Professional Documents

Culture Documents

Emulsions Microwave

Uploaded by

Joann HowardCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Emulsions Microwave

Uploaded by

Joann HowardCopyright:

Available Formats

World Academy of Science, Engineering and Technology

Vol:4 2010-02-27

Demulsification of Water-in-Oil Emulsions by

Microwave Heating Technology

Abdurahman H. Nour, Rosli M. Yunus, and Azhary. H. Nour

International Science Index Vol:4, No:2, 2010 waset.org/Publication/3899

AbstractThe mechanism of microwave heating is essentially

that of dielectric heating. After exposing the emulsion to the

microwave Electromagnetic (EM) field, molecular rotation and ionic

conduction due to the penetration of (EM) into the emulsion are

responsible for the internal heating. To determine the capability of

microwave technology in demulsification of crude oil emulsions,

microwave demulsification method was applied in a 50-50 % and 2080 % water-in-oil emulsions with microwave exposure time varied

from 20-180 sec. Transient temperature profiles of water-in-oil

emulsions inside a cylindrical container were measured. The

temperature rise at a given location was almost horizontal (linear).

The average rates of temperature increase of 50-50 % and 20-80 %

water-in-oil emulsions are 0.351 and 0.437 oC/sec, respectively. The

rate of temperature increase of emulsions decreased at higher

temperature due to decreasing dielectric loss of water. These results

indicate that microwave demulsification of water-in-oil emulsions

does not require chemical additions. Microwave has the potential to

be used as an alternative way in the demulsification process.

KeywordsDemulsification, temperature

Microwave heating, dielectric, volume rate.

profile,

emulsion.

I. INTRODUCTION

LECTROMAGNETIC radiation in the frequency range

300 MHz-300 GHz are known as microwaves, microwave

energy is a non-ionizing radiation that causes molecular

motion by migration of ions and dipole rotations, but does not

cause changes in molecular structure and wavelengths ranging

from a few cm to a few mm [2]. In the oil field, the two basic

types of emulsions are water-in-oil (w/o) and oil-in-water

(o/w). More than 95 % of the crude oil emulsion formed in the

oil field are of the w/o type [1]. The concept of microwave

heating of emulsions was first suggested by [5] and [14]. In

the past 20 years, Microwave (MW) energy has been widely

applied in food and chemical processing for heating, thawing

(melting), sintering of ceramics and many others [3] and [4].

Faster cooking times and energy savings over conventional

cooking methods are the primary benefits. Various oil-inwater (o/w) and water-in-oil (w/o) emulsions occur in

industrial operations, such as petroleum refining, oil and gas

production [4] and food processing industries. Efficient heating

of emulsions is required for a faster processing based on

industrial demand. Microwave heating, because of its

volumetric heating effects, offers a faster processing rate.

Authors are with Faculty of Chemical and Natural Resources Engineering,

University

Malaysia,

Pahang-UMP,

Malaysia

(e-mail:

nour2000_99@yahoo.com).

International Scholarly and Scientific Research & Innovation 4(2) 2010

In conventional thermal processing, energy is transferred to

the material through convection, conduction and radiation of

heat from the surfaces of the material. In contrast, microwave

energy is delivered directly to materials through molecular

interaction with the electromagnetic field. In heat transfer,

energy is transferred due to thermal gradients, but microwave

heating is the transfer of electromagnetic energy to thermal

energy and is energy conversion, rather than heat transfer [13].

This difference in the way energy is delivered can result in

many potential advantages to using microwaves for processing

of materials. Because microwaves can penetrate materials and

deposit energy, heat can be generated throughout the volume

of the material. The transfer of energy does not rely on

diffusion of heat from the surfaces and it is possible to achieve

rapid and uniform heating of thick materials.

In recent literature, many researchers report non-thermal

phenomena that have been broadly termed microwave

effects. Examples for microwave effect include enhanced

reaction rates of thermosetting resins during microwave curing

[10] and faster densification rates in ceramics sintering [11].

As materials are processed, they often undergo physical and

structural transformations that affect the dielectric properties.

Thus, the ability of microwaves to generate heat varies during

the process. Sharp transformations in the ability of

microwaves to generate heat can cause difficulties with

process modeling and control. Understanding the generation,

propagation and interaction of microwaves with materials is

critical. Because the processing equipment determines the

electromagnetic field, the design of microwave equipment is

particularly important. The properties of the electromagnetic

field, chemical composition of the material being processed,

structural changes that occur during processing, size and shape

of the object being heated and the physics of the

microwave/materials interactions all complicate microwave

processing.

II. MATERIAL AND METHODS

In this study, Elba domestic microwave oven model: EMO

808SS, its rated power output is 900 watts and its operation

frequency is 2450 MHz was used in heating water-in-oil

emulsion samples. A 900 mL graduated cylindrical glass was

used as sample container. The diameter and height of

emulsion sample in the container were 11.5 and 11 cm

respectively.

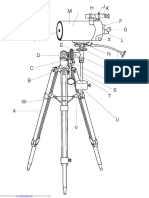

Three thermocouples type (K-IEC-584-3) were connected

to Pico-TC-08 data logging and then connected to microwave

oven as shown in Fig. 1. The data logger was connected to PC;

with PicoLog R5.08.3 software. The thermocouples were

inserted to different locations top, middle and bottom of the

emulsion sample to measure local temperatures.

