Professional Documents

Culture Documents

EP FE CS STD 001 01 E Company Standard For Access Roads

Uploaded by

agaricusOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EP FE CS STD 001 01 E Company Standard For Access Roads

Uploaded by

agaricusCopyright:

Available Formats

OMV PETROM EP Regulation

In the interests of simplicity and readability, the language of this statement is as far

as possible gender neutral. Where applicable, the masculine incorporates the

feminine

User Notes:

A controlled copy of the current version of this document is on OMV PETROM

Intranet EP. Before making reference to this document, it is the user's responsibility

to ensure that any copy is current. For assistance, contact the Document Issuer.

This document is the property of OMV PETROM EP. Neither the whole nor any part of

this document may be disclosed to others or reproduced, stored in a retrieval system,

or transmitted in any form by any means (electronic, mechanical, reprographic

recording or otherwise) without prior written consent of the owner.

Users are encouraged to participate in the ongoing improvement of this document by

providing constructive feedback.

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 2 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

Table of contents

CHAPTER I - GENERAL ................................................................................................................................... 7

Section 1 - Definitions, References, Classification .................................................................................. 7

1.1. Definitions ......................................................................................................................................... 7

1.2. General statement of principles...................................................................................................... 7

1.3. References - laws, orders, standards, normatives ........................................................................ 8

Section 2 - Scope of application ................................................................................................................ 9

1.4. Scope of application......................................................................................................................... 9

1.5. Classification in accordance with current legislation: construction categories of importance9

1.5.1. Construction categories of importance ................................................................................... 9

CHAPTER II - DESIGN OF OIL FIELD ROADS ............................................................................................. 10

Section 1 - Design statement ................................................................................................................... 10

2.1. Statement of design principles ..................................................................................................... 10

2.2. Standard references ....................................................................................................................... 10

2.3. Traffic description........................................................................................................................... 10

Section 2 - Road route alignment............................................................................................................ 12

2.4. Design of earthworks (route alignment) ...................................................................................... 12

2.4.1. Statement of design principles .............................................................................................. 12

2.4.2. Standard references ................................................................................................................ 12

2.4.3. Safety distances to adjacent elements.................................................................................. 12

2.4.4. Road safety zone ...................................................................................................................... 13

Section 3 - Horizontal route alignment................................................................................................... 14

2.4.5. Horiyontal and vertical road geometry.................................................................................. 14

2.4.5.1. Horizontal road geometry ................................................................................................ 14

2.4.5.1.1. General. Definitions.................................................................................................... 14

2.4.5.1.2. Road width .................................................................................................................. 26

2.4.5.1.3. Clearance ..................................................................................................................... 27

2.4.5.1.4. Intersections................................................................................................................ 27

2.4.5.1.5. Undercrossing and overcrossing .............................................................................. 28

2.4.5.1.6. Guardrails .................................................................................................................... 29

Section 4 - Vertical route alignment ....................................................................................................... 30

2.4.5.2. Vertical road geometry ..................................................................................................... 30

2.4.5.2.1. General. Definitions.................................................................................................... 30

2.4.5.2.2. Maximum ramp........................................................................................................... 30

2.4.5.2.3. Maximum crossfall ..................................................................................................... 31

2.4.5.2.4. Minimum vertical connecting radius ........................................................................ 32

2.4.5.2.5. Cutting slopes ............................................................................................................. 32

2.4.5.2.6. Embankment slopes ................................................................................................... 33

Section 5 - Road superstructure .............................................................................................................. 34

2.5. Superstructure design.................................................................................................................... 34

2.5.1. Design statement ..................................................................................................................... 34

2.5.2. Standard references ................................................................................................................ 34

2.5.2.1. Criteria of flexible road pavement determination: ........................................................ 34

2.5.2.2. Criteria of rigid road pavement determination: ............................................................. 35

2.5.2.3. Verification of pavement behaviour at freeze and thaw............................................... 35

2.5.3. Pavement design function of exploitation, construction cost and paving maintenance

requirements ...................................................................................................................................... 36

Section 6 - Water discharge ..................................................................................................................... 37

2.6. Collecting and discharging rain water ......................................................................................... 37

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 3 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

2.6.1. Design statement ..................................................................................................................... 37

2.6.2. Normative references .............................................................................................................. 37

2.6.3. Adjacent ditches to road ......................................................................................................... 37

2.6.4. Guard ditches ........................................................................................................................... 38

2.6.5. Other rain water collection and discharge devices.............................................................. 38

Section 7 - Art Works ................................................................................................................................ 39

2.7. Design art works and ancillary works .......................................................................................... 39

2.7.1. Design principles (A, B, C)....................................................................................................... 39

2.7.1.A. River bank protection works ........................................................................................... 39

2.7.1.B. Reinforcement works ....................................................................................................... 40

2.7.1.C. Bridges ............................................................................................................................... 40

2.7.2. Normative references .............................................................................................................. 41

Section 8 - Bridges .................................................................................................................................... 42

2.7.3. Bridges and culverts ................................................................................................................ 42

2.7.3.1. Bridges................................................................................................................................ 42

2.7.3.1.1. Bridge terminology..................................................................................................... 42

2.7.3.1.2. Classification of bridges............................................................................................. 42

2.7.3.1.3. Determination of bridge length and height ............................................................. 43

2.7.3.1.4. Free spaces on and under the bridge ....................................................................... 45

2.7.3.1.5. Loading ........................................................................................................................ 45

2.7.3.1.6. Calculation and dimensioning................................................................................... 45

2.7.1.7. Types of bridges ................................................................................................................ 46

Section 9 - Culverts ................................................................................................................................... 55

2.7.3.2. Culverts............................................................................................................................... 55

Section 10 - Consolidation and protection of river banks .................................................................... 57

2.7.4. Retaining walls ......................................................................................................................... 57

