Professional Documents

Culture Documents

Braxton Manufacturing

Uploaded by

Mujjo Sahb0 ratings0% found this document useful (0 votes)

63 views5 pagesBraxton-Manufacturing

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBraxton-Manufacturing

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

63 views5 pagesBraxton Manufacturing

Uploaded by

Mujjo SahbBraxton-Manufacturing

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Compared to screw machines, plastic extrusions, tubing and stampings,

Braxtons deep-drawing techniques offer many benefits:

Starting with flat stock and ending with a tubular part, this process minimizes

material waste.

Superior part-to-part and batch-to-batch repeatability are assured.

Slitting, flaring and hole punching, normally considered secondary operations,

can be performed on the drawing machine.

Intricate designs not previously possible can be produced.

Raw material is work hardened during the drawing process, therefore eliminating

the need for secondary heat treating on most finished parts.

Starting stock can be clad or pre-plated with gold prior to the deep-draw process,

guaranteeing even coverage of gold on both the OD & ID of microminiature tubes

with or without a closed end as small as 0.005" (0.13mm) ID. This process also

eliminates the threat of residual acid trapped in the parts, a type of contamination

that is commonly found in the barrel plating process.

Braxton is experienced in drawing a

comprehensive range of conventional and

special materials, including:

Aluminum

Beryllium Copper

Brass

Bronze

Copper

Gilding

Glass Sealing

Alloys 42, 52

and Ni/Fe48

Gold

Inconel

Invar

Kovar

Monel

Nichrome

Nickel

Nickel Silver

Phosphor Bronze

Plated Stock

Platinum

Platinum

Iridium

Platinum

Rhodium

Silver

Stainless Steel

Titanium

Slotting

Multiple

Diameters

Tabs

Shaped

Flanges

Knurling

Shaped

Piercing

Bead

Diameters

Tapers

Side

Holes

Critical Dimensions and Tolerances

We can deep-draw parts to 0.006" (0.15mm) OD, with wall thicknesses as low

as 0.0005" (0.013mm). Maximum length is 2" (50.8mm), and length-todiameter ratios greater than 55:1 are attainable. Finished part tolerances are

as low as 0.00015" (0.004mm), with surface finishes to 10 microinches rms.

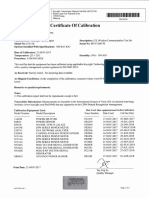

Braxton Manufacturing is ISO 9001:2000

certified. Quality is an essential part of our

manufacturing operation.

In addition to building our own drawing machines

and maintaining in-house die making facilities,

Braxton takes many other steps to ensure the

superior quality of our deep-drawn parts. The

members of our Quality Assurance staff have an

average of over 20 years of experience and are

highly trained in the technical aspects of

inspection and testing. Our precision inspection

equipment assists us in the measurement of all

dimensional requirements and enables us to work

to extremely tight tolerances. All inspection

equipment is regularly calibrated and traceable to

the National Institute of Standards and

Technology. An up-to-date statistical data

collection system, used to monitor and maintain

control of critical characteristics, also assists in

our problem-solving techniques.

Crimp

Forming

Like artistic drawing, superior deep drawing

takes talent and the right tools. Braxton

Manufacturing has both. Our skilled employees

take pride in creating parts that meet the

highest industry standards for precision. We

are able to maintain such exacting standards

because our proprietary drawing machines are

designed and built in-house, and have been for

more than 40 years. Coupled with our

advanced in-house carbide die making

facilities, our drawing machines enable us to

produce parts in more sizes, and with

significantly superior tolerances and finishes, in

comparison to competing products. With up to

25 independent tooling stations available on a

single machine, we can add features such as

holes, slots and flares, without secondary

operations. This not only reduces the costs of

additional handling, but also makes possible

intricate designs not previously practical.

Our CNC department has expanded to meet

the needs of our tool room and machine

building department. Use of the most advanced

equipment in multi-function CNC machining

technology allows us to manufacture and

supply the machine building department with

the precision components required to assemble

the complete drawing machine. Once the

components are fabricated, our experienced

machine builders can complete the assembly

process and have a new production machine

on line in as few as 2 or 3 weeks.

Braxton Manufacturing was founded

in 1964 in central Connecticut,

internationally known as a center of

precision tool and die making with a

highly skilled work force. In 1972, a

second manufacturing facility was

opened in southern California to

supply deep-drawn components to

our growing west coast customer

base. Today, the 60,000-square-foot

Watertown, Connecticut facility and

the 30,000-square-foot Tustin,

California facility are modern, state-ofthe-art production plants that provide

identical engineering and production

capabilities on both coasts. We

currently meet the demanding

requirements of customers in a wide

range of industries, including medical,

communications, aerospace, specialty

automotive and electronics.