144

scholar.waset.org/1999.0/3899

World Academy of Science, Engineering and Technology

Vol:4 2010-02-27

A. Sample Preparation and Procedures

The crude oil samples were obtained from Petronas refinery

at Malaka city, two types of crude oil were collected namely,

heavy oil and light crude oil. 50-50 and 20-80% water-in-oil

emulsions were prepared using the same volumes of oil and

water. Emulsions were prepared in 900 mL graduated beakers,

with ranges by volume of the water and oil phase.

flocculation takes place as water droplets approach each

other[2]. The purpose of heating water-in-oil emulsions with

microwave radiation is to separate water from oil. When

water-in-oil emulsion is heated with microwave radiation, two

phenomena will occur; the first one is the increase of

temperature, which causes reduction of viscosity and

coalescence. The result is separation of water without addition

of chemicals [6]. According to Stokes law, if oil is the

continuous phase, the settling velocity of water droplets is

given by:

w =

International Science Index Vol:4, No:2, 2010 waset.org/Publication/3899

Fig. 1 Elba microwave oven

The microwave radiation was set to its highest power

setting. The water phase is tab water. The emulsions were

agitated vigorously using a standard three blade propeller at

speed of 1600 rpm and temperature 28C for 7 min. The

concentrations of water in samples were 20-50% by volume.

The container of emulsion sample was placed in the center of

Elba domestic microwave oven model: EMO 808SS. Three

thermocouples were inserted in the emulsion sample at

different locations, top, middle and bottom. The emulsion

samples were heated with microwave radiation for 20, 40, 60,

80, 100, 120, 140, 160, 180 and 200 sec. Temperature profiles

of emulsions inside a cylindrical container during batch

microwave heating at 2450 MHz were recorded by Pico-TC08 data logging. The surfactant used in this study was the

commercially available Triton X-100: This Triton X-100 is a

non-ionic water soluble molecule. The emulsifying agent was

used as manufactured without further dilution. In order to

prepare water-in-oil emulsions, the agent-in-oil method was

followed; that is, in this study, the emulsifying agent (Triton

X-100) was dissolved in the continuous phase (oil), then water

was added gradually to the mixture. The volume of water

settled to the bottom was read from the scale on the beaker

with different times. The amount of water separation in

percent was calculated as separation efficiency (e) from

volume of water observed in the beaker as follows:

Percentage of water separation , e

=

(Vol. of water layer, mL)

100

(Original amount of water, mL)

(1)

The prepared emulsion was used to check for w/o or o/w

emulsions. All emulsions investigated were water-in-oil (w/o)

emulsion (oil-continuous).

B. Microwave Radiation

A number of studies were carried out on Microwave heating

(MW) of oil and water systems. Microwave heating because

of its volumetric heating effects, offers a faster processing

rate. The separation of emulsified water from crude oil has

several stages, due to gravity settling, water droplet/droplet

International Scholarly and Scientific Research & Innovation 4(2) 2010

(w o )gD 2

18 o

(2)

where, D is the diameter of the droplets. The viscosity of oil

very sensitive to temperature, as temperature increases,

viscosity decreases much faster than the density difference,

(w-o) does, the result when viscosity decreases, the droplets

size increases. Therefore, microwave heating increases the

velocity of water (vw) and accelerates the separation of

emulsion. The second phenomenon is coagulation. The higher

temperature and lower viscosity make the coagulation process

easier. The results are larger particle diameter D and rapid

separation.

C.

Microwave Power Generation

Using microwaves as a source of heat in the processing

(heating, melting, drying and thawing) of materials is one of

the advantageous because it results in faster, more uniform

heating than conventional heating does. This study, focus on

generation of microwaves in the oven, temperature

distribution, microwave power absorption as well as

separation of emulsified water from crude oil.

The variables affecting microwave power absorption by an

element are dielectric constant and dielectric loss, location and

microwave power incident at the load. For a sample in

cylinder container, the local microwave power flux calculated

as:

P =

0

453.2 + 59.8ln(m)

A

(3)

Where:

m = Mass (g) of the sample

A = Samples container area

The microwave power absorption density at any location

within the sample is one of the interesting terms, in this

regards, the electric field attenuates (decay) exponentially in x

and y directions within the sample due to dissipation as heat

and can be expressed as:

Pz = P0e2z

(4)

where, Pz is microwave power transmitted. The attenuation

factor can be calculated from the electromagnetic field theory

given by [15] as:

E =

145

2f 'r

c 2

1/ 2

1 + tan 2 1

scholar.waset.org/1999.0/3899

(5)

World Academy of Science, Engineering and Technology

Vol:4 2010-02-27

The above Eq. 5 will be used for calculation of volume rate of

heat generation by microwave radiation:

q MWz =

2 E

Pz

4.184

(6)

If the dielectric properties are assumed to be independent of

temperature at frequency 2450 MHz, the wavelength m and

penetration depth DP within a sample for a radiation of the

above frequency (2450 MHz) are related to dielectric constant

r and dielectric loss r as follows:

c

=

f

'

r

''

1 + 'r

r

2

+ 1

1/2

(7)

International Science Index Vol:4, No:2, 2010 waset.org/Publication/3899

and

Dp

' 1+

r

c

=

2 f

'' r

' 1

r

1/ 2

(8)

Since microwave heats materials volumetrically, it is possible

to calculate the volume rate of microwave heat generation

from energy balance equation as:

g MW =

4

hA

A ( Tm + 273.15 )

dT

+ C p

( Tm - Ta ) +

V

V - ( T + 273.15 )4

dt

(9)

The above Eq. 9 assumes that the rate of heat transfer from

emulsified water droplets to the continuous phase (oil) is very

rapid; therefore, water and oil practically have the same

temperature. The right hand side of Eq. 9 comprises of three

terms, convective heat transfer, radiative heat due to

microwave and conductive heat in the sample respectively.

