Professional Documents

Culture Documents

F10044-100-Qua-05 81-00040-C1

Uploaded by

adeoye_okunoyeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F10044-100-Qua-05 81-00040-C1

Uploaded by

adeoye_okunoyeCopyright:

Available Formats

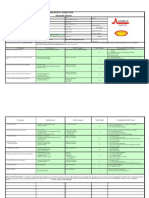

C1

16-06-05

REL

Construction / Release / Implementation

Juan Carlos

A2

23-05-05

COM

Client Review & Comments / Implementation

Juan Carlos D.Buccellato F.Girodet

Ramirez

A1

28-02-05

COM

Client Review & Comments / Implementation

Juan Carlos D.Buccellato F.Girodet

Ramirez

Rev.

Date

DD-MM-YY

Status

Issued for

Originator

F.Girodet

Checked

Approved

Company :

The Shell Petroleum Development Company

of Nigeria Limited (SPDC)

This document contains information which is proprietary to Shell Petroleum Development Company of Nigeria Ltd (SPDC). This information is to be held in

confidence. Disclosure, reproduction or other use of this document is prohibited without the prior written consent of SPDC.

Contractor :

SOKU LGSP DE-BOTTLENECKING PROJECT

Company contract No. :

Type of document :

E 15253

PROJECT PROCEDURE

Contractor's / Subcontractor's document identification :

Codes :

F 1 0 0 4 4

Other identification :

Rev.

1 0 0 Q U A 0 5 . 8 1 0 0 0 4 0 C 1

Saipem s.a.

Document title :

BACKFILLING AND CLEAN UP

Company document No. :

SPDC 2004 0091049

Company document Type :

E13

Page :

1/6

SOKU LGSP DE-BOTTLENECKING Project

16/06/05

BACKFILLING AND CLEAN UP

REVISION : C1

F10044 100 QUA 05.81 00040

CHANGE RECORD PAGE

REV. N

Status

Description of Revision

A1

COM

Client Review & Comments / Implementation

A2

COM

Client Review & Comments / Implementation

C1

REL

Construction / Release / Implementation

PAGE : 2 / 6

SOKU LGSP DE-BOTTLENECKING Project

16/06/05

BACKFILLING AND CLEAN UP

REVISION : C1

F10044 100 QUA 05.81 00040

INDEX

1.

SCOPE AND PURPOSE..................................................................................................................... 4

2.

REFERENCE DOCUMENTS.............................................................................................................. 4

3.

DEFINITIONS...................................................................................................................................... 4

4.

RESPONSABILITIES.......................................................................................................................... 4

5.

ACTIVITIES DESCRIPTION.............................................................................................................. 4

6.

INSPECTION AND TESTING.............................................................................................................. 5

7.

FLOW CHART.................................................................................................................................... 5

8.

SAFETY.............................................................................................................................................. 6

9.

QUALITY RECORDS.......................................................................................................................... 6

PAGE : 3 / 6

SOKU LGSP DE-BOTTLENECKING Project

16/06/05

BACKFILLING AND CLEAN UP

REVISION : C1

F10044 100 QUA 05.81 00040

1.

SCOPE AND PURPOSE

The scope of this Procedure is to establish a detailed description of operations that shall be performed

during padding, backfilling and clean up activities in the construction of flow lines for LGSP De-Bottlenecking

Project.

2.

REFERENCE DOCUMENTS

Quality Control Plan:

Inspection and Testing Plan

Project Specifications:

a- Construction Spec S-25

b- DEP 31.40.00.10

Applicable standards and codes:

a- ANSI/ASME B 31.8

3.

F10044-100-QUA-05.81-00025

F10044-100-QUA-05.81-00035

Pipeline Construction

Pipeline Engineering

Gas transmission and distribution pipeline system

DEFINITIONS

COMPANY :

Shell

CONTRACTOR : Saipem

CONTRACT: The whole set of documents enclosed in the volumes making up the Contract

documentation.

PROJECT: SOKU LGSP De-Bottlenecking project.

RECORD: Document that shows results achieved or providing evidence of activities performed.

SITE: The site locations where WORK is to be performed.

4.

RESPONSABILITIES

Quality Manager: He is responsible to prepare and issue this procedure, in co-operation with the Quality

Engineer

Project Manager: He is responsible to ensure that information concerning the work is available on site.

Construction Manager: He is responsible to ensure that the quality of the work is maintained.

The Site Superintendent: He is responsible to follow the requirements of this procedure to ensure that the

contents are applied, and also responsible for safe use, handling during joint coating activities.

