Professional Documents

Culture Documents

Tirupur Water and Waste Water Treatment Project - Final

Uploaded by

rajdeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tirupur Water and Waste Water Treatment Project - Final

Uploaded by

rajdeCopyright:

Available Formats

“Tirupur Water and

Wastewater

Treatment Project,

India”

SUBMITTED BY: - RAJDEEP SAINI

ROLL NO: - 47

PGDM (BANKING & FINANCE)

SEM - 4

Fact File:-

Key Data:

• Water Treatment Plant Capacity -185 million litres a day

• Plant Type - Conventional rapid gravity filter with Lamella clarifier

• Wastewater Treatment Plant Capacity - 15 million litres a day

(expandable to 30 million litres a day)

• Plant Type - Secondary treatment level - activated sludge

• Footprint - 5.2ha

• Estimated Cost - $220m

Project Timeline:

• Tirupur Area Development Project announced – 1991

• Special Purpose Vehicle (SPV) formation – 1995

• Tender / Contract Decided – 1999

• Financial Closure - March 2002

• Foundation Stone Laid - 20 June 2002

• Construction Began - October 2002

• Main Civil / Mechanical Work Completed - December 2004

• Pipeline Testing - March 2005

• Water Treatment Plant Commissioning - April 2005

• Tirupur Municipality Receives Water - August 2005

• Wastewater Treatment Plant Completed - February 2006

• Global Water Award - March 2006

Key Players:

SPV and Sponsor

• New Tirupur Area Development Corporation Limited (NTADCL)

Partner Institutions

• Tirupur Municipality, Tirupur Exporters Association (TEA), Infrastructure

Leasing and Financial Services (IL&FS), The Tamil Nadu Corporation for

Industrial Infrastructure Development (TACID), Indo-US

EPC 1 Contractor

• Hindustan Construction Co.

EPC 2 Contractor

• Mahindra & Mahindra and Larsen & Toubro (JVC)

Operation and Maintenance Contractor

• Mahindra Water Utilities Ltd - a Mahindra and United Utilities JVC

Tirupur project background:

• Tirupur is located in Tamil Nadu state and is India's largest producer of

cotton knitwear. With over 2,500 textile businesses located within a 25-

mile radius, earning some $1bn, the region – one of the most economically

dynamic in Southern India – accounts for over 75% of the entire country's

knitwear exports.

• "The project will provide a daily supply of 185 million litres of water."

• Water is essential to the industry, and historically groundwater and

tankers have been extensively used to overcome the city's lack of supply.

• However, the industry has heavily polluted the groundwater with chemical

dyes; it has been said – and not entirely frivolously – that the colour of the

region's water varies with the mood of Paris fashions.

• By 1990, the groundwater had become progressively more saline and

contaminated, and the need to address the situation had become of

pressing regional importance. This ultimately led to the instigation of the

project.

• While the need for an improved water system was clear, the challenge was

financing it. Ultimately, this required the formation of a Special Purpose

Vehicle (SPV) to access commercial funding and implement the project. In

1995, the New Tirupur Area Development Corporation Limited (NTADCL)

was formed for the role and subsequently began the process of

international competitive tendering.

• Since the municipal area also lacked an organized system of drainage,

sewage collection or treatment, it was decided to address both this and the

provision of potable water, as part of the Tirupur Area Development

Project. An associated wider scheme of works also encompasses additional

local infrastructure requirements including roads, telecommunications

and power. Drawing water in one of the slum areas. The project represents a

major step forward for a country where so much of the population has limited

access to safe drinking water or sanitation. (Photograph courtesy of WHO/P.

Virot.)

Tirupur water and wastewater treatment project:

• The project itself was split into three separate contracts, two awarded on a

engineer, procure and construct (EPC) basis and one to operate and

manage (O&M) the finished facility.

• Construction began in October 2002 and the main civil / mechanical work

was completed by December 2004. Pipeline testing began in March 2005.

The water treatment plant commissioning followed the next month and

the Tirupur Municipality began receiving project water on alternate days

in October 2005, after a two month trial period. The wastewater treatment

plant was originally scheduled for completion in October 2005, but was

delayed until February 2006 by a heavy monsoon and floods.

• "The system serves nearly 1,000 textile units and over 1.6 million residents

in Tirupur and its surrounding areas."

• The fully operational system serves nearly 1,000 textile units and over 1.6

million residents in Tirupur and its surrounding areas.