From results of this study, the effect of radiative term is very

small as well as convective term. Since the sample container

(glass) has low dielectric constant, therefore, its heat generated

assumed to be negligible. For calculation of volume rate of

heat generation in Eq. 9, the density () and (Cp) of the

emulsions calculated from mixing rules as:

m = w + o (1 )

(10)

C pm = C p,w + C p,o (1 )

III. RESULTS AND DISCUSSION

The microwave heating process was examined for water, oil

and emulsion samples. Transient temperature profiles of

water-in-oil emulsions inside a cylindrical container during

batch microwave heating were measured. Three temperature

readings were placed at the top, middle and bottom of the

sample container. Figs. 2 and 3 shows transient temperature

distribution of 50-50 and 20-80% water-in-oil emulsions

respectively, for microwave irradiation time varies from 20,

40, 60, 80, 100, 120, 140, 160 and 180 sec. From the both Fig.

2 and 3 the temperature rise at a given location was almost

linear (horizontal). This indicated that water-in-oil emulsions

were heated uniformly by microwaves; this was expected

result since the dielectric loss of oil is small.

The temperature increasing rates of irradiated samples and

their volume rates of heat generation were shown in Table I

and 2 respectively. These samples comprise water, crude oil,

50-50 and 20-80% water-in-oil emulsions. The temperatures

of emulsions were obtained from the average values of three

location temperature readings. The rate of temperature

increase was calculated from temperature increase divided by

radiation time. The average rates of temperature increase of

50-50 and 20-80% water-in-oil emulsions are 0.351 and 0.437

C sec1, respectively. It observed that, the rates of temperature

were decreases at temperature increases: This was the

expected results since the dielectric loss of water is small.

The energy balance Eq. 9 used to calculate the volume rate

of heat generation: This Eq. 9 included three terms, convective

heat transfer, irradiative heat transfer due to microwave and

conduction heat transfer respectively. From calculations of

this study, the contributions of convective and irradiation

terms are very small. Since the sample container is a glass

cylinder (transparent to microwave and has very low dielectric

constant), its heat loss assumed to be zero. The volume rates

of microwave heat generation of water and crude oil

calculated from the temperature measurements and Eq. 9 are

shown in Table I, while for 50-50 and 20-80% water-in-oil

emulsions are shown in Table II.

(11)

The volume rate of microwave heat generation of the water

and crude oil calculated from temperature measurements and

Eq. 9 are shown in Table I while heat generation values for

emulsion samples shown in Table II.

Table I and II shows the raw experimental results of

microwave heating, while Table III and IV shown the

calculated values of volume rates of heat generation.

International Scholarly and Scientific Research & Innovation 4(2) 2010

146

scholar.waset.org/1999.0/3899

World Academy of Science, Engineering and Technology

Vol:4 2010-02-27

TABLE I

EXPERIMENTAL RESULTS OF MICROWAVE HEATING (WATER AND CRUDE

OIL)

Rate

of Volume rate of

Radiation

Temp.

time

increase

Temp.Incr

heat

sec

T, C

ease,dT/dt,

generation

to=25.6C

C/s

q MW ,cal/s.c

TABLE II

EXPERIMENTAL RESULTS OF MICROWAVE HEATING FOR EMULSIONS

Radiation

Temp.

Rate of

Volume rate of

time

Increase

t, sec

heat

T, C

Increase,

generation q MW ,

to=25.6C

dT/dt, C/s

cal/s.cm3

11.1

0.555

0.321

50-50%

m3

w/o

20

Water

International Science Index Vol:4, No:2, 2010 waset.org/Publication/3899

Temp.

20

8.4

0.42

0.419

40

14.8

0.370

0.214

40

14

0.35

0.349

60

23.8

0.397

0.229

60

18.4

0.307

0.306

80

26.6

0.333

0.192

100

34.5

0.345

0.199

120

37.1

0.309

0.179

140

40.2

0.287

0.166

80

22.9

0.286

0.285

100

26.5

0.265

0.264

120

30.0

0.250

0.250

160

46.7

0.292

0.169

49.1

0.273

0.158

20

15.9

0.795

0.460

40

19.5

0.488

0.282

60

29.8

0.497

0.287

140

33.7

0.241

0.241

180

160

39.1

0.244

0.244

20-80%

180

44.2

0.246

0.246

w/o

Oil

20

6.8

0.340

0.138

40

10.5

0.263

0.107

80

33.2

0.415

0.240

100

41.1

0.411

0.238

120

43.6

0.363

0.210

140

46.2

0.330

0.191

60

15.1

0.252

0.102

80

20.2

0.253

0.103

100

24.8

0.248

0.101

160

51.4

0.321

0.186

180

55.7

0.309

0.179

120

28.7

0.239

0.097

140

33.0

0.236

0.096

160

36.5

0.228

0.093

180

42.2

0.234

0.095

Fig. 2 Temperature distributions of 50-50% w/o emulsions

Fig. 3

International Scholarly and Scientific Research & Innovation 4(2) 2010

147

Temperature distributions of 20-80% w/o emulsions

scholar.waset.org/1999.0/3899

World Academy of Science, Engineering and Technology

Vol:4 2010-02-27

TABLE III

VOLUME RATES OF HEAT GENERATION OF WATER AND CRUDE OIL BY

MICROWAVE RADIATION

International Science Index Vol:4, No:2, 2010 waset.org/Publication/3899

Radiatio

n

Time

t, sec

Water

20

40

60

80

100

120

140

160

180

Oil

20

40

60

80

100

120

140

160

180

Temp.

increas

e

T,C

to=25.6

C

Rate

of

Temp.