Discipline Supervisor (Foreman): Shall be responsible for performing all necessary activities to ensure that

the quality of the work has the minimum requested level of quality indicated by this procedure.

QC Supervisor: He is responsible to monitor and co-ordinate on site the execution of the job, collect all

relevant Quality Records verifying its adequacy and make sure if the records are correctly filled out and

archived.

The QC inspector: He shall be responsible for performing all necessary inspections, as established in this

document and in the Quality control plan, ITP and shall be responsible for issuing the related quality records,

obtaining all necessary approvals and preservation of the documents.

5.

ACTIVITIES DESCRIPTION

This Section of the procedure shall apply to under ground pipes (3 layers PE). Each of them has to be read

and interpreted in conjunction with the related specifications prepared for the project and described also in

Section 2, for backfilling and clean up activity.

PAGE : 4 / 6

SOKU LGSP DE-BOTTLENECKING Project

16/06/05

BACKFILLING AND CLEAN UP

REVISION : C1

F10044 100 QUA 05.81 00040

5.1

Prior to start of any backfilling operations, the pipeline section and its appurtenances shall be

checked to verify that the specified cover is assured

The section of the pipeline must be lowered on soft bed of the trench. This soft bed shall be prepared

from the soil of the excavation, and shall be free from gravel, rock or lumps of hard material. The

method of preparation of the soft bed shall be by mechanical or manual means. It shall be carefully

placed around the pipe in layers not exceeding 15 cms, deep and uniformly compacted. Placement

and compaction of soft surround material shall be continued up to a thickness of 20 cms above the

crown of the pipe across the full width of the pipe trench as per indicated in construction specifications

5.2

Similarly, backfill material shall be the same as material from the bulk excavation from the

trench, which shall also be free from gravel, rock or lumps of hard material

5.3

Where the trench has been excavated through or along drive ways, walks, roads, and at live

stock passage ways and other locations indicated on the Typical drawings, the padding shall be

thoroughly compacted by Contractor with approved hand tools, or mechanical equipment to achieve a

good compaction around the pipe and to avoid any settlement

5.4

While in track or roads crossings it is required to have the ground regarded to its original

contour where restoration is necessary to assure the safety of the pipeline and the passage of traffic,

for capping of backfilling along the pipeline conventional mounding over the pipeline without any

mechanical compaction shall be acceptable.

5.5 The backfill shall be completed by the formation of crown along the pipeline, shaped with grader

and without mechanical compaction.

If the backfill material (excavated material) is insufficient or cannot be rid off objectionable materials

e.g. rocks, stones, herbs etc thereby rendering it unsuitable for placement around the pipe, the

contractor shall locate and transport suitable soft material (which meets the requirements of the

specification) in sufficient quantities to completely surround the pipe and cover it to adequate depth.

The material shall be used both as bedding and padding material in areas of hard rock, stones or

where the natural ground is evident to be hard.

The thickness of the bedding shall be 150-mm minimum. This shall be guaranteed by taking spot

measurement and quality of the soft material.

Soft material used as padding material shall cover the pipe to at least 200mm thick.

5.6

If any road crossing by open cut method, the backfill shall be well compacted by mechanical

means and the surface shall be restored to its original uncut status.

To achieve the above objective and also to eliminate settlement problems, material (well compacted)

shall be used as backfill material over cut roads

5.7

The backfill material unless otherwise specified , along the trench line the cover form the top of

the pipe to consolidated mud or ground level shall not be less than 60 cms., except through irrigated

fields and rocky lands where the backfilling shall be completed in accordance with construction

specification S-25, clause 25.6.2 & 25.6.3.

6.

INSPECTION AND TESTING

The work performed will be monitored, verified and recorded in accordance with the Inspection and Test Plan

for Trenching mentioned at section 2.

The activities shall be recorded by Contractor discipline inspector in a daily activity report containing all the

pertinent information regarding padding, backfilling and clean up.

The Field Quality Control organization shall be responsible for collection and preservation of QA/QC

documentation, which shall be monitored by QC supervisor.

7.

FLOW CHART

N/A

PAGE : 5 / 6

SOKU LGSP DE-BOTTLENECKING Project

16/06/05

BACKFILLING AND CLEAN UP

REVISION : C1

F10044 100 QUA 05.81 00040

8.

SAFETY

All personnel concerned in the above mentioned activities shall follow the requirements of the HSE

design Plan No.F10044-100-SAF-05.81-02071 and F10044-100-HSE-05.81-00033, to prevent any

hazardous situation during trenching operations.