2.7.5. Piles ........................................................................................................................................... 57

2.7.6. Gabions ..................................................................................................................................... 58

2.7.7. Drains ........................................................................................................................................ 58

2.7.8. River bank protection works .................................................................................................. 58

Section 11 - Marking - Signing................................................................................................................. 63

2.7.9. Marking ..................................................................................................................................... 63

2.7.10. Traffic signs ............................................................................................................................ 63

2.7.11. Signing of maintenance and repair works .......................................................................... 63

CHAPTER III - CONSTRUCTION OF OIL FIELD ROADS............................................................................. 64

Section 1 - General overview and materials .......................................................................................... 64

3.1. General............................................................................................................................................. 64

3.2. Materials .......................................................................................................................................... 65

3.2.1. Earthworks................................................................................................................................ 65

3.2.1.1. Filling material ................................................................................................................... 65

3.2.1.2. Capping layer materials .................................................................................................... 65

3.2.2. Road pavement ........................................................................................................................ 65

3.2.2.1. Ballast pit aggregates ....................................................................................................... 65

3.2.2.2. Crushed stone and rubble ................................................................................................ 66

3.2.2.3. Macadam (SR 179:1995) ................................................................................................... 66

3.2.2.4. Semipenetrated and penetrated macadam.................................................................... 66

3.2.2.5. Aggregates, or cement stabilized soils ........................................................................... 66

3.2.2.6. Cement concrete ............................................................................................................... 67

3.2.2.7. Asphalt mixture ................................................................................................................. 67

3.2.2.8. Binder and asphalt concrete ............................................................................................ 67

3.2.2.9. Pavings of rubble and boulders ....................................................................................... 68

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 4 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

3.2.2.10. Rubble paving. Large, medium and small size paving setts....................................... 68

3.2.3. Water collection ancillary constructions ............................................................................... 68

3.2.4. Guardrails.................................................................................................................................. 68

3.2.5. Culverts ..................................................................................................................................... 68

3.2.6. Hydrotechnical works (river bank protection) ...................................................................... 69

3.2.6.1. Fascines .............................................................................................................................. 69

3.2.6.2. Woven and unwoven geosynthetic materials ................................................................ 69

3.2.6.3. Concrete. ............................................................................................................................ 69

3.2.7. Consolidation woks ................................................................................................................. 70

3.2.8. Bridge works ............................................................................................................................ 74

Section 2 - Construction requirements ................................................................................................... 80

3.3. Construction requirements............................................................................................................ 80

3.3.1. Earthworks................................................................................................................................ 80

3.3.2. The main and foundation layers............................................................................................. 80

3.3.3. Macadam................................................................................................................................... 80

3.3.4. The main layers and bituminous layers of mediumhard and hard macadam ................. 80

3.3.5. Cement concrete layers executed on settled shutters ........................................................ 81

3.3.5.1. Quality technical conditions............................................................................................. 81

3.3.5.2. The road concrete categories........................................................................................... 81

3.3.5.3. Preparation and placing of the cement concrete........................................................... 81

3.3.6. Concrete cement layers executed on slipping shutters ...................................................... 82

3.3.7. Hot executed cylinder bituminous layers.............................................................................. 82

3.3.8. Rough stone or boulders pavements..................................................................................... 82

3.3.9. Natural stone pavements. Ordinary, out of norms and pieces of pavements................... 82

3.3.10. Adjacent constructions for water storing and evacuation. Ditches, cassies, gravels .... 82

3.3.11. The bituminous treatments .................................................................................................. 83

3.3.12. Culverts ................................................................................................................................... 83

3.3.13. Guardrails ............................................................................................................................... 83

3.3.14. Construction requirements for consolidation works ......................................................... 83

3.3.15. Construction requirements for bridges ............................................................................... 95

3.4. Normative references..................................................................................................................... 96

3.5. Construction documentation ........................................................................................................ 96

3.6. Permits and authorizations according to the current law ......................................................... 96

3.7. Inspections and verifications......................................................................................................... 97

3.7.1. Verification processes ............................................................................................................. 97

3.7.2. Inspection procedures ............................................................................................................. 98

CHAPTER IV - ACCEPTANCE OF OIL FIELD ROADS.................................................................................. 99

4.1. Documentation ............................................................................................................................... 99

4.2. Construction manual ...................................................................................................................... 99

4.3. Tests ............................................................................................................................................... 100

4.3.1. Earthwork ............................................................................................................................... 100

4.3.2. Road pavement ...................................................................................................................... 101

4.3.3. Bridges .................................................................................................................................... 102

4.4. Acceptance of works at construction phases............................................................................ 102

4.5. Acceptance of works for opening to explotation...................................................................... 103

4.1.1. Definition ................................................................................................................................ 103

4.1.2. Phases ..................................................................................................................................... 103

CHAPTER V - EXPLOITATION OF OIL FIELD ROADS .............................................................................. 105

5.1. Surveillance of road behaviour ................................................................................................... 105

5.1.1. Current surveillance............................................................................................................... 105

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 5 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

5.1.2. Special surveillance - after special evants, with significant effects on road behaviour

during explotation (flooding, land sliding, etc.) ........................................................................... 107

CHAPTER VI - MAINTENACE OF OIL FIELD ROADS ............................................................................... 108

6.1. Road maintenace in summer....................................................................................................... 108

6.1.1. Maintenace of road platform ................................................................................................ 108

6.1.1.1. Curent maintenace works .............................................................................................. 108

6.1.1.2. The periodical maintaining works ................................................................................. 108

6.1.2. Providing road water drainage............................................................................................. 108

6.1.3. Maintenance of road traffic safety facilities........................................................................ 108

6.1.4. Providing road traffic aesthetic appearance ....................................................................... 108

6.1.5. Bridges maintenace ............................................................................................................... 109