Increa

se

dT/dt,

C/s

Vol.Rate of

heat

generation

3

qMW ,cal/s.cm

8.4

14

18.4

22.9

26.5

30

33.7

39.1

44.2

0.420

0.350

0.307

0.286

0.265

0.250

0.241

0.244

0.246

0.419

0.349

0.306

0.285

0.264

0.250

0.241

0.244

0.246

0.411

0.320

0.273

0.230

0.226

0.214

0.212

0.231

0.196

6.80

10.5

15.1

20.2

24.8

28.7

33.0

36.5

43.2

0.340

0.263

0.252

0.253

0.248

0.239

0.236

0.228

0.240

0.138

0.107

0.102

0.103

0.101

0.097

0.096

0.093

0.097

0.146

0.114

0.132

0.143

0.140

0.161

0.158

0.144

0.127

Experimental

Calculated

Values Values

In application of Eq. 9 for determination of volume rates of

heat generation, the emulsion density (m) and heat capacity

from Eq. 10 and 11 respectively. The

(Cp,m) calculated

calculated volume rates of heat generation of water and oil

from Eq. 3 through Eq. 11 were shown in Table III. While for

emulsions illustrated in Table IV. It observed that, for water

and emulsions, the experimental results greater than the

calculated, while for oil the reverse, the calculated results

greater than the experimental, this attributed due to shortage

of oil properties and used literature values.

Since the purpose of heating water-in-oil emulsions with

microwave is to separate water from oil [12], therefore, the

separation efficiency of 50-50 and 20-80% water-in-oil

emulsions calculated by using Eq. 1 were shown in Figs. 4

and 5 respectively. The same trend was reported by [8], [9]

and [7].

All experimental results showed that microwave radiation

is very effective in separation of water-in-oil emulsions.

TABLE IV

VOLUME RATES OF HEAT GENERATION OF EMULSIONS BY MICROWAVE

RADIATION

Radiatio

n

Time

t, sec

50-50%

w/o

20

40

60

80

100

120

140

160

180

20-80%

w/o

20

40

60

80

100

120

140

160

180

Fig. 4 Separation of water from 50-50% w/o emulsions

Temp

.

increa

se

T,C

to=25.

6C

Rate of

Temp.

Increase

dT/dt,

C/s

11.1

0.555

0.231

0.224

14.8

23.8

26.6

34.5

37.1

40.2

46.7

49.1

0.370

0.397

0.333

0.345

0.309

0.287

0.292

0.273

0.214

0.229

0.192

0.199

0.179

0.166

0.169

0.158

0.136

0.216

0.158

0.165

0.162

0.159

0.161

0.148

15.9

19.5

29.8

33.2

41.1

43.6

46.2

51.4

55.7

0.795

0.488

0.497

0.415

0.411

0.363

0.330

0.321

0.309

0.460

0.282

0.287

0.240

0.238

0.210

0.191

0.186

0.179

0.363

0.223

0.252

0.231

0.224

0.198

0.167

0.142

0.137

Fig. 5 Separation of water from 20-80% w/o emulsions

International Scholarly and Scientific Research & Innovation 4(2) 2010

148

scholar.waset.org/1999.0/3899

Vol. Rate

of heat

generation

3

q MW , cal/s.cm

Experimental

calculated

World Academy of Science, Engineering and Technology

Vol:4 2010-02-27

The wavelength (m) and penetration depth (Dp) were found

1.39 and 3.427 cm respectively. Fig. 8 shows the heating rate

of temperature increase for water, oil and emulsions versus

the radiation time.

IV. CONCLUSION

International Science Index Vol:4, No:2, 2010 waset.org/Publication/3899

Fig. 6 Rates of temperature increase for water and oil

The microwave heating process was examined for water,

oil and emulsion samples. Results of this study showed that,

microwave radiation is a dielectric heating technique with the

unique characteristics of fast, volumetric and effective heating

is feasible and has the potential to be used an alternative way

in the demulsification of water-in-oil emulsions.

From temperature distribution profiles of irradiated

emulsion, it appears water-in-oil emulsion has been heated

quickly and uniformly by microwaves rather than by

conventional heating. This new separation technology does

not require chemical addition. Furthermore, microwave

radiation appears to provide faster separation than the

conventional heating methods.

REFERENCES

[1]

Fig. 7 Rates of temperature increase for water and oil

[2]

[3]

[4]

[5]

[6]

[7]

Fig. 8 Rates of temperature increase for 50-50 and 20-80% w/o

[8]

[9]

[10]

[11]

[12]

Fig. 9 Heating rate vs. radiation time for water, oil and emulsions

[13]

[14]

Figs. 4 and 5 showed that, microwave radiation can raise

the temperature of emulsion, reduce the viscosity and

accelerate separation process as suggested by Eq. 2. The rates

of temperature increase were decrease at higher temperatures,

Fig. 6 shows the phenomenon for water and oil, while Fig. 7

shown the same phenomenon for 50-50 and 20-80% water-inoil emulsions respectively.