• A daily total of around 125 million litres of water is supplied to the

knitwear dyeing and bleaching industry, 25 million litres to the Tirupur

municipality, which includes 60,000 slum dwellers and 35 million litres is

shared between the region's remaining rural towns, villages and

settlements.

• Around 2,000 lorries make seven to ten trips a day to supply water to the

textile industry. Households get water supply for two hours on alternate

days.

• Sanitation provision within the scheme includes 100 of the city's

designated slum areas. The water treatment plant was built to a

conventional design, using a rapid gravity filter with a lamella clarifier to

provide the 185 million litres per day capacity.

• The wastewater facility takes domestic sewage only and uses an activated

sludge system to achieve secondary treatment standards. The plant

discharges into Noyyal river. Initially built with a capacity of 15 million

litres per day, its design allows eventual expansion to double that, when

sewer provision is extended to the remaining 15 of the town's 52 wards.

• Although the construction elements of the project were implemented in

two parts, their execution was effectively simultaneous. The EPC I work

involved building the water intake, the transmission pipeline from the

river to Tirupur and the master balancing reservoir, while the EPC 2

contract, covered the main feeder pipelines and distribution networks,

overhead and ground level storage tanks and the sewerage network in the

Tirupur town area.

• Once the construction work was completed and the master balancing

reservoir linked to the distribution network, Mahindra Water Utilities' 30-

year O&M contract came into effect.

Key players:

• NTADCL was the SPV and project sponsor. The EPC1 contractor was the

Hindustan Construction Company, with a Mahindra & Mahindra / Larsen

& Toubro joint venture responsible for the EPC2 contract. The O&M

contractor is Mahindra Water Utilities Ltd - a Mahindra/United Utilities

JVC.

• Other partner institutions in the project included the Tirupur Municipality

itself, Tirupur Exporters Association (TEA), Infrastructure Leasing and

Financial Services (IL&FS), The Tamil Nadu Corporation for Industrial

Infrastructure Development (TACID) and the Indo-US Financial

Institutions Reform and Expansion (FIRE). In addition, USAID and the

World Bank have also committed themselves to providing long-term aid.

Some pictures of the project

• India is no stranger to large water transmission schemes - 55km

of new pipeline were constructed as part of this project.

(Photograph courtesy of WHO/P. Virot)

• Available water supplies for many of India's poorest are often

very badly contaminated. For the first time, this project enabled

local residents to benefit directly from the regional industry's

need for reliable water services. (Photograph courtesy of

WHO/P. Virot)

• The new water plant: built to a conventional design, it has a

capacity of 185 million litres per day. (Photograph courtesy of

M.C. Shrikant, New Tirupur Area Development Corporation)

• Some 2,500 textile

businesses are located

within a 25 mile radius of

Tirupur, making it India's

largest producer of cotton

knitwear and accounting

for over 75% of the

country's knitwear

exports. (Photograph

courtesy of WHO/P.

Virot)

• The chief minister of Tamil Nadu, Ms J. Jayalalithaa, meeting

with representatives of the textile industry. The project used

cross subsidies from the textile units to help make the service

provision for local residents possible. (Photograph courtesy of

the Tamil Nadu Government)

• Drawing water in one of the slum areas. The project represents

a major step forward for a country where so much of the

population has limited access to safe drinking water or

sanitation. (Photograph courtesy of WHO/P. Virot)

You might also like

- Sajid HussainDocument48 pagesSajid HussainTimothy GarciaNo ratings yet

- EIA India TamilNaduDocument370 pagesEIA India TamilNaduZaber Moinul100% (2)

- Water Conservation in Sugar Industry: A Case Study of Lokmangal Sugar, Ethanol and Co-Generation Industries LTD, BhandarkavatheDocument7 pagesWater Conservation in Sugar Industry: A Case Study of Lokmangal Sugar, Ethanol and Co-Generation Industries LTD, BhandarkavatheIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- Final ReportDocument41 pagesFinal Reporttangtszloong100% (1)

- Higher Education in Rajasthan A Quite Revolution PDFDocument90 pagesHigher Education in Rajasthan A Quite Revolution PDFBala VishnuNo ratings yet

- Canal Structure KhadakwaslaDocument11 pagesCanal Structure KhadakwaslaPrajyot SapkalNo ratings yet

- Lahore College Water Conservation AssignmentDocument18 pagesLahore College Water Conservation AssignmentKhiZra ShahZad100% (2)

- Flyash ManagementDocument13 pagesFlyash ManagementShahinshaNo ratings yet

- Waste To Energy Guidebook - English Version 2015Document234 pagesWaste To Energy Guidebook - English Version 2015Khumairah ZulqaidahNo ratings yet

