Professional Documents

Culture Documents

Gamma Radiation Sterilization

Uploaded by

ananth67%(3)67% found this document useful (3 votes)

382 views2 pagesGamma Radiation Sterilization

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGamma Radiation Sterilization

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

67%(3)67% found this document useful (3 votes)

382 views2 pagesGamma Radiation Sterilization

Uploaded by

ananthGamma Radiation Sterilization

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

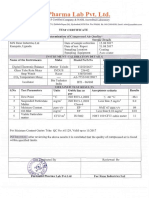

Title:

Gamma Radiation Sterilization

Guidance Number: 107

Prepared by:

Date:

Supersedes:

Checked by:

Date:

Date Issued:

Approved by:

Date:

Review Date:

Gamma Radiation Sterilization

Introduction

This document provides guidance for validation of gamma radiation sterilization

processes used to sterilize active pharmaceutical ingredients (API), drug products,

medical devices, and non-product items, such as, APA gowning articles, containers,

and closures with direct or potential contact with sterile raw materials (RM), APIs,

drug products, or medical devices.

1.

Critical Process Parameters for gamma radiation sterilization include:

Exposure time,

Timer setting (batch mode processing),

Conveyor speed (continuous mode processing),

Package size and bulk density, and

Dose measurement.

These parameters should be monitored or controlled and documented on the

sterilization record.

2.

Compatibility Studies should be performed according to an approved protocol

to demonstrate that the API, drug product, medical device, or non-product

item is not adversely affected by exposure beyond the sterilization radiation

dose limit. The evaluation should include the following:

Functionality;

Effects of gamma radiation on the API, drug product, or medical

device (i.e., bio-compatibility);

Appearance; and

Effects of aging determined by stability testing.

3.

Gamma Radiation

Commissioning and/or Qualification should include,

and not be limited to, documentation of the following:

Verification that the gamma irradiator is installed according to design

criteria;

Identification of irradiator location within the facility and flow of

materials through the facility;

Description of the construction and operation of the irradiator,

including the conveyor system and timer;

Description of the irradiation carriers, including materials of

construction and dimensions;

Identification of I/Es used to control, monitor, and record critical

process parameters;

8.

9.

AAMI Method VDMAX should be used to confirm a selected sterilization dose

according to the following requirements:

VDMAX 25 applies when the product has an average bioburden of

<1,000; and

VDMAX 15 applies when the product has an average bioburden of <1.5.

Substantiation of a Sterilization Dose Using AAMI Method VDMAX 25 for a

Single Production Batch includes the following steps:

a.

b.

c.

d.

e.

f.

g.

h.

i.

j.

10.

Determine the average indigenous bioburden of the API, drug product,

medical device, or non-product item using ten (10) randomly collected

samples;

Obtain the VDMAX 25 from the AAMI table using the average

bioburden and selected sterilization dose (see ANSI/AAMI/ISO

11137-2:2006);

Obtain ten (10) random samples and irradiate them at the VDMAX

obtained from the table;

Determine the dose applied to the samples;

Verify that the highest dose to the samples did not exceed the

Verification Dose* by more than ten (10) percent;

Verify that the arithmetic mean of the highest and lowest doses

delivered to the product is not less than ninety (90) percent of the

VDMAX 25;

Perform a sterility test on each of the ten (10) samples;

If there are no more than one positive sterility test from the ten (10)

sterility tests, then accept the verification dose and substantiate the

25kGy;

If there are two (2) positive sterility tests out of the ten (10) sterility

tests, a conformity verification dose experiment should be performed;

and

If there are more than two (2) positive sterility tests, the verification

dose should not be accepted.

Substantiation of a Sterilization Dose Using AAMI Method VDMAX 15 for a

Single Production Batch includes the following steps:

a.

b.

c.

d.

e.

f.

g.