International Scholarly and Scientific Research & Innovation 4(2) 2010

[15]

149

Ali, M.F. and M.H. Alqam, 2000. The role of asphaltenes, resins and

other solids in the stabilization of Water-in-Oil Emulsions and its

effects on oil production in Saudi oil fields. Fuel,79:13091316.DOI:10.1016/S0016 2361(99)00268-9

Ayappa, K.G.; Chatterjee,A and Basak, T. (1998). Analysis of

Microwave Sintering of Ceramics. AIChEJ.

Ayappa, K.G.; Davis, H.T.; Davis, E.A.; and Gordon, J. (1992). Two

Dimensional Finite Element Analysis of Microwave Heating. AIChEJ.

Kim, Y.H. et al., 1996. Demulsification of water-in-crude oil emulsions.

Effects of film tension, elasticity, diffusivity and interfacial activity of

demulsifier individual components and their blends. Dispers. Sci.

Technol., 17: 33-53.

Klaila, W.J. 1983. Method and apparatus for controlling fluency of high

viscosity hydrocarbon fluids. U.S. Patent 4,067.683.

Fang, C.S., B.K.L. Chang, P.M.C. Lai and W.J. Klaila, 1988.

Microwave demulsification. Chem. Eng. Commun.,73:227-239.

Fang, C.S. and P.M.C. Lai, 1995. Microwave heating and separation of

water-in-oil emulsions. J. Microwave Power Electromagnet. Energ., 30:

46-57.

Fang, C.S.; Lai, P.M.C.; Chang, B.K.L.; Klaila, W.J. 1989. Oil recovery

and waste reduction by microwave radiation. Environ.Prog. 235-238.

Chan, C.C. and C.C. Yeong, 2002. Demulsification of water-in-oil

emulsions by microwave radiation. Sep.Sci.Technol.,37:3407-3420.

Marand, E.; Baker, HR.; and Graybeal, JD. (1992). Comparison of

reaction mechanisms of epoxy resins undergoing thermal and

microwave cure from insitu measurements of microwave dielectric

properties and infrared spectroscopy. Macromolecules. 25 :2242-2252.

Janney, MA.; and Kimery, HD. (1991). Diffusion-controlled processes

in microwave fired oxide ceramics. In : Snyder Jr. WB, Sutton WH,

Iskander MF, Johnson DL Editors. Microwave processing of materials

II, Materials research society proceedings, 189. pp.215-227

Tanmay, B. and K.G. Ayappa, 1997. Analysis of microwave thawing of

slabs with effective heat capacity method. J. Am. Inst. Chem.

Eng., 43: 1662-1674.

Thostenson, E.T.; and Chou, T.W. (1999). M icrowave processing:

Fundamentals and Applications. Composite, part A.30, 1055-1071.

Wolf, N.O., 1986. Use of microwave radiation in separating emulsions

and dispersions of hydrocarbons and water. US Patent, 4582629.

Hippel, A.R. 1954. Dielectric Materials and Applications. MIT Press.

Cambridge. MA.

scholar.waset.org/1999.0/3899

You might also like

- Microwave Dehydrator An Environmental Friendly Step Toward Improving Microwave Demulsification of Petroleum EmulsionsDocument14 pagesMicrowave Dehydrator An Environmental Friendly Step Toward Improving Microwave Demulsification of Petroleum EmulsionsesatjournalsNo ratings yet

- Kha Thir 2021Document8 pagesKha Thir 2021Monyet...No ratings yet

- Performance Testing of An Inline Electrocoalescer Device With Medium and Heavy CrudesDocument10 pagesPerformance Testing of An Inline Electrocoalescer Device With Medium and Heavy CrudesAlvaro Andres Blanco GomezNo ratings yet

- Electrorheological Materials and Potential Applications in TextilesDocument4 pagesElectrorheological Materials and Potential Applications in TextilesArt PlanteurNo ratings yet

- Castor OilDocument6 pagesCastor OilÖzlem YılmazNo ratings yet

- Utilization Possibilities of Palm Shell As A Source of Biomass Energy in Malaysia by Producing Bio-Oil in Pyrolysis ProcessDocument10 pagesUtilization Possibilities of Palm Shell As A Source of Biomass Energy in Malaysia by Producing Bio-Oil in Pyrolysis ProcessAtie AtirahNo ratings yet

- Chen 2007Document9 pagesChen 2007Arisya JulvianaNo ratings yet

- Comparation Glycerol Degradation by Microwave Heating and by Hydrothermal TreatmentDocument6 pagesComparation Glycerol Degradation by Microwave Heating and by Hydrothermal TreatmentzaedmohdNo ratings yet

- Abdul Rahman 2014Document13 pagesAbdul Rahman 2014Hassan ShahNo ratings yet

- Catalysts: Kinetic Study On Microwave-Assisted Oligomerization of 1-Decene Over A HY CatalystDocument18 pagesCatalysts: Kinetic Study On Microwave-Assisted Oligomerization of 1-Decene Over A HY CatalystSnunkhaem EcharojNo ratings yet