Connecticut Facility

Braxton's engineering department and

proprietary drawing machines

consistently meet the unique size,

tolerance and finish requirements of

the most challenging applications. If

you have critical parts requirements,

contact Braxton today to learn how our

precision deep drawing process can

provide you with enhanced production

efficiencies and cost savings over

traditional manufacturing methods.

California Facility

Braxton Manufacturing Co., Inc.

858 Echo Lake Road P.O. Box 429 Watertown, CT 06795

Tel: 860-274-6781 Fax: 860-274-9195

Braxton Manufacturing Co. of California, Inc.

2641 Walnut Avenue P.O. Box 425 Tustin, CA 92780

Tel: 714-508-3570 Fax: 714-508-3571

Email: sales@braxtonmfg.com

ISO 9001: 2000

CERTIFIED

www.braxtonmfg.com

Braxton Manufacturing Co., Inc. 2007 2-07-2.5M

You might also like

- Quran Manzil With Urdu TarjumaDocument20 pagesQuran Manzil With Urdu Tarjumahumayun ikramNo ratings yet

- INDUS Univ B.Tech(E) Refrigeration & Air Conditioning Lab Manual Fall 2018Document2 pagesINDUS Univ B.Tech(E) Refrigeration & Air Conditioning Lab Manual Fall 2018Mujjo SahbNo ratings yet

- CX-9500 Pro-Optical Emission Spectrometer__Technical LiteratureDocument7 pagesCX-9500 Pro-Optical Emission Spectrometer__Technical LiteratureMujjo SahbNo ratings yet

- Hajj Ka TareeqaDocument3 pagesHajj Ka TareeqaMujjo SahbNo ratings yet

- Building Power Distribution (3!6!08)Document8 pagesBuilding Power Distribution (3!6!08)renyrjnNo ratings yet

- Prototyping Workshop EquipmentDocument1 pagePrototyping Workshop EquipmentMujjo SahbNo ratings yet

- Electrical Design Guide for GreenhousesDocument8 pagesElectrical Design Guide for GreenhousesarefalsabreeNo ratings yet

- HVAC Practical Journal PDFDocument43 pagesHVAC Practical Journal PDFMujjo SahbNo ratings yet

- Bed Design NyDocument42 pagesBed Design NyMujjo Sahb100% (1)

- Precast Post-Tensioned Segmental Pole System PatentDocument11 pagesPrecast Post-Tensioned Segmental Pole System PatentMujjo SahbNo ratings yet

- Creo 3 F000 ReadmeDocument8 pagesCreo 3 F000 Readmesonu thigleNo ratings yet

- HVAC Practical Journal PDFDocument43 pagesHVAC Practical Journal PDFMujjo SahbNo ratings yet

- Technical data on carbide end mills and drillsDocument1 pageTechnical data on carbide end mills and drillsenricoNo ratings yet

- SMEDA Intensive Goat Breeding FarmDocument44 pagesSMEDA Intensive Goat Breeding FarmSuhail Shaikh100% (8)

- International Solar Alliance Forum at Intersolar Europe 2018Document4 pagesInternational Solar Alliance Forum at Intersolar Europe 2018Mujjo SahbNo ratings yet

- Technical data on carbide end mills and drillsDocument1 pageTechnical data on carbide end mills and drillsenricoNo ratings yet

- Improving Comfort and Efficiency in Professional KitchensDocument8 pagesImproving Comfort and Efficiency in Professional KitchensMujjo SahbNo ratings yet

- HVAC Practical Journal PDFDocument43 pagesHVAC Practical Journal PDFMujjo SahbNo ratings yet

- PTI's Naya Pakistan Housing Project to Provide Affordable HomesDocument8 pagesPTI's Naya Pakistan Housing Project to Provide Affordable HomesMujjo SahbNo ratings yet

- Learn To Build Your Own Solar Panels Even With No ExperienceDocument24 pagesLearn To Build Your Own Solar Panels Even With No ExperienceMujjo SahbNo ratings yet

- 15 Cutting Tool Materials of Common UseDocument9 pages15 Cutting Tool Materials of Common UsePRASAD326100% (4)

- Bottled Natural Mineral WaterDocument8 pagesBottled Natural Mineral WaterMujjo SahbNo ratings yet

- The Wetter Water ReportDocument8 pagesThe Wetter Water Report5wishesNo ratings yet

- Comparative Assessment of Pak National Drinking Water Quality StandardsDocument15 pagesComparative Assessment of Pak National Drinking Water Quality StandardsMujjo SahbNo ratings yet

- Certification Services Pakistan (PVT) LTDDocument2 pagesCertification Services Pakistan (PVT) LTDMujjo SahbNo ratings yet