6.1.5.1. The present maintenance works of the bridges .......................................................... 109

6.1.5.1 Periodical maintenance works of the bridges............................................................... 109

6.2. Maintenace of roads in winter .................................................................................................... 109

6.2.1. Preparing of roads for the winter season............................................................................ 109

6.2.2. Supply of antiskidding materials ......................................................................................... 109

6.2.3. Manual and mechanical snow removal ............................................................................... 110

CHAPTER VII - CURRENT REPAIRS AND OVERHAULS .......................................................................... 111

7.1. Normal exploitation time according to current law (HG no. 2139/2004) ............................... 111

7.2. Standards for planning repair works at roads and road structures........................................ 114

7.3. Guidelines concerning overhauls of roads and ancillaries....................................................... 115

7.4. Planning and providing road overhauls ..................................................................................... 115

7.4.1. Documentation of overhauls ................................................................................................ 115

7.4.2. Providing overhauls (RK)....................................................................................................... 116

7.4.3. Surveillance of overhauls execution and verification ........................................................ 116

7.4.4. Acceptance of works ............................................................................................................. 116

CHAPTER VIII - CLOSING AND CASSATION............................................................................................ 117

CHAPTER IX - FINAL RECOMMENDATIONS............................................................................................ 118

CHAPTER X - ANNEXES ............................................................................................................................. 119

ANNEX No. 1 ............................................................................................................................................ 120

ANNEX No. 2 ............................................................................................................................................ 122

ANNEX No. 6 ............................................................................................................................................ 124

ANNEX No. 7 ............................................................................................................................................ 127

ANNEX No. 8 ............................................................................................................................................ 128

ANNEX No. 9 ............................................................................................................................................ 129

ANNEX No.10...........................................................................................................................................147

ANNEX No.11...........................................................................................................................................152

ANNEX No.12...........................................................................................................................................153

ANNEX No.13...........................................................................................................................................154

ANNEX No.14...........................................................................................................................................155

ANNEX No.15...........................................................................................................................................156

ANNEX No. 16 .......................................................................................................................................... 156

ANNEX No.17...........................................................................................................................................158

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 6 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

CHAPTER I - GENERAL

Section 1 - Definitions, References, Classification

1.1. Definitions

This company standard sets out the general rules for the design, construction,

exploitation, maintenance, repair and acceptance of roads and platforms used for the

exploitation works at the crude oil and gas production branches of the Trading Company

OMV OMV PETROM S.A.

The design and construction works of these roads will be carried out in conformity

with the requirements, as per Law no. 10/1995 and other specific requirements of the

constructions quality system, to provide and maintain on the entire service life the quality

standards of resistance and stability, exploitation safety, fire safety, hygiene, peoples

health, environment reconstruction and protection.

This company standard refers to new and existing roads, which are subject to

maintenance, systematization and upgrading.

This standard is applicable to the design of roads supporting tyre-vehicles traffic.

This standard provisions do not apply to public roads arranged for oil exploitation

and other purposes (social, industrial, forestry, agriculture, travelling); the design of these

roads will be based on, either current standards requirements, or the technical conditions

determined from case to case, by mutual agreement with the interested entities.

The requirements of the normatives below are also mandatory for the design,

construction, maintenance and repair of oil field roads:

- Labour protection norms of OMV OMV PETROM; labour protection departamental

norms in the domain of road, water and air transportation;

- General fire safety norms relevant for the design and execution of constructions and

installations, fire safety departamental normatives that are currently applied by OMV OMV

PETROM;

- current standards documentation mentioned under 1.3.;

- current technical requirements for roads, provided they do not contradict this

company standard.

Note: this Standard replaces EP FA replaces EP FA CS 01 ST.-COMPANZ OIL STANDARD

REGARDING DESIGN, CONSTRUCTION, MAINTENANCE AND REPAIR OF OIL FIELD

ROADS

1.2. General statement of principles

Oil field roads will be located in conformity with the local planning sketches, and will

be designed, to provide connections to the ancillaries, production, social and administrative

buildings related to oil field activities.

Local oil field roads will be designed, to meet the road transportation demands of all

the oil field units located in the respective area and to provide the connection between the

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 7 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

oil field area and public roads. With this end in view, the concerned entities must be

contacted, to mutually establish design requirements, relating to the design project theme.

The oil field roads will be designed at the highest traffic intensity resulting from:

- future technological traffic considered at final transport capacity of the crude oil and

gas production branch of S.C. OMV PETROM SA.;

- site traffic during construction works;

- traffic resulting from other related local activities.

The oil field roads will be located as far as possible, on weathered unproductive soil.

Relief, ground morphology, hydrological and hydro-geological conditions,

meteorological conditions, vegetation, local materials are relevant factors to be considered

in establishing the route alignment and the road pavement system. They will be determined

based on topographical surveys, geotechnical and hydrological studies, economic

assessments and land inspections.

Design phases (Order MFP/MLPTL no. 1013/873 of July 2001)

- Prefeasibility study

- Feasibility study

- Technical project and technical specifications for construction works

- Detailed design

(No prefeasibility study is required for overhauls, repair, consolidation and

dismantling of constructions and installations)

1.3. References - laws, orders, standards, normatives

The requirements below are mandatory for the design, construction, and maintenance of

OMV PETROM SA oil field roads:

- Law 10/1995, regarding quality requirements in constructions and application regulations

of this law

- Law no. 82/1998 for the approval of the Governmental Order no. 43/1997 regarding the

legal regime of roads

- Law no. 137/1995 regarding environmental protection

- Labour protection Law no. 90/1996

- Governmental Order no. 273/1994 for the approval of the regulations related to the

acceptance of the construction works and installations

- The Law for authorizing of construction works

- Law of waters no. 107/1996

- Governmental Order 766/1997 for the approval of construction works quality regulations

- MFP and MLPTL Order no. 1013/873/2001 regarding the tender offer procedures for

public acquisition of services

- General labour protection norms. Regulations regarding labour protection and hygiene

of construction works - NPGM/2002

- Fire prevention and fire fighting norms: fire fighting equipment

- Standards, norms, normatives of Annex 9

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 8 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

Section 2 - Scope of application

1.4. Scope of application

The company standard regarding design, construction, exploitation, maintenance

and repair of oil field roads at crude oil and gas production branches of S.C. OMV PETROM

S.A is relevant for oil exploitation works.