- PUMPS: Types, Components, Working PrinciplesDocument20 pagesPUMPS: Types, Components, Working PrinciplesEICQ/00154/2020 SAMUEL MWANGI RUKWARONo ratings yet

- Multi Parameter WaterTesting SystemsDocument28 pagesMulti Parameter WaterTesting SystemsAlex SullivanNo ratings yet

- PPTDocument29 pagesPPTAnaytullah AnsariNo ratings yet

- Sustainable Water Resources Management of Chennai BasinDocument20 pagesSustainable Water Resources Management of Chennai BasinDhilip Anand TNo ratings yet

- Site Water Balance: MAC-ENC-PRO-059Document21 pagesSite Water Balance: MAC-ENC-PRO-059Yazid Eriansyah PradantaNo ratings yet

- Waste MGMT & Env ControlDocument45 pagesWaste MGMT & Env ControlMasrawana Mohd Masran100% (1)

- 10-17-2017 Dr. Iko MitsuiDocument71 pages10-17-2017 Dr. Iko MitsuiAndriAmdNo ratings yet

- Performance Audit of Water Pollution in IndiaDocument279 pagesPerformance Audit of Water Pollution in IndiaSonali PiseNo ratings yet

- Membrane Drinking Water TreatmentDocument16 pagesMembrane Drinking Water TreatmentRamesh SoniNo ratings yet

- Pengolahan Sampah Week 2 (Sampah Dan Pengolahan)Document46 pagesPengolahan Sampah Week 2 (Sampah Dan Pengolahan)Muhammad HarisNo ratings yet

- Water Pollution and SocietyDocument12 pagesWater Pollution and SocietyRaja_ne23100% (1)

- 2012 Kme PresentationDocument38 pages2012 Kme PresentationEnoch Ofori KwartengNo ratings yet

- WaterDocument6 pagesWaterAbhishek KumarNo ratings yet

- 1.0tph palm fruite crushing mill-印尼 PDFDocument5 pages1.0tph palm fruite crushing mill-印尼 PDFAgus AriyantoNo ratings yet

- Application of Ponding Systems in The Treatment ofDocument10 pagesApplication of Ponding Systems in The Treatment ofbenjiy80No ratings yet

- Treatment of Sugar Industry WastewaterDocument4 pagesTreatment of Sugar Industry WastewaterLuu TonyNo ratings yet

- Effluent Treatment Plant (ETP) - Process Flow DiagramDocument4 pagesEffluent Treatment Plant (ETP) - Process Flow DiagramshimanthNo ratings yet

- Hydraulic StructureDocument56 pagesHydraulic StructureMahesh RamtekeNo ratings yet

- Eia Report of Expansion of Thermal Power Plant: Tamnar, Tehsil Gharghoda, Dist Raigarh (Chhattisgarh)Document16 pagesEia Report of Expansion of Thermal Power Plant: Tamnar, Tehsil Gharghoda, Dist Raigarh (Chhattisgarh)Agila R RamamoorthyNo ratings yet

- Coal Quality Improvement Technology Brief-EngDocument10 pagesCoal Quality Improvement Technology Brief-EngRiko C PribadiNo ratings yet

- Water Treatment. Project WorkDocument6 pagesWater Treatment. Project WorkMuluken MelesseNo ratings yet

- CGWA Guidelines for NOC IssuanceDocument39 pagesCGWA Guidelines for NOC IssuanceVishal Duggal100% (1)

- Palm Oil Effluent Treatment SchemeDocument11 pagesPalm Oil Effluent Treatment SchemebathalapalliNo ratings yet

- Restoring Polluted Lakes Using Structural and Non-Structural ApproachesDocument145 pagesRestoring Polluted Lakes Using Structural and Non-Structural ApproachesSugumar BalasubramaniamNo ratings yet

- Waste Water Punjab - 21 March 2019Document48 pagesWaste Water Punjab - 21 March 2019Mohd IshfaqNo ratings yet

- Sludge Treatment, Utilisation and DisposalDocument53 pagesSludge Treatment, Utilisation and DisposalFrinaldi Abi Duo PutiNo ratings yet

- Fly Ash Utilization A Case StudyDocument8 pagesFly Ash Utilization A Case StudyKadayam GuruswamiNo ratings yet

- Wall Isulation Using Oil Palm FibreDocument17 pagesWall Isulation Using Oil Palm Fibrezakzaku501No ratings yet

