Professional Documents

Culture Documents

Harness LanyardInspectionReport

Uploaded by

Hamza ShehzadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Harness LanyardInspectionReport

Uploaded by

Hamza ShehzadCopyright:

Available Formats

INSPECTION AND MAINTENANCE CHECKLIST FOR FALL ARREST SYSTEMS

Warnings: Always read all instructions and warnings

contained on the product and packaging before using

any fall protection equipment.

CLEANING

Competent Person in the proper use of fall protection

equipment.

Basic care of all safety equipment will prolong the

durable life of the unit and will contribute toward the

performance of its vital safety function. Proper storage

and maintenance after use are as important as cleaning

the equipment of dirt, corrosives, or contaminants.

Storage areas should be clean, dry and free of exposure

to fumes or corrosive elements.

Regulations: Understand all Federal, State and Local

Nylon or PolyesterRemove all surface dirt with a

Inspection: All fall protection equipment should be

inspected prior to each use.

Training: All workers should be trained by a

Regulations pertaining to fall protection before selecting

and using the equipment.

System Only: Components that are fully compatible

with one another Components: should be used. Fall

arrest systems that are designed and tested as complete

systems should be used in this way.

sponge dampened in plain water. Squeeze the sponge

dry. Dip the sponge in a mild solution of water and

commercial soap or detergent. Work up a lather with a

vigorous back and forth motion; then wipe with a clean

cloth. Hang freely to dry, but away from excessive heat.

DryingEquipment should dry thoroughly without close

exposure to heat, steam, or long periods of sunlight.

AFTER A FALL OCCURS, ALL COMPONENTS OF THE FALL ARREST

SYSTEM SHOULD BE REMOVED FROM SERVICE AND DESTROYED

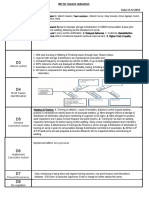

HARNESS INSPECTION (see diagram below)

1. WebbingGrasp the webbing with your hands 6

inches to 8 inches apart. Bend the webbing in an

inverted "U". The surface tension resulting makes

damaged fibers or cuts easier to detect. Follow this

procedure for the entire length of the webbing,

inspecting both sides of each strap. Look for frayed

edges, broken fibers, pulled stitches, cuts, burns,

and chemical damage

1

2. D-RingsCheck D-rings for distortion, cracks,

breaks, and rough or sharp edges. The D-ring

should pivot freely.

3. Attachment of BucklesInspect for any

unusual wear, frayed or cut fibers, or broken

stitching of the buckle or D-ring attachments.

4. Tongue/GrommetsThe tongue receives heavy

wear from repeated buckling and unbuckling.

Inspect for loose, distorted or broken grommets.

Webbing should not have additional holes punched.

5. Tongue BucklesBuckle tongues should be free

of distortion in shape and motion. They should

overlap the buckle frame and move freely back and

forth in their socket. Roller should turn freely on the

frame. Check for distortion or sharp edges.

6. Friction and Mating BucklesInspect the

buckle for distortion. The outer bars and center bars

must be straight. Pay special attention to corners

and attachment point at the center bar.

INSPECTION AND MAINTENANCE CHECKLIST FOR FALL ARREST SYSTEMS

LANYARD INSPECTION

When inspecting lanyards, begin at one end and work to the

opposite end, slowly rotating the lanyard so that the entire

circumference is checked.

Hook

1. Hardware

Latch

Snaps: Inspect

Lock

closely for hook and

eye distortions,

cracks, corrosion, or

pitted surfaces. The

Nose

keeper (latch) should

seat into the nose

Latch

without binding and

Eye

should not be

distorted or obstructed. The keeper spring should

exert sufficient force to firmly close the keeper.

Keeper locks must prevent the keeper from opening

when the keeper closes.

Thimbles(rope lanyard): The thimble must be

firmly seated in the eye of the splice, and the splice

should have no loose or cut strands. The edges of

the thimble must be free of sharp edges, distortion,

or cracks.

2. Web Lanyardwhile bending webbing over a

pipe, observe each

side of the webbed

lanyard. This will

reveal any cuts or

breaks. Swelling,

discoloration,

cracks

and

charring are obvious signs of

chemical or heat damage.

Observe closely for any breaks

in stitching.

3. Rope LanyardRotation of

the

rope

lanyard

while

inspecting from end-to-end for

any fuzzy, worn, broken or cut fibers. Weakened

areas from extreme loads will appear as a

noticeable change in original diameter. The rope

diameter should be uniform throughout, following a

short break-in period.