If the road is used for other activities, the interested entities will be contacted, to

establish the design requirements, the design and exploitation project theme.

1.5. Classification in accordance with current legislation: construction categories of

importance

According to Governmental Order no. 19/21.08.92, the following standard categories

were currently prepared in Romania in 1992:

- Romanian standards - SR

- Professional standards

- Company standards

The Governmental Order no. 39 of 30.01.1998 brough ammendments and the

annulment of the Governmental Order no. 19/21.08.92. According to this latest Order, the

Company standard is no longer individualized as such and the term Technical

Regulations has been issued.]

Law 355 of 06.06.2002 passed the approval for the Governmental Order no. 39/1998

regarding the national Romanian standardization, where the term Technical Regulations

defined in the respective Governmental Order is maintained.

The company standard regarding design, construction, exploitation, maintenance

and repair of oil field local roads is similar to the Technical Regulations, where technical

requirements are stated, either directly, or by reference to other standard, technical

specification, code of practice, as well as by assuming the entire content of the latter.

1.5.1. Construction categories of importance

The assessment of the oil field roads category of importance shall be performed in

accordance with the requirements, as per the Regulations regarding the assessment of

constructions category of importance issued by INCERC (Constructions Bulletin no.

4/1996).

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 9 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

CHAPTER II - DESIGN OF OIL FIELD ROADS

Section 1 - Design statement

2.1. Statement of design principles

Oil field roads have been classified into several types of roads, such as: axial roads

(collector roads, main roads) and access roads leading to oil field works locations (oil wells,

parks, compressors stations, etc.) and other locations (premises, social buildings).

Axial roads or access roads are differently defined, in point of geometry and

construction, depending on their economic relevance that is function of the exploitation

period, the mean annual traffic and the design speed.

The design speed, which is used to determine the geometry and construction

features of the oil field roads, is determined function of the land morphology and the

prospective mean annual traffic, and means the maximum speed attained by trucks without

trailer on the most difficult road sectors, under total traffic safety conditions, good pavement

and favourable weather conditions.

The geometry recommended in this normative provides vehicle traffic speed from 10

to 50 km/hour. Under most difficult conditions, this geometry covers curves with minimum

10 m radius and up to 12% slope (considering idle travel without loading).

The 10 m radius curves will be applied only exceptionally.

The design speed values and the technical characteristics are not restrictive; highest

design speed values and wide geometry elements must be adopted, provided the cost of

the investment is not to be significantly increased.

2.2. Standard references

Standards relevant for the design of oil field roads:

- STAS 863-85

- STAS 2900-79

- C 79-80

- PD 67-80

- Order of Ministry of

Transports no. 45/1998

- Order of Ministry of

Transports no. 44/1998

Road

works.

Geometry

of

route

alignment.

Design requirements

Road works. Road width

Normative for the design, construction and acceptance of

industrial roads

Departamental normative regarding the design of forestry

roads for vehicle traffic

Technical norms for the design and upgrading of roads

Technical norms regarding environmental protection

against road effects

2.3. Traffic description

Local oil field roads must accommodate permanent and long term access of vehicles,

installations, cranes, trailers and other mobile equipment, such as snow ploughs, fire

extinguishers and other emergency vehicles to all the oil field locations.

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 10 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

These vehicles are representative of the current traffic specific for public roads as

well.

For heavy duty convoys trafficking on the oil field roads and exceeding the normal

width (over 2.50 m), over 5.00 m in height, with convoy length over 22 m (fig. 1, STAS 86385), and axle loads higher than estimated design loads, special projects will be set up,

subject to approval of OMV PETROM, the Police and the public roads Authorities (if these

are to traffick on public roads also).

For the purpose of road and bridge design, the designer together with the beneficiary

(OMV PETROM) shall determine the prospective road traffic (for the period of construction

works and 10 to 15 years service life), by vehicle categories (per day), axle loading etc.

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 11 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

Section 2 - Road route alignment

2.4. Design of earthworks (route alignment)

2.4.1. Statement of design principles

The land requirement boundaries that accommodate the route of oil field roads must

avoid as far as possible agriculture land, forests, etc. for the low potential land areas.

It is recommended to select areas with adequate soil stratification and good exposure

to sun and wind, which require small volume of bridge, protection and consolidation works.

The route alignment shall be adapted to ground peculiarities, to reduce the volume of

earthworks and road structures.

River crossings will be designed under normal configuration, in the narrowest valley

areas.

Horizontal radii will be used that need no arrangements (conversions or

superelevations), and the least gradient. Step slopes, as well as maximum and exceptional

gradient slopes are to be avoided, if the funding is to stay unchanged.

In all cases, the final solution must be based on the technical and economic

assessment of different alternatives.

2.4.2. Standard references

- STAS 1243/88

- STAS 2914/84

- STAS 2916-87

- STAS 1709/2

- STAS 863-85

Foundation ground. Classification and identification of soils

Road works. Earthworks. General quality requirements

Slope and ditch protection

Freeze and thaw effect on road works. Prevention and remedy of

damages by freeze and thaw. Technical requirements

Geometry of route alignment

2.4.3. Safety distances to adjacent elements

From the closest margin of the carriageway and fixed adjacent elements, the

following are minimum safety distances that must be applied:

- to fences and buildings..5.25 m (shoulder 1.50 m + guardrail 0.75 m +

ditch 1.50 m + side walk 1.50 m)

- to the railway axis...20 m (Emergency Governmental Order no. 12/7

July 1998 regarding the Romanian railway transport and reorganization of the

Romanian Railways Society)

In curves, visibility must be provided by widening.