Constant care is to be taken considering that the activity is carried out in a corridor between existing

live pipelines and other facilities

The foreman and supervisor shall take special care when moving and working are done under power

and telephone lines

Contractor Safety Engineer will closely monitor and supervise safety precautions.

9.

Suitable Personal Protective Equipment will be provided for all staff deployed for BACKFILLING

activities. Use of PPE shall be enforced by close supervision of all activities.

Hazards associated with BACKFILLING activities and safeguarding measures must be identified

QUALITY RECORDS

9.1 Backfilling inspection record F10044-100-QUA-13.62-13000

PAGE : 6 / 6

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- JHA Civil WorksDocument2 pagesJHA Civil Worksethelchudi100% (11)

- Occidental Oil and Gas Corporation Mechanical Integrity StandardDocument7 pagesOccidental Oil and Gas Corporation Mechanical Integrity StandardedwinsazzzNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Jsa Installation of HV ApparatusDocument6 pagesJsa Installation of HV ApparatusLuqman OsmanNo ratings yet

- Sample Company RegulationDocument7 pagesSample Company RegulationAlpha100% (1)

- Maj HazDocument60 pagesMaj HazVasant Kumar Varma100% (1)

- UT PCN NotesDocument113 pagesUT PCN NotesThiru Raja95% (19)

- WIS 10 Interp ExeDocument67 pagesWIS 10 Interp Exelembugs100% (1)

- Calamity and DisasterDocument14 pagesCalamity and DisasterJoveLyn Asuncion100% (1)

- Processing the RadiographDocument5 pagesProcessing the Radiographkanwar1992singhNo ratings yet

- k2s-Ng01007551-Gen-ra7754-00004 Specification For Line Pipe Protective Coating RepairDocument15 pagesk2s-Ng01007551-Gen-ra7754-00004 Specification For Line Pipe Protective Coating Repairadeoye_okunoyeNo ratings yet

- Bus Bar HV Test MethodDocument6 pagesBus Bar HV Test MethodPandrayar MaruthuNo ratings yet

- CP ManualDocument48 pagesCP ManualFaddy Faris100% (7)

- CIPSDocument6 pagesCIPSadeoye_okunoyeNo ratings yet

- AKT ProjectDocument1 pageAKT Projectadeoye_okunoyeNo ratings yet

- Non Destructive Examination 2Document148 pagesNon Destructive Examination 2adeoye_okunoyeNo ratings yet

- Calibration CertificateDocument1 pageCalibration Certificateadeoye_okunoye100% (1)

- Cswip 3 2 BookDocument316 pagesCswip 3 2 Bookadeoye_okunoyeNo ratings yet

- Model Question Paper WeldingDocument4 pagesModel Question Paper Weldingjasminnee100% (1)

- RT Level I BookDocument366 pagesRT Level I Bookadeoye_okunoyeNo ratings yet

- Radiographic Interpreter Weld DefectDocument22 pagesRadiographic Interpreter Weld Defectadeoye_okunoyeNo ratings yet

- Model Question Paper WeldingDocument4 pagesModel Question Paper Weldingjasminnee100% (1)

- 9 77 Pages Mutiple Questions For CSWIP Question Answers Solved Past Papers Cswip 3.1Document77 pages9 77 Pages Mutiple Questions For CSWIP Question Answers Solved Past Papers Cswip 3.1Umah SangarNo ratings yet

- DC-Voltage Gradient (DCVG) Surveys Using MCM's Integrated Pipeline Survey Test Equipment and Database Management PackageDocument60 pagesDC-Voltage Gradient (DCVG) Surveys Using MCM's Integrated Pipeline Survey Test Equipment and Database Management Packageadeoye_okunoyeNo ratings yet

- B P S L: Redero Ipeline Ervices ImitedDocument4 pagesB P S L: Redero Ipeline Ervices Imitedadeoye_okunoyeNo ratings yet

- DCVGDocument8 pagesDCVGadeoye_okunoyeNo ratings yet

- QP071Document3 pagesQP071adeoye_okunoyeNo ratings yet

- QP075Document3 pagesQP075adeoye_okunoyeNo ratings yet

- Tds Handy Cap Rev1 Aug13Document2 pagesTds Handy Cap Rev1 Aug13adeoye_okunoyeNo ratings yet

- QP073Document3 pagesQP073adeoye_okunoyeNo ratings yet

- Ceramapure Repair ProcedureDocument1 pageCeramapure Repair Procedureadeoye_okunoyeNo ratings yet

- CP Testing EquipmentDocument5 pagesCP Testing Equipmentadeoye_okunoyeNo ratings yet