4. Shock Absorber PackThe outer portion of the

pack should be examined for burn holes and tears.

Stitching on areas where the pack is sewn to Drings. Belts, or lanyards should be examined for

loose strands, rips, and deterioration.

5. Shock-Absorbing LanyardShock-absorbing

lanyards should be examined as a web lanyard

(described in Item 3 above). However, also look

for the warning flag or signs of deployment. If the

flag has been activated, remove this shockabsorbing lanyard from service.

6. Self-Retracting Lanyard

Check Housing Before every use, inspect the units

housing for loose fasteners and bent, cracked,

distorted, worn, malfunctioning or damaged parts.

Retraction and Tension Test

the lifeline retraction and

tension by pulling out several

feet of the lifeline and allow it to

retract back into the unit.

Always maintain a light tension

on the lifeline as it retracts. The

lifeline should pull out freely

and retract all the way back into

the unit. Do not use the unit if

the lifeline does not retract.

Lifeline - The lifeline must be

checked regularly for signs of

damage. Inspect for cuts,

burns, corrosion, kinks, frays or

worn areas. Inspect any sewing (web lifelines) for

loose, broken or damaged stitching.

Braking Mechanism The braking mechanism must

be tested by grasping the lifeline above the impact

indicator and applying a sharp steady pull downward

which will engage the brakes. There should be no

slippage of the lifeline while the brakes are engaged,

once tension is released, the brakes will disengage

and the unit will return to the retractable mode. Do

not use the unit if the brakes do not engage.

INSPECTION AND MAINTENANCE CHECKLIST FOR FALL ARREST SYSTEMS

BODY HARNESS AND LANYARD INSPECTION REPORT

Inspector:

Date:

Month

JANUARY

FEBRUARY

MARCH

APRIL

MAY

JUNE

JULY

AUGUST

SEPTEMBER

OCTOBER

NOVEMBER

DECEMBER

Harness Serial

Number

Lanyard Serial

Number

Certification or Data Tag

Hook Safety Latch

Lanyard & Deceleration

Device

Rivets & Eyelets

All Stitching

1. All parts of the body harness and its attachments

must be inspected for wear and damage.

2. This symbol is for YES or OK.

This x symbol is for NO or REPLACE.

3. Inspect and document monthly

4. Maintain the completed inspection report so that

it is readily available for review.

Harness Webbing

and/or Leather

Instructions:

D-Ring(s) & Buckle(s)

if applicable

Plant:

You might also like

- 8689-2018 Sixco Chain SlingDocument2 pages8689-2018 Sixco Chain SlingAnonymous wuugFvOBjZNo ratings yet

- APLO - Crane InspectionDocument37 pagesAPLO - Crane Inspectionmou mouNo ratings yet

- GP Handling The WeaponDocument2 pagesGP Handling The WeaponBeder MirjanNo ratings yet

- Sn. Kim Ear 196 Chain Sling WLL 7.5 T Grade 80: Report of A Thorough Examination of Lifting EquipmentDocument1 pageSn. Kim Ear 196 Chain Sling WLL 7.5 T Grade 80: Report of A Thorough Examination of Lifting Equipmentoriza100% (1)

- Daily Forklift Inspection Form Tracks Equipment SafetyDocument1 pageDaily Forklift Inspection Form Tracks Equipment SafetyAjai BNo ratings yet

- OSHA Rigging Guidelines SummaryDocument11 pagesOSHA Rigging Guidelines SummaryRefibrian Dwiki LukidaNo ratings yet

- Catalogo 511Document4 pagesCatalogo 511Luis Oswaldo R PNo ratings yet

- Pallet-Racking System Test Report by SGS - Sahiwal Warehouse Hall CDocument11 pagesPallet-Racking System Test Report by SGS - Sahiwal Warehouse Hall CengsergiomarquesNo ratings yet

- Metallic Material Specification for 2.25 Cr-1 Mo Alloy with 85 KSI Yield StrengthDocument6 pagesMetallic Material Specification for 2.25 Cr-1 Mo Alloy with 85 KSI Yield StrengthReginaldo SantosNo ratings yet

- JD Manager-Machine ShopDocument2 pagesJD Manager-Machine ShopParveen (Atam Valves)No ratings yet

- Harness Inspection FormDocument1 pageHarness Inspection FormRajkumsr VNo ratings yet

- Standard Operating ProcedureDocument55 pagesStandard Operating Procedureboy tryadi100% (1)

- ES Audit Checkpoints 1Document12 pagesES Audit Checkpoints 1Anonymous j5apk2AumNo ratings yet