In the case of cutting and embankment roads, the minimum distances shall be those

mentioned under 2.4.4., for safety areas.

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 12 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

2.4.4. Road safety zone (as per Governmental Order 43/1997 published in Official

Bulletin of Romania, part I, no. 541/1.IX.2001)

The area of the oil field road contains: territory, safety zones and protection zones.

The road territory means the land area occupied by the road construction elements:

carriageway, shoulders, ditches, gutters, slopes, guard ditches, retaining walls and other

road structures.

The safety zones means the land areas located on both sides of the road

territory, exclusively used for traffic signing, road green area, maintenance and exploitation

related activities, for traffic safety and protection of landowners located in the road area. The

safety areas also include the land areas used to provide visibility in curves and intersections,

as well as the areas of the roadbed consolidation works.

Outside localities, minimum limits of the road safety zones in current carriageway

and in alignment are provided in Annex 1 of the Governmental Order no. 43/97, that is:

The safety zones are located from the outer limit of the road territory up to:

- 1.50 m from the outer margin of ditches, for the roads located at ground level;

- 2.00 m from the slope toe, for the roads in embankment;

- 3.00 m from the top of the road slope in cutting, with height up to 5.00m inclusive;

- 5.00 m from the top of the road slope in cuttings higher than 5.00 m.

Agriculture crops and forestry are not admitted in the safety areas.

Protection zones means land areas located on both sides of the safety areas,

necessary for future road protection and development. The protection land limits are

between the exterior margins of the safety zones and the road zone margins.

The distance from the road axis to the exterior margin of the oil field road zone,

which is also current village road, is 18 m.

The protection zones are left for administration to legal and individual entities that

have right of their management and ownership, provided they do not cause prejudice to

road or traffic safety by:

a) failure to provide adequate water discharge;

b) constructions, fences and plantations, that may result in snow-drifting on road

and affect road visibility;

c) works affecting road stability or changing ground and surface waters regime.

Land owners in the vicinity of oil field roads must allow the installation on these areas

of snow protection panels free of charge, provided these procedures do not affect

agriculture works and crops in the area.

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 13 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

Section 3 - Horizontal route alignment

2.4.5. Horiyontal and vertical road geometry

2.4.5.1. Horizontal road geometry

Specific elements of horizontal road geometry have been considered:

- aliniaments

- curves, curves radius, respectively

The road geometry is to be set up, either directly, according to current regulations, or

by calculation based on parameters indicated in these regulations.

Prospective traffic intensity is of utmost relevance in establishing design, (reference)

speed.

Oil field roads design speed is 10 to 50 km/hour and it will be calculated for different

road categories, depending on the local relief.

The following relief specifications are relevant in this case:

- flat open country regions include: plains, plateaus, mountain depressions and

major riverbeds;

- the hill regions include: hill areas and vally flanks with slopes up to 2025g;

- mountain regions include valleys with flank slopes over 25g, zones with irregular

relief and river gorges.

The design speed shall be selected function of the road category and the local relief:

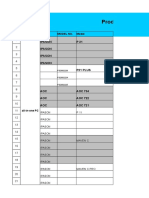

Road category

- principal (axial, collector roads)

- secondary (access roads)

Design speed,

function of relief, km/hour

plains

hills

50

40

30

10-30

mountains

25

10-20

2.4.5.1.1. General. Definitions

Parameters for road geometry calculation:

Coefficient of transversal friction, f, between vehicle tyres and road paving, is from

0.05 to 0.15.

Description of situations relevant for the friction force generated in curves:

f = 0.10 the curve is not perceived

f = 0.15 the curve is perceived

f = 0.20 the curve is perceived and the travellers have an unpleasant feeling of

insecurity

For oil field roads, the maximum value f = 0.15 shall be adopted

The comfort coefficient K has been approximated as the ratio between friction effect

(f) and superelevation (superelevation rate) (i), to avoid the skidding effect in curves,

according to the folloing ratio:

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 14 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

K=

f

i

where K = 1.53

The lower K value is, the lesser the friction effect, as compared to superelevation

effect, and better travel comfort is provided in traffic.

For oil field roads, the maximum value, K = 3 is recommended.

With respect to comfort conditions (f; K), oil field roads display poor travel conditions

as compared to public roads and better travel conditions as compared to forestry roads:

Road category

Public roads (STAS 863-85)

0.05 - 0.13

1.3 - 2.35

Oil field roads

0.08 - 0.14

2.28 - 3.00

Forestry roads (PD 67-80)

0.10 - 0.18

2.93 - 3.20

The superelevation rate, i, (crossfall) is determined in alignment by the type of

paving (2% for cement concrete, 2.5% for asphalt, 3% for hard core, etc.).

Variation j of the normal acceleration (centrifugal force) in progressive connection

arcs determines the length of the arcs. The value of j is from 0.5 to 1.0 m/s3.

The comfort status is determined by the value of j, which practically varies from 0.5 to

0.7 m/s3. The lower the value of j is, the longer the length of arc connections and the better

the comfort.

It is recommended j = 0.7 m/s3 (as compared to j 0.5 on national roads).

Progressive curves shall only be introduced between route alignments and arc

curves, when the axial road must be arranged for speed values of minimum 25 km/hour,

ground conditions permitting, no significant additional works being required and the oil field

road being public road as well.