Determine the average indigenous bioburden of the API, drug product,

medical device, or non-product item using ten (10) randomly collected

samples;

Obtain the VDMAX 15 from the AAMI table using the average bioburden

and selected sterilization dose (see ANSI/AAMI/ISO 11137-2:2006);

Obtain ten (10) random samples and irradiate them at the VDMAX

obtained from the table;

Determine the dose applied to the samples;

Verify that the highest dose to the samples did not exceed the

verification dose by more than 0.1kGy or by more than ten (10)

percent, whichever is greater;

Verify that the arithmetic mean of the highest and lowest doses

delivered to the product is not less than ninety (90) percent of the

VDMAX 15;

Perform a sterility test on each of the ten (10) samples;

You might also like

- Val SteDocument16 pagesVal SteThaísa ScheuerNo ratings yet

- Guidelines For Validation Radiation SterilizationDocument2 pagesGuidelines For Validation Radiation SterilizationmarcosbrefeNo ratings yet

- Biocontamination Control for Pharmaceuticals and HealthcareFrom EverandBiocontamination Control for Pharmaceuticals and HealthcareRating: 5 out of 5 stars5/5 (1)

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersFrom EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNo ratings yet

- Good Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsFrom EverandGood Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsNo ratings yet

- ICH Quality Guidelines: An Implementation GuideFrom EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNo ratings yet

- Pharmaceutical Quality Management System (QMS) Questions and AnswersFrom EverandPharmaceutical Quality Management System (QMS) Questions and AnswersNo ratings yet

- Sterilization Validation QsiteDocument52 pagesSterilization Validation Qsiteskype2121No ratings yet

- Validation of Sterilization ProcessesDocument3 pagesValidation of Sterilization ProcessesNovitra DewiNo ratings yet

- Validation ProtocolDocument9 pagesValidation ProtocolVikram ChhabraNo ratings yet

- Ethylene+oxide+Gas+Sterilization 한신메디칼+ (호환+모드)Document30 pagesEthylene+oxide+Gas+Sterilization 한신메디칼+ (호환+모드)SACHIN KUMARNo ratings yet

- ETO Sterilization ValidationDocument44 pagesETO Sterilization ValidationCRYSTAL2100100% (1)

- Ethylene Oxide Sterilization Validation ProtocolDocument26 pagesEthylene Oxide Sterilization Validation ProtocolEmina Omeragić100% (5)

- EO Sterilization Product Adoption RationaleDocument18 pagesEO Sterilization Product Adoption RationaleJavier Cardona50% (2)

- Previews 1981650 PreDocument12 pagesPreviews 1981650 Prekhaled msalbiNo ratings yet

- Questions On EO Sterilization ValidationDocument2 pagesQuestions On EO Sterilization ValidationSACHIN KUMARNo ratings yet

- Biocompatibility in Eu MDRDocument11 pagesBiocompatibility in Eu MDRsachinNo ratings yet

- EO Annual Requalification ReviewDocument30 pagesEO Annual Requalification ReviewVenkatesh VenkateshNo ratings yet

- How To Validate An AutoclaveDocument3 pagesHow To Validate An AutoclaveqhpuongNo ratings yet

- Process Validation Protocol Packaging Validation (Performance Qualification) of Oii Axis Revision Knee SystemDocument16 pagesProcess Validation Protocol Packaging Validation (Performance Qualification) of Oii Axis Revision Knee SystemMJ SapiterNo ratings yet

- GMED Guide Biological Assessment MD ISO10993-1 Standard-4Document12 pagesGMED Guide Biological Assessment MD ISO10993-1 Standard-4almudena gomezNo ratings yet

- Sterilization Validation ReportDocument10 pagesSterilization Validation ReportCompliance DepartmentNo ratings yet

- Microbiological Test of Medical DevicesDocument5 pagesMicrobiological Test of Medical Devicesbijendra_sinhaNo ratings yet

- 12 Performance Qualification of EO Process Method CDocument4 pages12 Performance Qualification of EO Process Method CRakeshNo ratings yet

- Process Validation Sample Protocol - PharmaguidelineDocument3 pagesProcess Validation Sample Protocol - PharmaguidelineD Tech Dental Technologies100% (1)

- Compressed Air - 2 PDFDocument18 pagesCompressed Air - 2 PDFnuwaNo ratings yet

- Media Fills and Environment Atl Monitoring 26 July 2011 Presentation OneDocument18 pagesMedia Fills and Environment Atl Monitoring 26 July 2011 Presentation OneRiccardo TorelliNo ratings yet

- Sterilization Validation Report SampleDocument2 pagesSterilization Validation Report SampleHamidAliShahNo ratings yet

- MicroDocument3 pagesMicroPrince MoniNo ratings yet

- AG TCF 1 06. Biological Evaluation Report Non Absorbable Suture) 12 ClauseDocument5 pagesAG TCF 1 06. Biological Evaluation Report Non Absorbable Suture) 12 ClauseKarina GorisNo ratings yet