- Chain&AccessoriesDocument57 pagesChain&AccessoriesAnonymous YggO6T6GzNo ratings yet

- PT BMI Presentation 29.05.2017Document42 pagesPT BMI Presentation 29.05.2017Bayumi Tirta JayaNo ratings yet

- Trade Test Questions For WelderDocument2 pagesTrade Test Questions For WelderMd ishteyaque100% (1)

- Team Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitDocument1 pageTeam Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitRakesh KumarNo ratings yet

- Handling and Care of Pipes and ConnectionsDocument3 pagesHandling and Care of Pipes and ConnectionsMichael VelascoNo ratings yet

- Lifting Equipment ChecklistDocument4 pagesLifting Equipment ChecklistRuzaini MohamedNo ratings yet

- LEEA-016 Correspondence Course Prospectus 2012-13docDocument7 pagesLEEA-016 Correspondence Course Prospectus 2012-13docAjith KumarNo ratings yet

- Company Introduction - Shinwoo ValveDocument26 pagesCompany Introduction - Shinwoo ValveLe Cam NhanNo ratings yet

- Calibration Gas DatasheetDocument15 pagesCalibration Gas DatasheetMashur Al JunaibiNo ratings yet

- Sec.2-61 Sky Climbers & Suspended Power PlatformsDocument6 pagesSec.2-61 Sky Climbers & Suspended Power Platformsbravo2uniform2736No ratings yet

- EIAC RQ IB 001 - Rev. - 2Document14 pagesEIAC RQ IB 001 - Rev. - 2Kannan LakshmananNo ratings yet

- Body HarnessDocument1 pageBody HarnessXuân HòaNo ratings yet

- International Limited: Certificate of Visual Examination and MpiDocument8 pagesInternational Limited: Certificate of Visual Examination and MpiMichael OkwuwaNo ratings yet

- Year Wise Fund Requirement and Projected Financial Statements for Growth of Ookayama Ltd 2017-2021Document46 pagesYear Wise Fund Requirement and Projected Financial Statements for Growth of Ookayama Ltd 2017-2021monir_jokkyNo ratings yet

- Product Maintenance Information: KM SeriesDocument12 pagesProduct Maintenance Information: KM Seriesdzamir203No ratings yet

- Bench SawDocument4 pagesBench SawimranNo ratings yet

- RADIANT NDT SERVICES REPORT PROVIDES ULTRASONIC TESTING RESULTSDocument1 pageRADIANT NDT SERVICES REPORT PROVIDES ULTRASONIC TESTING RESULTSGoutam Kumar Deb100% (1)

- Draft Tech Proposal NTB UtmDocument20 pagesDraft Tech Proposal NTB Utmdudi hidayatNo ratings yet

- Hot Weather Heat Stress ProcedureDocument6 pagesHot Weather Heat Stress ProcedureJay-Jay JapsNo ratings yet

- DPT Report 02Document2 pagesDPT Report 02Amit Hasan100% (1)

- Alloy Chain Sling InspectionDocument2 pagesAlloy Chain Sling InspectionIky Pui Yee0% (1)

- Bash-P General CatalogueDocument123 pagesBash-P General CatalogueAri Rizki RivaldoNo ratings yet

- Adhesion Cross-Cut Test ExampleDocument2 pagesAdhesion Cross-Cut Test ExampleRaduNo ratings yet

- ILR Bearing Housing Assembly ProcedureDocument10 pagesILR Bearing Housing Assembly ProcedureAlejandroZegarraNo ratings yet

- Handle Parts Carefully & Zero Tolerance To Be Maintained As Regards To Nicks, Scratches & DentsDocument1 pageHandle Parts Carefully & Zero Tolerance To Be Maintained As Regards To Nicks, Scratches & DentsSAKTHIVEL ANo ratings yet

- Definition of Lifting EquipmentDocument4 pagesDefinition of Lifting Equipmentadriancovalciuc4863No ratings yet

- SOP - LatheDocument2 pagesSOP - LatheQuality PFPLNo ratings yet

- LEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories Non Fixed Load Lifting Attachments - Version 2 - Feb 2015Document17 pagesLEEA-059-4 Documentation and Marking - Part 4 Lifting Accessories Non Fixed Load Lifting Attachments - Version 2 - Feb 2015Ulviyye ElesgerovaNo ratings yet

- F - OPN - 05 R1 Assessment Form - Earthmoving EquipmentDocument1 pageF - OPN - 05 R1 Assessment Form - Earthmoving EquipmentJanaoo. comNo ratings yet