The length of clothoids is calculated by using the following ratio:

L=

V3

; (m)

47 j R

where:

V = speed, km/hour

j = 0.3 to 0.7 m/s3

R = = radius of central arc (m)

(47 = from the transformation v3 m/sec in V3 km/hour)

3

V3

1000

v = V

47

3600

3

Resulting clothoid length values:

V,

km/hour

50

40

30

25

20

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 15 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

15

10

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

L (m)

55*

45*

35*

20*

15

10

10

* As per STAS 863, clause 6

The displacement of the arc (R) to the center will be:

R =

L2

L4

L6

+

24 R 2688 R 3 506880 R 5

The calculation of road geometry also includes the following elements:

The horizontal visibility distance (at curves and intersections) and the longitudinal

visibility distance (in hilly areas), which affect the vehicles traffic speed on roads

The length of vehicles maximum 2.50m wide engaged in road traffic, which

determines road widening in curves

Horizontal connections on oil field roads will be provided as follows:

Axial (collector) roads, with central arcs and clothoids.

In areas with irregular land, at designer recommentation, the beneficiary may

approve that the connections are only provided by arcs

The access roads route alignment, with arc curves.

The oil field roads geometry function of the design speed is presented in the table

below:

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 16 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

Geometry

Design speed, km/hour

Ite

m

Geometry elements

50

40

30

25

20

15

10

100

90

65

60

35

32

25

22

16

14

10

10

10

10

100

106

114

123

135

150

171

201

246

246

360

65

68

73

79

86

96

110

129

157

157

230

35

38

41

44

49

54

62

72

89

89.

130

25

27

28

31

34

38

43

50

62

62.

90

16

17

18

20

22

24

27

32

39

39.

57

10

10

10

11

12

14

15

18

22

22.

32

10

10

10

10

10

10

10

10

10

10.

20

> 360

> 230

> 130

> 90

> 57

> 32

> 20

Comments

Radii of central arcs, m

1

minimum (superelevation rate 6%)

exceptional (superelevation rate 7%)

The arc radii from minimum radii (exceptional) to

current radii, expressed in m, at the following

superelvation rates expressed in superelevation %

6.0

5.5

5.0

a) arc and clothoides for

4.5

V = 2550 km/hour

4.0

b) arc for V = 1020 km/hour

3.5

3.0

2.5

2.0

Current radii, m, (arc + conversion)

Recommended radii, m, (crest as in alignment)

Arc connections

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 17 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

(f < 0,14

and K 3;

K

f

)

i

OMV PETROM EP Regulation

5A

5B

5C

Minimum curves length (1.4 V)

Length of widening and converting lc2 (outside the

circle), m

Length of widenings, conversions and superelevations

lc3 (outside the circle), m

Ite

m

6

Geometry elements

70

56

42

35

28

21

14

30

25

20

15

10

10

10

45

35

15

15

50

40

15

10

30

25

15

Design speed, km/hour

30

25

20

Comments

Arc and clothoid connections

1)

6A

Minimum length of clothoid arcs, with central arc, m,

6B

551)

451)

351)

201)

15

10

10

Minimum length of clothoid arcs, without central arcs,

m

702)

602)

402)

352)

25

15

15

6C

Superelevation length, expressed in m, , without

central arcs, Lc4, on clothoids

50

40

30

25

20

10

10

6D

Superelevation

clothoids) Lc2

30

25

20

15

10

10

10

Minimum visibility distances, m, for:

- traffic safety in curves on two traffic lane roads

90

70

50

40

30

20

15

- safe overtaking

200

150

125

100

80

50

30

and

conversion

length

(outside

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 18 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

As per

STAS 86385 clause 6

2)

As per

STAS 86385 clause 7

OMV PETROM EP Regulation

9

10

Vertical Intersection Points distance, m,

minimum

exceptional

Alignment longitudinal gradient values, %

maximum

exceptional

Maximum ramp, at idle travel, %

60

40

50

30

50

30

50

25

40

20

30

20

20

20

7

8

7

8

8

8.5

8

9

8

9

8

9

8

9

10

11

12

12

8

8

8

9

8.5

9

9

9

9

9

9

9

9

9

10

11

12

12

Skew slope, %

11

maximum, %

exceptional

exceptional, at idle

travel

Ite

m

Geometry elements

12

Minimum longitudinal gradients, %, in intervals

between successive curves of contrary directions with

radii lesser than recommended (in areas with zero

superelevation rate, inducing water swamping)

13

17

Design speed, km/hour

50

40

30

25

20

15

10

0.5

1.0

0.5

1.0

0.5

1.0

0.5

1.0

0.5

1.0

0.5

1.0

0.5

1.0

Maximum longitudinal gradients, %, in ground areas

free of irregularities, at bridge ramps and passages

4.5

4.5

5.0

5.5

5.5

5.5

5.5

Minimum radii, m, of vertical curves for connecting

successive gradients d1 and d2 at:

- concave connections (valleys)

- convexe connections (hills)

1000

1300

1000

1000

500

800

300

500

150

200

80

150

80

100

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 19 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

Comments

OMV PETROM EP Regulation

Road width in alignment for:

- two traffic lane roads

18

8.0

9.0

6.0

7.0

2x0.2

5

8.0

9.0

6.0

7.0

2x0.2

5

8.0

9.0

6.0

7.0

2x0.2

5

8.0

9.0

6.0

7.0

2x0.2

5

platform

carriageway

framing lanes

5.50

3.50

2x0.2

5

5.50

3.50

2x0.2

5

platform

carriageway

framing lanes

- one traffic lane roads

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 20 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

7.00

7.00

7.00

5.50

5.50

5.50

4.50

3.00

4.50

3.00

4.50

3.00

OMV PETROM EP Regulation

Winding road

In areas with irregular relief and significant grade differences, where roads generally

climb up and down steep flanks, winding route alignment shall be provided to avoid

expensive works. This requires turning and changing of travel direction with angles of

almost 400g (3600).