- Cara Kerja IncineratorDocument7 pagesCara Kerja Incineratordarfil11No ratings yet

- Makalah Seminar Instalasi Pengolahan Lindi SuwungDocument24 pagesMakalah Seminar Instalasi Pengolahan Lindi SuwungCamelia Indah MurniwatiNo ratings yet

- 9.7 MLD DPR PDFDocument56 pages9.7 MLD DPR PDFAjay ShindeNo ratings yet

- Energy Conversion Engineering: Steam Power PlantsDocument73 pagesEnergy Conversion Engineering: Steam Power Plantsanuragburman17No ratings yet

- Raw Water Intake, Screening, and Aeration in Water Supply ProjectDocument22 pagesRaw Water Intake, Screening, and Aeration in Water Supply ProjectSwaminathan S. Raamanathan100% (10)

- Turbo Charger by ERIDocument35 pagesTurbo Charger by ERIRamzi HamiciNo ratings yet

- Bap - Uf SystemDocument88 pagesBap - Uf SystemGloria HamiltonNo ratings yet

- Water Application Value EngineDocument10 pagesWater Application Value EngineAndres Felipe Castellanos PulidoNo ratings yet

- Solid Waste Management - Indoor MethodDocument19 pagesSolid Waste Management - Indoor MethodraaaaajjjjjNo ratings yet

- Consolidated Draft EIA Report-GJEP, KOCHI - CompressedDocument426 pagesConsolidated Draft EIA Report-GJEP, KOCHI - Compressedbinu kNo ratings yet

- BAB 5 Seawater DesalinationDocument75 pagesBAB 5 Seawater DesalinationShanna Sinaga100% (1)

- Introduction To Water Supply EngineeringDocument5 pagesIntroduction To Water Supply EngineeringzamzuraneeNo ratings yet

- Sewage Treatment Plant...... LLLLLLLDocument7 pagesSewage Treatment Plant...... LLLLLLLaishwarya wagh100% (1)

- Rainwater HarvestingDocument11 pagesRainwater Harvestingapurva dhawdeNo ratings yet

- Ground Water Recharge Techniques 2Document141 pagesGround Water Recharge Techniques 2Ravi Bhushan SharmaNo ratings yet

- Municipal Solid Waste Management in Moradabad City, IndiaDocument11 pagesMunicipal Solid Waste Management in Moradabad City, IndiaJames Konthou50% (2)

- Treatment of Grey Water Using Technique of PhytoremediationDocument8 pagesTreatment of Grey Water Using Technique of PhytoremediationAnonymous kw8Yrp0R5rNo ratings yet

- Co-Composting of Palm Oil Mill WasteDocument6 pagesCo-Composting of Palm Oil Mill Wasteedison58No ratings yet

- Water Supply Engineering Tutorials 4 To 7Document5 pagesWater Supply Engineering Tutorials 4 To 7Dr. Akepati Sivarami ReddyNo ratings yet

- Modeling, Simulation and Design of Membrane Based Palm Oil Mill Effluent (Pome) Treatment Plant From Pilot Plant StudiesDocument59 pagesModeling, Simulation and Design of Membrane Based Palm Oil Mill Effluent (Pome) Treatment Plant From Pilot Plant StudiesstefqthinkNo ratings yet

- Introduction To Water Treatment PlantDocument15 pagesIntroduction To Water Treatment PlantRahul KhedkarNo ratings yet

- Tirupur Water and Wastewater Treatment Project, IndiaDocument11 pagesTirupur Water and Wastewater Treatment Project, IndiaveeraiipmNo ratings yet

- Tirupur Water Supply Case Study 03Document3 pagesTirupur Water Supply Case Study 03SRNo ratings yet

- Marine InsuranceDocument7 pagesMarine Insurancerajde50% (2)

- Balance of Payments Definition: Summary Statement ofDocument16 pagesBalance of Payments Definition: Summary Statement ofrajdeNo ratings yet

- Standard Chartered BankDocument19 pagesStandard Chartered BankrajdeNo ratings yet

- Swaps and Indian Swap MarketDocument16 pagesSwaps and Indian Swap Marketrajde100% (3)

- Infrastructure CompaniesDocument20 pagesInfrastructure CompaniesrajdeNo ratings yet

- 07.08 Einstein S Falls HonorsDocument3 pages07.08 Einstein S Falls Honorsjackson combassNo ratings yet

- Example Butcher TestDocument1 pageExample Butcher TestCalvinNo ratings yet

- Farmer's Lung Disease ReviewDocument1 pageFarmer's Lung Disease ReviewYulia DevinaNo ratings yet