- Lin 2001Document8 pagesLin 2001Navid AhadiNo ratings yet

- EuroDrying'2013 Proceeding JSDocument10 pagesEuroDrying'2013 Proceeding JSWolfblood4No ratings yet

- Evaporation of Excess Alcohol in Biodiesel in A Microchannel Heat Exchanger With PeltierDocument9 pagesEvaporation of Excess Alcohol in Biodiesel in A Microchannel Heat Exchanger With PeltierAnonymous vqOhvhaoH2No ratings yet

- Spe 149779 Ms Gasbarri UcvDocument17 pagesSpe 149779 Ms Gasbarri Ucvraifelmb100% (1)

- Special Molecular Distillation Prototype To Characterization Petroleum ResidueDocument6 pagesSpecial Molecular Distillation Prototype To Characterization Petroleum ResidueSangetha ChelladoraiNo ratings yet

- Microwave (BMIM) CLDocument7 pagesMicrowave (BMIM) CLh297No ratings yet

- Microwave Synthesis of Wollastonite Powder From EggshellsDocument6 pagesMicrowave Synthesis of Wollastonite Powder From Eggshellscollin samuelNo ratings yet

- EOR. Termal MethodsDocument2 pagesEOR. Termal MethodsMukhtarov Pg100% (1)

- FR3 Further Studies of A Vegetable-Oil-FilledDocument8 pagesFR3 Further Studies of A Vegetable-Oil-FilledSebastián Díaz GálvezNo ratings yet

- Hamzah 2013Document17 pagesHamzah 2013Theo MartinezNo ratings yet

- Design and Control of A Methyl Acetate Process Using Carbonylation of Dimethyl EtherDocument18 pagesDesign and Control of A Methyl Acetate Process Using Carbonylation of Dimethyl Ethersheida shNo ratings yet

- Application of Electromagnetic Waves and Dielectric Nanoparticles In-With-Cover-Page-V2Document10 pagesApplication of Electromagnetic Waves and Dielectric Nanoparticles In-With-Cover-Page-V2ashish dutt sharmaNo ratings yet

- s11814 017 0002 8Document10 pagess11814 017 0002 8Augusto Antonio MenzelNo ratings yet

- Applied Thermal Engineering: Ibrahim S. Al-Mutaz, Irfan WazeerDocument10 pagesApplied Thermal Engineering: Ibrahim S. Al-Mutaz, Irfan WazeerizhharkamaluddinNo ratings yet

- Hydrogen Production Methods Efficiency Coupled To An Advanced High Temperature Acelerator Driven SystemDocument21 pagesHydrogen Production Methods Efficiency Coupled To An Advanced High Temperature Acelerator Driven SystemMarvin kakindaNo ratings yet

- Kerone (An Iso 9001: 2008 Certified Company)Document36 pagesKerone (An Iso 9001: 2008 Certified Company)aashishNo ratings yet

- Experimental Ocean Thermal Energy Conversion (OTEC) Project On The Reunion IslandDocument8 pagesExperimental Ocean Thermal Energy Conversion (OTEC) Project On The Reunion IslandtrishanuNo ratings yet

- A Novel Enhanced-Multi Effect Thermal Separation Technology (E-Mets) For DesalinationDocument15 pagesA Novel Enhanced-Multi Effect Thermal Separation Technology (E-Mets) For DesalinationassurendranNo ratings yet

- Ceramic Processing Research: Natt Makul and Dinesh AgrawalDocument4 pagesCeramic Processing Research: Natt Makul and Dinesh AgrawalShivaram RamNo ratings yet

- Estimación de La Entalpía de Reacción de Cerámicos PDFDocument12 pagesEstimación de La Entalpía de Reacción de Cerámicos PDFBRYAN ANDRADENo ratings yet

- Seminar ThesisDocument28 pagesSeminar ThesismadhuNo ratings yet

- Membrane DistillationDocument14 pagesMembrane DistillationMuhammad Ali100% (1)

- Microwave Treatment in Oil Refining PDFDocument8 pagesMicrowave Treatment in Oil Refining PDFRonikaGoswamiNo ratings yet

- Hidratación de Oxido de Etileno Cinética PDFDocument5 pagesHidratación de Oxido de Etileno Cinética PDFangieNo ratings yet

- Modeling Steam Distillation of Essential OilDocument9 pagesModeling Steam Distillation of Essential OilThomas Yoga AlfanioNo ratings yet

- Transesterification of Mafura Oil To Biodiesel Using 10ni 10W/Al-MCM-41 Bimetallic Catalyst and Analysis of Engine Characteristics On VCR EngineDocument8 pagesTransesterification of Mafura Oil To Biodiesel Using 10ni 10W/Al-MCM-41 Bimetallic Catalyst and Analysis of Engine Characteristics On VCR EngineSekarNo ratings yet

- Technical Paper PresentationDocument27 pagesTechnical Paper PresentationBhagyashree BachhavNo ratings yet

- Basic Guidelines For Microwave Reactor and ReactionsDocument43 pagesBasic Guidelines For Microwave Reactor and ReactionsDrSoumitra SoniNo ratings yet

- Microwave Drying 2010Document7 pagesMicrowave Drying 2010Griet Van VaerenberghNo ratings yet

- A Study On Palm Oil-Based Oil Moisture Absorption Level and Voltage Breakdown PDFDocument4 pagesA Study On Palm Oil-Based Oil Moisture Absorption Level and Voltage Breakdown PDFvvingtsabtaNo ratings yet