Characteristic winding road geometry:

Design speed km/h

Item

1

2

3

4

5

6

7

8

Winding parameters

Maximum travel speed on the main curve,

km/hour

Minimum radius of the main curve, m

Maximum crossfall, %

Minimum radius of the auxiliary curve, m

Maximum gradient at axis of main curve %

- exceptional

Minimum length of alignments between

reverse curves, m

Vertical Intersection Points distance, m

- minimum

- exceptional

Visibility distances, m

50

40

30

25

20; 15

and

10

25

25

20

15

10

20

6

100

3.5

-

20

6

70

3.5

4.0

15

6

60

4

5

10

6

50

4

5

10

6

35

4

5

45

35

30

25

15

60

40

40

50

30

40

50

30

30

50

25

20

40

25

15

A. Arrangement of arc curves

a) Isolated curves (Te Ti > 3lc2)

Conversion

Profile conversion will be provided on length lc2 in alignment up to tangent points, by

bottom to top rotating around the road axis, of the semiprofile which on curve corresponds

to curve exterior (up to p%).

Shoulders outside curves shall be converted at the same slope p with that of the

converted pavement

Superelevation

Conversion and superelevation on length lc3 shall be provided.

Shoulders outside curves follow pavement slopes i.

b) Arrangement of succesive curves (Te Ti < 3 lc2)

Arc curves

1. Conversion

a) Successive curves of the same direction: conversion to be maintained on the interval

between curves.

b) Reverse curves.

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 21 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

The converted profile of the first curve is to be rotated on road axis starting from the exit

tangent, proportionally to the distance between curves, reaching the middle of this distance

in horizontal position (zero superelevation rate), and the superelevation rate in the entry

tangent of the second curve, in opposite direction.

2. Superelevation

a) In the same direction

Between curves of the same direction, the profile with the superelevation rate i1 of the

first curve maintains its direction, but it rotates on the road axis proportionally, until it

reaches superelevation rate i2 of the second curve.

b) In reverse directions

Between arc curves of contrary directions, the profile with the superelevation rate i1 of

the first curve rotates proportionally on the road axis, changing direction until it reaches

value i2 in the second curve, by means of horizontal profile (zero superelevation rate) that

must be situated between the tangents of the two curves (distance between Te 1 and Ti 2

will be minim lc3).

B. Arcs and clothoids

a. Isolated curves

Widening and conversion will be provided on the length mentioned at point 6D (outside

the clothoids) and the superelevation will be provided on the length of the clothoid arc.

These values remain constant on the length of the arc.

b. Succesive curves

The connection of converted elements, or superelevations will be done by the

connecting of the two heights, so that the slopes of the two margins of the carriageway

should vary liniary on the entire connection length (lc2).

In case that the oil field road will accommodate public traffic, the geometry will be

according to the requirements, as per STAS 863-85.

The minimum distances that must be provided between two succesive curves, necessary

to introduce the horizontal connection and spatial arrangement are indicated in the tables

below (A and B):

A) Arc connections

Item

Curve 1

0

1

Modul de amenajare

1

Unarranged (negative

superelevation rate p)

Unarranged (negative

superelevation rate p)

Curve 2

Table A

Minimum length of

alignments between

entry and exit tangents

Te - Ti

4

Direction

Arrangement

Irrelevant

No

Arrangement

Te1 Ti2 0

Conversion

Te1 Ti2 0

Irrelevant

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 22 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

Unarranged (negative

superelevation rate p)

Conversion

Conversion

Superelevation

Irrelevant

Superelevation

Same direction

Reverse

direction

Same direction

Reverse

direction

Same direction

Reverse

direction

Te1 Ti2 0

Te1 Ti2 0

Conversion

Te1 Ti2 lc2 (5B)

Te1 Ti2 15 m

Superelevation

Te1 Ti2 lc3 (5C)

Te1 Ti2 15 m

Superelevation

Te1 Ti2 lc3 (5C)

B. Connections by arc and clothoid

Item

Curve 1

1

2

Curve 2

Table B

Minimum length of

alignments between

entry and exit tangents

Te1, Oe1 and Ti2, Oi2

Arrangement

Direction

Arrangement

Unarranged (negative

superelevation rate-p)

Unarranged (negative

superelevation rate p)

Unarranged (negative

superelevation rate p)

Irrelevant

No

arrangement

Te1 Ti2 0

Conversion

Te1 Ti2 0

Superelevated

(clothoid)

Te1 Oi2 0

Conversion

Conversion

Superelevation (i1)

Irrelevant

Irrelevant

Same direction

Reverse

direction

Same direction

Reverse

direction

Same direction

Reverse

direction

Te1 Ti2 0

Conversion

Superelevation

(clothoid)

Te1 Ti2 lc2 (6D)

Te1 Oi2 15 m

Te1 Oi2 lc2 (6D)

Oe1 Oi2 0

Superelevation

Oe1 Oi2 lc2 (6D)

Widening of carriageway and platform in curves

To accommodate long vehicles traffic, the road carriageway in curves with smaller

radius than 225 m shall be widened by width e per each traffic lane.

Road platform shall be widened by the same width as the carriageway.

The superelevation shall be provided inside the curve, but as an exception, in order to

avoid heavy duty works, or demolishing, the widening may be provided individually, on

each traffic lane, on the right side of the traffic direction.

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 23 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

The transition from the normal width of the carriageway in alignment to the widened

curve width will be proportional on the length (lc2) indicated at clause 5B-6D for the road

geometry, outside the tangent point on alignment, or on adjacent curve that requires no

arrangement.

The widening e (cm) of each traffic lane for vehicles, maximum 2.50 m in width, for

oil field roads, are shown in the tables below:

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 24 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

A) Widening in curves with radius 20 m

Widening e of each traffic lane, cm, per curve radius R, m:

R, m

20

22

25

30

35

40

50

70

100

101

115

116

150

151

225

e, cm

200

185

160

135

115

100

80

60

40

35

30

25

B) Widening in curves with radius < 20 m, by category of vehicles

Widening e of each traffic lane, cm,

per curve radius, m:

R, m

e,

cm

10

15

18

Category of vehicles

Without trailer

310

200

200

Single axle trailer, 6 m

325

225

200

Single axle trailer 9 m

550

375

325

Note: Interpolated widenings will be rounded by adding to 5 cm.