- Early Management of Severe Trauma Course PrepDocument2 pagesEarly Management of Severe Trauma Course PrepalimonyNo ratings yet

- Merck Case Study AnalysisDocument42 pagesMerck Case Study Analysisswathibeliya100% (1)

- Financial Assistance ApplicationDocument4 pagesFinancial Assistance ApplicationMulu Kindu MihretNo ratings yet

- Develop Maximum Strength While Staying Fresh For BoxingDocument3 pagesDevelop Maximum Strength While Staying Fresh For Boxinggtlaau50% (2)

- Teaching Complementary Colors and Harmony in PaintingDocument17 pagesTeaching Complementary Colors and Harmony in PaintingMary Jean EmpengNo ratings yet

- 11 Emergency Preparedness PlanDocument6 pages11 Emergency Preparedness PlanMAHESH SHAWNo ratings yet

- East Texas Regional Landlord IntroductionsDocument5 pagesEast Texas Regional Landlord Introductionsapi-345082978No ratings yet

- Eleaf MELO RT 22 User ManualDocument1 pageEleaf MELO RT 22 User ManualDemetrisNo ratings yet

- Terapia Gestalt Patricia BaumgarderDocument185 pagesTerapia Gestalt Patricia BaumgarderTpta Alexander ECNo ratings yet

- Nduba Landfil1Document6 pagesNduba Landfil1rrutayisire50% (2)

- Bipolar or Borderline (Or PTSD or ADHD) ?Document10 pagesBipolar or Borderline (Or PTSD or ADHD) ?NortonMentalHealth100% (5)

- Memo On Implementation of Daily Online COVID-19 Self AssessmentDocument1 pageMemo On Implementation of Daily Online COVID-19 Self AssessmentAdmin Headquarters RMFB7No ratings yet

- "The Life and Times of Mr. Nicholls" Michael George Nicholls-Pierce Liberal Studies LIBS 390-01 Intellectual AutobiographyDocument5 pages"The Life and Times of Mr. Nicholls" Michael George Nicholls-Pierce Liberal Studies LIBS 390-01 Intellectual Autobiographyapi-573024890No ratings yet

- Managing Workplace Safety and HealthDocument15 pagesManaging Workplace Safety and HealthnitinmtNo ratings yet

- Assessing Mothers' Knowledge of Neonatal Danger SignsDocument45 pagesAssessing Mothers' Knowledge of Neonatal Danger Signsbirhanu Ayenew AnleyNo ratings yet

- Psychological Incapacity - Persons NotesDocument9 pagesPsychological Incapacity - Persons NotesBeatriz VillafuerteNo ratings yet

- Concepts, Principles, and Theories in The Care of ElderlyDocument11 pagesConcepts, Principles, and Theories in The Care of ElderlyMerry Joy DeliñaNo ratings yet

- Impetigo & Ecthyma Treatment, Symptoms & Causes Merck Manuals - Dermatologic Disorders - MSD ManuaDocument5 pagesImpetigo & Ecthyma Treatment, Symptoms & Causes Merck Manuals - Dermatologic Disorders - MSD ManuaFarid Fauzi A ManwanNo ratings yet

- Wasp Sting EmergencyDocument2 pagesWasp Sting EmergencynaphNo ratings yet

- Perkins 1998Document10 pagesPerkins 1998Emma AzNo ratings yet

- What Is Acute Myocardial Infarction?Document6 pagesWhat Is Acute Myocardial Infarction?Md Sherajul HaqueNo ratings yet

- JGC Arabia LTD.: Drawin and Do UM NT Ransmi ADocument26 pagesJGC Arabia LTD.: Drawin and Do UM NT Ransmi AElezer BatchoNo ratings yet

- Sodium Bicarbonate SDSDocument8 pagesSodium Bicarbonate SDSMohamed HalemNo ratings yet

- Aisyah GDM ArticleDocument18 pagesAisyah GDM ArticleBesari Md DaudNo ratings yet

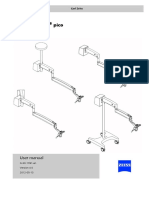

- Zeiss s100 Opmi PicoDocument292 pagesZeiss s100 Opmi PicoAnonymous 58LGc3100% (1)

- 2 AILS StudyDocument48 pages2 AILS StudyRashid Nisar DarogeNo ratings yet

- Definitions Health, Fitness, and Physical ActivityDocument9 pagesDefinitions Health, Fitness, and Physical ActivityKana NgaiNo ratings yet