- Dial IndicatorDocument2 pagesDial IndicatorStudent ForeignNo ratings yet

- 14 Scaffolding-Training-PresentationDocument190 pages14 Scaffolding-Training-PresentationRobert EcleoNo ratings yet

- LCC DOCS-11568884-V1-HS-PRO-013 Working in On Over or Adjacent To WaterDocument13 pagesLCC DOCS-11568884-V1-HS-PRO-013 Working in On Over or Adjacent To WaterabogadieNo ratings yet

- Inspection Date: Period: Brand and Type of Tools & Equipments: Valid Until: Color Code Capacity: Inventory No.: Result (Hasil) Remark Good BadDocument1 pageInspection Date: Period: Brand and Type of Tools & Equipments: Valid Until: Color Code Capacity: Inventory No.: Result (Hasil) Remark Good BadilyasNo ratings yet

- HR RPP-40736 R1 - Freight Container Lifting StandardsDocument28 pagesHR RPP-40736 R1 - Freight Container Lifting StandardsMinh Nguyen VanNo ratings yet

- Management of Lifting Equipment - Part7Document1 pageManagement of Lifting Equipment - Part7WandaNo ratings yet

- Flipkart 2015Document4 pagesFlipkart 2015Raj DubeyNo ratings yet

- Aluminum Alloy Characteristics and Applications ChartDocument2 pagesAluminum Alloy Characteristics and Applications ChartManish MNo ratings yet

- Safe Use of Lifting Machines and Lifting TackleDocument59 pagesSafe Use of Lifting Machines and Lifting TackleJakesNo ratings yet

- Daily Component and Work Area Checklist: B1 B4 B5 B8 B7Document2 pagesDaily Component and Work Area Checklist: B1 B4 B5 B8 B7Lenaldy Nuari GarnokoNo ratings yet

- Ed Staff Meeting MinutesDocument3 pagesEd Staff Meeting Minutesapi-236445988No ratings yet

- EU-Type Exam Certificate for Dual Band RadioDocument3 pagesEU-Type Exam Certificate for Dual Band RadioanshadNo ratings yet

- Template Quality Assurance Inspection and Test PlanDocument2 pagesTemplate Quality Assurance Inspection and Test PlanSiva Naga Prasad TadipartiNo ratings yet

- Fall Protection Equipment ChecklistDocument2 pagesFall Protection Equipment ChecklistMubashir AbbasNo ratings yet

- Harness Insp. and Maint. Daily ChecklistDocument3 pagesHarness Insp. and Maint. Daily ChecklistSarojini VeeraraghavanNo ratings yet

- Harness (And Body Belt) Inspection: WebbingDocument3 pagesHarness (And Body Belt) Inspection: WebbingUlviyye ElesgerovaNo ratings yet

- Cleaning: Inspection and Maintenance Checklist For Fall Arrest SystemsDocument3 pagesCleaning: Inspection and Maintenance Checklist For Fall Arrest Systemsal mubarokNo ratings yet

- Harness LanyardInspectionReportDocument3 pagesHarness LanyardInspectionReportNarantsatsralt RavdandorjNo ratings yet

- Oil & Gas Safety Regulation 1974Document82 pagesOil & Gas Safety Regulation 1974Hamza Shehzad100% (3)

- Arc Flash Safety PDFDocument76 pagesArc Flash Safety PDFEdwin53No ratings yet

- Carbon-Tec Safety Data Sheet SummaryDocument4 pagesCarbon-Tec Safety Data Sheet SummaryHamza ShehzadNo ratings yet

- Oil Gas Industry GuidelinesDocument90 pagesOil Gas Industry GuidelinesAdhia Prenata Putra HuzaNo ratings yet

- Afg AtexDocument4 pagesAfg AtexHakim YahiaouiNo ratings yet

- 4 AWARE Struck by Caught BetweenDocument41 pages4 AWARE Struck by Caught BetweenHamza ShehzadNo ratings yet

- Control of WorkDocument51 pagesControl of WorkHamza ShehzadNo ratings yet

- Jez Hunter 19 Jul 05Document33 pagesJez Hunter 19 Jul 05Hamza ShehzadNo ratings yet

- 4 AWARE Struck by Caught BetweenDocument41 pages4 AWARE Struck by Caught BetweenHamza ShehzadNo ratings yet

- Dust After Falling of Rock Soil Happened On 11-06-2015 While Offloading Was in Progress. Fortunately All Personnel Remained SafeDocument3 pagesDust After Falling of Rock Soil Happened On 11-06-2015 While Offloading Was in Progress. Fortunately All Personnel Remained SafeHamza ShehzadNo ratings yet