- Shelf Life of Medical DevicesDocument23 pagesShelf Life of Medical DevicesKarl Angelo MontanoNo ratings yet

- USP 1207 Guidance HerneticidadDocument44 pagesUSP 1207 Guidance HerneticidadEusebio Rodriguez BarraganNo ratings yet

- Guideline For Sterilization Process ValidationDocument21 pagesGuideline For Sterilization Process Validationboddarambabu100% (1)

- Validation Req. in CTD & ProcessDocument38 pagesValidation Req. in CTD & ProcessOula HatahetNo ratings yet

- Sealing Process Validation Guideline - enDocument14 pagesSealing Process Validation Guideline - enyadu100% (1)

- 30 Overview of An Eo ValidationDocument2 pages30 Overview of An Eo Validationskype2121100% (1)

- SOP For Handling of Market ComplaintDocument32 pagesSOP For Handling of Market Complaintsubbu_281No ratings yet

- Sterilization Process Validation ManualDocument10 pagesSterilization Process Validation ManualVenkata Rama50% (2)

- Thermal Validation Information Manual & GuideDocument10 pagesThermal Validation Information Manual & Guideviethuong96No ratings yet

- PDA Journal SeptemberDocument19 pagesPDA Journal SeptemberZia100% (2)

- General Chapters - 1222 - Terminally Sterilized Pharmaceutical Products-Parametric ReleaseDocument5 pagesGeneral Chapters - 1222 - Terminally Sterilized Pharmaceutical Products-Parametric ReleaseSuman Katteboina0% (1)

- ISO STANDARDS - Health Care TechnologyDocument9 pagesISO STANDARDS - Health Care TechnologyvesnaNo ratings yet

- AGALLOCO Aseptic-Processing-Validation PDFDocument13 pagesAGALLOCO Aseptic-Processing-Validation PDFJOHN CARO100% (1)

- 30 ML Moulded Vial Filling OQDocument15 pages30 ML Moulded Vial Filling OQSubhash NaiduNo ratings yet

- Attachment 4 - Technical Bulletin - Selection of EpcdDocument2 pagesAttachment 4 - Technical Bulletin - Selection of Epcdyagnaashi90920% (1)

- Sampling in Cleaning Validation in Pharmaceutical Industry - Pharmaceutical GuidelinesDocument2 pagesSampling in Cleaning Validation in Pharmaceutical Industry - Pharmaceutical GuidelinesASHOK KUMAR LENKANo ratings yet

- Risk Assessment in DispensingDocument6 pagesRisk Assessment in Dispensinghina babar aliNo ratings yet

- Pda Technical Report 48 Moist Heat Sterilizer SystemsDocument70 pagesPda Technical Report 48 Moist Heat Sterilizer SystemsDuc100% (2)

- Process Capability EngDocument11 pagesProcess Capability EngApoloTrevinoNo ratings yet

- Hold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104Document8 pagesHold Time Stability Studies in Pharmaceutical Industry Review 2167 7689.1000104iloveit52252No ratings yet

- Technical Tip: Product Adoption For Ethylene Oxide SterilizationDocument2 pagesTechnical Tip: Product Adoption For Ethylene Oxide SterilizationSyed Hassan Waqar Gilani100% (1)

- Oos GuidanceDocument48 pagesOos GuidanceAnjamSoodNo ratings yet

- Procedure For Media-Fill Simulation of Aseptic TechniqueDocument5 pagesProcedure For Media-Fill Simulation of Aseptic Techniquelimiyanto100% (1)

- Pdajpst 2015 01079Document21 pagesPdajpst 2015 01079ErikaNo ratings yet

- Temperature Mapping Study and Qualification - Vacker UAEDocument15 pagesTemperature Mapping Study and Qualification - Vacker UAEVacker Group UAE100% (3)

- Ich Stability Guidelines FinalDocument23 pagesIch Stability Guidelines FinalAjitha AzhakesanNo ratings yet

- Checklist of Validation of Dy Heat SterilizerDocument8 pagesChecklist of Validation of Dy Heat Sterilizersami2210No ratings yet

- Installation and Operation For Climate IncubatorDocument29 pagesInstallation and Operation For Climate IncubatorFilipa ChinêsNo ratings yet

- Best Practice Paper Visual Inspection Vs 3 2Document16 pagesBest Practice Paper Visual Inspection Vs 3 2Dimitris PlotasNo ratings yet

