratings yet

- Rules Regulation On Electric Cycles in The European Union May 2017Document29 pagesRules Regulation On Electric Cycles in The European Union May 2017mirrorman_tmNo ratings yet

- Scorpio - Developing Brand IdentityDocument14 pagesScorpio - Developing Brand IdentitypiyushssethiNo ratings yet

- Chieftain 1400 Inclined Screen BrochureDocument1 pageChieftain 1400 Inclined Screen BrochureBisharat RazzaqNo ratings yet

- SupraguideDocument9 pagesSupraguidevolrothNo ratings yet

- Null PDFDocument1 pageNull PDFyuliNo ratings yet

- Sima Kui 2010 Ing 307Document4 pagesSima Kui 2010 Ing 307Ratna WiwaraNo ratings yet

- Autocar ProfessionalDocument2 pagesAutocar ProfessionalRAHUL_AGRAWALNo ratings yet

- Eoa Model LesDocument4 pagesEoa Model LesJagan RajNo ratings yet

- B626 Ray ZRDocument56 pagesB626 Ray ZRsitaramsahandsonsNo ratings yet

- x737 V5 ChecklistDocument6 pagesx737 V5 ChecklistDiegoEspinNo ratings yet