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 25 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

2.4.5.1.2. Road width

The cross section represents the intersection of the road corpus and the surface of

the natural ground with a vertical plan, normal on the road axis.

The cross sections contain elements of road infrastructure construction, such as:

dimensions, slope levels, road platform width, carriageway, turning areas, characteristic

features of road structures and water drainage devices etc.

The road platform consists of the consolidated central part for traffic that is the

carriageway, partially or totally consolidated shoulders (framing lanes), water discharge

areas, guardrail areas etc.

The width of the carriageway in alignment

Width of component platform elements is to be determined function of the traffic

intensity on the respective road.

The width of current vehicles varies from 1.70 to 2.00 m for cars and 2.25 to 2.90 m

for trucks and buses (generally 2.50 m).

Usually, the minimum traffic lane width must be 3.00 m.

In the case of intense traffic roads and high traffic speed (40-60 km/h) the required

width is 3.50 m.

Therefore, generally roads carriageway width is 6.00 m, while for roads with intense

traffic 7.00 m.

According to the specifications of the Order for the approval of technical norms

regarding design, construction and upgrading of roads, issued by the Ministry of Transport,

Constructions and Tourism (no. 45/27.01.98), the road width is:

Local roads

3501-8000

III

3.50

80

50

40

Low

750-3500

IV

3.00

60

40

30

Medium

Low

Low

Very low

Very low

3501-8000

750-3500

750-3500

sub 750

sub 750

III

IV

IV

V

V

2

2

2

2

2

3.50

3.00

3.00

2.75

2.75

80

60

60

50

50

50

40

40

40

40

40

30

30

25

25

Traffic lane

width (m)

Medium

Technical

category

Number of

traffic lanes

mountain

Village roads

hill

County roads

plain

Principal national roads

Secondary national

roads

Traffic

intensity

Annual daily

average (for the

next 15 years)

Physical

vehicles / 24

hours

Road category

Speed km/h

The oil field roads usually accommodate what is called low traffic (750-3500

physical vehicles in 24 hours); these are roads with two traffic lanes of minimum 6.00 m

carriageway width and 8.00 m platform.

When required (traffic, servicing and other social and economic objectives) the oil

field road carriageway will be 7.00 m and the platform 9.00 m.

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 26 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

For short time access, one lane roads may be provided. These can be carried out on

sections with minimum 150 m visibility and conditions for stop and leave (4-5% maximum

gradient) in areas arranged for intersection.

The intersection stations have 5.50 to 6.00 m wide carriageways (traffic lane

included), 15 to 20 m minimum in length; they are to be designed considering necessary

visibility, but not longer than 300 to 400 m (to be located generally on the right side, in idle

travel direction).

The carriageway and platform width values (in alignment) are given below:

50

Traffic lane width of roads, m:

- with one traffic lane

- with two traffic lanes

Carriageway width of roads, m:

- with one traffic lane

- with two traffic lanes

Shoulder width, m:

Road platform width, m:

- with one traffic lane

- with two traffic lanes

40

Design speed, km/hour

30

25

20

15

10

3.50

3.50 3.00 3.00

3.50

3.00

3.00

2.75

3.00

2.75

3.00

2.75

3.50

7.00 6.00 6.00

1.00 1.00 1.00

3.50

6.00

1.00

3.00

5.50

0.75

3.00

5.50

0.75

3.00

5.50

0.75

5.50

9.00 8.00 8.00

5.50

8.00

4.50

7.00

4.50

7.00

4.50

7.00

The platform and the carriageway shall be provided by construction with:

crest with two slopes in alignment and in curves with radii longer than recommended

slope in curves that need conversion or superelevation, in the case of one traffic lane

roads and hill roads, where the gradient is provided towards the flank, to avoid

vehicles sliding into valley.

Crest slopes may be: 1; 2; 3; 4; 5; 6%, depending on the carriageway paving and the

spatial arrangement of curves (superelevation).

-

2.4.5.1.3. Clearance

The maximum clearance necessary for vehicle trafficking is equal to the width of the

road platform (carriageway and shoulders STAS 2900-89) and the free height 5.00 m (Order

of Transport Ministry no.. 45/27.01.98).

2.4.5.1.4. Intersections

Intersections of oil field roads shall be designed considering the traffic intensity and

the type of future traffic on intersecting roads.

At grade arrangements of intersections between oil field roads and public roads will

be designed in conformity with the requirements, as per Normative for at grade

arrangement of public roads intersections outside localities, indicative C 173-86.

RO-EP-FE-CS-STD-001-01-E

Company Standard Regarding Design, Construction,

Exploitation, Maintenance and Repair of Oil Field Roads

Page 27 of 157

at Crude Oil and Gas Production Branches of S.C. OMV

OMV PETROM S.A.

Valid from: june 2010

Edition: 2

OMV PETROM EP Regulation

The arrangement of intersections, as per C 173-86 will be subject to approval of

relevant authorities, in accordance with the instructions elaborated by the Ministry of

Transport, Constructions and Tourism, and the Ministry of Internal Affairs and

Administration.

The road intersections design consists in:

- determining intersection dimensions

- providing visibility

- determining location and dimensions of pedestrian crossings

- placing the traffic signs

- providing water drainage

Connection of carriageway shall be provided by arcs with minimum radius of 8-12 m

(at kerb). The minimum radius shall only be used in difficult cases, providing the traffic lane

width, including the respective superelevation.

Intersections at grade with railways will be designed in areas with adequate road and

railway visibility, with arrangement and signing, as per SR 1244-1:1996; SR 1244-2:2004 and