- Vibratory SifterDocument1 pageVibratory SifterananthNo ratings yet

- 2-O&c of Paam Af 90 TDocument6 pages2-O&c of Paam Af 90 Tananth100% (1)

- Certifying A Cleanroom To ISO 14644-1 Class 5Document3 pagesCertifying A Cleanroom To ISO 14644-1 Class 5Hassan HoudoudNo ratings yet

- 5-Operation & Cleaning of Ropp Sealing MachineDocument3 pages5-Operation & Cleaning of Ropp Sealing MachineananthNo ratings yet

- 43-O&C Strip Sealing MachineDocument6 pages43-O&C Strip Sealing MachineananthNo ratings yet

- FI MM SDintegration PDFDocument25 pagesFI MM SDintegration PDFGopa Kambagiri SwamyNo ratings yet

- 44-O&C Blister Packing MachineDocument7 pages44-O&C Blister Packing MachineananthNo ratings yet

- Sch. L1 Open LetterDocument4 pagesSch. L1 Open LetterananthNo ratings yet

- Ten Good Reasons To Learn Sas Software'S SQL Procedure: Sigurd W. Hermansen, Westat, Rockville, MDDocument5 pagesTen Good Reasons To Learn Sas Software'S SQL Procedure: Sigurd W. Hermansen, Westat, Rockville, MDashishkr3No ratings yet

- Pratibha779 782Document4 pagesPratibha779 782BANDI N BHARADWAJNo ratings yet

- 57-Online Rejection Note, Material ReturnDocument3 pages57-Online Rejection Note, Material Returnananth100% (1)

- CR013 SOP Statistical Analysis PlanDocument4 pagesCR013 SOP Statistical Analysis PlanananthNo ratings yet

- The NDAC (Gastroenterology & Hepatology) NewDocument4 pagesThe NDAC (Gastroenterology & Hepatology) NewananthNo ratings yet

- Tips For Preparing For AuditDocument24 pagesTips For Preparing For Auditananth100% (1)

- Licensing and Technology Transfer in The Pharmaceutical IndustryDocument32 pagesLicensing and Technology Transfer in The Pharmaceutical Industryvikram singh nitkNo ratings yet

- Licensing and Technology Transfer in The Pharmaceutical IndustryDocument32 pagesLicensing and Technology Transfer in The Pharmaceutical Industryvikram singh nitkNo ratings yet

- Laminar Air Flow - For WebsiteDocument2 pagesLaminar Air Flow - For WebsiteananthNo ratings yet

- Specs RlamfiltersDocument4 pagesSpecs RlamfiltersananthNo ratings yet

- 1.3 Capsules and Effective Encapsulation - Shaikh ChandDocument62 pages1.3 Capsules and Effective Encapsulation - Shaikh Chandananth50% (2)

- Heat SanitizationDocument2 pagesHeat SanitizationananthNo ratings yet

- RHLlowresDocument4 pagesRHLlowresananthNo ratings yet

- Sterilization or Depyrogenation Validation - Non ProductDocument2 pagesSterilization or Depyrogenation Validation - Non ProductananthNo ratings yet

- CD09 - Iversen - Jorgen - 20130927 - Interpretation of The Output From The OpenCDISC ValidatorDocument23 pagesCD09 - Iversen - Jorgen - 20130927 - Interpretation of The Output From The OpenCDISC ValidatorananthNo ratings yet

- Unplanned Cleanroom Power Outage Time Limit and Recovery Determinations For Aseptic Processing AreasDocument2 pagesUnplanned Cleanroom Power Outage Time Limit and Recovery Determinations For Aseptic Processing Areasananth100% (1)

- Repeal of The Enactment and Orders Hindi (15!11!2011)Document1 pageRepeal of The Enactment and Orders Hindi (15!11!2011)ananthNo ratings yet

- Presentation On Special Establishment Inspection by Sh. Venkateswaran VDocument21 pagesPresentation On Special Establishment Inspection by Sh. Venkateswaran VParikshit PrabhudesaiNo ratings yet

- Food Safety and Standards Rules 2011Document65 pagesFood Safety and Standards Rules 2011Anonymous EAineTizNo ratings yet

- Particle Monitoring Requirements in Pharmaceutical CleanroomsDocument7 pagesParticle Monitoring Requirements in Pharmaceutical CleanroomsananthNo ratings yet