- Detailed connection design rules for cellular beamsDocument9 pagesDetailed connection design rules for cellular beamsMujjo SahbNo ratings yet

- Chapter100 - Administration and Design ContractsDocument19 pagesChapter100 - Administration and Design ContractsMujjo SahbNo ratings yet

- AVT ProfileDocument22 pagesAVT ProfileMujjo SahbNo ratings yet

- Green Building Technology and Sustainable Construction in Austria vs. The U.S.ADocument25 pagesGreen Building Technology and Sustainable Construction in Austria vs. The U.S.AAmjad PervazNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Metra 18C and Metrawin 90 Modular Calibration System, CPDocument8 pagesMetra 18C and Metrawin 90 Modular Calibration System, CPeddieipenza100% (1)

- Keysight E7515ADocument2 pagesKeysight E7515AVlad LecherNo ratings yet

- D4182-Standard Practice For Evaluation of Laboratories Using ASTM Procedures in The Sampling and Analysis of Coal and CokeDocument15 pagesD4182-Standard Practice For Evaluation of Laboratories Using ASTM Procedures in The Sampling and Analysis of Coal and CokeAyaNo ratings yet

- Itrans - Rev 16.0 - EN (77023554-1) - 0 PDFDocument88 pagesItrans - Rev 16.0 - EN (77023554-1) - 0 PDFaepriyadiNo ratings yet

- Calibratie Mast NijghoekDocument28 pagesCalibratie Mast NijghoekFolkwin LapNo ratings yet

- Reflective Pavement Marking GuideDocument14 pagesReflective Pavement Marking GuideDritta Anies Cahaya100% (1)

- NOH10N NOH10NH, Display Parameters 280211Document5 pagesNOH10N NOH10NH, Display Parameters 280211cristian faundesNo ratings yet

- Chen BilogDocument6 pagesChen BilogMagesh SamundiNo ratings yet

- Si 0187Document5 pagesSi 0187cesar luis gonzalez rodriguez75% (4)

- SURVEX ManualDocument43 pagesSURVEX ManualAlexidosNo ratings yet

- 900 Series Manual PDFDocument9 pages900 Series Manual PDFhenry307No ratings yet

- Chapter 1Document39 pagesChapter 1Muhammad Haroon OsamaNo ratings yet

- GB SOLO V1.201 User Manual BDocument98 pagesGB SOLO V1.201 User Manual Bnino16041973100% (1)

- Operating Instructions Labmaster-Aw Neo: Novasina Versions: V1.11 and HigherDocument49 pagesOperating Instructions Labmaster-Aw Neo: Novasina Versions: V1.11 and HigherDavid ThNo ratings yet

- 4 Construction Work Procedure For Foundation Load Test 13 09 11 PDFDocument41 pages4 Construction Work Procedure For Foundation Load Test 13 09 11 PDFBiswajit Sahoo100% (1)

- Pressure Transmitter SOPDocument2 pagesPressure Transmitter SOPambesh100% (1)

- IEC-61395 Creep Test Procedure For ConductorsDocument11 pagesIEC-61395 Creep Test Procedure For ConductorsRavindra Singh RajawatNo ratings yet

- 4e HydraulischePressen PDFDocument28 pages4e HydraulischePressen PDFDenis Yasmin AlineNo ratings yet

- Medical Compressor Maintenance ManualDocument35 pagesMedical Compressor Maintenance ManualGustavo Huamán Mallma100% (1)

- Asset Management FrameworkDocument8 pagesAsset Management FrameworkSreekanthMylavarapuNo ratings yet

- Gilibrator ManualDocument28 pagesGilibrator ManualKonstanze Guzman SalinasNo ratings yet

- Tds - Fischer ProductlineDocument24 pagesTds - Fischer Productlinesrpati_55555No ratings yet

- Mega SeedDocument32 pagesMega SeedКолки АвтосервісNo ratings yet

- Technical Specification of STAY WIREDocument25 pagesTechnical Specification of STAY WIRESantosh GairheNo ratings yet

- Iricell PDFDocument190 pagesIricell PDFDouglas BarbosaNo ratings yet

- ISO 11223 Measurement of Content of Storage TankDocument62 pagesISO 11223 Measurement of Content of Storage Tankneosucre syukriNo ratings yet

- Quality Management System in Garments Manufacturing by SujanDocument27 pagesQuality Management System in Garments Manufacturing by SujanSujan sahaNo ratings yet

- TSI, DustTrak - DRX Model 8533, 8534, 8535Document84 pagesTSI, DustTrak - DRX Model 8533, 8534, 8535johnsmithNo ratings yet

- TESA General CatalogueDocument1 pageTESA General CatalogueAsif HameedNo ratings yet