- Application Instruction & Data Sheet - Bitutape PrimerDocument2 pagesApplication Instruction & Data Sheet - Bitutape Primeradeoye_okunoyeNo ratings yet

- Kaspersky UserguideDocument71 pagesKaspersky Userguideadeoye_okunoyeNo ratings yet

- 420111009M - Operator Response To NOA - 09292011Document128 pages420111009M - Operator Response To NOA - 09292011adeoye_okunoyeNo ratings yet

- Pipeline Earthing Isolation AccessoriesDocument31 pagesPipeline Earthing Isolation AccessoriesMohd Zaieri100% (1)

- Manual Metal Arc WeldingDocument35 pagesManual Metal Arc Weldingadeoye_okunoyeNo ratings yet

- TENDER OF PLANT BUILDING & EQUIPMENT INSTALLATION - HitungDocument51 pagesTENDER OF PLANT BUILDING & EQUIPMENT INSTALLATION - HitungRini AdelinaNo ratings yet

- Mit RT CDR 2012Document92 pagesMit RT CDR 2012Mannam Sarath SarathNo ratings yet

- European Standard EN 1838 Norme Europeenne Europaische NormDocument12 pagesEuropean Standard EN 1838 Norme Europeenne Europaische NormAts ByNo ratings yet

- A Risk Reducer A Quantitative Study of The Effect of VTS Great BeltDocument7 pagesA Risk Reducer A Quantitative Study of The Effect of VTS Great BeltamNo ratings yet

- HermannUltrasonicsDialogSpeed ControlDocument20 pagesHermannUltrasonicsDialogSpeed ControlUrielMGNo ratings yet

- Cleaning Mud Mixing Tanks JSADocument7 pagesCleaning Mud Mixing Tanks JSAAziz AndriyantoNo ratings yet

- Height Work Permit: Date: Project: Checked byDocument2 pagesHeight Work Permit: Date: Project: Checked bykumar kannan100% (1)

- Tc009 em Veh Weight Reg Fama Iafc 111122Document14 pagesTc009 em Veh Weight Reg Fama Iafc 111122shabasNo ratings yet

- Guardmaster® Safedge™ Pressure Sensitive Safety Edge System Installation and User Manual 440FDocument24 pagesGuardmaster® Safedge™ Pressure Sensitive Safety Edge System Installation and User Manual 440Fsuresh putNo ratings yet

- Analysis of A High-Potential Business: Sqreen: Application Security Management PlatformDocument13 pagesAnalysis of A High-Potential Business: Sqreen: Application Security Management Platformhinaya khanNo ratings yet

- Ethics EssayDocument2 pagesEthics Essayapi-645158545No ratings yet

- PA 1309 - 10. Topaz. Service Manual TRAD. Philips Electronic Manufacturing TechnologyDocument260 pagesPA 1309 - 10. Topaz. Service Manual TRAD. Philips Electronic Manufacturing TechnologyLeopoldo Medina100% (2)

- Cutmaster 120Document126 pagesCutmaster 120Berling Encarnacion RosarioNo ratings yet

- Guard Rail CP-BP Tebal 4,5 MM (Tipe B)Document1 pageGuard Rail CP-BP Tebal 4,5 MM (Tipe B)rani wulansariNo ratings yet

- Takara Bio Lenti-X Concentrator Material Safety Data SheetDocument8 pagesTakara Bio Lenti-X Concentrator Material Safety Data SheetMildred MondayNo ratings yet

- Dr.-Ing. Alexander Schloske Funktionale SicherheitDocument97 pagesDr.-Ing. Alexander Schloske Funktionale SicherheitGirish KasturiNo ratings yet

- Hazardous Area Classification ToolDocument1 pageHazardous Area Classification ToolPelin AktenNo ratings yet

- Midterm Task and AnswerDocument2 pagesMidterm Task and AnswerPeko HuNo ratings yet

- Circuit BreakerDocument31 pagesCircuit BreakervehocurriNo ratings yet

- HSE Site Instruction For Contractor FormDocument1 pageHSE Site Instruction For Contractor FormAsif HussainNo ratings yet

- Safety culture assessment tools for improving healthcareDocument7 pagesSafety culture assessment tools for improving healthcareVeigner Whyng CabugayanNo ratings yet

- How Is Reasonably Practicable' Defined?Document7 pagesHow Is Reasonably Practicable' Defined?Haritharan ManiamNo ratings yet

- Black Toner SDSDocument8 pagesBlack Toner SDSArnys JoseNo ratings yet