- The Tanzania Food, Drugs and Cosmetics Act, 2003Document89 pagesThe Tanzania Food, Drugs and Cosmetics Act, 2003ananthNo ratings yet

- Snubbing PDFDocument134 pagesSnubbing PDFNavin SinghNo ratings yet

- Community Support For IYCF As of 22 SeptDocument57 pagesCommunity Support For IYCF As of 22 SeptMJ ArcillaNo ratings yet

- GSM Controlled RobotDocument33 pagesGSM Controlled RobotAbhishek KunalNo ratings yet

- Tan vs. CincoDocument2 pagesTan vs. CincoKing Badong67% (3)

- 3 Filtration Lecture NotesDocument16 pages3 Filtration Lecture NotesRuben SIbayanNo ratings yet

- Profile 5930 Series Dispersoil. Viscosity Reducer RSKDocument1 pageProfile 5930 Series Dispersoil. Viscosity Reducer RSKIwan SetiawanNo ratings yet

- 21S18052 - Joshua Partogi Hutauruk - Review BUSNOV - Umbrella - WarsDocument5 pages21S18052 - Joshua Partogi Hutauruk - Review BUSNOV - Umbrella - WarsJoshua HutaurukNo ratings yet

- Learning Dynamics and Vibrations by MSC AdamsDocument80 pagesLearning Dynamics and Vibrations by MSC AdamsFrancuzzo DaniliNo ratings yet

- Financial Ratio Analysis FormulasDocument4 pagesFinancial Ratio Analysis FormulasVaishali Jhaveri100% (1)

- Nishat ISDocument11 pagesNishat ISSaeed MahmoodNo ratings yet

- JPCC PDFDocument86 pagesJPCC PDFvenkatakrishna1nukalNo ratings yet

- CASE DIGEST: Teodoro Acap Vs CA, Edy Delos Reyes G.R. No. 118114 December 7, 1995 (251 SCRA 30) (Yellow Pad Digest)Document7 pagesCASE DIGEST: Teodoro Acap Vs CA, Edy Delos Reyes G.R. No. 118114 December 7, 1995 (251 SCRA 30) (Yellow Pad Digest)Laiza MayNo ratings yet

- Case Study 1 - Signal Cable CompanyDocument5 pagesCase Study 1 - Signal Cable CompanyTengku SuriaNo ratings yet

- Prime Time FeaturesDocument15 pagesPrime Time FeaturesPruthwish PatelNo ratings yet

- Wire Rope ExaminationDocument74 pagesWire Rope ExaminationAkhileshNo ratings yet

- Krishna Yadav Cell#+91-9540308010: BjectiveDocument6 pagesKrishna Yadav Cell#+91-9540308010: BjectiveIssac JohnNo ratings yet

- 12 C AdminstrationDocument2 pages12 C AdminstrationMuditNo ratings yet

- P12. & P.13 Faculty List With Designation, Qualification, Joining Date, Publication, Citation, R&D, Interaction DetailsDocument11 pagesP12. & P.13 Faculty List With Designation, Qualification, Joining Date, Publication, Citation, R&D, Interaction DetailsNeelamani SamalNo ratings yet

- Unified HACKTBDocument15 pagesUnified HACKTBKali PentesterNo ratings yet

- 100 Free Fonts PDFDocument61 pages100 Free Fonts PDFzackiNo ratings yet

- JSSG-2010-7 - Crash Systems Handbook PDFDocument155 pagesJSSG-2010-7 - Crash Systems Handbook PDFdaymonNo ratings yet

- 24 Antiseizure DrugsDocument71 pages24 Antiseizure DrugsThea MallariNo ratings yet

- PneumaxDocument2 pagesPneumaxandresNo ratings yet

- Operating Instruction PMD55Document218 pagesOperating Instruction PMD55Dilip ARNo ratings yet

- Guillang Vs Bedania and SilvaDocument2 pagesGuillang Vs Bedania and Silvajdg jdgNo ratings yet

- C&DS Lab Manual UpdatedDocument182 pagesC&DS Lab Manual UpdatedJesmin MostafaNo ratings yet

- Ahi Evran Sunum enDocument26 pagesAhi Evran Sunum endenizakbayNo ratings yet

- Profitability at BranchDocument21 pagesProfitability at Branchdabeernaqvi100% (1)

- UPDATED CV-Neeraj KR - Sharma-2021.Document5 pagesUPDATED CV-Neeraj KR - Sharma-2021.supriyaNo ratings yet