- Hidrogel Biocat2Document22 pagesHidrogel Biocat2carolasbdNo ratings yet

- 1 s2.0 S1876610214000654 MainDocument10 pages1 s2.0 S1876610214000654 Maincpgcha57No ratings yet

- Al QaraghulivfgDocument9 pagesAl Qaraghulivfgoverdose500No ratings yet

- Cell Failure Mechanisms in PEM Water ElectrolyzersDocument10 pagesCell Failure Mechanisms in PEM Water ElectrolyzersAravind KandaswamiNo ratings yet

- Mitigation and Remediation Technologies of Waxy Crude OilsDocument35 pagesMitigation and Remediation Technologies of Waxy Crude OilsChandran UdumbasseriNo ratings yet

- Impact of Oils Degradation On The Cooling Capacity of Power TransformersDocument5 pagesImpact of Oils Degradation On The Cooling Capacity of Power TransformersJosé SánchezNo ratings yet

- Esterification and Transesterification Assisted by Microwaves of Crude Palm Oil. Homogeneous CatalysisDocument6 pagesEsterification and Transesterification Assisted by Microwaves of Crude Palm Oil. Homogeneous CatalysisMáximo Décimo MeridioNo ratings yet

- Estermineralbased PDFDocument4 pagesEstermineralbased PDFCRISTIAN CAMILO MORALES SOLISNo ratings yet

- Electro CoalescenciaDocument7 pagesElectro CoalescenciaiqubaldoNo ratings yet

- Electromagnetic HeatingDocument8 pagesElectromagnetic HeatingflausenNo ratings yet

- The Potential of Microwaves in The Manufacture of Biodesel by Using Cpo (Crude Palm Oil)Document9 pagesThe Potential of Microwaves in The Manufacture of Biodesel by Using Cpo (Crude Palm Oil)Sandhy YunsariNo ratings yet

- Continuous Electrostatic Dehydrator 에 의한 Water-in -Crude oil Emulsions 의 DemulsificationDocument5 pagesContinuous Electrostatic Dehydrator 에 의한 Water-in -Crude oil Emulsions 의 DemulsificationYoga WiranotoNo ratings yet

- Sani 2009Document3 pagesSani 2009Ravi PrakashNo ratings yet

- Industrial Training ReportDocument22 pagesIndustrial Training ReportEja RotiKeju100% (1)

- Model Predictive Controller Design of Hydrocracker ReactorsDocument9 pagesModel Predictive Controller Design of Hydrocracker ReactorsM Ahmed LatifNo ratings yet

- Pyrolysis Using Microwave Heating: A Sustainable Process For Recycling Used Car Engine OilDocument7 pagesPyrolysis Using Microwave Heating: A Sustainable Process For Recycling Used Car Engine OilSalman Raza NaqviNo ratings yet

- Production of Clean Hydrogen by Electrochemical Reforming of Oxygenated Organic CompoundsFrom EverandProduction of Clean Hydrogen by Electrochemical Reforming of Oxygenated Organic CompoundsNo ratings yet

- Biofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationFrom EverandBiofilms in Bioelectrochemical Systems: From Laboratory Practice to Data InterpretationNo ratings yet

- Flashback Mechanisms in Lean Premixed Gas Turbine CombustionFrom EverandFlashback Mechanisms in Lean Premixed Gas Turbine CombustionNo ratings yet

- Biohydrogen III: Renewable Energy System by Biological Solar Energy ConversionFrom EverandBiohydrogen III: Renewable Energy System by Biological Solar Energy ConversionNo ratings yet

- Mechanical Systems Evaluation - RFPDocument13 pagesMechanical Systems Evaluation - RFPJoann HowardNo ratings yet

- Full 2884Document8 pagesFull 2884Joann HowardNo ratings yet

- HSE Paper Ver Submission2Document9 pagesHSE Paper Ver Submission2Joann HowardNo ratings yet

- 96 IMechE RelAss TRMJDADocument14 pages96 IMechE RelAss TRMJDAJoann HowardNo ratings yet

- LP111Document2 pagesLP111Joann HowardNo ratings yet

- Friction ReducersDocument6 pagesFriction ReducersJoann HowardNo ratings yet

- E. G. Phillips, M.A., M.Sc. - Functions of A Complex Variable With Applications (Eighth Edition, 1961) (1963)Document160 pagesE. G. Phillips, M.A., M.Sc. - Functions of A Complex Variable With Applications (Eighth Edition, 1961) (1963)Joann HowardNo ratings yet

- Using Microbubbles To Improve Transmission Oil in PipesDocument4 pagesUsing Microbubbles To Improve Transmission Oil in PipesJoann HowardNo ratings yet

- Boehler AcconstDocument7 pagesBoehler AcconstJoann HowardNo ratings yet

- Contact With Friction Contact With FrictionDocument34 pagesContact With Friction Contact With FrictionJoann HowardNo ratings yet

- Downloaded From Manuals Search EngineDocument19 pagesDownloaded From Manuals Search EngineJoann HowardNo ratings yet

- Aceleración de Coriolis en TurbomaquinariaDocument18 pagesAceleración de Coriolis en TurbomaquinariaJoann HowardNo ratings yet