- The Key To Hand Injury PreventionDocument24 pagesThe Key To Hand Injury PreventionHamza ShehzadNo ratings yet

- Confined Space TrainingDocument45 pagesConfined Space TrainingShogan05100% (1)

- Process Financial Transactions and Extract Interim Reports - 025735Document37 pagesProcess Financial Transactions and Extract Interim Reports - 025735l2557206No ratings yet

- Consensus Building e Progettazione Partecipata - Marianella SclaviDocument7 pagesConsensus Building e Progettazione Partecipata - Marianella SclaviWilma MassuccoNo ratings yet

- Lewis Corporation Case 6-2 - Group 5Document8 pagesLewis Corporation Case 6-2 - Group 5Om Prakash100% (1)

- Empanelment of Architect-Consultant - Work Costing More Than 200 Lacs. (Category-B)Document6 pagesEmpanelment of Architect-Consultant - Work Costing More Than 200 Lacs. (Category-B)HARSHITRAJ KOTIYANo ratings yet

- Aries Computer Repair SolutionsDocument9 pagesAries Computer Repair SolutionsedalzurcNo ratings yet

- SiloDocument7 pagesSiloMayr - GeroldingerNo ratings yet

- STS Prelim ExamDocument2 pagesSTS Prelim ExamMychie Lynne MayugaNo ratings yet

- CDI-AOS-CX 10.4 Switching Portfolio Launch - Lab V4.01Document152 pagesCDI-AOS-CX 10.4 Switching Portfolio Launch - Lab V4.01Gilles DellaccioNo ratings yet

- Indian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewDocument8 pagesIndian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewPRINCIPAL BHILWARANo ratings yet

- IELTS Speaking Q&ADocument17 pagesIELTS Speaking Q&ABDApp Star100% (1)

- Financial Analysis of Wipro LTDDocument101 pagesFinancial Analysis of Wipro LTDashwinchaudhary89% (18)

- Bengali (Code No - 005) COURSE Structure Class - Ix (2020 - 21Document11 pagesBengali (Code No - 005) COURSE Structure Class - Ix (2020 - 21Břîšťỹ ÃhmęđNo ratings yet

- Cell Organelles ColoringDocument2 pagesCell Organelles ColoringThomas Neace-FranklinNo ratings yet

- Precision Machine Components: NSK Linear Guides Ball Screws MonocarriersDocument564 pagesPrecision Machine Components: NSK Linear Guides Ball Screws MonocarriersDorian Cristian VatavuNo ratings yet

- There Is There Are Exercise 1Document3 pagesThere Is There Are Exercise 1Chindy AriestaNo ratings yet

- BenchmarkDocument4 pagesBenchmarkKiran KumarNo ratings yet

- Easa Management System Assessment ToolDocument40 pagesEasa Management System Assessment ToolAdam Tudor-danielNo ratings yet

- Philippine Population 2009Document6 pagesPhilippine Population 2009mahyoolNo ratings yet

- CFO TagsDocument95 pagesCFO Tagssatyagodfather0% (1)

- Desana Texts and ContextsDocument601 pagesDesana Texts and ContextsdavidizanagiNo ratings yet

- JM Guide To ATE Flier (c2020)Document2 pagesJM Guide To ATE Flier (c2020)Maged HegabNo ratings yet

- Fast Aldol-Tishchenko ReactionDocument5 pagesFast Aldol-Tishchenko ReactionRSLNo ratings yet

- Display PDFDocument6 pagesDisplay PDFoneoceannetwork3No ratings yet

- PeopleSoft Security TablesDocument8 pagesPeopleSoft Security TablesChhavibhasinNo ratings yet

- EA Linear RegressionDocument3 pagesEA Linear RegressionJosh RamosNo ratings yet

- Statistical Quality Control, 7th Edition by Douglas C. Montgomery. 1Document76 pagesStatistical Quality Control, 7th Edition by Douglas C. Montgomery. 1omerfaruk200141No ratings yet

- Bala Graha AfflictionDocument2 pagesBala Graha AfflictionNeeraj VermaNo ratings yet

- The Service Marketing Plan On " Expert Personalized Chef": Presented byDocument27 pagesThe Service Marketing Plan On " Expert Personalized Chef": Presented byA.S. ShuvoNo ratings yet

- GS16 Gas Valve: With On-Board DriverDocument4 pagesGS16 Gas Valve: With On-Board DriverProcurement PardisanNo ratings yet

- Beauty ProductDocument12 pagesBeauty ProductSrishti SoniNo ratings yet