- Physics From Symmetry: Jakob SchwichtenbergDocument294 pagesPhysics From Symmetry: Jakob SchwichtenbergJoann HowardNo ratings yet

- Sharp Plasmacluster Air Purifier IG-BC2UDocument48 pagesSharp Plasmacluster Air Purifier IG-BC2UJoann HowardNo ratings yet

- Water System Tank: Owner's ManualDocument24 pagesWater System Tank: Owner's ManualJoann HowardNo ratings yet

- HH 175: A Giant HH Flow Emanating From A Multiple Protostar: Bo Reipurth and Per FribergDocument12 pagesHH 175: A Giant HH Flow Emanating From A Multiple Protostar: Bo Reipurth and Per FribergJoann HowardNo ratings yet

- Magnetobydrodynamic Equilibrium and Stability of StellaratorsDocument202 pagesMagnetobydrodynamic Equilibrium and Stability of StellaratorsJoann HowardNo ratings yet

- Vacuum Drying MethodsDocument28 pagesVacuum Drying MethodsJoann HowardNo ratings yet

- Skin Friction Drag Reduction Within Turbulent FlowsDocument289 pagesSkin Friction Drag Reduction Within Turbulent FlowsJoann HowardNo ratings yet

- MDB Lesson 8 Helical SpringsDocument10 pagesMDB Lesson 8 Helical Springspoliman2017No ratings yet

- Survey of Temperature Sensors Used in Various Thermal SystemsDocument3 pagesSurvey of Temperature Sensors Used in Various Thermal SystemsRavi PatilNo ratings yet

- Sae j419 1983 Methods of Measuring Decarburization PDFDocument8 pagesSae j419 1983 Methods of Measuring Decarburization PDFSumeet SainiNo ratings yet

- Tds Calde Cast LW 121 CGDocument1 pageTds Calde Cast LW 121 CGAfronie Cepoz D'nextNo ratings yet

- Elastic Properties of Materials: GoalsDocument12 pagesElastic Properties of Materials: GoalsKris OiraNo ratings yet

- Calcul HigrotermicDocument21 pagesCalcul HigrotermicVlad SpataruNo ratings yet

- d = 4 l F π E ∆lDocument6 pagesd = 4 l F π E ∆lNurmasturinaNo ratings yet

- Nitinol: by Keshav Jasoriya BARCH/10028/18Document6 pagesNitinol: by Keshav Jasoriya BARCH/10028/18Keshav JasoriyaNo ratings yet

- PHT Problems PDFDocument196 pagesPHT Problems PDFRakesh PatnaikNo ratings yet

- Graduation ProjectDocument18 pagesGraduation Projectmohamed moradNo ratings yet

- Acetone, ComsolDocument8 pagesAcetone, ComsolIñ SafNo ratings yet

- Hetro JunctionDocument30 pagesHetro JunctionKamalesh DebnathNo ratings yet

- Analysis of Mechanical Properties of Mild Steel Applying Various Heat TreatmentDocument4 pagesAnalysis of Mechanical Properties of Mild Steel Applying Various Heat Treatmentফিনাইলআইসোসায়ানাইডNo ratings yet

- Electrostatis Worksheet McqsDocument23 pagesElectrostatis Worksheet Mcqsns857471No ratings yet

- IJRASETDocument7 pagesIJRASETCharlosNo ratings yet

- CE009 Midterm 1 Introduction To StrainDocument57 pagesCE009 Midterm 1 Introduction To StrainJAMES TRIXIAN PARAJASNo ratings yet

- Water Properties Lab ReportDocument2 pagesWater Properties Lab Reportapi-454228134100% (2)

- Study of Cracks in Buildings: January 2009Document15 pagesStudy of Cracks in Buildings: January 2009sharathr22No ratings yet

- Answer PHYSIC STPM Trial Sem 1 2013Document6 pagesAnswer PHYSIC STPM Trial Sem 1 2013Zuraini ArshadNo ratings yet

- Duratherm: Application EnvironmentalDocument4 pagesDuratherm: Application EnvironmentalMalek MahmoudNo ratings yet

- Final Exam 259 Answer KeyDocument20 pagesFinal Exam 259 Answer KeyYasmeenNo ratings yet

- DymanicsDocument5 pagesDymanicsYongjin JiangNo ratings yet

- Paper 6Document14 pagesPaper 6UmaibalanNo ratings yet

- Module 6 Drawing-Lecture 1 PDFDocument8 pagesModule 6 Drawing-Lecture 1 PDFDevlina GaharwarNo ratings yet

- FM and SM Lab ManualDocument87 pagesFM and SM Lab ManualGeorge OliverNo ratings yet

- HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudDocument16 pagesHKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH Ekud HKKJRH EkudOMEGA CONSULTANT SERVICESNo ratings yet

- Bolted Connections: Institute For Steel Development & GrowthDocument75 pagesBolted Connections: Institute For Steel Development & Growthnupur50% (2)

- A Simple Method For The Syntheses of Nanomaterials: ElectrodepositionDocument10 pagesA Simple Method For The Syntheses of Nanomaterials: ElectrodepositionMouna KallelNo ratings yet

- 名 称(Title) 2016-N D0031Document25 pages名 称(Title) 2016-N D0031jenwitbunjongsatNo ratings yet

- Esfueros Insitu Colombia SPE 81074 FDocument13 pagesEsfueros Insitu Colombia SPE 81074 Fsantiago ruedaNo ratings yet